Track skidding

-

Jan_Donadoni

- Posts: 151

- Joined: Fri May 21, 2010 8:20 am

- Location: Italy

- Has liked: 2 times

- Been liked: 6 times

Track skidding

Hello,

here's the second part of my first trip out with the Tiger.

The other (second) issue is directly related to the specific model.

I tried to tension enough the tracks, but on one side, in particular situations it happened that the sprocket (only on one side) started to skid on the track with a big nasty noise. Fortunately no damage at all.

I believe that it is simply a question of having more tension on the track, but would like to have a confirmation from other users.

here's the second part of my first trip out with the Tiger.

The other (second) issue is directly related to the specific model.

I tried to tension enough the tracks, but on one side, in particular situations it happened that the sprocket (only on one side) started to skid on the track with a big nasty noise. Fortunately no damage at all.

I believe that it is simply a question of having more tension on the track, but would like to have a confirmation from other users.

-

Christoffer Ahlfors

- Posts: 702

- Joined: Sun Feb 14, 2010 5:19 pm

- Location: Stockholm, Sweden

- Has liked: 746 times

- Been liked: 360 times

-

Jan_Donadoni

- Posts: 151

- Joined: Fri May 21, 2010 8:20 am

- Location: Italy

- Has liked: 2 times

- Been liked: 6 times

-

Andy Payne

- Posts: 76

- Joined: Sat Sep 15, 2007 12:47 pm

- Location: Cairns AUSTRALIA

- Been liked: 2 times

I've noticed that my Tiger has a tendency for the rearward traveling track only, to climb the sprocket.This really only occurs on surfaces that don't allow the tracks to skid freely.I don't consider this to be a real problem and tend to treat the Tiger cautiously when reversing,as they did on the full size machine.My track tension is set so that the track lightly touches the top of the second road wheel.

Regards

Andy

Regards

Andy

-

Andy Payne

- Posts: 76

- Joined: Sat Sep 15, 2007 12:47 pm

- Location: Cairns AUSTRALIA

- Been liked: 2 times

-

Phil Woollard

- Posts: 4281

- Joined: Mon Mar 01, 2010 4:48 pm

- Location: Cornwall

- Has liked: 2282 times

- Been liked: 7196 times

Oh the joys of a tracked vehicle i have a 1.5ton mini digger that will throw a track in certain conditions, you could check the rear idler alignment with the sprocket (using a piece of line or a straight edge) but i doubt that it would be out.Generally the problem gets better as the running gear "beds in", the crews of the 1/1 Tigers had much the same problem on occasion the track would ride over the sprocket and could bind so tightly that the only way to release the tension was to flame cut a link out or even destroy the vehicle under battle conditions if it could not be recovered.

I am not saying that you should destroy the vehicle but if you do please video it for me!

If you just wind up the tension to stop it slipping and there is something out of line it will still ride off the sprocket and force the suspension up on the 1st and 2nd road wheels as this slackens the track a tad (if you add weight, say if you stand on your tiger the tracks will become loose) as they are in constant tension from all those torsion bars.

Try to avoid traverseing a slope at an angle as this will almost certainly throw a track, take the slope evenly at a right angle. try to think like the driver would have done respect the engineering it was on it's limits with all that weight back in the 1940's even modern tanks suffer with running gear issuses.

You will eventually learn to keep a few select tools in your back pocket when you head out, all this adds to the fun but above all enjoy it!

So maybe keep the tracks just a little bit tighter.......cheers Phil

I am not saying that you should destroy the vehicle but if you do please video it for me!

If you just wind up the tension to stop it slipping and there is something out of line it will still ride off the sprocket and force the suspension up on the 1st and 2nd road wheels as this slackens the track a tad (if you add weight, say if you stand on your tiger the tracks will become loose) as they are in constant tension from all those torsion bars.

Try to avoid traverseing a slope at an angle as this will almost certainly throw a track, take the slope evenly at a right angle. try to think like the driver would have done respect the engineering it was on it's limits with all that weight back in the 1940's even modern tanks suffer with running gear issuses.

You will eventually learn to keep a few select tools in your back pocket when you head out, all this adds to the fun but above all enjoy it!

So maybe keep the tracks just a little bit tighter.......cheers Phil

Mechanical engineer.

