Page 7 of 8

Re: Norwegian 2021 07 build

Posted: Fri Jan 28, 2022 1:38 pm

by Armortek

Søren Sandvold wrote: ↑Thu Jan 27, 2022 8:59 pm

Have a bit of a snag on one of the motors During my first bench test, I thought there was a throwout on one axle, and my dial has confirmed what I saw. I dont think this is useable as is, given how thight the gear works

What do you guys think?

Your gauge is showing a runout of 0.075mm (0.004"). This is within tolerance.

Re: Norwegian 2021 07 build

Posted: Fri Jan 28, 2022 3:43 pm

by Søren Sandvold

Armortek wrote: ↑Fri Jan 28, 2022 1:38 pm

Søren Sandvold wrote: ↑Thu Jan 27, 2022 8:59 pm

Have a bit of a snag on one of the motors During my first bench test, I thought there was a throwout on one axle, and my dial has confirmed what I saw. I dont think this is useable as is, given how thight the gear works

What do you guys think?

Your gauge is showing a runout of 0.075mm (0.004"). This is within tolerance.

Thanks for reply Armortek

Ok, might be within spec, but I'll have to mill out the gear housing to give the pinion room to rotate freely. Not a big issue to do, but are considering dismantling the gearbox to have the shaft straighten. (would not be the first shaft I have straighten for close to zero runout

) I'll first mill out the gearbox, then bluemark the gears and run them to check for contactmarks.

Its not a Ferrari gearbox, so it might be ok as is

Re: Norwegian 2021 07 build

Posted: Fri Jan 28, 2022 8:02 pm

by Søren Sandvold

As Donald Suttie has pointed out in a separate post, the motor pinion gear might rub against the drive cases . I had the same issue, but only on one side. This is something that's easily missed during a build, so well worth to check out. I opted for milling out the pocket for pinion gear, but this can be fixed by other means as well. Milled out 0.6mm, this gives 0.2mm airgap between the gear and case. As I have a runout one one axle, I had to bore out the pocket as well. The gear is scraping the sides as it wobbles around. Easyfix with a mill, but would be doable with a Dremel to.

Will probably dismantle the motorshaft and straighten it. May be within spec and work without an issue, but it will probably tickle my mechanical OCD forever if i leave it be

Small hickups, but I'm still a happy camper. I kind of like resolving small issues like this. If the kit was 100% perfect in fit&finish, I'll probably would be bored long before completion

Re: Norwegian 2021 07 build

Posted: Fri Jan 28, 2022 9:10 pm

by Donald Suttie

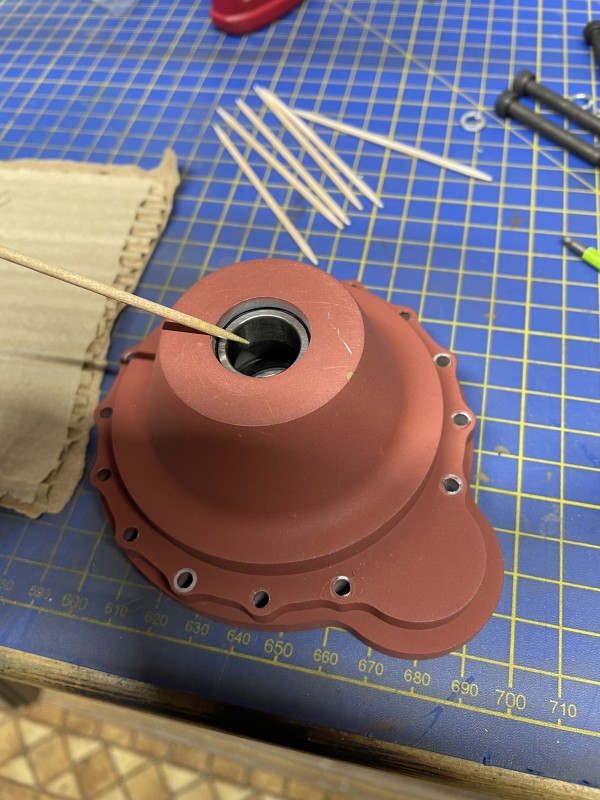

I was going to leave this for my build page but ill include it here as well as i think its important,the assembly of the gear casing its self

i puzzled over this for a number of days and didn't want the whole casing all covered in Loctite and grease all in the wrong place

i tested and retested the fit a number of times and came up with this solution to correct assembly

