Roy's StuG III (no. 2020/10)

-

simon_manning

- Posts: 2055

- Joined: Fri Nov 02, 2007 8:51 pm

- Location: new forest,hampshire,u.k.

- Been liked: 1732 times

Re: Roy's StuG III (no. 2020/10)

Good work going on in this stug section, just a note to you all, always allow some easy access to the internals, magnets and easy to remove decks is a good idea, and don't forget the extra weight on the front end when the motors are fitted, counter act this by setting your suspension slightly higher at the front, it will lower in time, regards simon manning.

- Roy Beukeveld

- Posts: 191

- Joined: Fri Feb 14, 2020 7:23 pm

- Location: The Netherlands

- Has liked: 171 times

- Been liked: 118 times

- Contact:

Re: Roy's StuG III (no. 2020/10)

Hi Simon,

Thank you for your advice, it will definitely be taken into account.

With regards to the motor weight compensation, i don't know if it is possible to balance the motors out with the batteries.

My option packs arrive shortly and then i can start measuring and balancing things out.

Or would you advice in any case (even with a balanced cog) to raise the front suspension a bit?

Thank you for your advice, it will definitely be taken into account.

With regards to the motor weight compensation, i don't know if it is possible to balance the motors out with the batteries.

My option packs arrive shortly and then i can start measuring and balancing things out.

Or would you advice in any case (even with a balanced cog) to raise the front suspension a bit?

Kind regards,

Roy

Roy

-

simon_manning

- Posts: 2055

- Joined: Fri Nov 02, 2007 8:51 pm

- Location: new forest,hampshire,u.k.

- Been liked: 1732 times

Re: Roy's StuG III (no. 2020/10)

Hi Roy, Raise the front a little, the Panzer 111 and stugs do suffer from a little sag over time on the front end, and once packed with all the electrics, difficult to get at the Torsion Bar's to adjust, hold all the Electric's with Velcro so you can remove and service the vehicle, on my Kingtiger's, Tiger's there's a lot more space and freedom to do some adjustment's, regards simon manning.

-

yves mouton

- Posts: 1042

- Joined: Fri Nov 06, 2009 7:55 pm

- Location: Belgium

- Has liked: 1 time

- Been liked: 699 times

Re: Roy's StuG III (no. 2020/10)

Hello Simon,

The torsion bar setings are easy to change on the stug,

the countersink screws to change the angle are on the side of the hull and the grub screws on the bottom plate of the stug.

Best regards Yves

The torsion bar setings are easy to change on the stug,

the countersink screws to change the angle are on the side of the hull and the grub screws on the bottom plate of the stug.

Best regards Yves

-

Tom OBrien

- Posts: 145

- Joined: Wed Nov 07, 2018 8:49 pm

- Has liked: 5 times

- Been liked: 67 times

Re: Roy's StuG III (no. 2020/10)

Roy et al,

RE: Lifting/reinforcing the front

I'm wondering if adding springs to the front shocks would help in lieu of adjusting the torsion bars.

I've added light weight springs but since this is my first medium tank build, I don't know if it's going to assist the front torsion bars in preventing sag.

If necessary, I can always replace the lightweight springs (thinner spring wire, more "springy") with a heavier weight spring.

Tom

RE: Lifting/reinforcing the front

I'm wondering if adding springs to the front shocks would help in lieu of adjusting the torsion bars.

I've added light weight springs but since this is my first medium tank build, I don't know if it's going to assist the front torsion bars in preventing sag.

If necessary, I can always replace the lightweight springs (thinner spring wire, more "springy") with a heavier weight spring.

Tom

- Roy Beukeveld

- Posts: 191

- Joined: Fri Feb 14, 2020 7:23 pm

- Location: The Netherlands

- Has liked: 171 times

- Been liked: 118 times

- Contact:

Re: Roy's StuG III (no. 2020/10)

Hi Simon, okay, I will take that into account and set the front a little higher than the other arms. Adjusting the torsion bars can be done from outside the hull, so as long as the wheelarm doesn't come in front of it adjusting should be quite easy. I will show/tell how it went.simon_manning wrote: ↑Mon Dec 14, 2020 8:56 amHi Roy, Raise the front a little, the Panzer 111 and stugs do suffer from a little sag over time on the front end, and once packed with all the electrics, difficult to get at the Torsion Bar's to adjust, hold all the Electric's with Velcro so you can remove and service the vehicle, on my Kingtiger's, Tiger's there's a lot more space and freedom to do some adjustment's, regards simon manning.

Hi Tom, yes that could be an option as well, but somehow I'm under the impression that it will be easier to get the angle right by adjusting the fixed ends. Replacing the spring isn't difficult to do but finding the proper spring might be.Tom OBrien wrote: ↑Mon Dec 14, 2020 2:37 pmRoy et al,

RE: Lifting/reinforcing the front

I'm wondering if adding springs to the front shocks would help in lieu of adjusting the torsion bars.

I've added light weight springs but since this is my first medium tank build, I don't know if it's going to assist the front torsion bars in preventing sag.

