My Tiger I engine

-

Roland Mann

- Posts: 174

- Joined: Thu Jul 12, 2007 4:45 pm

- Location: Stavenow, Germany

- Been liked: 19 times

My Tiger I engine

Hi all,

after some very fundamental thinking I could't resist any longer. The objective is a Tiger I engine, precisely a Maybach HL 210 P45 for my early Tiger I. OK the HL 230 is a bit bigger but there are no precise plans/drawings to work from. And last not least I do not have an original engine in my garage.

So I started the project with the intention to have a running engine in 1/6 as close as posible to the original. There are some air cooled V12 engines on the market but to my knowledge there is no water cooled one with a proper oil circuit.

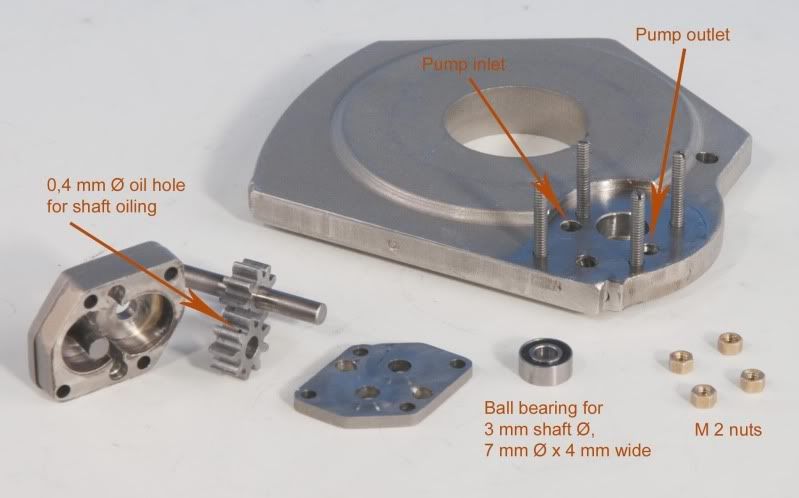

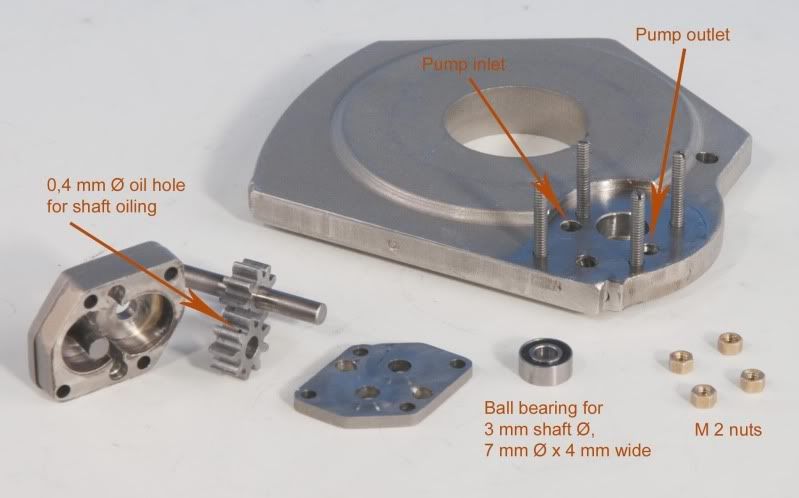

So the practical start was with the oil pumps. One is for the fresh oil - the pressure pump to the main oil gallery. The othe two are sucction pumps to drain the used oil from the pan since it is a dry sump system.Like the original. Hope you enjoy my pictures and please cross your fingers it will run one day. If not the block will make an interesting paperweight on my desc.

[img][img]http://i95.photobucket.com/albums/l134/ ... pulled.jpg[/img][/img]

[img][img]http://i95.photobucket.com/albums/l134/ ... in1to6.jpg[/img]

So fare the oil pumps for your first impressions.

Roland

after some very fundamental thinking I could't resist any longer. The objective is a Tiger I engine, precisely a Maybach HL 210 P45 for my early Tiger I. OK the HL 230 is a bit bigger but there are no precise plans/drawings to work from. And last not least I do not have an original engine in my garage.

So I started the project with the intention to have a running engine in 1/6 as close as posible to the original. There are some air cooled V12 engines on the market but to my knowledge there is no water cooled one with a proper oil circuit.

