Hi All,

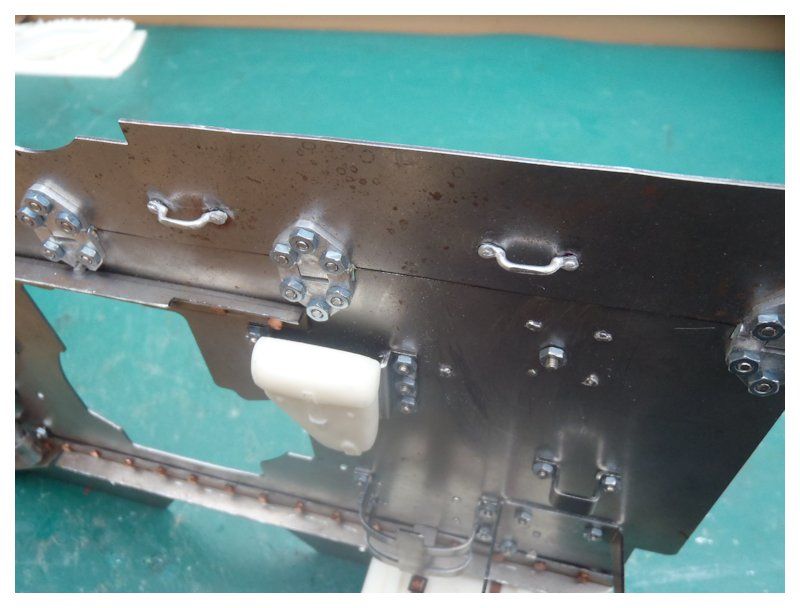

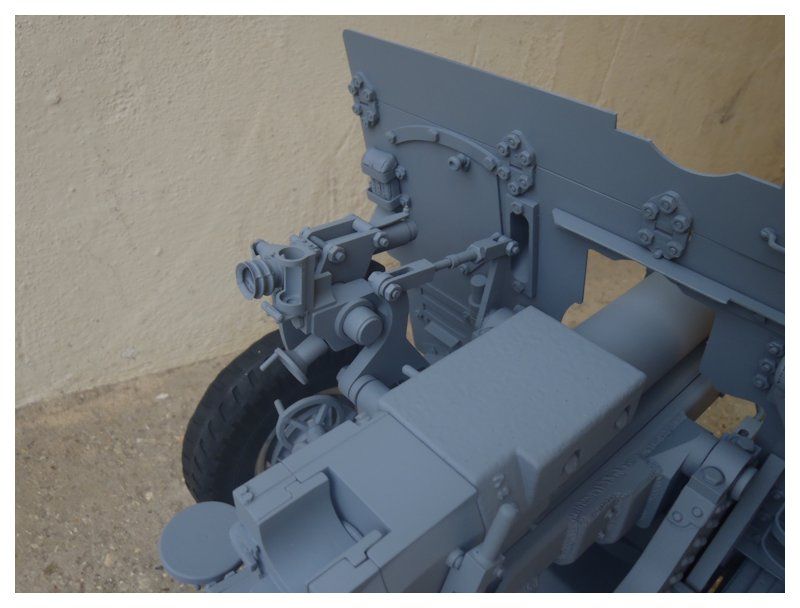

Most of the smaller parts on the casting blocks that have a thin carrier can be removed with a sharp craft knife or scalpel (which I use). Score along the carrier till the part is free rather than cutting straight through. Parts can then be cleaned up with needle files, a knife and I use sponge sanding blcoks as well.

