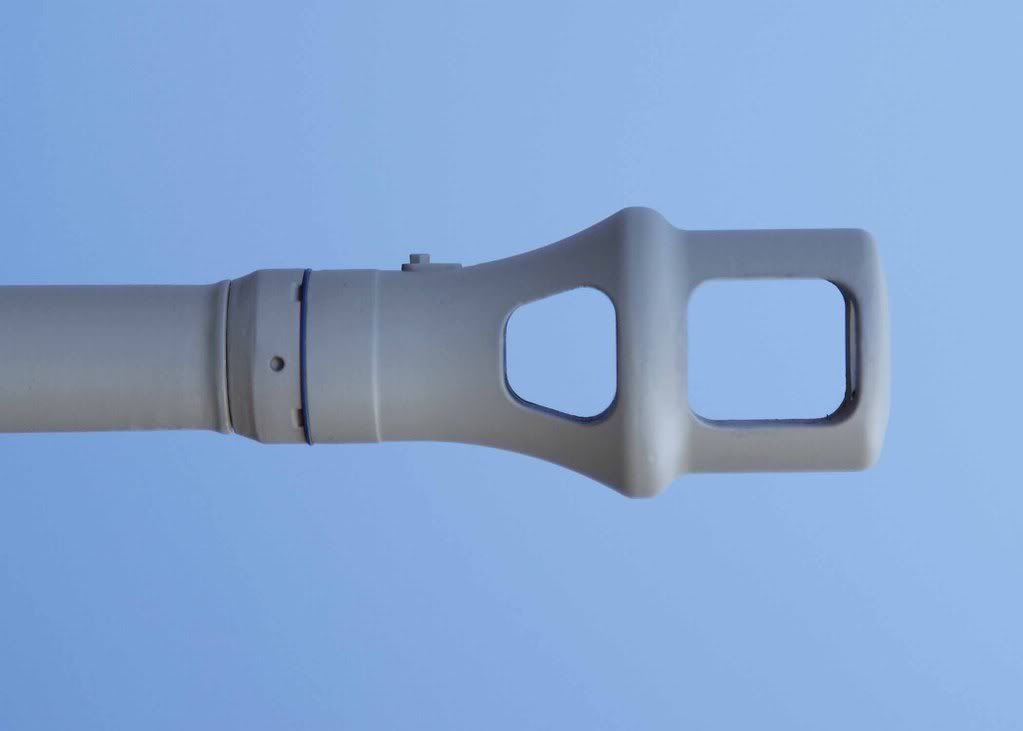

Finally took care of this. Still contemplating whether or not to do the interior of the muzzle as well. I have yet to make the washer that goes between the collar and the break.

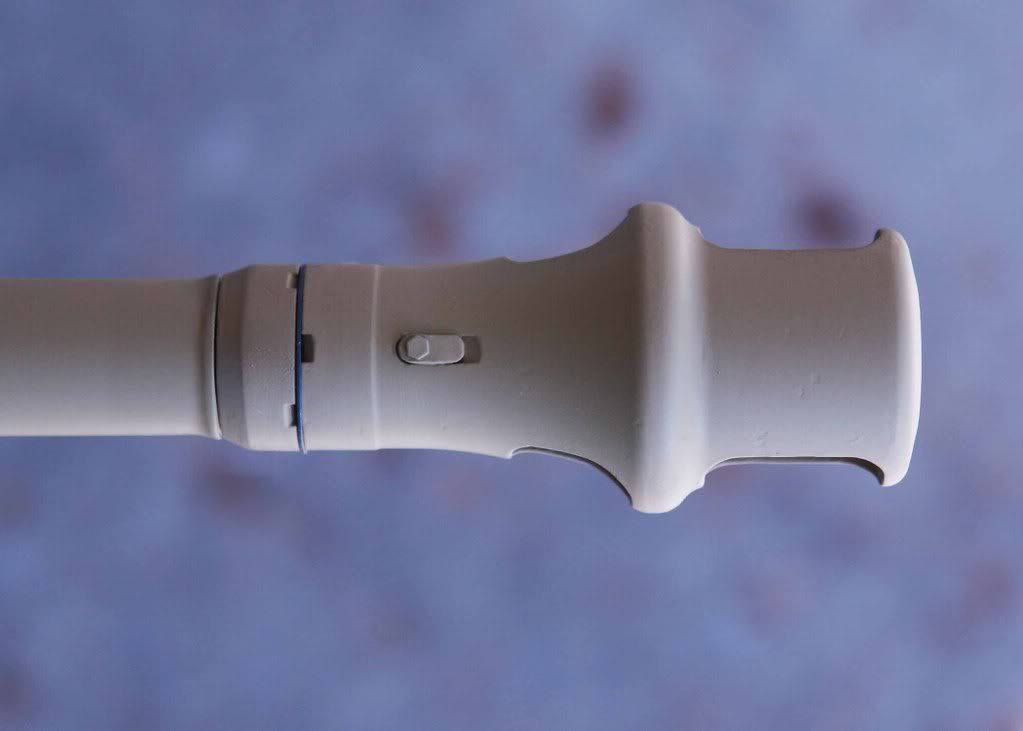

The real thing off of Littlefield,s Panther Ausf A (missing the center-lock tab). From what I could tell, the ausf G did not have the flange on the barrel before the muzzle break and the collar is thicker on the G. This photo courtesy of Bob Morey

Regards

Tim