So the practical start was with the oil pumps. One is for the fresh oil - the pressure pump to the main oil gallery. The othe two are sucction pumps to drain the used oil from the pan since it is a dry sump system.Like the original. Hope you enjoy my pictures and please cross your fingers it will run one day. If not the block will make an interesting paperweight on my desc.

[img][img]http://i95.photobucket.com/albums/l134/ ... pulled.jpg[/img][/img]

[img][img]http://i95.photobucket.com/albums/l134/ ... in1to6.jpg[/img]

So fare the oil pumps for your first impressions.

Roland

Der Weg ist das Ziel.

- Adrian Harris

- Posts: 5134

- Joined: Thu Jul 12, 2007 10:46 pm

- Location: Berkshire (UK)

- Has liked: 1492 times

- Been liked: 1699 times

-

Tim Bowman

- Posts: 1762

- Joined: Fri Jul 13, 2007 4:53 am

- Location: Northern California

- Been liked: 177 times

- Contact:

-

Brian Leach

- Posts: 363

- Joined: Tue Nov 18, 2008 4:15 pm

- Location: Auburn, Wa USA

- Been liked: 3 times

-

Sven Strobbe

- Posts: 301

- Joined: Mon Jan 12, 2009 11:08 am

- Location: Belgium,Gent

- Been liked: 11 times

- Contact:

Roland

Is your hand so big...?

Impressive work and very good idea...

I was also on the look for drawings of the Engine but in my case its a HL230 P30.

The only thing i could find so far in the archives is some rough measerments of the outside but no details or drawings of each component.

Good luck with your build.

Regards

Sven

Is your hand so big...?

Impressive work and very good idea...

I was also on the look for drawings of the Engine but in my case its a HL230 P30.

The only thing i could find so far in the archives is some rough measerments of the outside but no details or drawings of each component.

Good luck with your build.

Regards

Sven

It's a beautiful day to go out in my King Tiger

-

Roland Mann

- Posts: 174

- Joined: Thu Jul 12, 2007 4:45 pm

- Location: Stavenow, Germany

- Been liked: 19 times

Hi Adrian,

can't wait as well. But there is still a long way to go. Pictures will follow to keep you informed.

Hi Tim,

thank you for your comments. Try to make it run and not to dissapoint you.

HiBrian,

thank you for your trust. As said before I try not to dissapoint you.

Hi Sven,

that's the problem. Drawings are difficult to get. So I worked from the two drawings in Spielbergers book Der Panzer-Kampfwagen Tiger und seine Abarten page 43. After some study I know it is a HL 210 - just what I wanted.

/img]

You all have a beautiful Christmas evening.

can't wait as well. But there is still a long way to go. Pictures will follow to keep you informed.

Hi Tim,

thank you for your comments. Try to make it run and not to dissapoint you.

HiBrian,

thank you for your trust. As said before I try not to dissapoint you.

Hi Sven,

that's the problem. Drawings are difficult to get. So I worked from the two drawings in Spielbergers book Der Panzer-Kampfwagen Tiger und seine Abarten page 43. After some study I know it is a HL 210 - just what I wanted.

/img]

You all have a beautiful Christmas evening.

Der Weg ist das Ziel.

-

Jeffrey Goff

- Posts: 805

- Joined: Thu Jul 12, 2007 12:52 pm

- Location: NORTHAMPTON

- Has liked: 20 times

- Been liked: 737 times

-

Sven Strobbe

- Posts: 301

- Joined: Mon Jan 12, 2009 11:08 am

- Location: Belgium,Gent

- Been liked: 11 times

- Contact:

Roland

It really is marvelous what you're doing...

May i ask which machine you're using to make these pretty little things...?

I'm planning to buy a CNC-mill from Wabeco Germany if my finances allow it...

http://www.mdaprecision.com/

Regards

Sven

It really is marvelous what you're doing...

May i ask which machine you're using to make these pretty little things...?

I'm planning to buy a CNC-mill from Wabeco Germany if my finances allow it...

http://www.mdaprecision.com/

Regards

Sven

It's a beautiful day to go out in my King Tiger

- Robert E Morey

- Posts: 2355

- Joined: Wed Jul 18, 2007 12:59 am

- Location: Seattle, WA USA

- Has liked: 163 times

- Been liked: 849 times

Roland,

Awesome work on the oil pumps. Your engine will be fantastic as the rest of your model already is. Can't wait to watch your progress. I admire your ambition and skill.