If necessary, I can always replace the lightweight springs (thinner spring wire, more "springy") with a heavier weight spring.

Tom

If i start out by setting the front arms to let's say 35 degrees (too much?) and the others at 30 degrees, the whole should be good controllable and adjustable.

Kind regards,

Roy

Roy

- Roy Beukeveld

- Posts: 191

- Joined: Fri Feb 14, 2020 7:23 pm

- Location: The Netherlands

- Has liked: 171 times

- Been liked: 118 times

- Contact:

Re: Roy's StuG III (no. 2020/10)

Hi everyone,

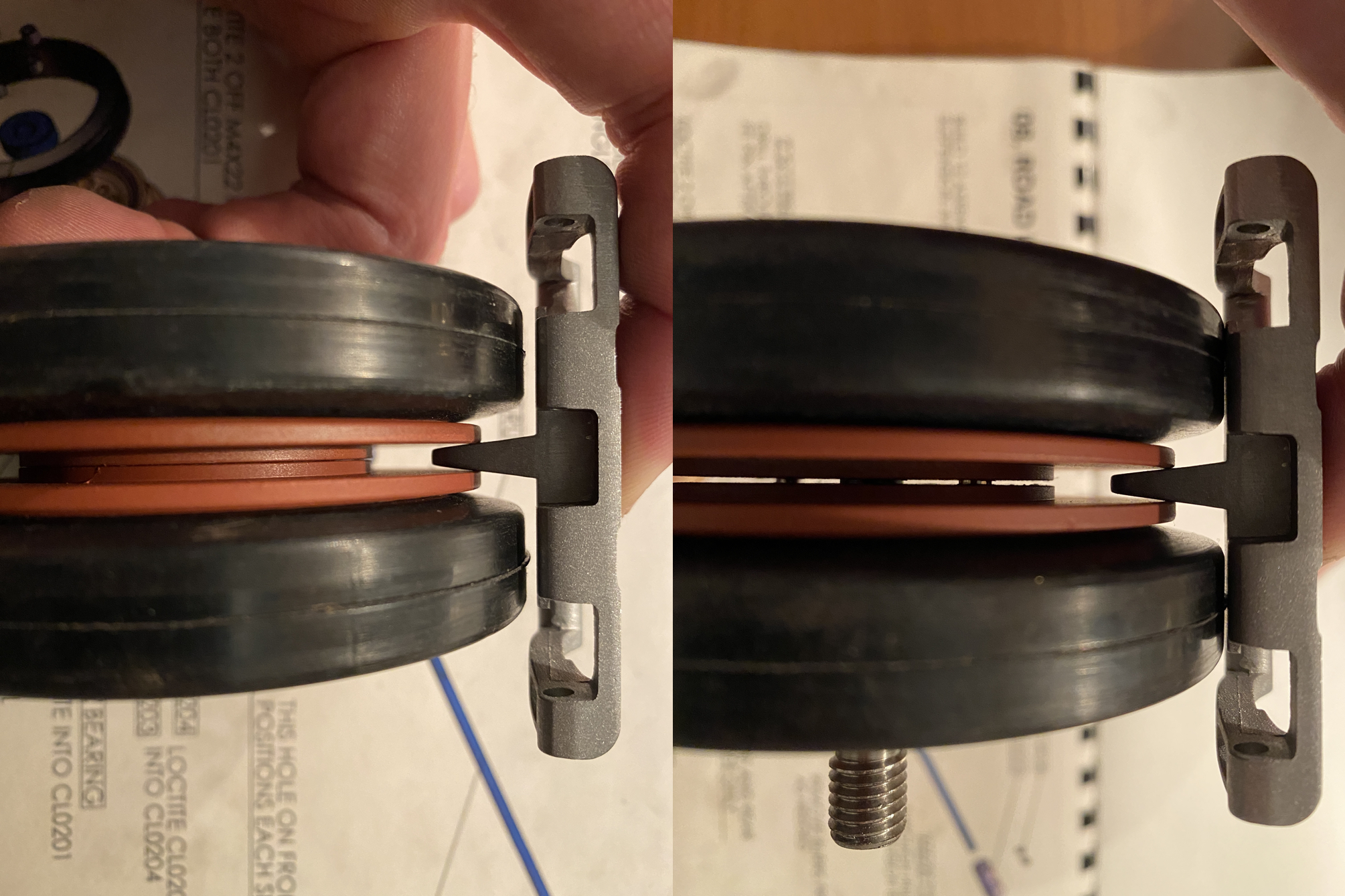

I am currently working on the wheel assemblies. When I assemble the two wheel halfs against each other I notice that the tires won't touch the tracklink.

When I separate the halfs to I guess around 0,8mm it does touch the link.

I'm thinking of printing some 45mm rings of 0,8mm thick to place between them so they can be clamped.

But the end of the shaft will then unfortunately be a bit recessed to the bearings inner ring.

Does anyone else encountered this or am I doing something wrong perhaps...?

I am currently working on the wheel assemblies. When I assemble the two wheel halfs against each other I notice that the tires won't touch the tracklink.

