Hi All,

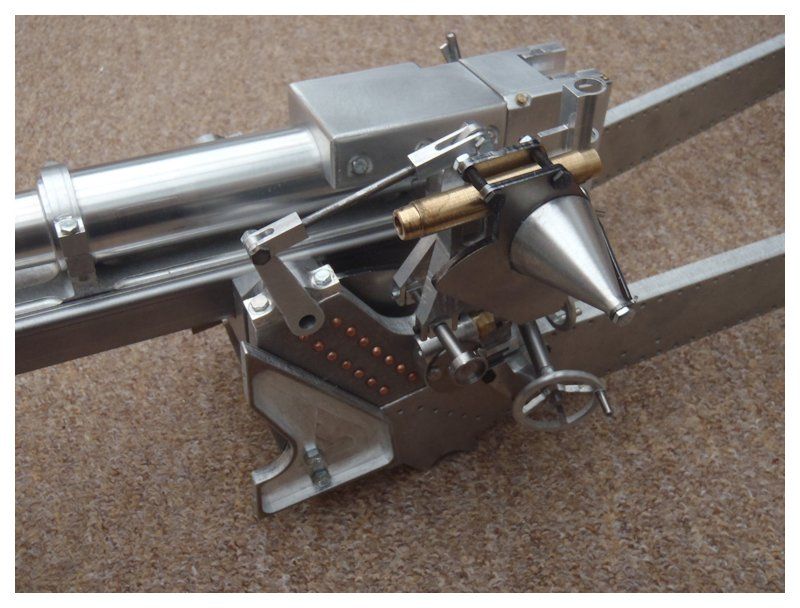

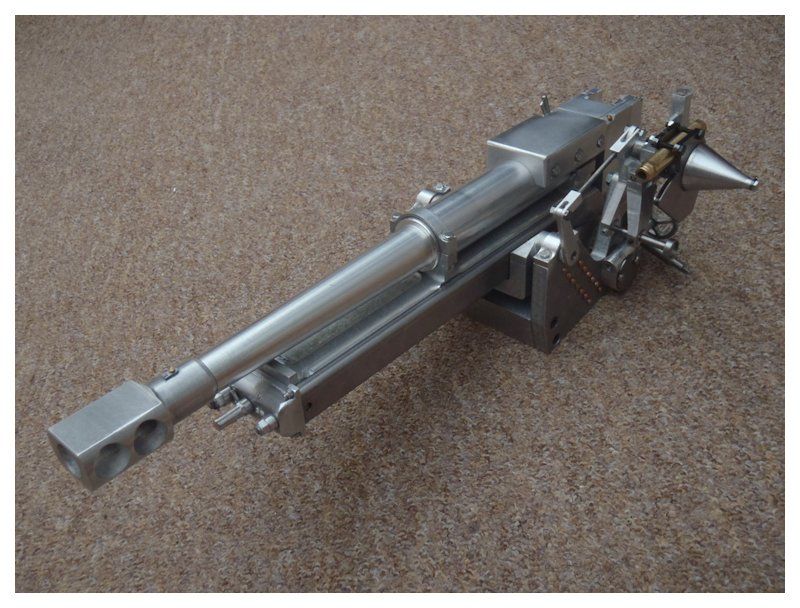

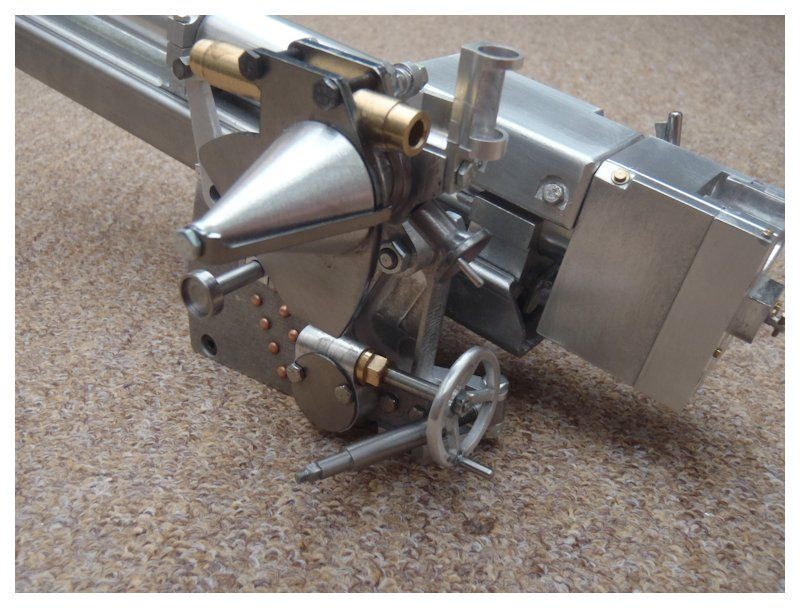

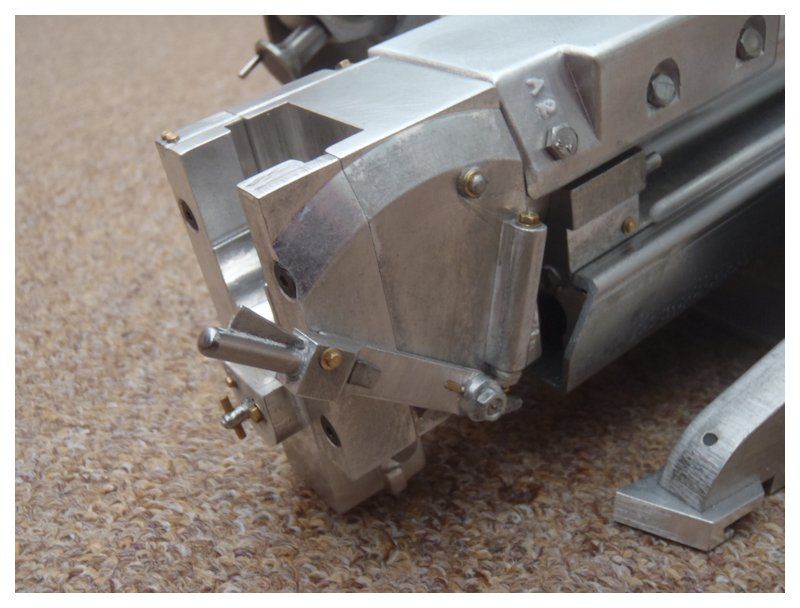