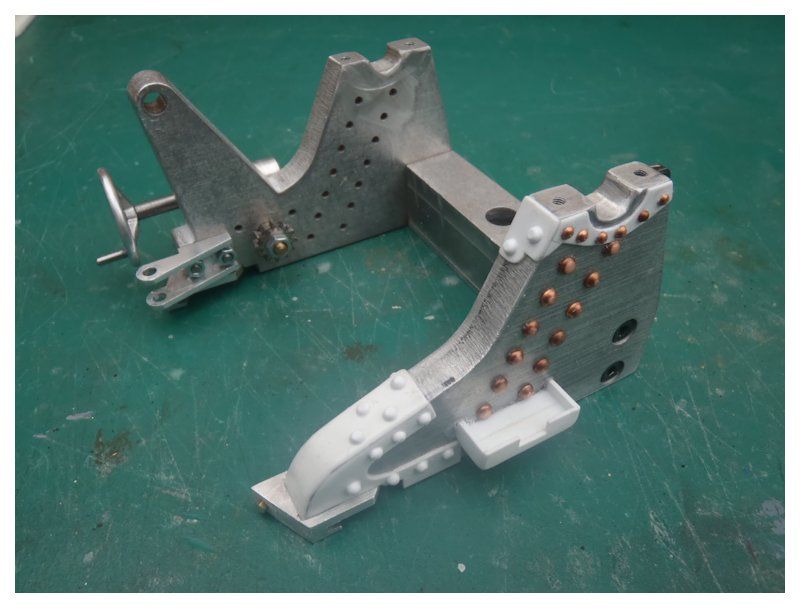

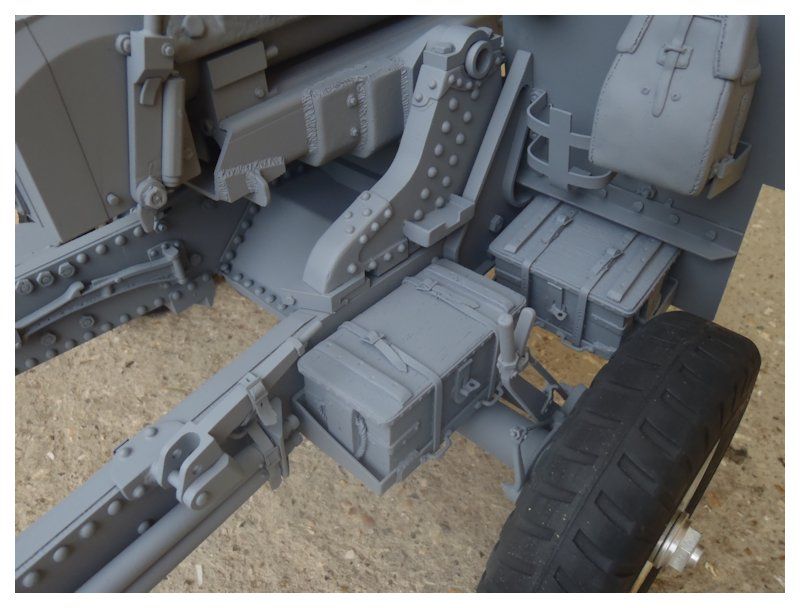

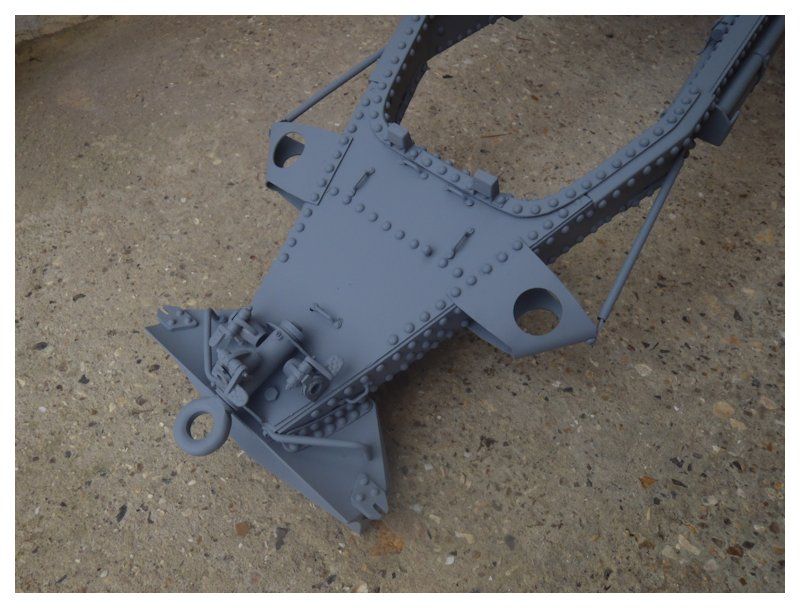

The large flat back parts should not need too much sanding and I recommend a sheet of wet and dry flat on the bench then sand the part in a circular motion. This prevents rounding of the underside and gives a nice flat finish. Same principle applies to the boxes with the larger casting blocks. You can cut away some of the block if its big enough, if not steady sanding in a circular motion till its done. Keep checking so you dont go too far.

For the best results stick to slow and steady rather than hacking loads off with power sanders.

