> Do you have to worry about heat distortion when using the braze rod?

On the parts I'd brazed so far there doesn't seem to have been any distortion.

It's very scary to start with as you have no idea how hot the aluminium is becoming or how much futher you have before reaching melting point.

> Thats going to be a job to get those parts separated without damage.

They're all separated now, with just a few of the end connector wedges still having the remnants of screws stuck in them.

> Maybe soak the whole track in kerosine?

I tried diesel fuel, WD40, PlusGas and even the homebrew of acetone and auto transmission fluid but none seemed to have any effect on the parts. The only thing which worked reliably was heat from a butane torch. That was how I removed the track pins - clamp the pin in the vice, heat the track link for ten or fifteen seconds and then grip it tightly in a pair of leather gauntlets and twist the link from the pin.

I found it much easier to remove the screws from the end connectors using an allen key head in a small cordless screwdriver than to use a hand tool. I think the cordless started with enough of a jerk to release the screws. Of course, a few broke in the process as well though

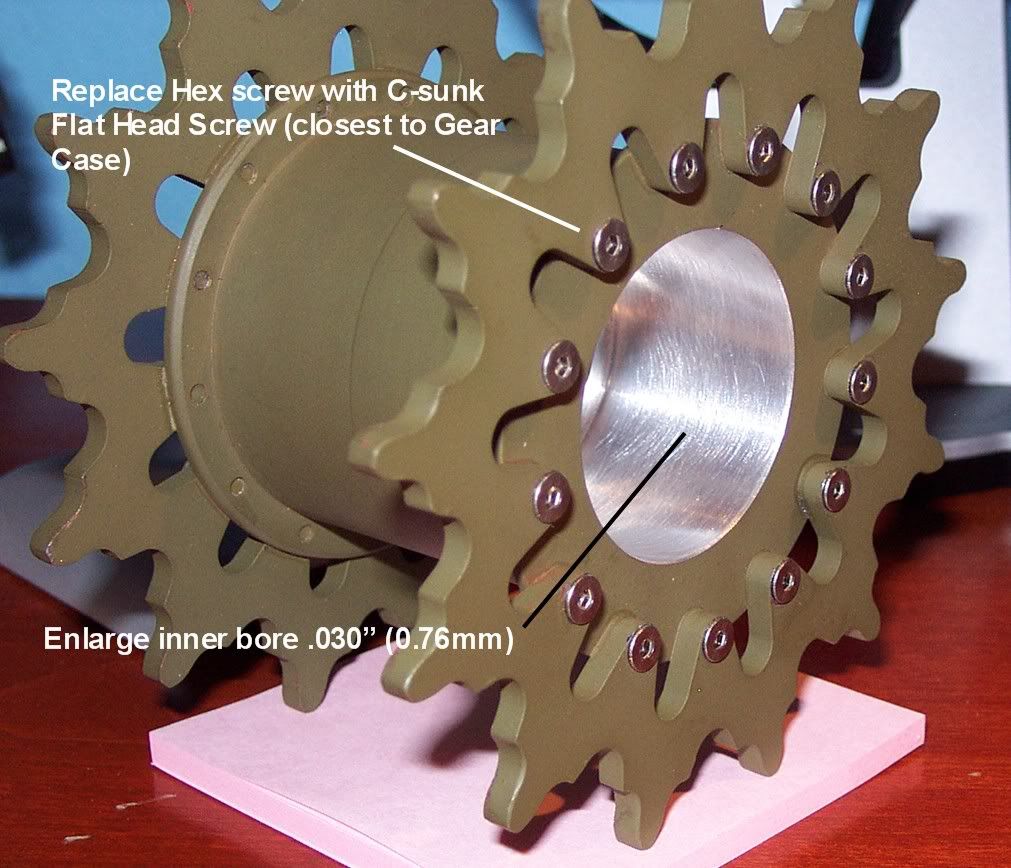

> I replaced the hex nuts on the inner sprockets with flat head screws

I think this is a must.

> I had problems with the sprocket inner bore rubbing the boss of the gear case, so I relieved the inner diameter of the sprocket a bit.

There are witness marks on one of the casing hubs from where the sprocket has loosened and rubbed. I may ease out the inners as well, to give more clearance, though if I can't get the seven broken screws out of one of the sprocket centres, I may end up turning new ones from scratch.

Adrian.

Bob

Bob