2 Youtube channels, Phil Woollard and Magpiespyro. Facebook/ Phil Woollard.

Commission builds considered. Pm for my email.

2 Youtube channels, Phil Woollard and Magpiespyro. Facebook/ Phil Woollard.

Commission builds considered. Pm for my email.

-

David Ward

- Posts: 90

- Joined: Thu Jul 12, 2007 5:17 pm

- Location: Broadstairs, Kent

Hello Jan

Check out this old topic. You may have done it but if not it should help

http://www.armortek.co.uk/forum/viewtopic.php?t=284

David

Check out this old topic. You may have done it but if not it should help

http://www.armortek.co.uk/forum/viewtopic.php?t=284

David

-

Jan_Donadoni

- Posts: 151

- Joined: Fri May 21, 2010 8:20 am

- Location: Italy

- Has liked: 2 times

- Been liked: 6 times

Hello,

just one more question. Do you check tensioning with loaded conditions (that is with the tank on the ground) or unloaded (with the tank somehow suspended, I actually use some plates with free rotating tires, which allow me to move the tanks without effort when they are stored and with no batteries) with the track NOT touching the ground.

just one more question. Do you check tensioning with loaded conditions (that is with the tank on the ground) or unloaded (with the tank somehow suspended, I actually use some plates with free rotating tires, which allow me to move the tanks without effort when they are stored and with no batteries) with the track NOT touching the ground.

-

Phil Woollard

- Posts: 4281

- Joined: Mon Mar 01, 2010 4:48 pm

- Location: Cornwall

- Has liked: 2282 times

- Been liked: 7196 times

-

Tim Bowman

- Posts: 1762

- Joined: Fri Jul 13, 2007 4:53 am

- Location: Northern California

- Been liked: 177 times

- Contact:

Hi Jan,

I know two fellow builders who have spent a great deal of time perfecting the performance of their Tiger I tracks and running gear. In the end, it all came down to two main problems, both regarding the teeth on the drive sprocket.