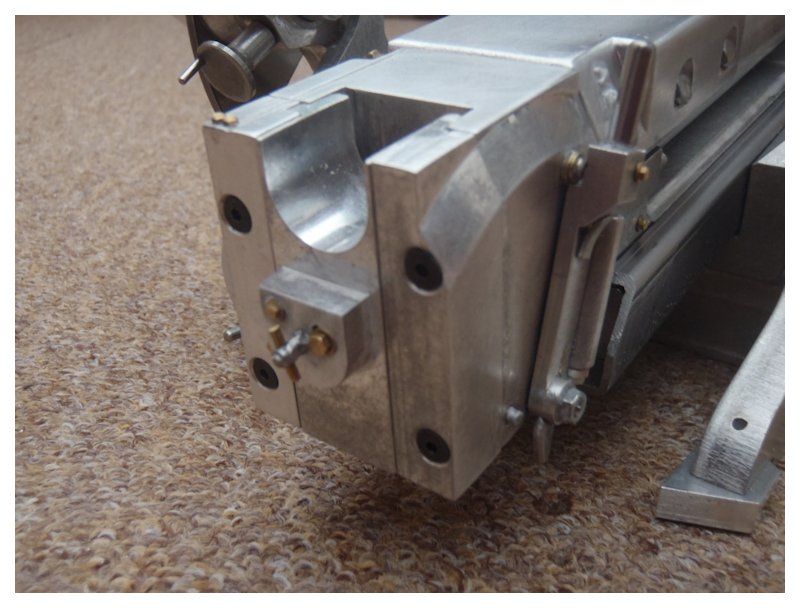

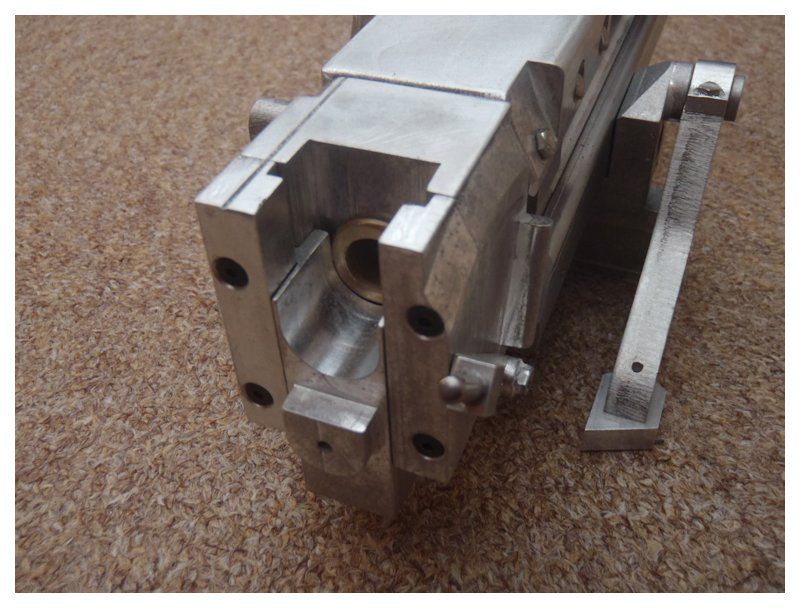

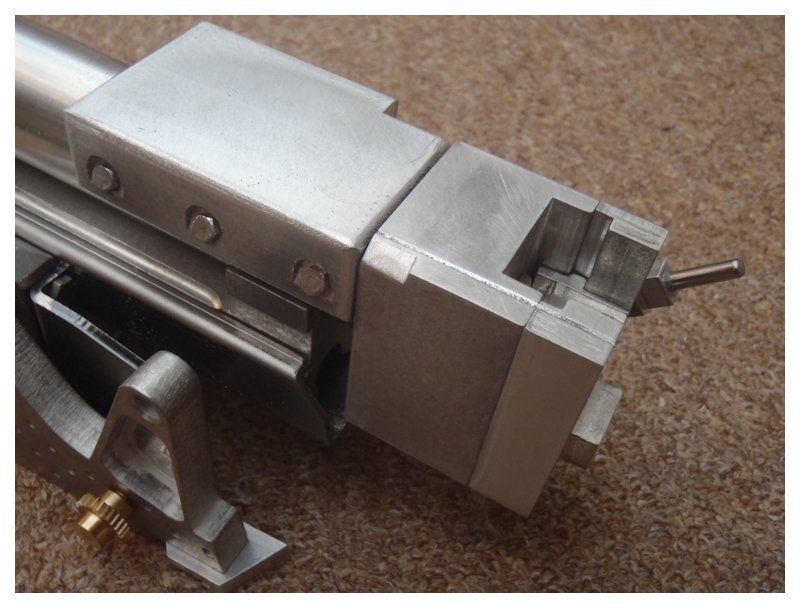

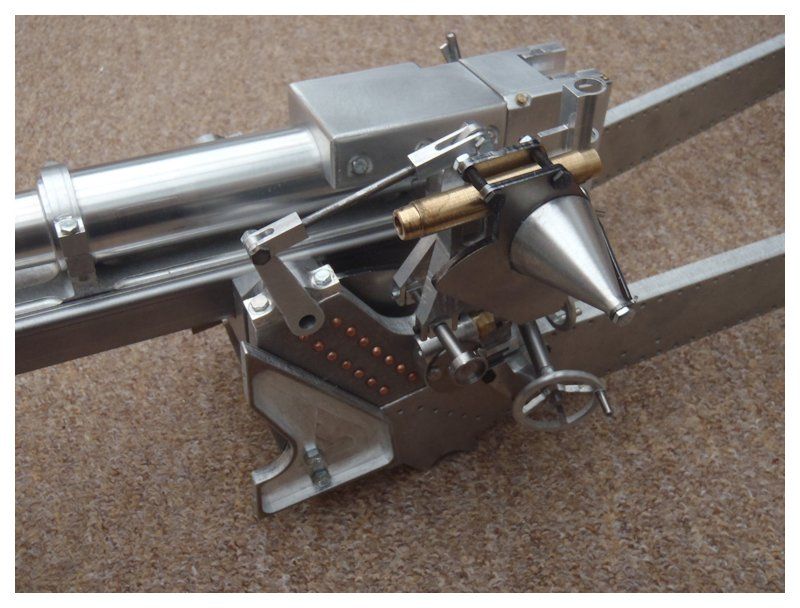

