We all get the same boxes so I'll spare you that. I thought I'd start where I thought I could do something different from the standard build.

Anything I do as changes from the standard model we all receive is entirely my responsibility,no one is obligated and I am not urging anyone to make changes,some modifications require additional knowledge without which you may damage parts which are 100 percent usable, who is not sure of his actions, it is better to stick to the instructions of the Armortek

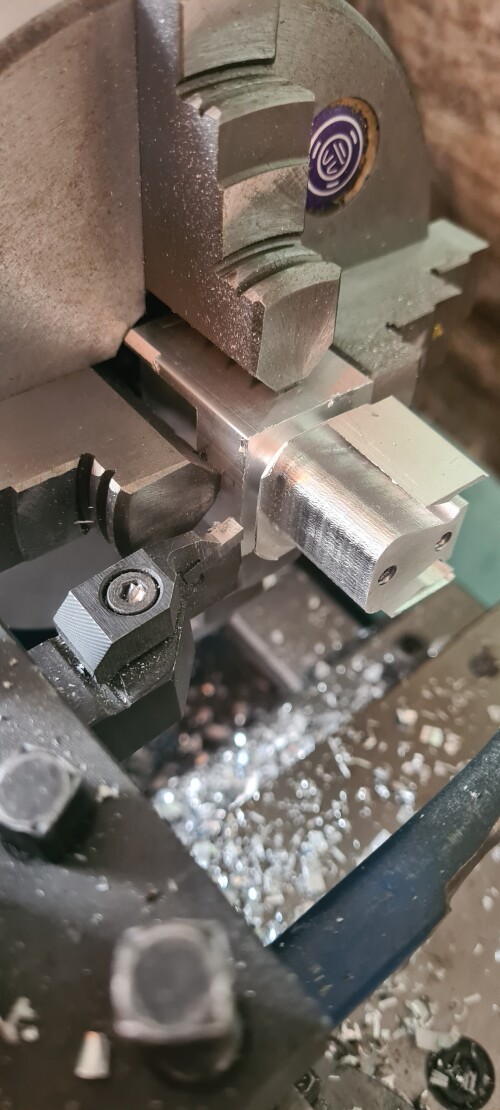

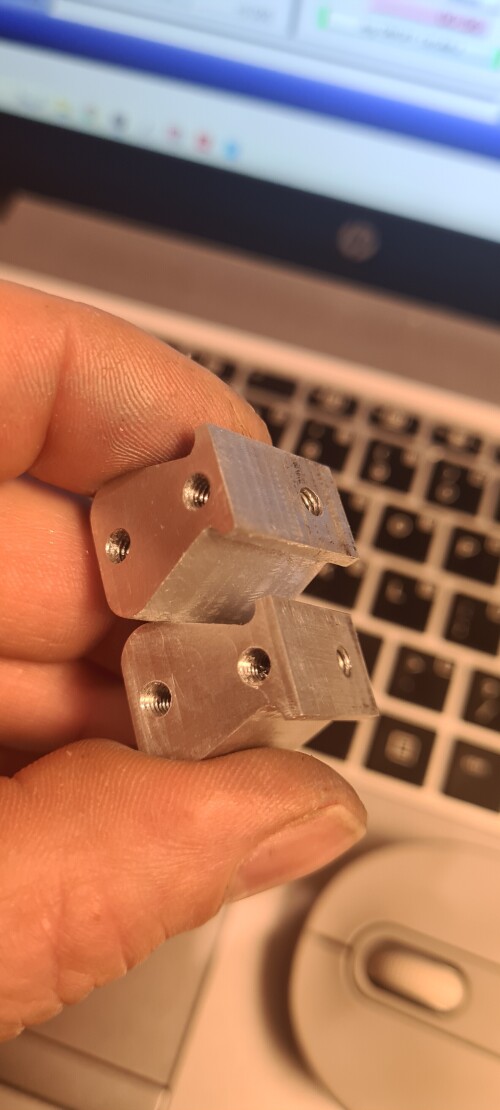

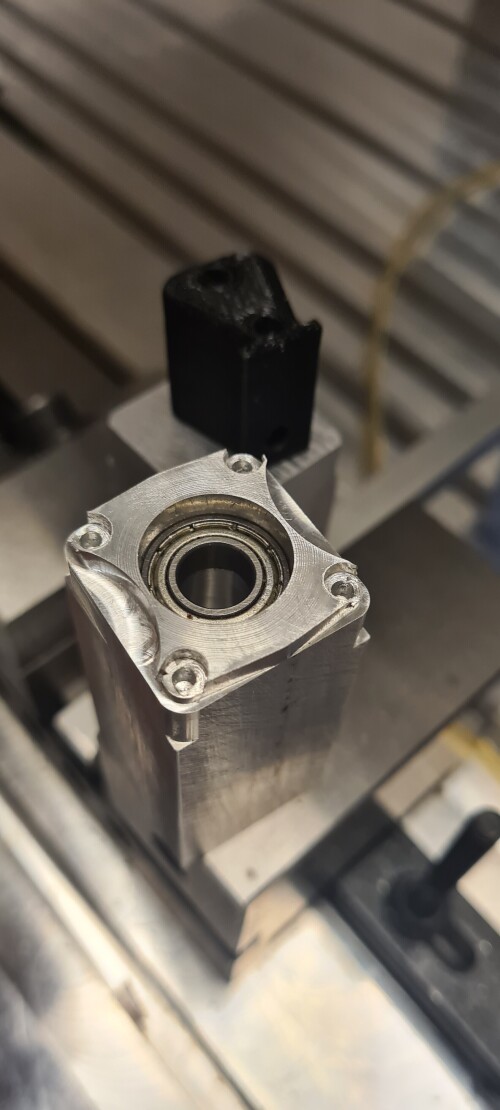

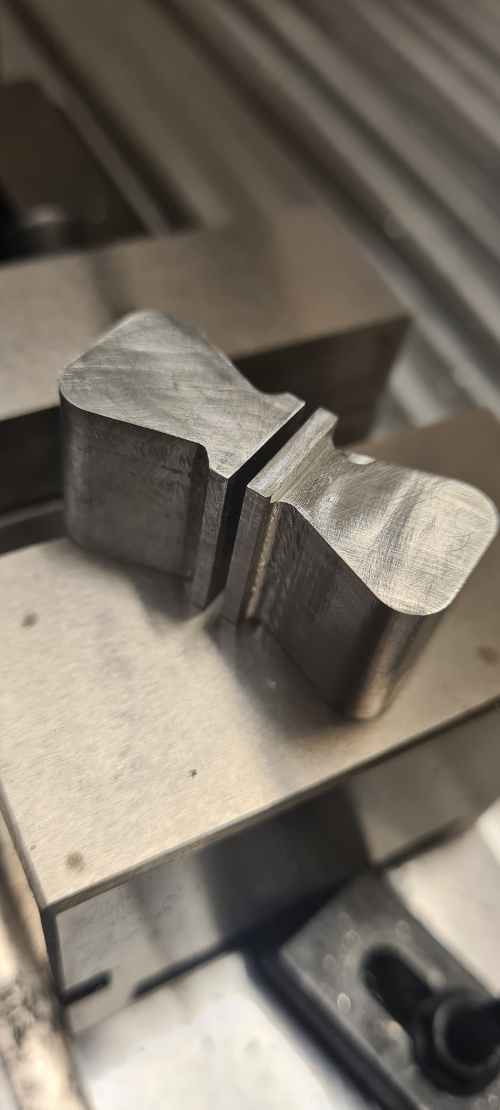

I will start with SPROCKET ASSEMBLY. I will add two details to stop the axial movement of the axle with the gear

Тhe sequence of the photos shows the order of manufacture

Тhe video shows the end result