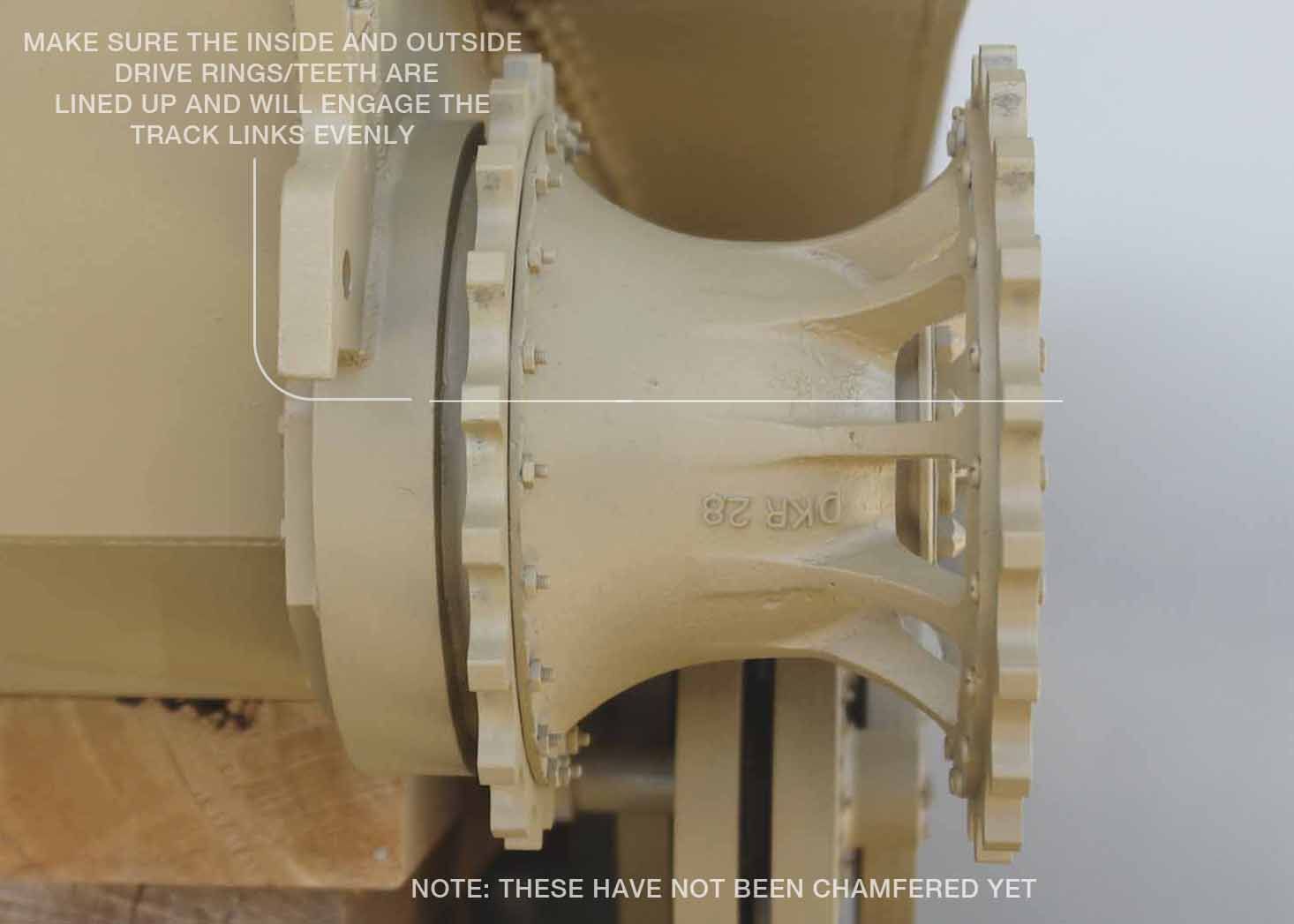

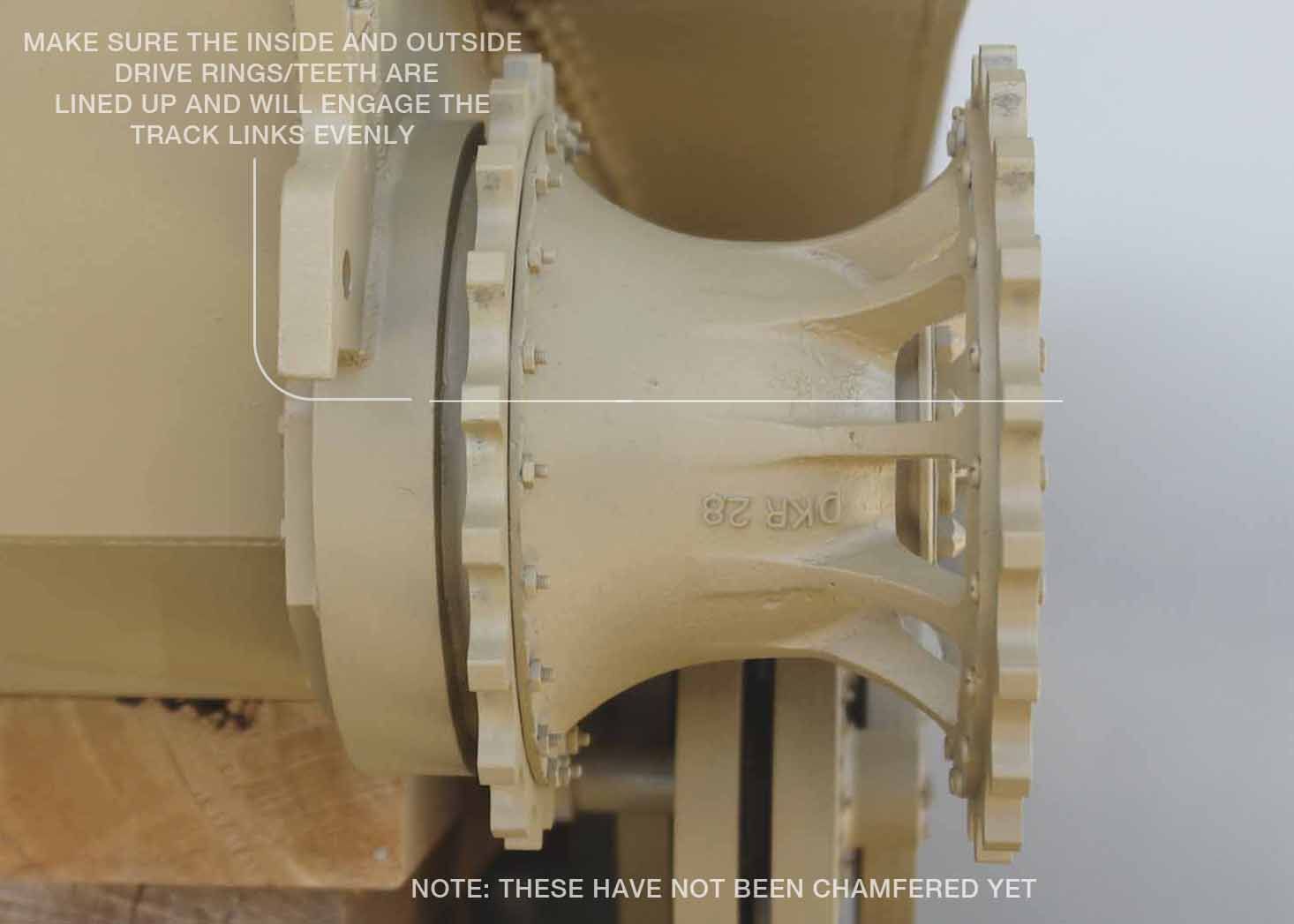

1. First ensure the inner and outer sprocket rings and teeth are lined up and all mounting holes are lined up. The holes can be drilled slightly if needed to allow for alignment. This can be checked and done by stacking the rings together while not mounted to the hub.

This photo is to show the alignment I am referring to.

If these are not aligned, the track will attempt to engage unevenly and cause one side or the other to ride up the teeth of one side.

2. Chamfer all teeth on all four sides.

Photo courtesy of Tim McCarthy

The difference in smoothness of running after adding the chamfers is amazing. A few years ago, Sean Cleary went through this whole exercise and I can tell you, his Tiger can run at full speed, spin on a dime with both tracks moving in opposite directions and climb steep inclines at any angle without any problems and the most amazing and noticeable thing was how quiet his tracks were compared to my Panthers. My Panther was clacking away(assuming the sound was from the corners of the teeth). Sean's Tiger was just purring along like a finely tuned machine.