Sven, the Wabeco's are expensive but very very nice machines. You won't be dissapointed - that is a fantastic Christmas present to yourself! The Mach3 CNC controller is excellent and easy to use. I have a D6000 lathe (non CNC) and I love it. Best lathe I've ever owned.

Merry Christmas all...

Bob

Awesome work on the oil pumps. Your engine will be fantastic as the rest of your model already is. Can't wait to watch your progress. I admire your ambition and skill.

Sven, the Wabeco's are expensive but very very nice machines. You won't be dissapointed - that is a fantastic Christmas present to yourself! The Mach3 CNC controller is excellent and easy to use. I have a D6000 lathe (non CNC) and I love it. Best lathe I've ever owned.

Merry Christmas all...

Bob

-

Roland Mann

- Posts: 174

- Joined: Thu Jul 12, 2007 4:45 pm

- Location: Stavenow, Germany

- Been liked: 19 times

Thank you all for your nice words.

Sven, my lathe is an old MEUSER from Frankfurt, medium size, built in 1952 with friction bearing of the king pin. Very smooth and vibration free running machine. Very heavy as well - about 2 tons.

My mill is a medium size tool maker machine of 1972 built by SINN. Very heavy as well but most important it is precise down to 0,01 mm.

My drill is very small. From 400 to 16000 RPM and from 7 mm to 0,1mm. Weight of this small machine is an unbelievable 35 kg. Built in 1963.

So as you can see, no CNC. There is only you, the machine and a drawing to produce a part. Since I have an existing machine park there is no need for me to spend money for modern equipment. If you start from scratch go for the modern machines. They offer much more possibillities, reduce some of your efforts and saving time in making parts.

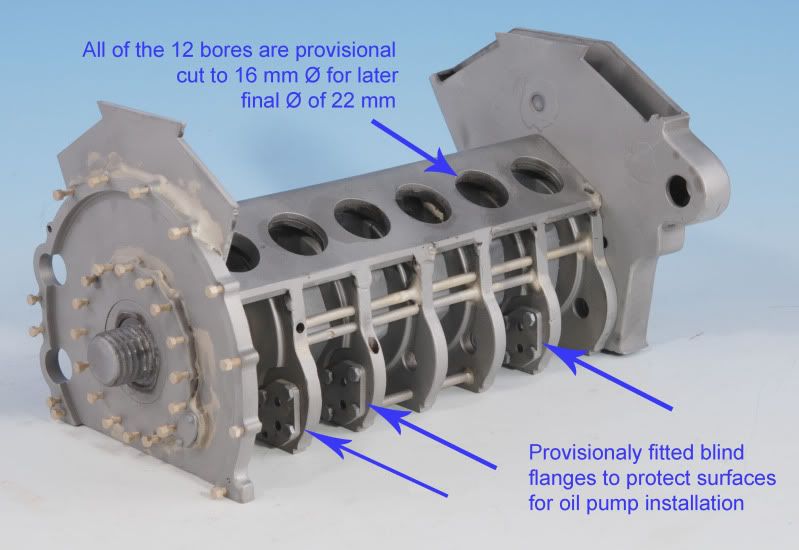

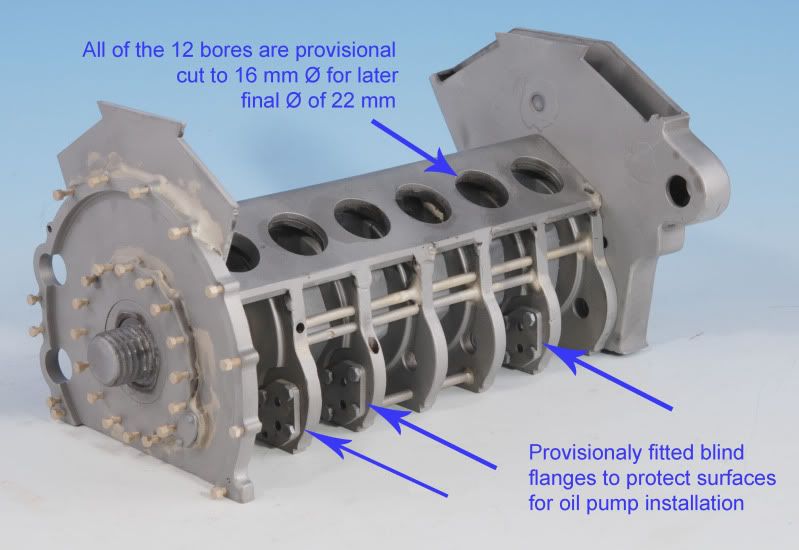

Robert, the oil pump enjoyed me by design and when tested on the bench. For trial it was fitted in place on one of the seven webs forming the block and shown on the last two pictures.

