Radius arms

-

Dale jordan

- Posts: 1460

- Joined: Fri Jul 13, 2007 1:10 am

- Location: Port Macquarie Australia

- Been liked: 525 times

- Contact:

Radius arms

Can someone give me their thoughts on how to do the holes in the sherman radius arms to take the nuts to hold down the slide pads . I don't own a milling machine . I do have a good drill press can the hole be drilled and filed . and if so what size are they ?? And should the holes go right the way though?? Dale

Online

- Robert E Morey

- Posts: 2356

- Joined: Wed Jul 18, 2007 12:59 am

- Location: Seattle, WA USA

- Has liked: 166 times

- Been liked: 849 times

Dale,

These are slots and should be milled ideally. I don't recommend going all the way through the arm as this would weaken the arm too much. If you have a lathe you might set something up to mill the slots that way? I.E. Hold the cutter bit in the lathe spindle, and fasten the arm to the cross slide at the correct height. Then machine the slots on one side and flip the part around and mill the other two slots.

Its possible to do this way without a mill.

Bob

These are slots and should be milled ideally. I don't recommend going all the way through the arm as this would weaken the arm too much. If you have a lathe you might set something up to mill the slots that way? I.E. Hold the cutter bit in the lathe spindle, and fasten the arm to the cross slide at the correct height. Then machine the slots on one side and flip the part around and mill the other two slots.

Its possible to do this way without a mill.

Bob

-

Dale jordan

- Posts: 1460

- Joined: Fri Jul 13, 2007 1:10 am

- Location: Port Macquarie Australia

- Been liked: 525 times

- Contact:

RADIUS ARM

Now thats a good idea Bob !!! . I have a metal working lathe . I have already made a mess of one of the radius arms . So I will try your way. Bob I think I read somewhere on the forum that you cut the brass nuts in half , then glued them in place under the slid pads is this correct?? Dale.

-

David Ward

- Posts: 90

- Joined: Thu Jul 12, 2007 5:17 pm

- Location: Broadstairs, Kent

-

Allan Richards

- Posts: 743

- Joined: Thu Jul 12, 2007 10:34 am

- Location: Kent

- Been liked: 10 times

Dale,

I don't think cutting slots will weaken the arms too much, I cut mine by drilling two holes to from the ends of the slots then filing bewtween them to make the slot. This way you can use 2mm csk screws and nuts to hold the guide plates on.

I think it was Fabrice who used the half nut technique.

I don't think cutting slots will weaken the arms too much, I cut mine by drilling two holes to from the ends of the slots then filing bewtween them to make the slot. This way you can use 2mm csk screws and nuts to hold the guide plates on.

I think it was Fabrice who used the half nut technique.

Allan Richards

-

Dale jordan

- Posts: 1460

- Joined: Fri Jul 13, 2007 1:10 am

- Location: Port Macquarie Australia

- Been liked: 525 times

- Contact:

sherman

Thanks for the help guys . David the photos are great help as well . One more question Please . What is the best way to do the casting numbers on the bogies . ?? Did they have letters as well as numbers ? Where they batch numbers our serial numbers . Would the same numbers be on each bogies for the same tank . Dale

- Adrian Harris

- Posts: 5134

- Joined: Thu Jul 12, 2007 10:46 pm

- Location: Berkshire (UK)

