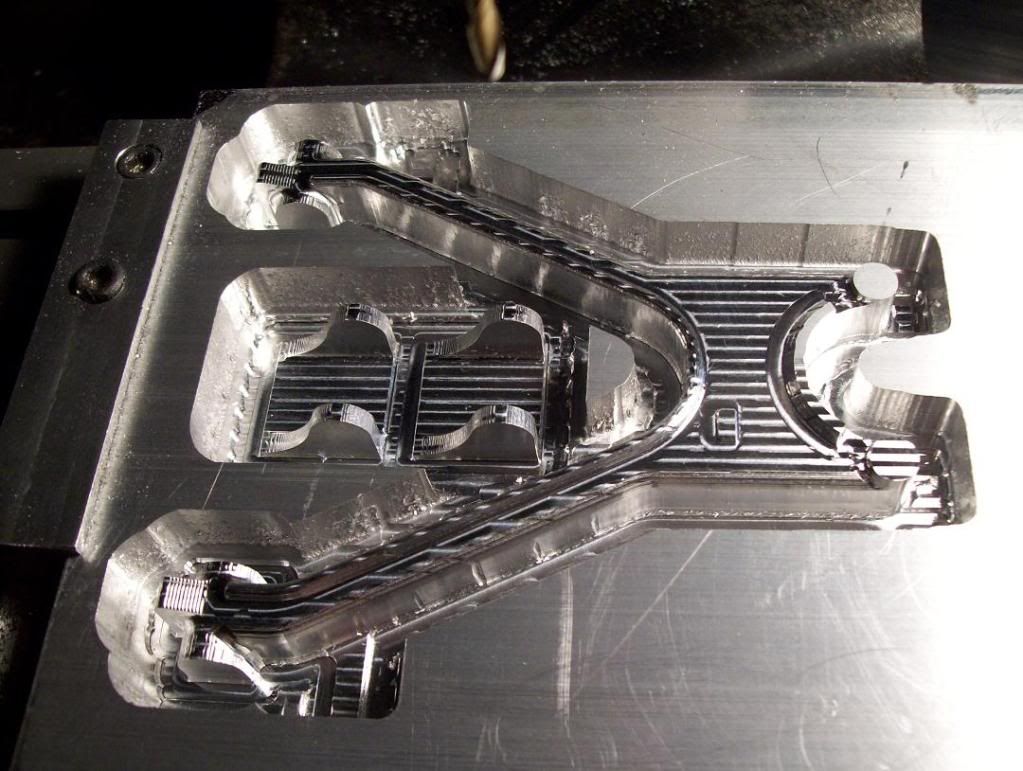

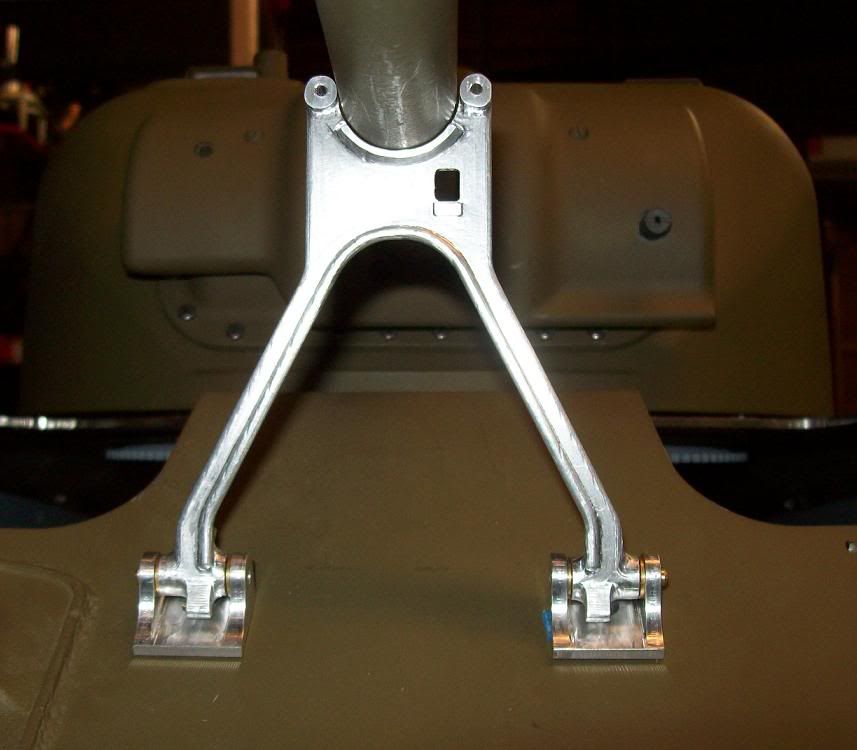

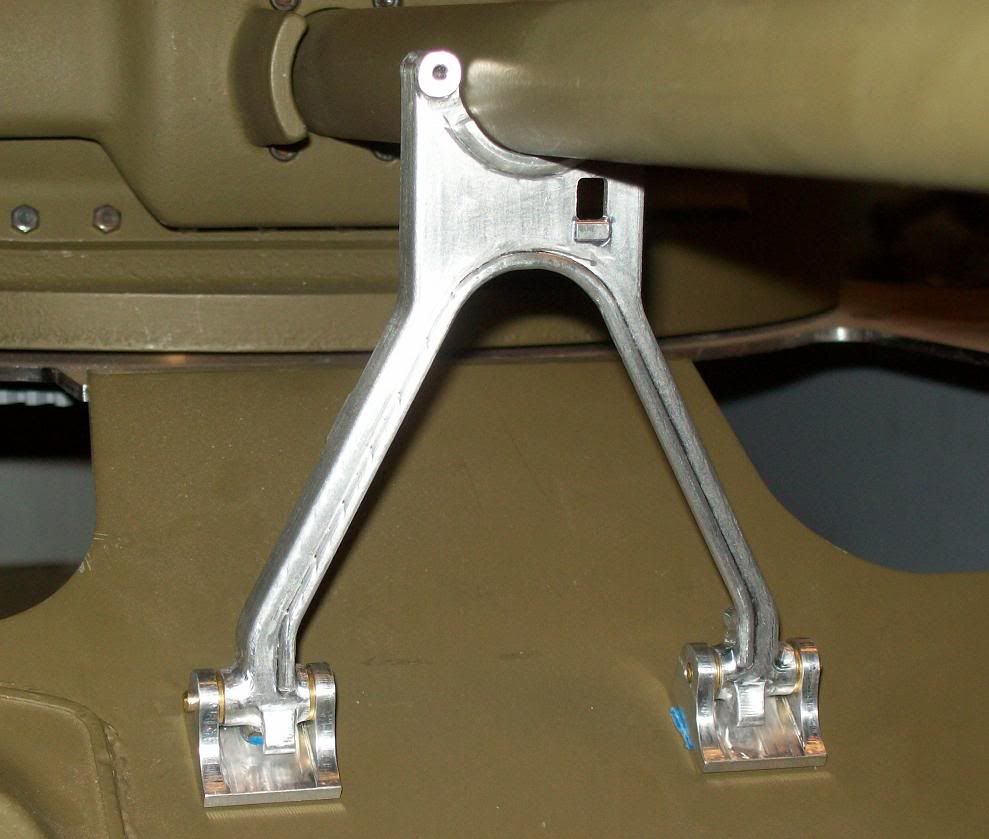

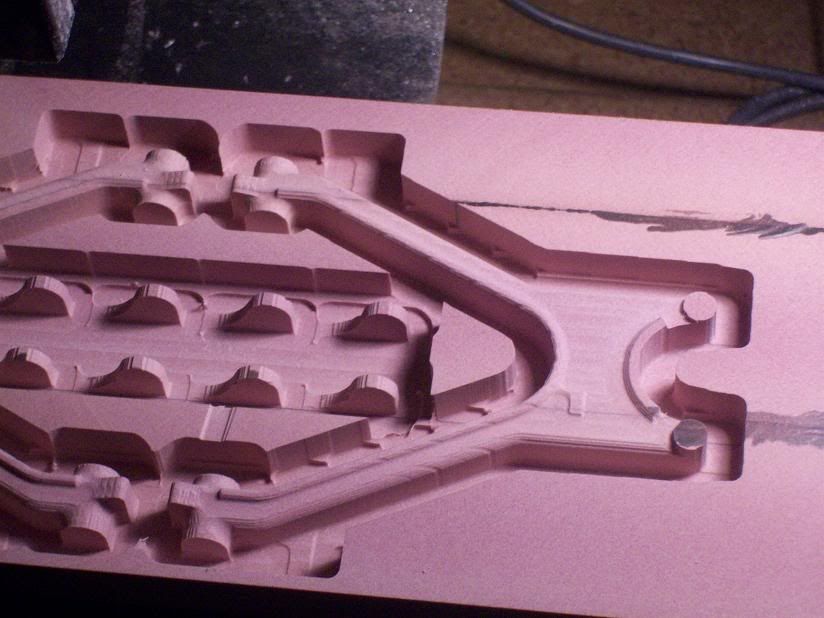

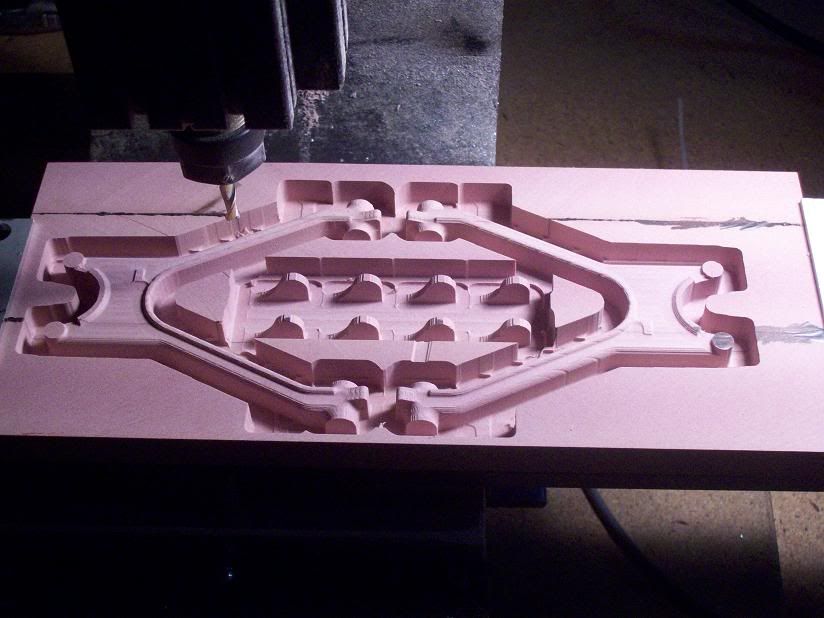

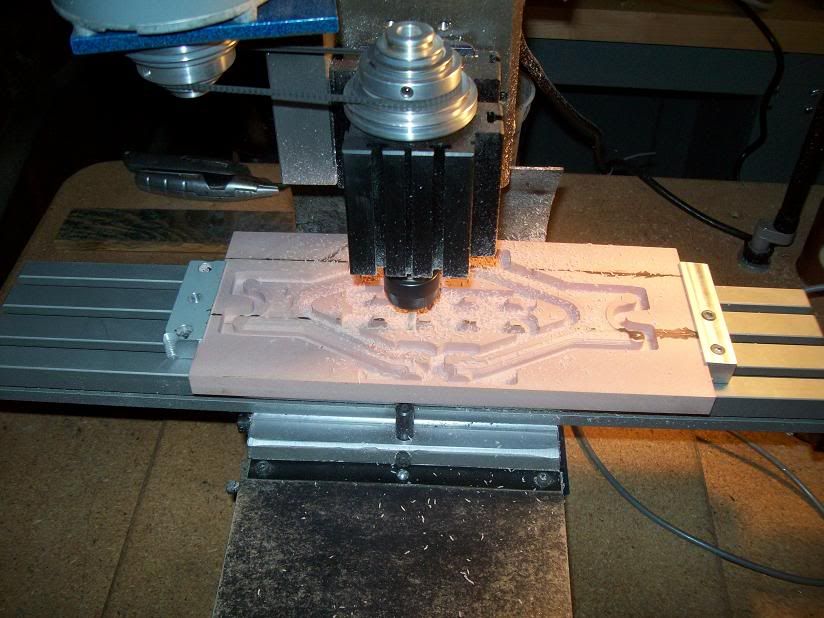

The material is Urethane foam board to test the CNC program. This is the top side program. Now to flip the material over and machine the back side details. Once the programs are proven out, I will machine the parts in Aluminum. I will put one on my Sherman and use the other as a casting master to eventually make a spin cast mold. Stay tuned for a white metal kit possibly later next year (09)?? The "bumps" in the center are the hinge pieces which mount the gun travel lock to the glassis plate. The black lines are epoxy which bonds the three pieces of foam board together.

Happy holidays everyone! Bob