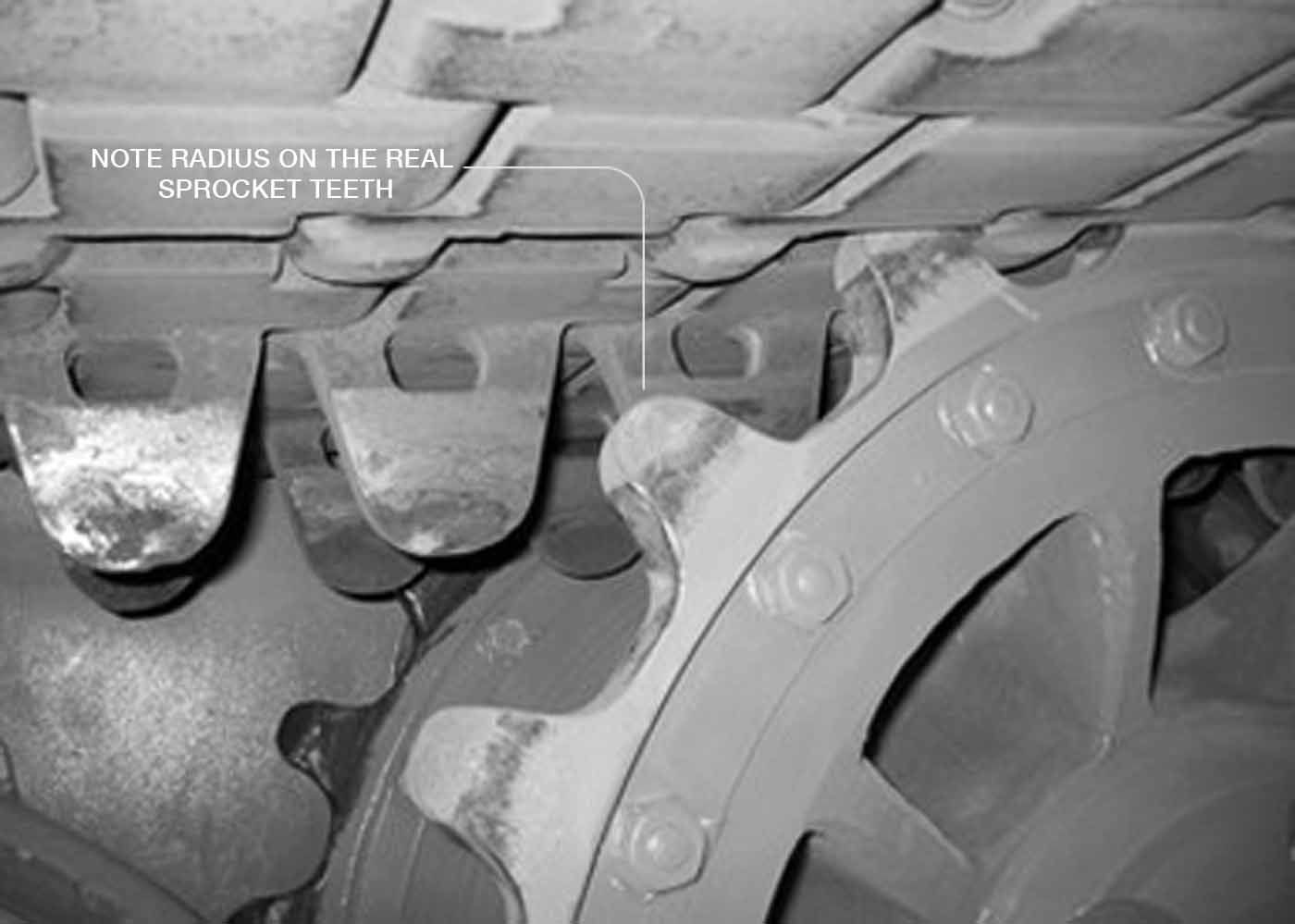

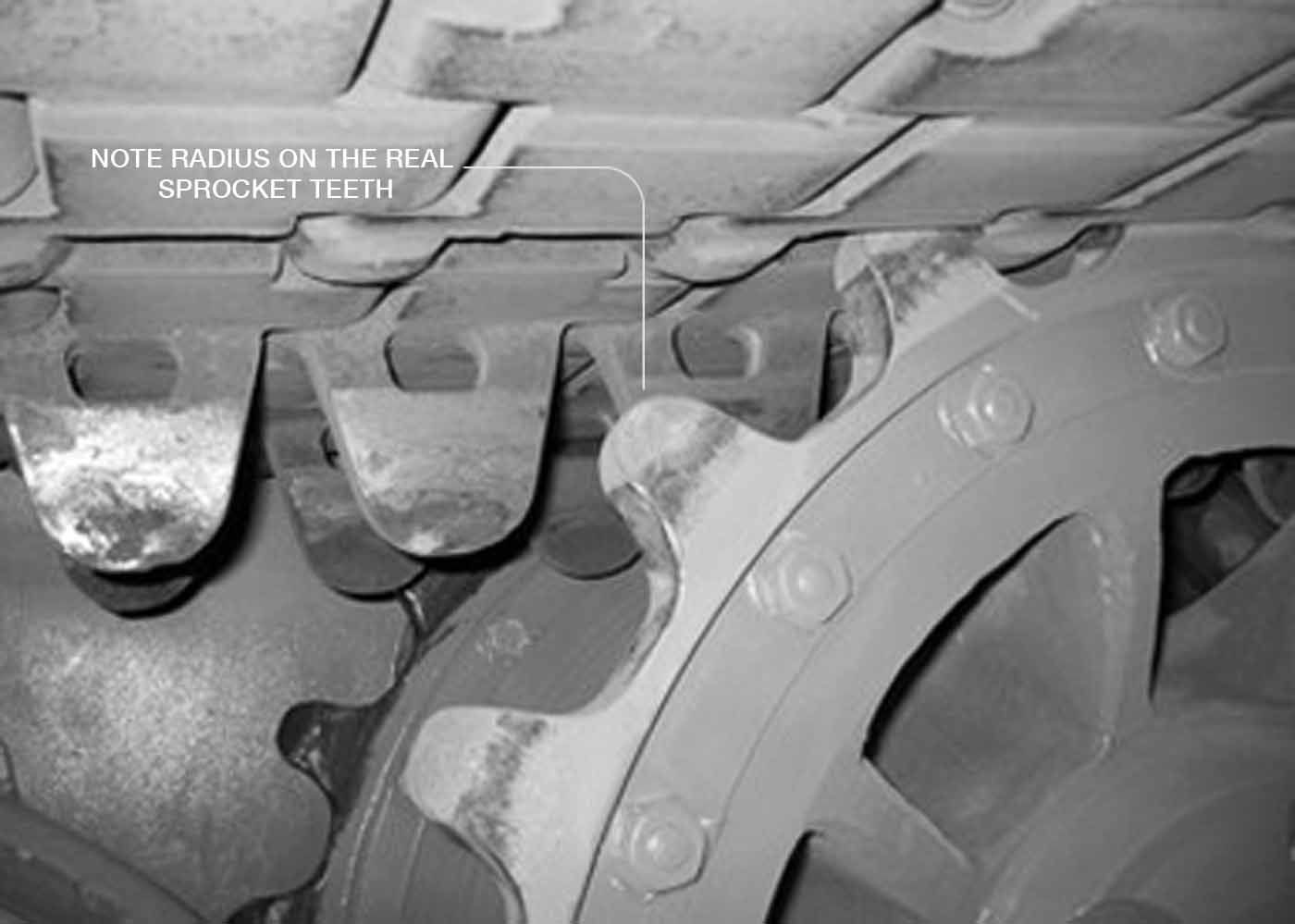

Notice how the real sprockets are radiused and chamfered. Some from wear but they are in the new parts as well. This allows them to easily find the guide-holes in the links.

Photo courtesy of alanhamby.com

Again, after much work and trying every tension combination, the two above modifications fixed all track/running issues.

Hope this is helpful

All the best Jan

Tim

I know two fellow builders who have spent a great deal of time perfecting the performance of their Tiger I tracks and running gear. In the end, it all came down to two main problems, both regarding the teeth on the drive sprocket.

1. First ensure the inner and outer sprocket rings and teeth are lined up and all mounting holes are lined up. The holes can be drilled slightly if needed to allow for alignment. This can be checked and done by stacking the rings together while not mounted to the hub.

This photo is to show the alignment I am referring to.

If these are not aligned, the track will attempt to engage unevenly and cause one side or the other to ride up the teeth of one side.

2. Chamfer all teeth on all four sides.

Photo courtesy of Tim McCarthy

The difference in smoothness of running after adding the chamfers is amazing. A few years ago, Sean Cleary went through this whole exercise and I can tell you, his Tiger can run at full speed, spin on a dime with both tracks moving in opposite directions and climb steep