Page 1 of 4

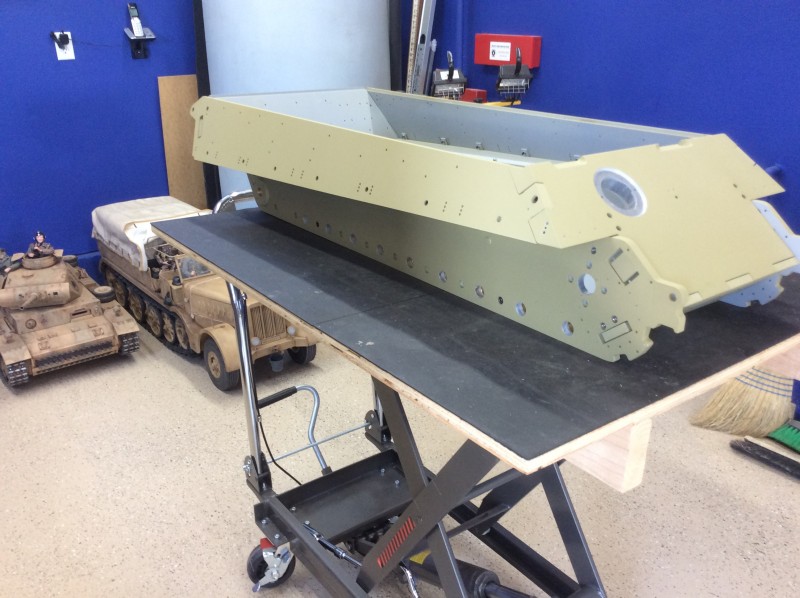

Tom's King Tiger Build 2019 Hull 53

Posted: Sat Jul 11, 2020 6:42 pm

by Tom Miller

Hello everyone,

Now that the Panzer and FAMO are complete I have started on the KT project. The project has started rather smoothly except for all the fitting required to get the hull together correctly. The upper and lower side plates had a significant bow in them that I got out by placing the parts on the shop floor with a block of wood at each end and jumping on the center. This is something Armortek should have remedied before shipping. There is also a lot of filling necessary to get all the parts to line up correctly. Not difficult just a lot of it. The rear plate in my kit is about 3/16 of an inch too hi. Since the part is too big to fit in my bench mill I resorted to filling slots in the part where it meets the frame to get it down so the top plates would line up correctly. With all that behind me the rest of the project has bee very enjoyable.

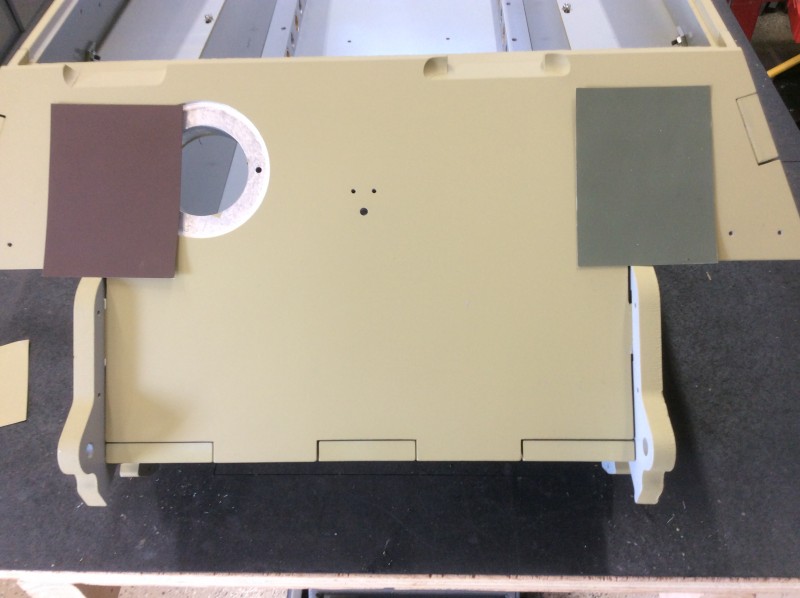

- Assembled hull painted RAL 7028.

- Shown are samples of the camo colors RAL 8017 and RAL 6003 I will use.

- Here you can see how much I had to lower the rear plate to get the top surfaces to line up correctly.

- Torsion bar assemblies painted and dry lubed.

- Resilient wheels. Lots of screws!!

- Track parts chemically blacken and ready for assembly.

- Track parts on the drying rack after blackening.

I am now waiting for the option paks to arrive. I want to install the drive motors while that area is accessible. Meanwhile I will start applying all the welds where appropriate.

Happy modeling,

Tom

Re: Tom's King Tiger Build 2019 Hull 53

Posted: Sat Jul 11, 2020 8:38 pm

by Phil Young

Hi Tom

I too had banana shaped hull sides and jumped up and down on them... but unfortunately not heavy enough to make an impression! Not having equipment to straighten them meant filing the decking to suit the bend. Also had to modify the track tensioner on one side to aligne the tensioner bolt with the tensioner slot. Yes, the rear plate needed adjusting too! There are other challenges you’ll come across, including decking brackets that cover fixing holes for the cable retaining brackets. It will be interesting to hear how you get on with the turret! Apart from that, it’s a great model and worth overcoming the challenges to produce a magnificent beast of a tank!

All the best with your build,

Phil.

Re: Tom's King Tiger Build 2019 Hull 53

Posted: Wed Aug 05, 2020 9:14 pm

by Tom Miller

Hi Guys,

I have been installing the option paks in my KT. Everything went together smoothly and works great. I love the main gun sound.