When drilling and sanding resin make sure you are in a well ventilated area and I would recommend a dust mask. The sanded resin is a very fine powder and gets everywhere. Don't do it in the living room

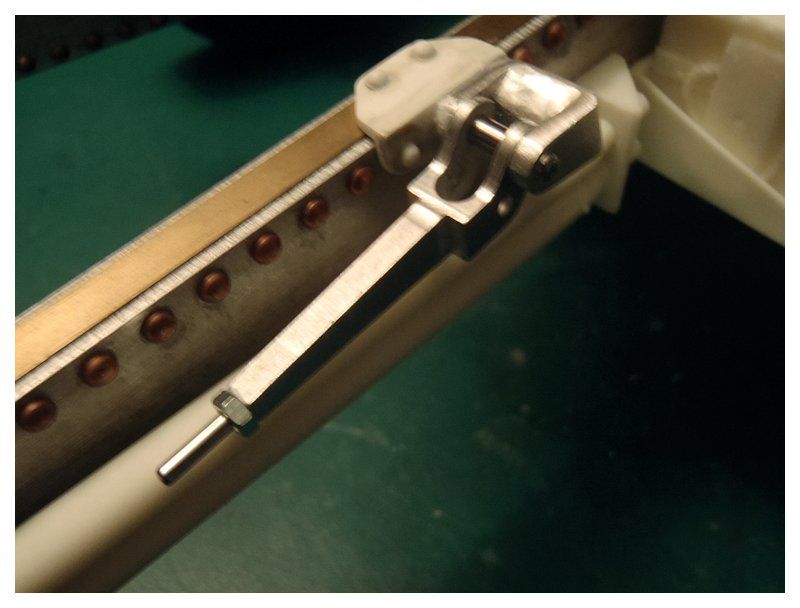

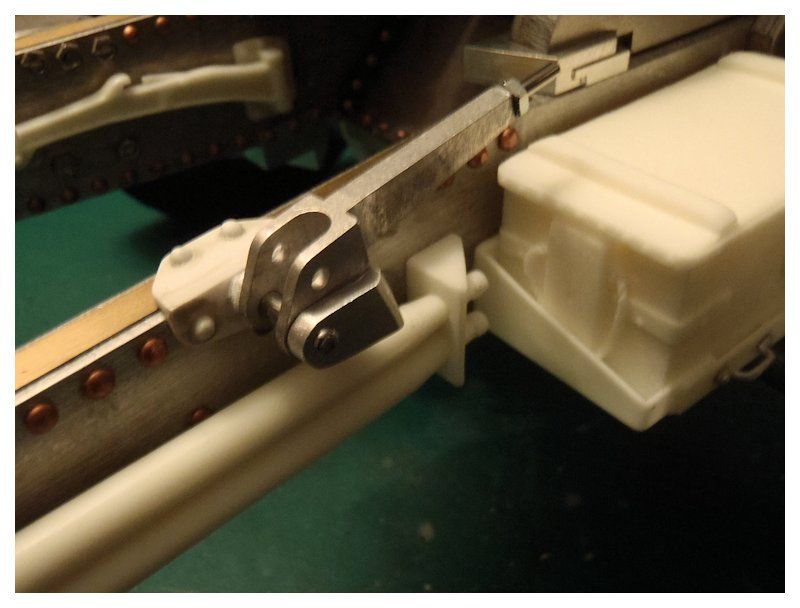

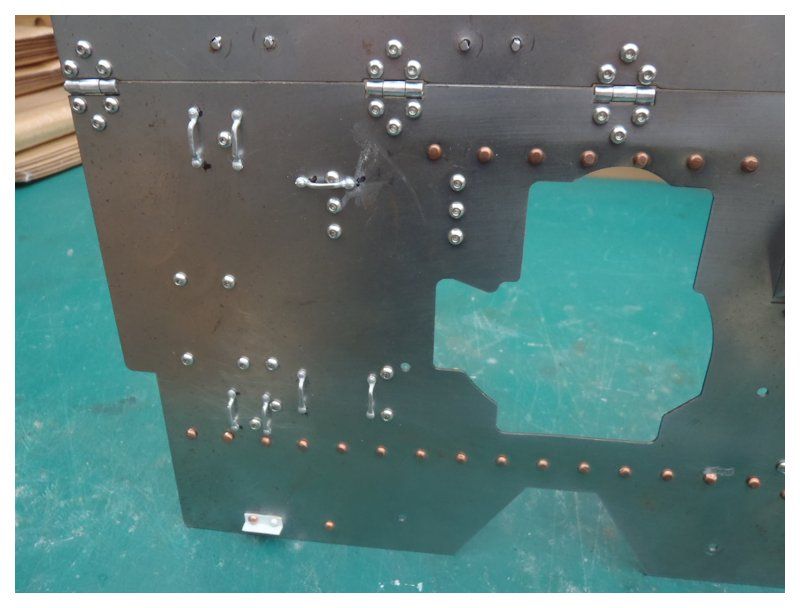

I use normal superglue for most parts but you can also use epoxy like Aralidite for a stronger bond. On things like the rear trail sole plate I cut off 4 of the rivet heads, drilled it and used 4 of the copper rivets to make it a little stronger as the rear of the gun is less protected than other parts.

I use no release agents when casting and prime my resin parts straight from the moulds with Halfords grey primer.

Best regards

Dave