inclines at any angle without any problems and the most amazing and noticeable thing was how quiet his tracks were compared to my Panthers. My Panther was clacking away(assuming the sound was from the corners of the teeth). Sean's Tiger was just purring along like a finely tuned machine.

Notice how the real sprockets are radiused and chamfered. Some from wear but they are in the new parts as well. This allows them to easily find the guide-holes in the links.

Photo courtesy of alanhamby.com

Again, after much work and trying every tension combination, the two above modifications fixed all track/running issues.

Hope this is helpful

All the best Jan

Tim

"So long as one isn't carrying one's head under one's arm, things aren't too bad." – Erwin Rommel

-

Phil Woollard

- Posts: 4281

- Joined: Mon Mar 01, 2010 4:48 pm

- Location: Cornwall

- Has liked: 2282 times

- Been liked: 7196 times

Some excellent advice there Tim, I am in the process of installing A pair of new sprockets to a late tiger so I will chamfer all the surfaces that you mentioned rather than letting it bed in cheers Phil

Mechanical engineer.

2 Youtube channels, Phil Woollard and Magpiespyro. Facebook/ Phil Woollard.

Commission builds considered. Pm for my email.

2 Youtube channels, Phil Woollard and Magpiespyro. Facebook/ Phil Woollard.

Commission builds considered. Pm for my email.

-

David Gray

- Posts: 289

- Joined: Tue Jul 24, 2007 7:22 pm

- Location: chesterfield derbyshire

- Been liked: 1 time