I modified the rear deck assembly to be removable like Simon Manning did in his KT build post. In addition I slotted the 3 holes in the rear mounting bracket to make the hatch easier to remove. Now the batteries can be removed by only removing the rear deck. Inside the hinged hatch in the rear deck is a great place to install the charging plug, on/off switches and smoke refill tubes. The small hatches in the front deck make good access the the volume knob and binding switch on the receiver.

Re: Tom's King Tiger Build 2019 Hull 53

Posted: Thu Aug 06, 2020 7:47 am

by Chang

Building is fast and very good.

The "16:3" writing on the drive motor, what is it stand for?

Regards,

Lerh Chang

Re: Tom's King Tiger Build 2019 Hull 53

Posted: Thu Aug 06, 2020 8:28 am

by Vince Cutajar

I suspect that's the gear ratio of the motor gearbox.

Vince

Re: Tom's King Tiger Build 2019 Hull 53

Posted: Fri Aug 07, 2020 8:58 pm

by Brian Ostlind

Tom looking good! What kind of burnishing liquid did use for the tracks?!

Re: Tom's King Tiger Build 2019 Hull 53

Posted: Sat Aug 08, 2020 2:25 am

by Tom Miller

Hi Brian,

Here is a link to the article I posted in the knowledge base.

viewtopic.php?f=32&t=8150

Re: Tom's King Tiger Build 2019 Hull 53

Posted: Sat Aug 08, 2020 4:23 am

by Brian Ostlind

Re: Tom's King Tiger Build 2019 Hull 53

Posted: Mon Aug 10, 2020 2:25 pm

by RChianese

Hi Tom,

Looking good! On your hull construction, did you find the upper hull sides to be difficult to line up? On my No. 18, the screw hole to the upper front plate is off by quite a bit. The solution appears to be to put it up on a mill and skim 0.0625 or more where the side plate meets the back of the front glacis plate. Your post suggests a lot of filing, but I just want to see how you did yours.

Thanks

Robert

Re: Tom's King Tiger Build 2019 Hull 53

Posted: Mon Aug 10, 2020 4:50 pm

by Tom Miller

Hi Robert,

My parts lined up pretty well at the front. If you can fit the parts in a mill that would be a lot easier and accurate than filing. These parts have a lot of angles on them and in Armortek's defense, even the smallest misalignment in machining will make huge misalignment with parts of this size. The whole assembly was very frustrating. I am in the process of adding welds to all the seems 1. for realism and 2. to cover the less than perfect seams. Hang in there. The kit is a lot more fun once you get past the hull stage.

Tom

Re: Tom's King Tiger Build 2019 Hull 53

Posted: Tue Aug 11, 2020 2:05 am

by Jerry Carducci

Phil Young wrote: ↑Sat Jul 11, 2020 8:38 pm

Hi Tom

I too had banana shaped hull sides and jumped up and down on them... but unfortunately not heavy enough to make an impression! Not having equipment to straighten them meant filing the decking to suit the bend. Also had to modify the track tensioner on one side to aligne the tensioner bolt with the tensioner slot. Yes, the rear plate needed adjusting too! There are other challenges you’ll come across, including decking brackets that cover fixing holes for the cable retaining brackets. It will be interesting to hear how you get on with the turret! Apart from that, it’s a great model and worth overcoming the challenges to produce a magnificent beast of a tank!

All the best with your build,

Phil.

I'm curious about this bent hull side issue. How bent are these pieces? I have a KT kit that I've yet to begin and I want to know what I'm up against.

I do have machine tools but up to this point I've been working on 1/10 scale so my machine can handle some larger bits but there will be limits. I

have a 20 ton hydraulic press but don't wish to over do it..assuming it can fit these things.

Jerry

Re: Tom's King Tiger Build 2019 Hull 53

Posted: Tue Aug 11, 2020 2:33 am

by Tom Miller

Hi Jerry,

The upper and lower sides in my kit had about a 1/4" of bow in them. Your press should do the job assuming they will fit. You should support the parts at each end and press down in the center. I stood in the center and bounced up and down. It worked for me because I am 6' 8" and weigh 230lbs. If you do not try to straighten the sides, some of the bow will come out when they are bolted to other parts.

Good Luck

Re: Tom's King Tiger Build 2019 Hull 53

Posted: Tue Aug 11, 2020 1:32 pm

by RChianese

Thanks for the feedback Tom! I was able to make some headway last night and got it together.

What product are you using for your weld seams and how do you plan to fill in the large holes? I was thinking epoxy putty for weld seams and larger holes while using car bondo for any screw holes. Someone suggested using solder for the screw holes and possibly melting casting blocks for the larger ones. Any opinions?

Re: Tom's King Tiger Build 2019 Hull 53

Posted: Tue Aug 11, 2020 5:08 pm

by Tom Miller

Robert,

I use an automotive body filler sold a NAPA made by Martin Senour paints called pro grip. It comes in an 8oz pouch and is a two part product. Nice because it is a small pouch. Most body fillers com in big cans and you can mix small quantities. I use it to fill large and small holes, flat head screw holes and cracks.

I use Milliput modeling clay for weld simulation. Available in most hobby shops or on line. It comes in several varieties. I use the standard product. It also is a two part product. I mix the two parts and roll it out into "worms" about 3/16 thick and press it into place. Then use a flat tip tool to make weld bead impressions.

Have fun.

Tom

Re: Tom's King Tiger Build 2019 Hull 53

Posted: Sat Aug 15, 2020 4:42 pm

by Brenton Dolter

Hello Tom

When you lowered your rear hull plate did you have to remove extra material off of the bottom that protruded past the lower hull side plates ? Do you agree that the rear hull plate when fit should sit on top of side plates to look right. I can raise my rear plate and still make everything fit and level but don’t think it looks right. Here are some pics of how my back end looks at the moment

Brent