Hi

The second box did arrive, thanks to Gill giving UPS a rocket!

All you 'cat' owners, out there, especially those slow, overweight Tigers, beware!

There will shortly be a Firefly with a sting in its tail..... all 17lbs of discarding sabot sting!

seriously, you my have gathered from my early posts, that i do not have many engineering skills or knowledge (under statement). So I need to ask some very basic questions.

My Firefly is going to built straight from the 'box'. With only minor additions. I dont posess the tools or the skills to do much more!

1st question:-

I had to buy a countersink to deepen the holes in the flanges, that attach the flanges to the dif case parts. On reading the instructions on the card, after i had completed the operation, it said i should have lubricated the countersink during the cutting opperation,

! What do you use to lubricate cutting tools on aluminium?

2nd question:-

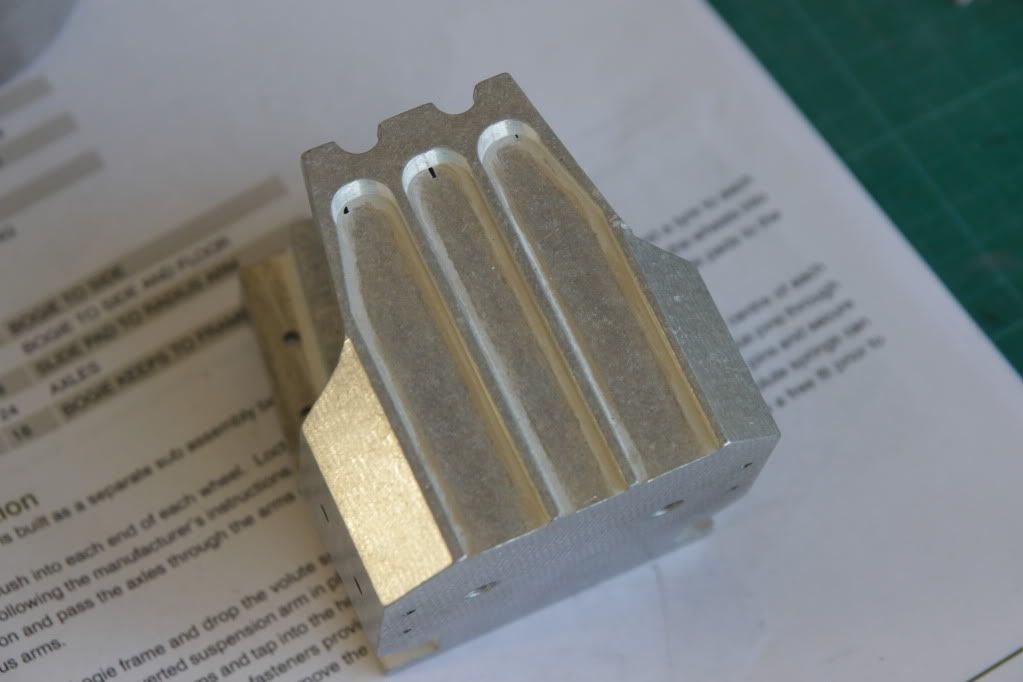

