Hi Adrian,

Well a CNC mill is a great present, but it is pretty involved I've found to get one to make parts. Once mastered though there is no end to what can be made for our models..

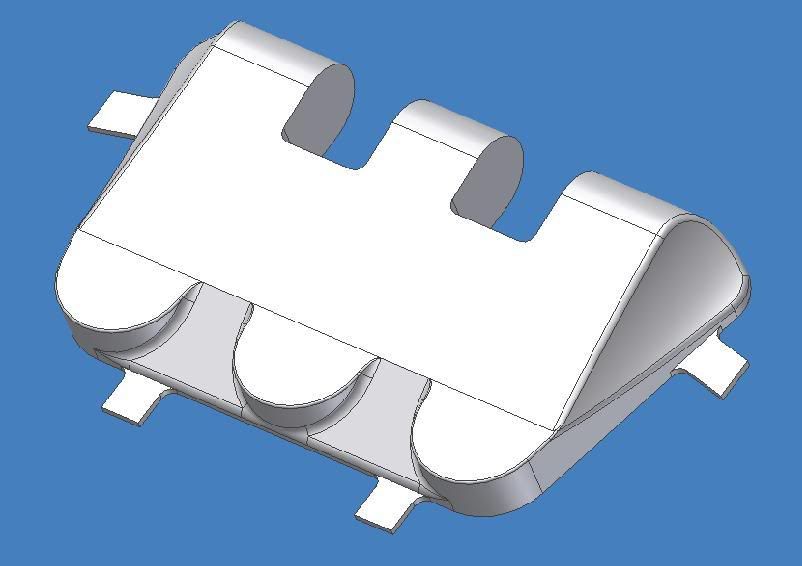

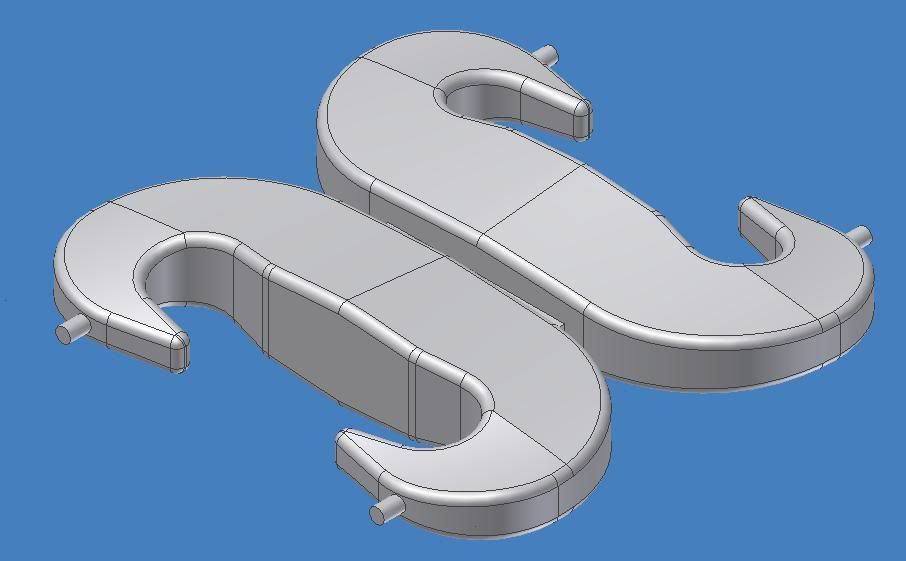

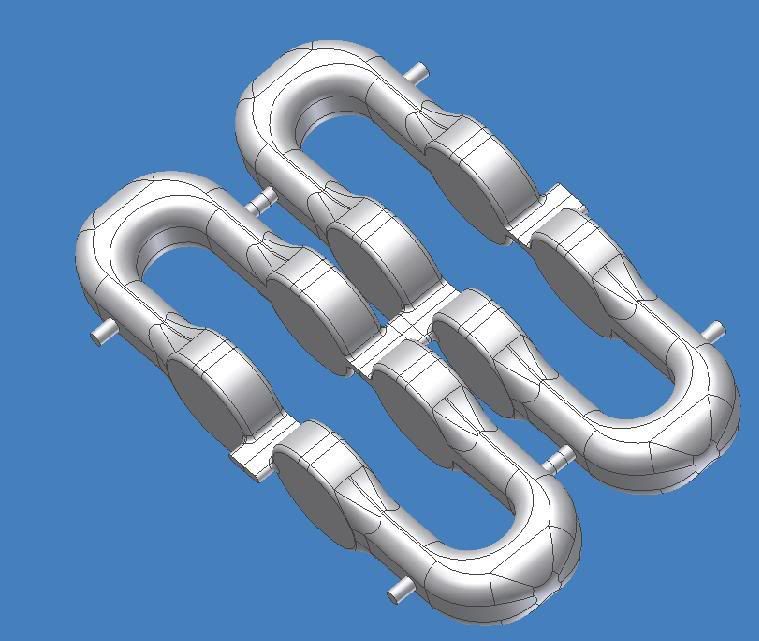

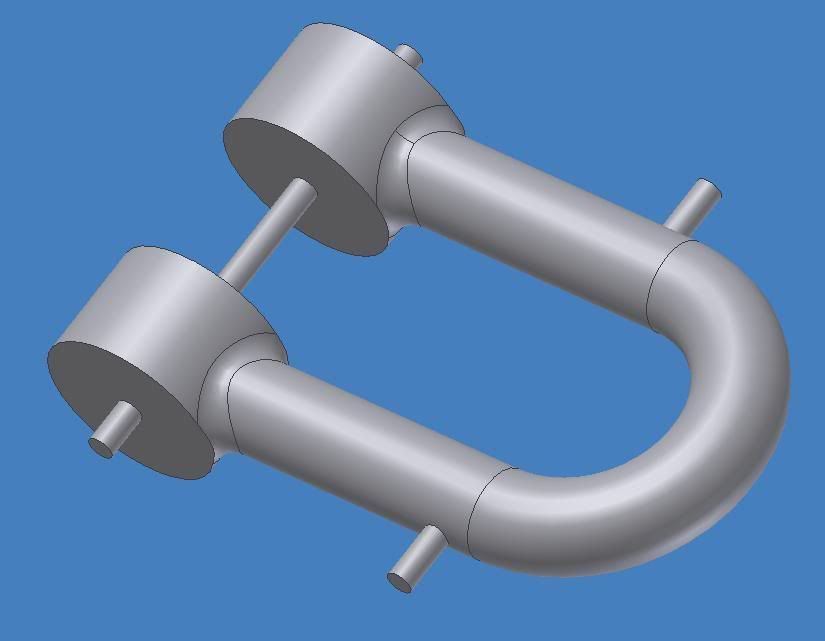

To answer your question on the shackle, the front and back halves are made with the same program. However, this process will only work if the part is symetrical, i.e. the same front and back. The shackles I made are symetrical, and the recovery hook as well - so the same program can be used for the front and back sides. Just run it twice. If the part is different on front to back, then you must have a different program for front and back halves.

Now the registration is another matter. Whenever you create any program you have a defined start point (X,Y, Z coordinate for the program zero pt). You must remember this point when you flip the part over to machine the back side. You must zero the tool from the same edges on the top and bottom side programs - otherwise the part will not come out correct. For example, if your zero point for the top side program is the lower left corner, when you flip the part over to machine the back side, the zero point will be the lower right corner (keeping same zero edge for the tool). Hopefully this makes since?

CNC is a pretty complicated process, but its not impossible for the average person to learn. One must have a pretty good grasp of manual machine processes and practices before digging into CNC.

The TAIG and Sherline CNC machines are both good investments for the money, and are great machines to learn CNC on. I think the TAIG is a more robust and capable machine than the Sherline, as the TAIG has more steel construction (heavier, more rigid). The Sherline is all Aluminum construction (except for lead screws, bearings, motor, chuck, etc). A good version of either machine can usually be bought on E-bay.

Another piece of the CNC puzzle you must conside is software. There is where the biggest learning curve is. In general there is control software (to control machine tool), CAD software for creating the part model you want to make, and program creating software (convert your CAD model to CNC language).

Feel free to e-mail me any additional questions you have via the Armortek private message forum or at

bobmorey2@yahoo.com.

Good luck and keep us posted on your progress.

Bob