Best regards Roland[/img]

Sven, my lathe is an old MEUSER from Frankfurt, medium size, built in 1952 with friction bearing of the king pin. Very smooth and vibration free running machine. Very heavy as well - about 2 tons.

My mill is a medium size tool maker machine of 1972 built by SINN. Very heavy as well but most important it is precise down to 0,01 mm.

My drill is very small. From 400 to 16000 RPM and from 7 mm to 0,1mm. Weight of this small machine is an unbelievable 35 kg. Built in 1963.

So as you can see, no CNC. There is only you, the machine and a drawing to produce a part. Since I have an existing machine park there is no need for me to spend money for modern equipment. If you start from scratch go for the modern machines. They offer much more possibillities, reduce some of your efforts and saving time in making parts.

Robert, the oil pump enjoyed me by design and when tested on the bench. For trial it was fitted in place on one of the seven webs forming the block and shown on the last two pictures.

Best regards Roland[/img]

Der Weg ist das Ziel.

-

Alan Hamby

- Posts: 44

- Joined: Fri Jul 13, 2007 12:37 am

- Location: Atlanta, GA, United States

- Contact:

-

Sven Strobbe

- Posts: 301

- Joined: Mon Jan 12, 2009 11:08 am

- Location: Belgium,Gent

- Been liked: 11 times

- Contact:

Robert

Talked to you before about it but due to the crisis had to put aside the idea... Now i'm totally self employed and got some good contracts ahead i started thinking about it again and went on looking for machinery with a good price/quality.

And i have to make expenses so we'll see what the first monts will bring and then see if i can buy it.

Roland

Thanks for the info, you're really a craftsman wich isn't easy to find...

Also loved your gun in the Gallery, a masterpiece...

http://www.armortek.co.uk/gallery/main. ... temId=4632

If you had the resources you'de probably made your own 1/1 scale model...

I don't own a machinepark or at least not one to do some metalwork...

So i have to look out to something new.

Still i really look forward to see where your project goes.

Regards

Sven

Talked to you before about it but due to the crisis had to put aside the idea... Now i'm totally self employed and got some good contracts ahead i started thinking about it again and went on looking for machinery with a good price/quality.

And i have to make expenses so we'll see what the first monts will bring and then see if i can buy it.

Roland

Thanks for the info, you're really a craftsman wich isn't easy to find...

Also loved your gun in the Gallery, a masterpiece...

http://www.armortek.co.uk/gallery/main. ... temId=4632

If you had the resources you'de probably made your own 1/1 scale model...

I don't own a machinepark or at least not one to do some metalwork...

So i have to look out to something new.

Still i really look forward to see where your project goes.

Regards

Sven

It's a beautiful day to go out in my King Tiger

-

Roland Mann

- Posts: 174

- Joined: Thu Jul 12, 2007 4:45 pm

- Location: Stavenow, Germany

- Been liked: 19 times

Next step after preparing the pumps is the block itself. There are seven webs in a row forming the bearing tunnel. Intention is to use ball bearings for the cranck shaft as it was with the original. For now the center bores are only 20 mm Ø to assist with a 20 mm shaft for assemling. Later the block will be bored up to the final Ø for the ball bearings with 45 mm OD.

Hope you enjoy this step. It now looks more and more what is should bee one day. The side walls will be fitted ones every thing is in place. Most important are the oil lines. There is no access ones the block is closed.

[/img]

[/img]

[/img]

[/img]

[/img]

[/img]

![Image]()

![Image]()

[img]

[img]

Roland

Hope you enjoy this step. It now looks more and more what is should bee one day. The side walls will be fitted ones every thing is in place. Most important are the oil lines. There is no access ones the block is closed.

[/img]

[/img] [/img]

[/img] [/img]

[/img]

[img]

[img]Roland

Der Weg ist das Ziel.

-

Tim Bowman

- Posts: 1762

- Joined: Fri Jul 13, 2007 4:53 am

- Location: Northern California

- Been liked: 177 times

- Contact:

-

Lucien Runge

- Posts: 48

- Joined: Sun Jul 15, 2007 3:28 pm

- Location: California