- Has liked: 1495 times

- Been liked: 1699 times

Online

- Robert E Morey

- Posts: 2356

- Joined: Wed Jul 18, 2007 12:59 am

- Location: Seattle, WA USA

- Has liked: 166 times

- Been liked: 849 times

Dale,

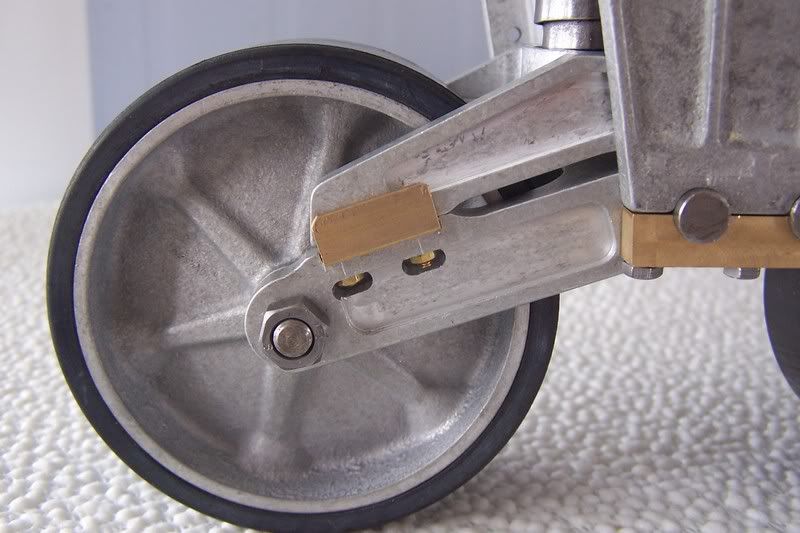

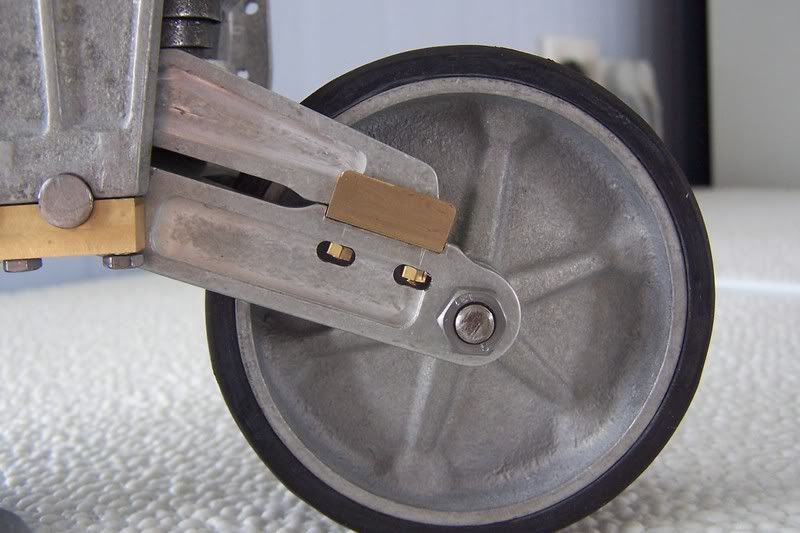

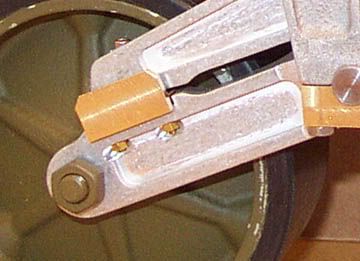

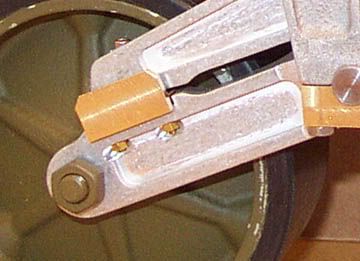

No I used full nuts on the arms. The screws are flat heads and go through the brass slide pad into the nuts holding the part on. Cut the slots just deep enough for the nut to go on the screw shaft. Or as some suggest, cut the slot all the way through and put a full nut on.

See photo below.

As for casting numbers on the models you can get small plastic styrene numbers from rail road supply places. Then cyano them to the model and paint. They're not perfect, but look pretty good. See below.

No I used full nuts on the arms. The screws are flat heads and go through the brass slide pad into the nuts holding the part on. Cut the slots just deep enough for the nut to go on the screw shaft. Or as some suggest, cut the slot all the way through and put a full nut on.

See photo below.

As for casting numbers on the models you can get small plastic styrene numbers from rail road supply places. Then cyano them to the model and paint. They're not perfect, but look pretty good. See below.

-

Dale jordan

- Posts: 1460

- Joined: Fri Jul 13, 2007 1:10 am

- Location: Port Macquarie Australia

- Been liked: 525 times

- Contact:

sherman

Great info Bob. Nice photos as well . I think I will source some of those numbers. It's these little things that take our models to the next level. Dale

-

Dale jordan

- Posts: 1460

- Joined: Fri Jul 13, 2007 1:10 am

- Location: Port Macquarie Australia

- Been liked: 525 times

- Contact:

sherman

After walking around my sherman for a couple of days and looking at my plain radius arms . I decided to have another go at milling the holes for the nuts under the slide pads . So I took Bobs advice , and last night sent up my lathe as he suggested . It was easy , once It got the packing height right and the speed correct away you go . As you can see they look much better . Dale.

-

Dale jordan

- Posts: 1460

- Joined: Fri Jul 13, 2007 1:10 am

- Location: Port Macquarie Australia

- Been liked: 525 times

- Contact:

-

Dale jordan

- Posts: 1460

- Joined: Fri Jul 13, 2007 1:10 am

- Location: Port Macquarie Australia

- Been liked: 525 times

- Contact:

-

Allan Richards

- Posts: 743

- Joined: Thu Jul 12, 2007 10:34 am

- Location: Kent

- Been liked: 10 times

Online

- Robert E Morey

- Posts: 2356

- Joined: Wed Jul 18, 2007 12:59 am

- Location: Seattle, WA USA

- Has liked: 166 times

- Been liked: 849 times

hello Robert,

do you have any pictures of the bolt modification that you put in the ends of the suspension arms, mainly the end you cant see in your pictures, just want to know if the end of the bolt is flush with the bottom side of the arm so it rubs on the slide pad, and what would this bolt have done on the real thing! also do you think the slide pad wound have been bolted on the top of the arm or recessed down like you have done, the few pictures i have look like the pad sits on top, whats your view.

many thanks, chris.

do you have any pictures of the bolt modification that you put in the ends of the suspension arms, mainly the end you cant see in your pictures, just want to know if the end of the bolt is flush with the bottom side of the arm so it rubs on the slide pad, and what would this bolt have done on the real thing! also do you think the slide pad wound have been bolted on the top of the arm or recessed down like you have done, the few pictures i have look like the pad sits on top, whats your view.

many thanks, chris.