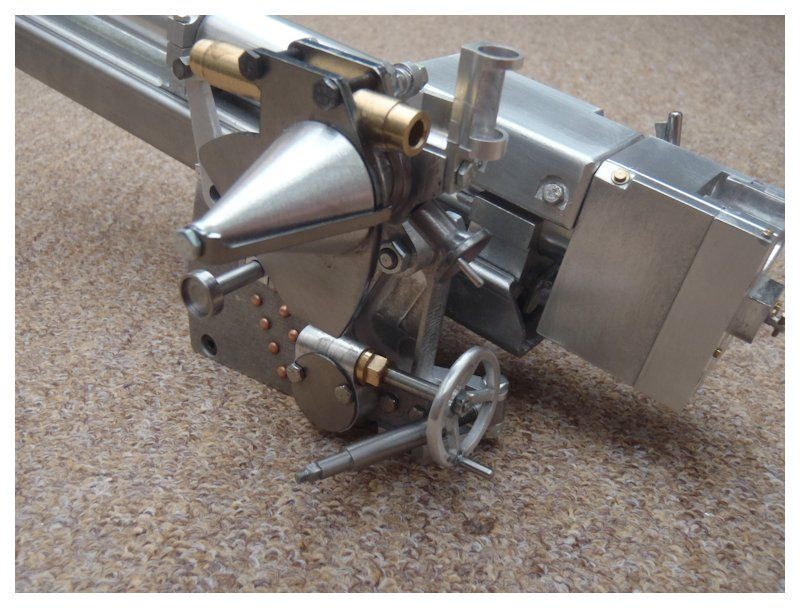

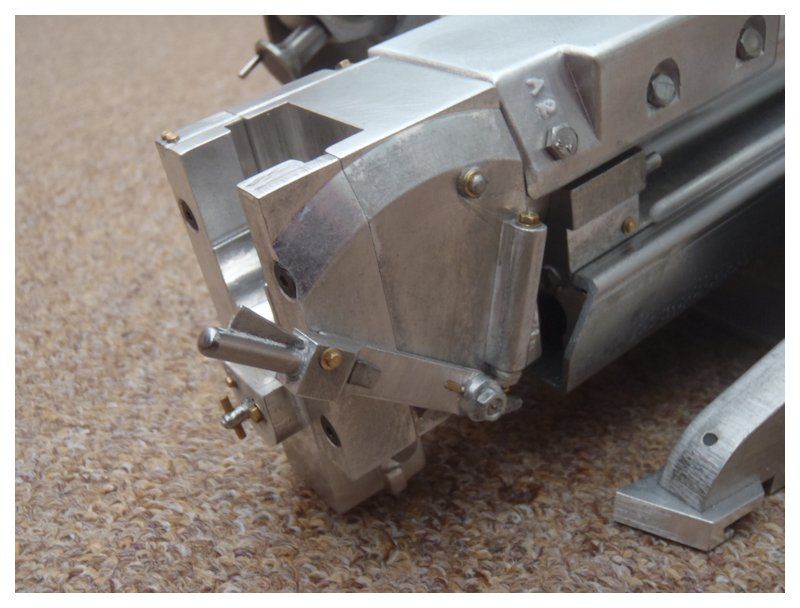

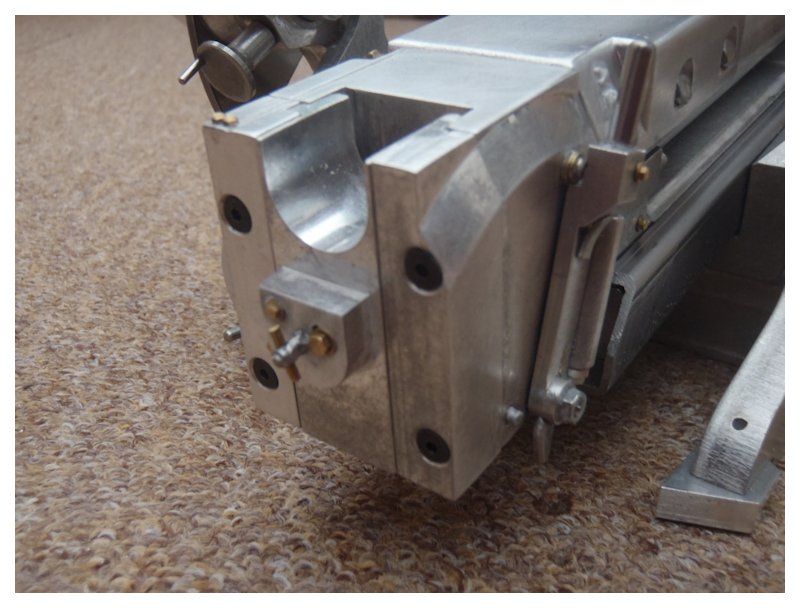

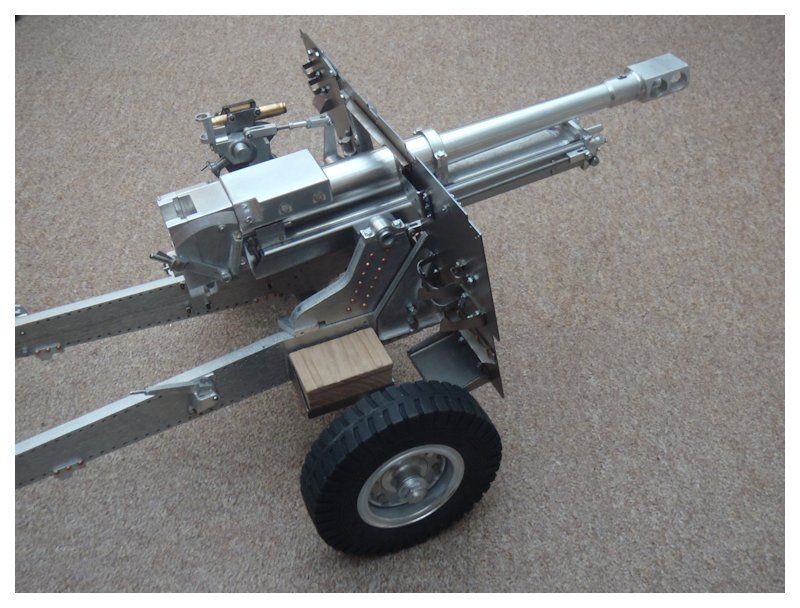