- First off i replaced the stock supplied bearings for high quality ones for 2 reasons,1:i had slight play in these out the packet,the high quality ones have no play,2:these bearings are not easy to access when loctited into position

- spacer was etch primed but had to sand off the outer edge to fit

- Bottom bearing placed in and secured loctite on outer edge only

- top bearing loctited outer edge only

- ok the tricky part.red grease very sparingly on inner gear face,and very small ring at bottom of shaft of loctite

- a closer look at the loctite and grease

- then using a drop of loctite on the inner bearing (outer on outside)applied with cocktail stick

thats it,insert the shaft and wipe away any excess loctite pushed through,while the grease is NOT recommended by armortek i added it due to where the tank is stored at my house and also the fact if it starts to rust i would not be able to access it after assembly

i thought i would add this in as this is a slightly different set up to previous versions of the driveshaft and casing

i hope it helps

Donald

Re: Norwegian 2021 07 build

Posted: Fri Jan 28, 2022 10:49 pm

by Søren Sandvold

Thanks Donald

Re: Norwegian 2021 07 build

Posted: Sat Jan 29, 2022 2:03 pm

by Søren Sandvold

For those of you that always wondered whats inside the gearbox

Enjoy

Re: Norwegian 2021 07 build

Posted: Sat Jan 29, 2022 5:25 pm

by Søren Sandvold

Ok, probably boring you with this stuff, but managed to massage the output shaft into better tolerance.

Not zero, but close enogh. Its amazing what can be done with a hammer, wise and a good measuring dial

Will exchange both bearings since they already are out. The bearings are the same as the ones in the drive cases, and are easy to swap out

https://youtube.com/shorts/R_xI4aq2Pwk?feature=share

https://youtube.com/shorts/R_xI4aq2Pwk?feature=share

Back to building a Tiger

Re: Norwegian 2021 07 build

Posted: Wed Feb 02, 2022 7:45 pm

by Søren Sandvold

Dayjob is still all time high, and with the entire family down with Covid, it's getting harder to squeeze in some quality time with the kit.

But have played some more with Mr Surfacer. I really enjoy working with this stuff. Instant result, and easy to tone down if you get carried away

Did the idler shaft and exhaust armour.

As I'm about to install the idler assy, I though it would be a good idea to mount the wheels to check alignment with the idler. All wheels are 100% in line.

Was a bit surprised on how little it is possible to torque down the idler center bolt, before compressing the bearings. Wouldn't it be a good ide to have a spacer between the bearings, so we could torque it down properly?

Getting the wheels on was an exercise where I wish I had a couple of arms extra. Whatever you do, check each wheel that it actually glides onto the shafts, before trying to mount them all in one go. I had on stubborn one from excess primer build up. Not a fun experience.

Btw, got my motor together with fresh SKF bearings. Running true now

Did also mount SKF bearings in the drive cases.

Re: Norwegian 2021 07 build

Posted: Thu Feb 03, 2022 11:51 pm

by Søren Sandvold

I have not glued the bearing for the idle shafts yet, as I'm not quite shure of the correct position of the idler wheels, not more than a couple of mm sideplay to adjust with though. Mounted some tracks around the idler and roadwheels to check how they tracked, test the track tensioner and to test each tracklink. Found 5-6 links so far that will need some fettling to be usable. Rotation of tracks was surprisingly smooth.

Kind of a motivation kick to see it with wheels and tracks on

The cat is getting heavy now though, need a pair of extra hands to get her on the floor, to test rotation under weight

Re: Norwegian 2021 07 build

Posted: Fri Feb 04, 2022 3:19 pm

by Donald Suttie

can i ask what you used on the barrel sleeve ,it says Loctite but the treadlock/studlock stuff eats ABS type plastic,the sleeve in the past builds was brass,this time its ABS or Nylon by the looks of it

Donald

Re: Norwegian 2021 07 build

Posted: Fri Feb 04, 2022 4:25 pm

by Søren Sandvold

Donald.