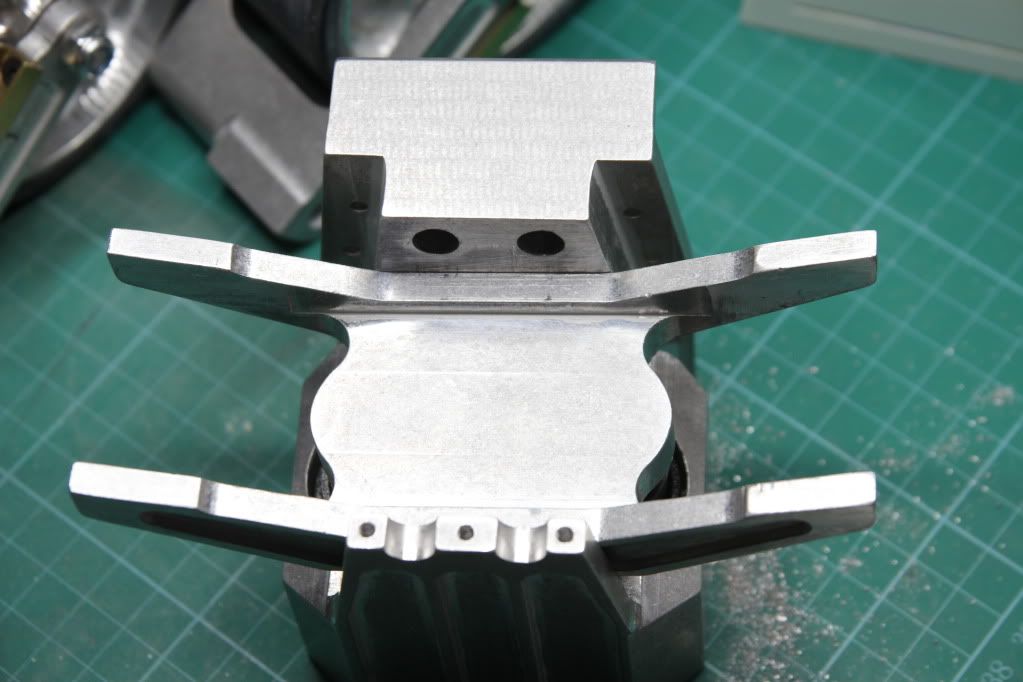

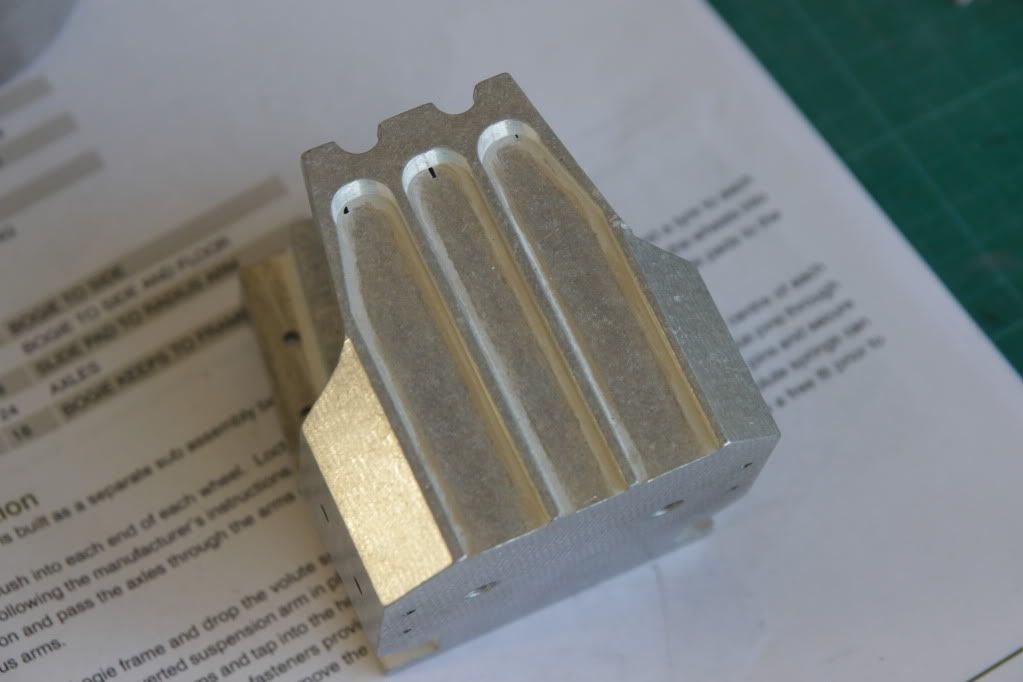

I would like to radius the top edge of the bogies, to keep it looking like the original. Is there a simple way to do this? I have files, and a Dremel!

3rd question:-

In the instructions, for the construction of the bogies, it says 'Loctite can be used to retain the bushes'in the wheels. Having looked on the internet, there are a lot of Loctite products, which one would be most suitable?

4th question:-

What adhesive would you use to bond the tyres to the wheels?

My apologies if these questions seem trivial, i'm on a very steep learning curve!

To all those who send replies to my questions, my I thank you now!

To all those members of the forum who follow my build and smile, or frown, at my questions (or howl with laughter) there will be many opportunities to smile and or frown, during the coming months.

Regards to all

John Wiggins