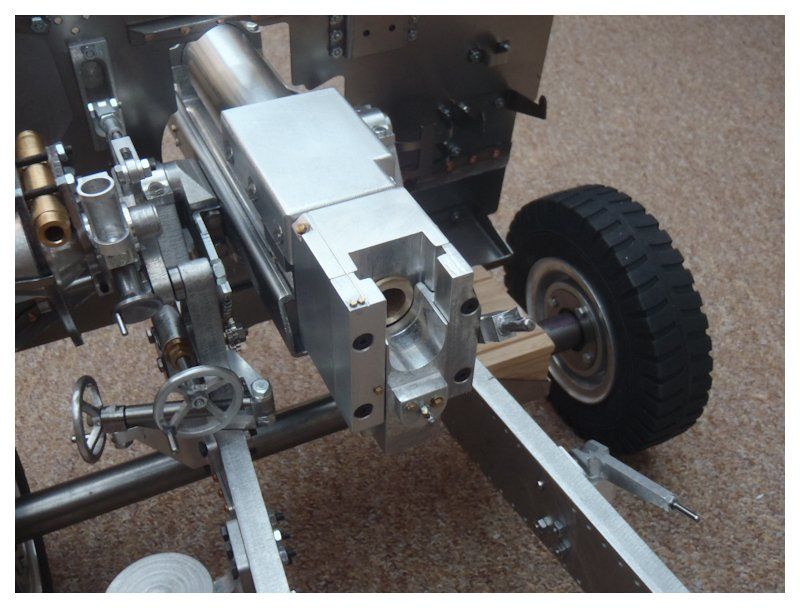

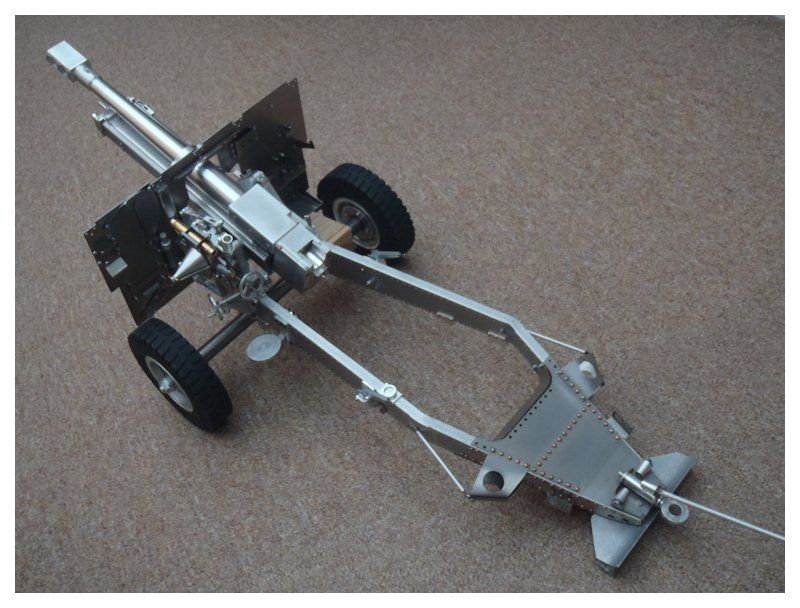

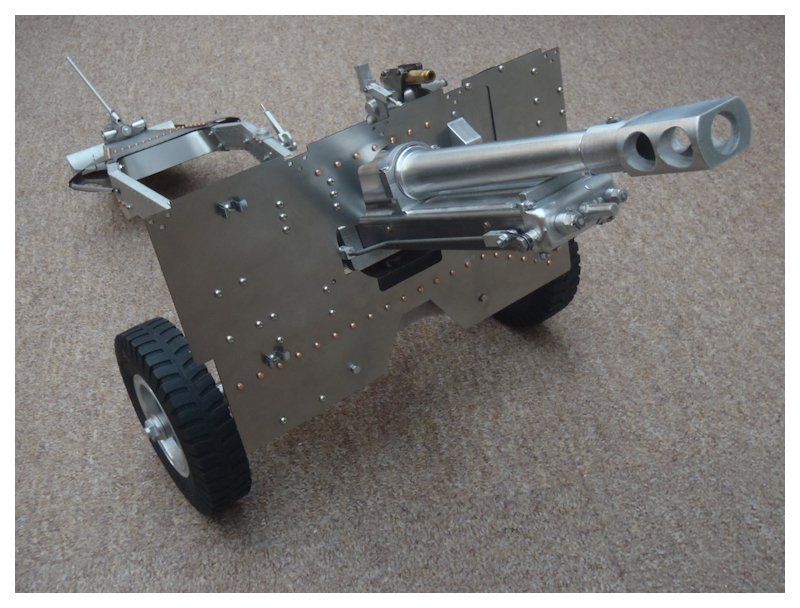

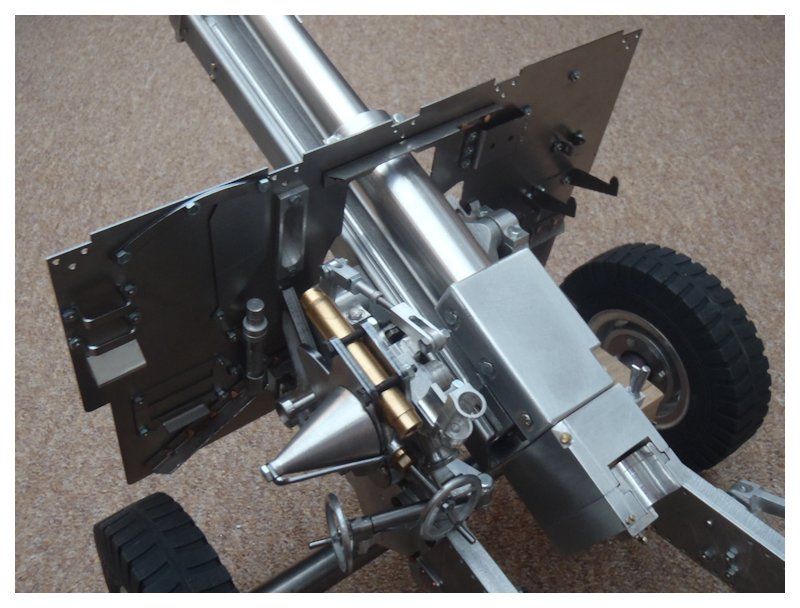