When I separate the halfs to I guess around 0,8mm it does touch the link.

I'm thinking of printing some 45mm rings of 0,8mm thick to place between them so they can be clamped.

But the end of the shaft will then unfortunately be a bit recessed to the bearings inner ring.

Does anyone else encountered this or am I doing something wrong perhaps...?

Kind regards,

Roy

Roy

- Steen Vøler

- Posts: 771

- Joined: Mon Nov 19, 2012 2:45 pm

- Location: Denmark

- Has liked: 62 times

- Been liked: 500 times

-

yves mouton

- Posts: 1042

- Joined: Fri Nov 06, 2009 7:55 pm

- Location: Belgium

- Has liked: 1 time

- Been liked: 699 times

Re: Roy's StuG III (no. 2020/10)

Hello Roy,

I just look at my wheels and the tracklinks rest nice on the rubber tyres,

and there is room enough between the 2 half wheels for the trackhorns.

Best regards Yves

I just look at my wheels and the tracklinks rest nice on the rubber tyres,

and there is room enough between the 2 half wheels for the trackhorns.

Best regards Yves

- Roy Beukeveld

- Posts: 191

- Joined: Fri Feb 14, 2020 7:23 pm

- Location: The Netherlands

- Has liked: 171 times

- Been liked: 118 times

- Contact:

Re: Roy's StuG III (no. 2020/10)

Hi Steen, thank you in advance

Hi Yves, good to hear that they fit alrightyves mouton wrote: ↑Wed Dec 16, 2020 6:31 pmHello Roy,

I just look at my wheels and the tracklinks rest nice on the rubber tyres,

and there is room enough between the 2 half wheels for the trackhorns.

Best regards Yves

Your two wheel halfs have no separation at all?

Kind regards,

Roy

Roy

-

yves mouton

- Posts: 1042

- Joined: Fri Nov 06, 2009 7:55 pm

- Location: Belgium

- Has liked: 1 time

- Been liked: 699 times

-

Tom OBrien

- Posts: 145

- Joined: Wed Nov 07, 2018 8:49 pm

- Has liked: 5 times

- Been liked: 67 times

Re: Roy's StuG III (no. 2020/10)

Roy,

I saw this as a potential issue early in the build. Kian pointed out that the tracks ride on the tires, so the track horns fitting in the space between the wheel halves should not be a problem as the track horns should ride high enough so that they do not have to ride between the wheel halves.

Just as a precaution, I took a large triangular file (a three-sided rough file) and filed just a small bit of metal from the top of the two wheel halves. This was relatively easy because you can leave the two wheel halves together as they are designed to be, while you file. (Of course, remove the tires first).

The track return rollers appear to be fine in their current configuration.

Cheers,

Tom

I saw this as a potential issue early in the build. Kian pointed out that the tracks ride on the tires, so the track horns fitting in the space between the wheel halves should not be a problem as the track horns should ride high enough so that they do not have to ride between the wheel halves.

Just as a precaution, I took a large triangular file (a three-sided rough file) and filed just a small bit of metal from the top of the two wheel halves. This was relatively easy because you can leave the two wheel halves together as they are designed to be, while you file. (Of course, remove the tires first).

The track return rollers appear to be fine in their current configuration.

Cheers,

Tom

- Roy Beukeveld

- Posts: 191

- Joined: Fri Feb 14, 2020 7:23 pm

- Location: The Netherlands

- Has liked: 171 times

- Been liked: 118 times

- Contact:

Re: Roy's StuG III (no. 2020/10)

Well I must say, I didn't notice this on forehand. I did a dry fit on the wheel assemblies but did not put on the tires...

Well anyway, the difference is very small, I made a 0,8mm thick spacer and placed it between the wheel halfs.

That makes a world of difference, the track horn now runs free with even a little margin.

Some other good news is that the option packs arrived today A day earlier then UPS communicated, luckily someone was home.

A day earlier then UPS communicated, luckily someone was home.

So when the wheel assemblies are fitted then its time to figure the packs out and start making a component layout.

There may be a lockdown here in Holland but I'm far from bored

Well anyway, the difference is very small, I made a 0,8mm thick spacer and placed it between the wheel halfs.

That makes a world of difference, the track horn now runs free with even a little margin.

Some other good news is that the option packs arrived today

So when the wheel assemblies are fitted then its time to figure the packs out and start making a component layout.

There may be a lockdown here in Holland but I'm far from bored

Kind regards,

Roy

Roy

-

florian rudolf

- Posts: 678

- Joined: Mon Feb 29, 2016 10:53 am

- Has liked: 297 times

- Been liked: 645 times

- Contact:

Re: Roy's StuG III (no. 2020/10)

Hello Roy,

think about that the rubber wheels wear out a bit. you need a little more space

think about that the rubber wheels wear out a bit. you need a little more space

- Steen Vøler

- Posts: 771

- Joined: Mon Nov 19, 2012 2:45 pm

- Location: Denmark

- Has liked: 62 times

- Been liked: 500 times