The sleeve is just a temporary mockup item for my part. I'm rebuilding the entire Gun, muzzle brake, recoil, breech. Will probably use the alu barrel, but it will be sleeved with something easier to ceep clean from Black Powder gunk

The sleeve will be replaced with a rather large linear bearing.

Re: Norwegian 2021 07 build

Posted: Fri Feb 04, 2022 4:38 pm

by Søren Sandvold

I didn't like that fact that torqueing down the idler wheels centerbolt compresses the bearings. So I made couple of spacers that goes between the bearings, by doing this the bolt can be torqed for King and Country

A easyfix if you have access to a lathe. Some finetuning of the lenght is required to get it just right.

BTW, as the last member of the household I've just tested positive for the Covid crap. Feeling fine so far, and I'm to be in quarantine for 4 days. How terrible

4 days to play with my toy

My furry friend Tsar looks like he has gone in a mode of hibernation and quarantine also

Re: Norwegian 2021 07 build

Posted: Sat Feb 05, 2022 3:35 pm

by Søren Sandvold

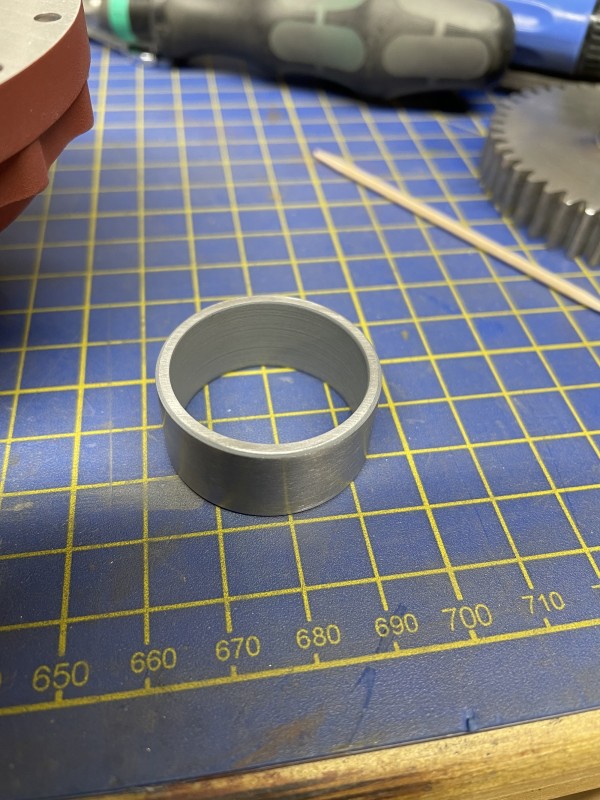

I have read about some conserns about main gear loosening adhere to the bearings and then end up scraping against the hull side. There's probably more than one way to skin a cat, but here is my take on the (potensial) issue.

I've turned a pocket in the main gear to make room for a plastic bushing. Not sure exactly what they are made of, but we use them at work and I know they can withstand a lot of pressure, heat/cold, wear and tear. Now, hopefully they will never do their job, but if the driveshaft should loosen up, the gear will not make contact with the hull.

As mounted the the bushing will have a slightly airgap between gear and hull.

Re: Norwegian 2021 07 build

Posted: Sat Feb 05, 2022 4:15 pm

by Brian Ostlind

Hi Søren that’s nice looking piece of work you have done. I have tried to pry out bearings before that were glued using the loctite 638. It’s impossible. The only way these gear will break loose is if the glue is not used properly and smeared on the inside of the bearing and the outside of the shaft. Not too much, just a light coat. You must be planning to do a lot of running?!

Btw how is Covid I’m struggling with my case.

Re: Norwegian 2021 07 build

Posted: Sat Feb 05, 2022 4:33 pm

by Søren Sandvold

Hi Brian.

I read that you are in same situ as I am, regarding Covid. For me its just like a light cold, but I get very quick tired if I do some heavy work or try to exercise. So no running with Husky these days

I'm probably over engineered the build, must be some of my German genes that are kicking in

I agree that the bearings will be hard stuck in the case, but the axle could brake free by impact, use and abuse. This mod was quick and easy to do, so better safe than sorry in this case