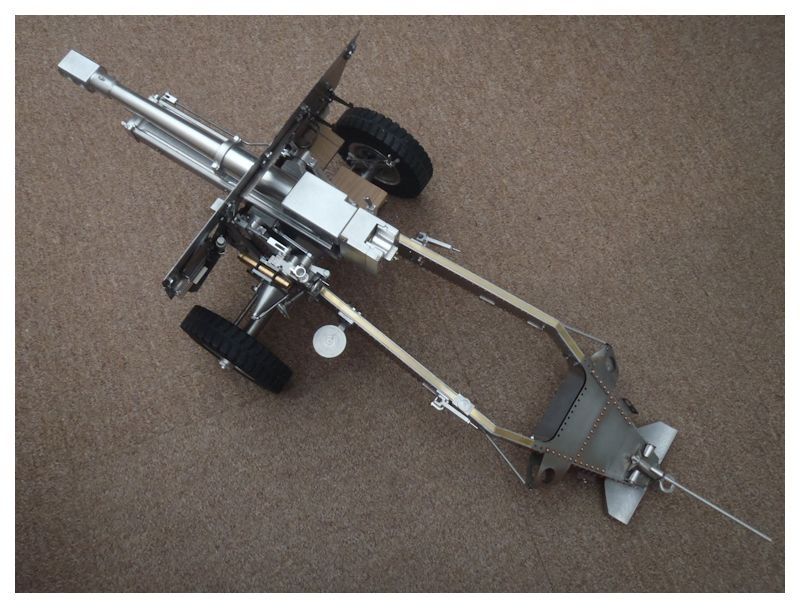

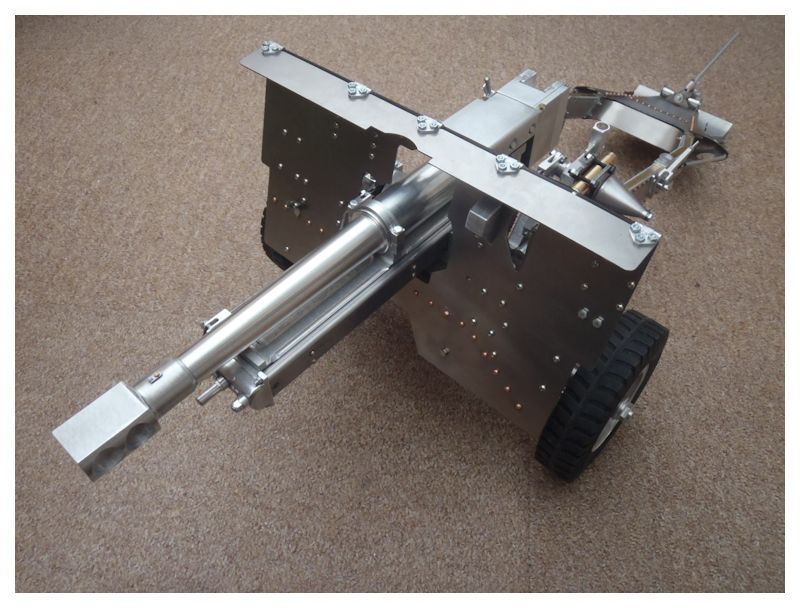

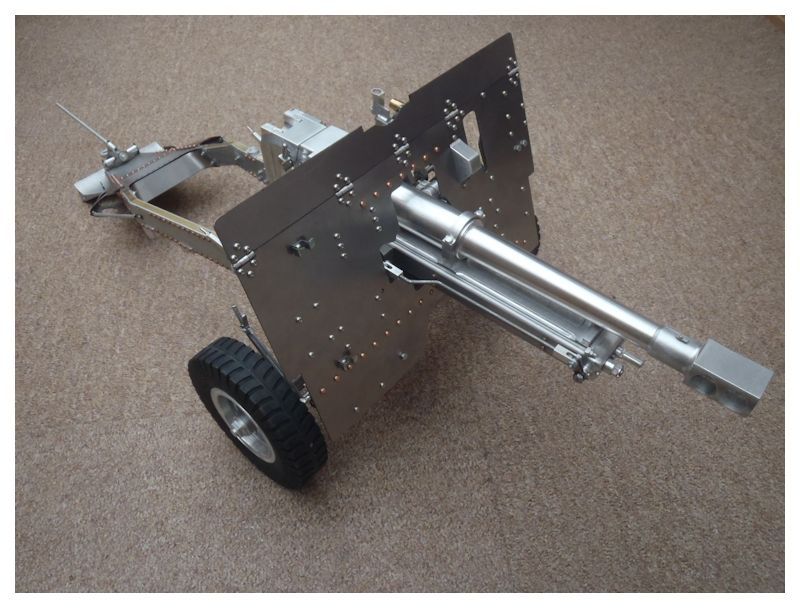

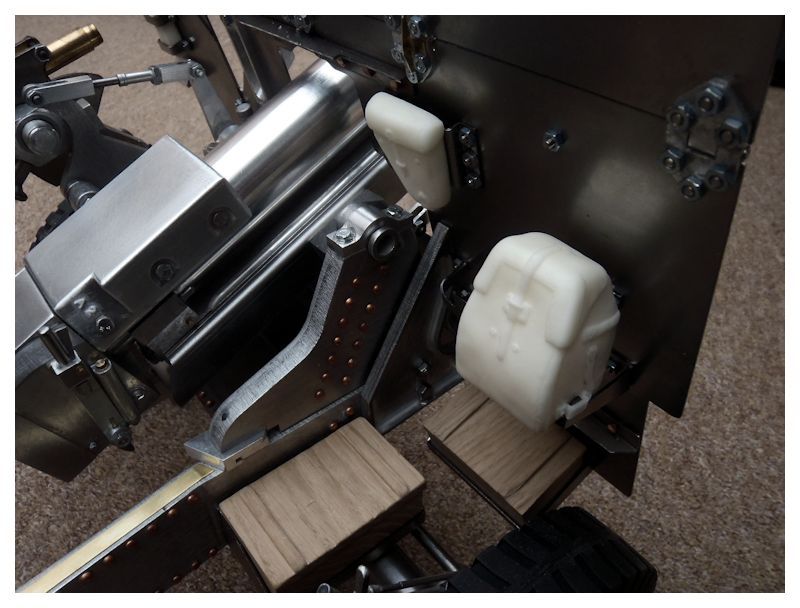

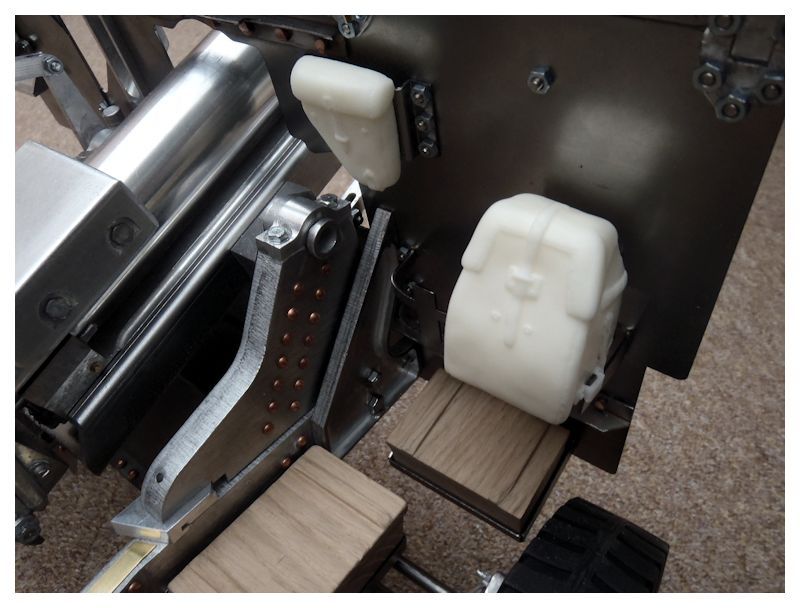

