As with all things, there's more than one way to denude a feline:

This is Dave Battson's method, gratefully received by email:

I profiled my wheels using the steps below;

1. Fix the wheel onto the chuck

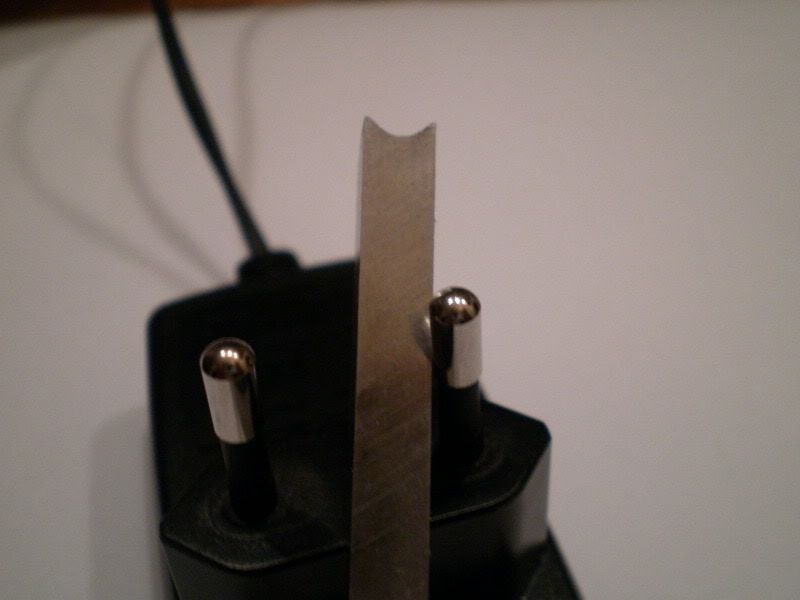

2. Set the tool to touch the wheel at the at the middle (highest point) of the required bump

3. Fix a dial gauge to the top-slide, with it's axis parallel to the lathe bed

4. Create an exact 'negative' template of the required bump profile

5. Fix the template to lathe bed, so that it touches the dial gauge at a point corresponding to 2 above ie. middle of the dip

6. Set dial gauge to zero

7. Start up lathe and move cross-slide back and fourth whilst using the top-slide to keep dial gauge reading zero

Obviously, well worth practising the cross-slide/ top-slide coordination first, before committing to a wheel, but it's not too difficult to master with time.