Page 1 of 1

Setting the suspension shaft technique late tiger?

Posted: Sat Jun 21, 2008 2:35 am

by Tim McCarthy

G'day Fellows

I am setting the suspension arms on my late tiger and I an curious as to what technique did you use to set the suspension arm angle in relation to marking ,filling, milling to get all the first 6 arms at the same angle?

Regards

Tim

Posted: Sat Jun 21, 2008 7:01 am

by Roland Mann

Hi Tim,

there is a topic "tiger suspension" in this section. It tells you everthing you like to know. Good luck and best regards from an early Tiger man

Roland

Posted: Sat Jun 21, 2008 11:37 pm

by Dale jordan

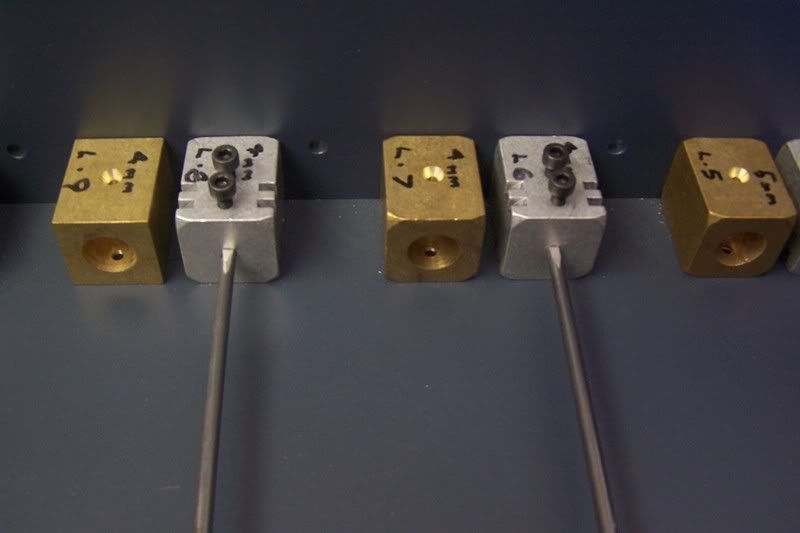

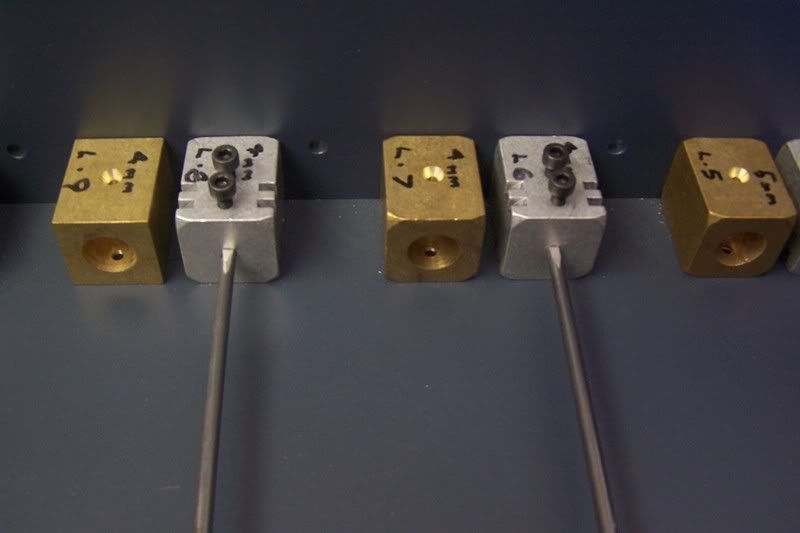

Hello Tim .. Here is a photo of the jig that I made out of scrap timber . when you have work out the height of the hole in the jig to give the correct angle clamp the torsion bar in a vice and file the end parrel to your bench . the flat should be 20mm long 3mm wide .

Posted: Sat Jun 21, 2008 11:38 pm

by Dale jordan

Tim this is how the other end should look . Tim notice how the flat tapers back to the round of the torsion bar .

Posted: Sat Jun 21, 2008 11:42 pm

by Dale jordan

Tim good news I have just found my long lost CD showing all my early mod's on my tiger . So today I will make you and Adrian a copy and post them off to you both . Dale

Posted: Sun Jun 22, 2008 8:01 am

by Adrian Harris

That's great Dale - many thanks

That's an ingenious rig for setting the angle and yet beautifully simple.

It hadn't occured to me until recently that the angle of the axle end will be unknown until it has been screwed into the swing arm. I had assumed I could just file the flats at set angles on the torsion bars

Adrian

Posted: Sun Jun 22, 2008 12:03 pm

by Dale jordan

Adrian one more tip for you !! Have a look at the photo above see the torsion bar axle with the big blob on it . I removed all of them a turned them down on my lathe to the same dia as the radius of the cast Drop arm . I carnt remember why It was a while ago .. I think it hit the next wheel or something . I'm at home tonight , when I go to work tommorow I will post a photo . let me know if this will help . One thing I know was it was a pain to strip my running gear down to re- do it , I wish someone had told me about it .. Dale

Posted: Fri Jun 27, 2008 11:57 am

by Tim McCarthy

G'day Dale

Thanks for the CD.

I will study next week.

Once you had done yours was each axle perfect or what variants did you have?

Tim

Posted: Fri Jun 27, 2008 7:42 pm

by Allan Richards

Tim,

Here are the pictures of the jig I made, which I hope are fairly self explanatory. The jig only took an hour to make but it guarranttees that each bar is ground to the same angle.

Posted: Sat Jun 28, 2008 5:02 am

by Tim McCarthy

Thanks Alan for the reply.

Thanks Roland for the referral link.

From yourself and Dale I have made a temp jig but something is not right as when I put them in the angles are changing 2 degrees plus or minus.

Should i get the angle close then slight file to get perfect.

Regards

Tim

Posted: Mon Jun 30, 2008 6:00 am

by willie leonard

Thanks Gentlemen! for the insite about filing the torsion bar flats.I had no idea how to get all of them exact,and your pictures of the custom jigs were just what I needed.I just spent the last three hours going through my jadgpanther manual and I know this will not be my last inquiry.