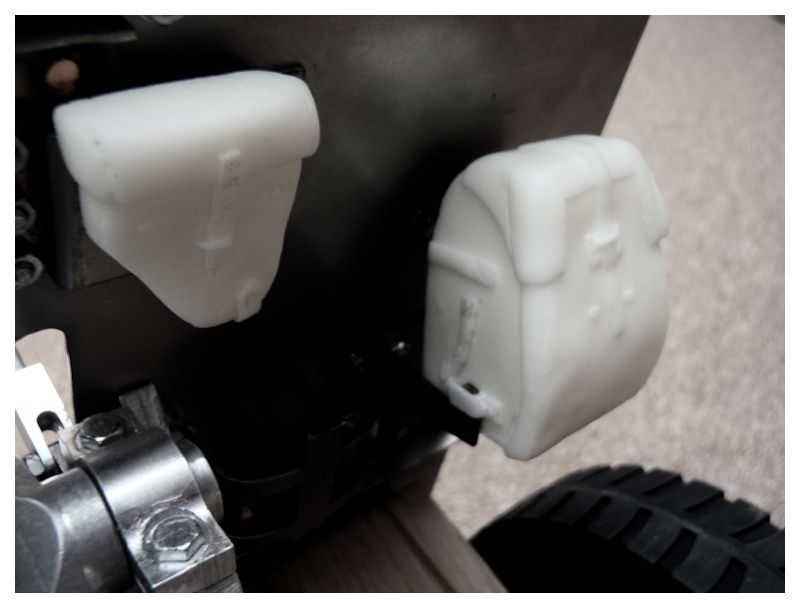

I've followed Leon's lead and reshaped the elevating wheels, I've also re-profiled the recoil slide nose casting.

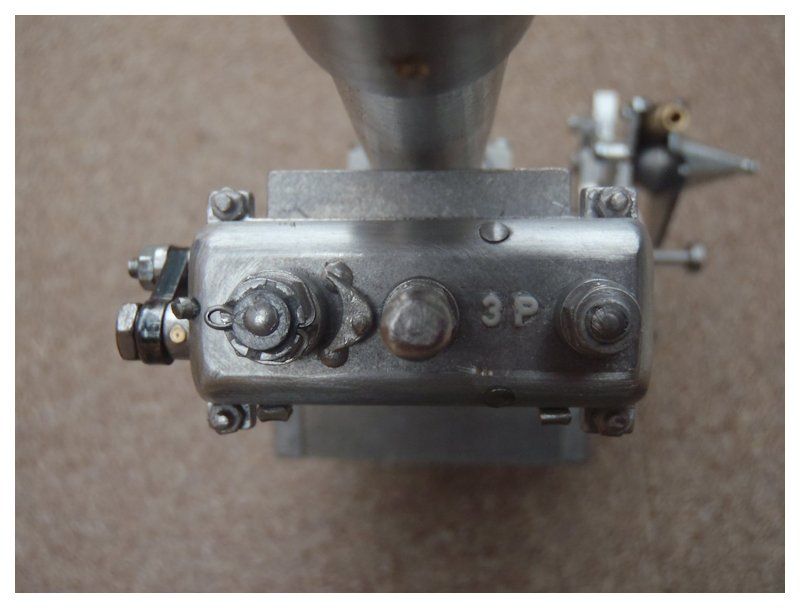

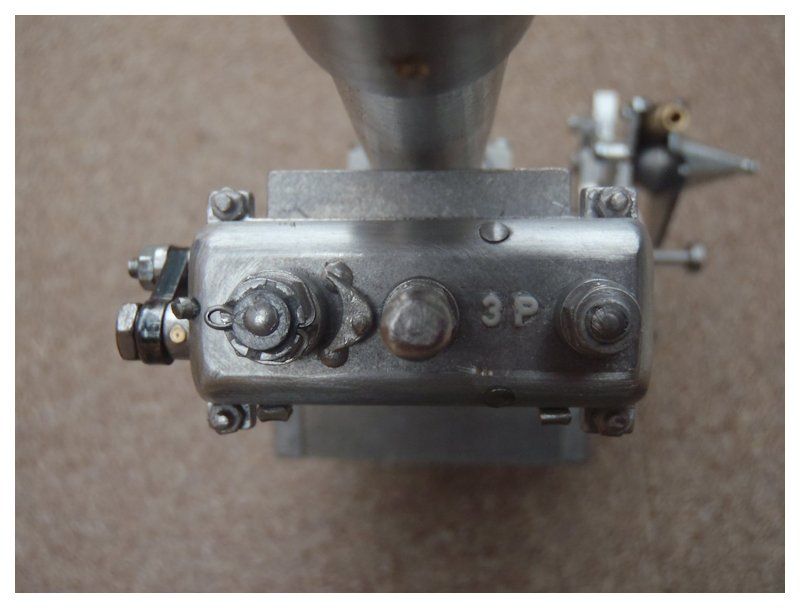

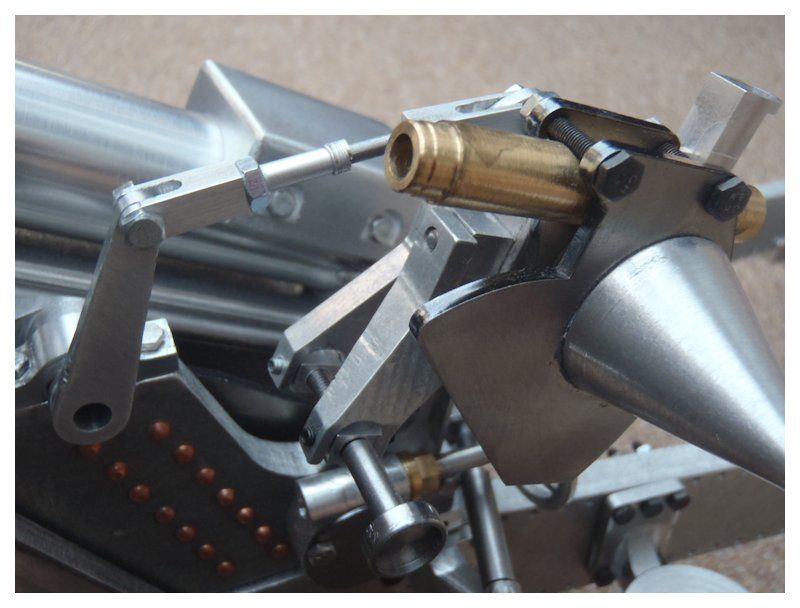

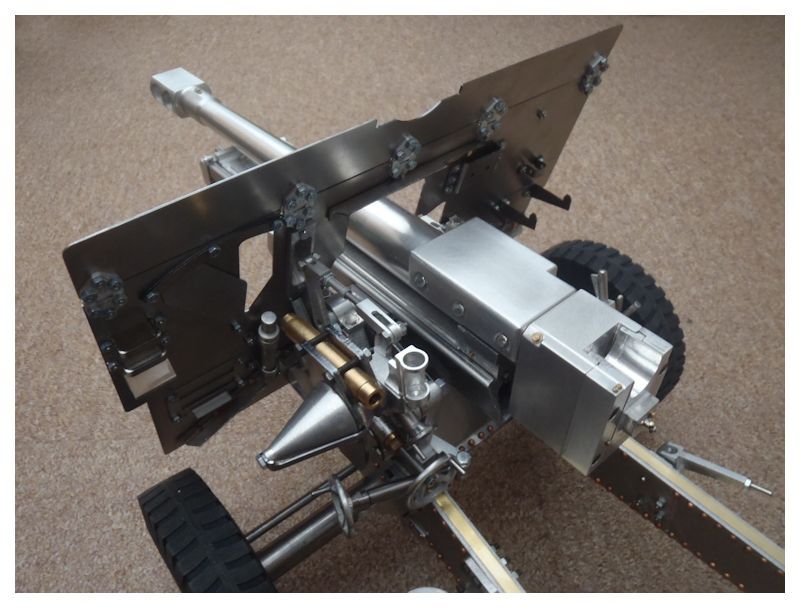

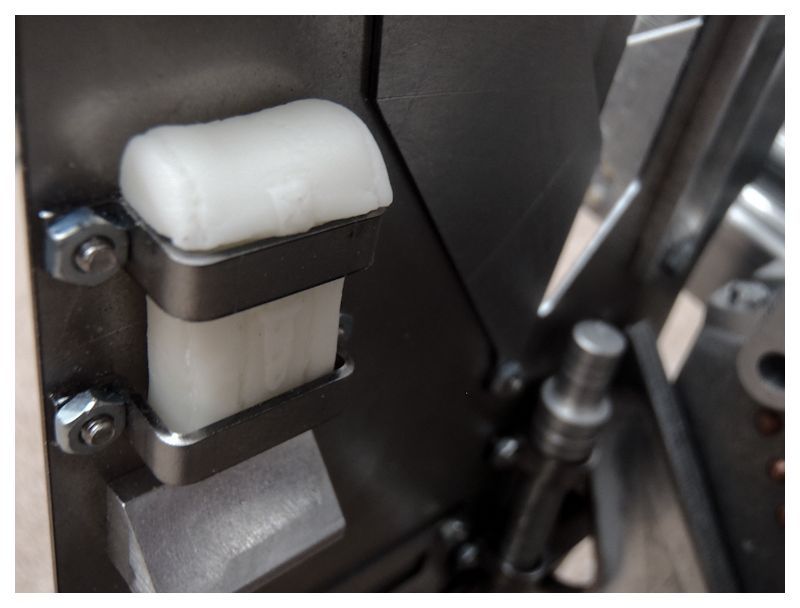

I have been hanging on to all sorts of little left over parts from the old Spearhead models and these have found a use in the detailing of the nose casting and breach block. The breach handle has been detailed and lots of lubricating points and adjusters added from EKP brass bolts.

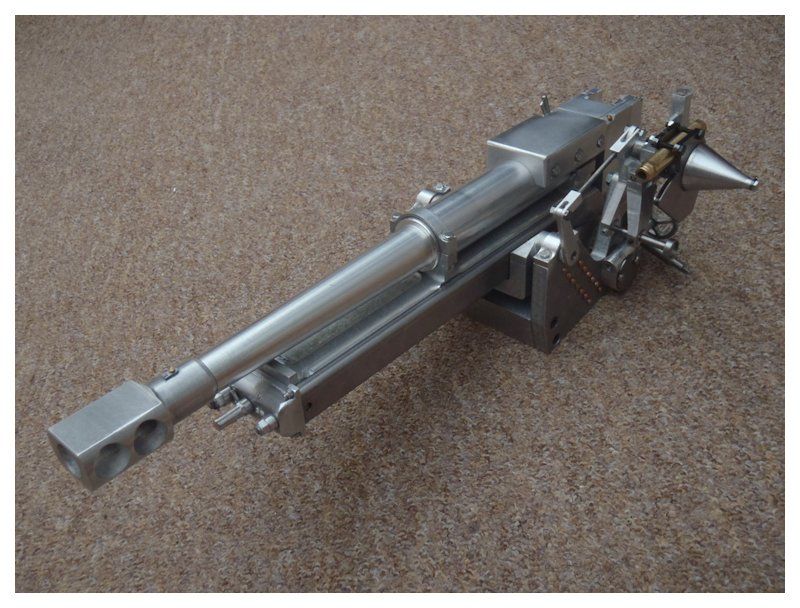

It would probably be easier to make some of the parts from plastic but I am trying to keep as much of the model in metal as possible.

I have settled for a friction lock on the breach handle and have just put the elevation mechanism together. The elevation works perfectly and I am sure the slew will also once assembled.

So far I have found my normal model making kit of needle files, scalpel, small vice and Dremel to be sufficient for most of what is shown. The only exceptions are I have used a larger engineering vice and full size files for re-profiling the breach counter weight and a full size hacksaw to modify the slide so it sits further forward over the recoil slide nose.

The Dremel is not proving up to the job of drilling the recoil slide for the bolts I want to add so that will have to be done with a pillar drill.

Best regards

Dave