Firefly 008 build

-

John Wiggins

- Posts: 292

- Joined: Fri Jun 03, 2011 2:49 pm

- Location: North Staffordshire

- Has liked: 257 times

- Been liked: 147 times

-

John Wiggins

- Posts: 292

- Joined: Fri Jun 03, 2011 2:49 pm

- Location: North Staffordshire

- Has liked: 257 times

- Been liked: 147 times

Re: Firefly 008 build

Came across the photo of the Berlin bigade tank. It was taken in a local scrap yard, nearly 20 years ago, Andrew is now 27, he must have been 8 or 9 when the photo was taken. I remember the turret being extremely cramped, even without the TOGS system!

Regards

John

Regards

John

-

John Wiggins

- Posts: 292

- Joined: Fri Jun 03, 2011 2:49 pm

- Location: North Staffordshire

- Has liked: 257 times

- Been liked: 147 times

Re: Firefly 008 build

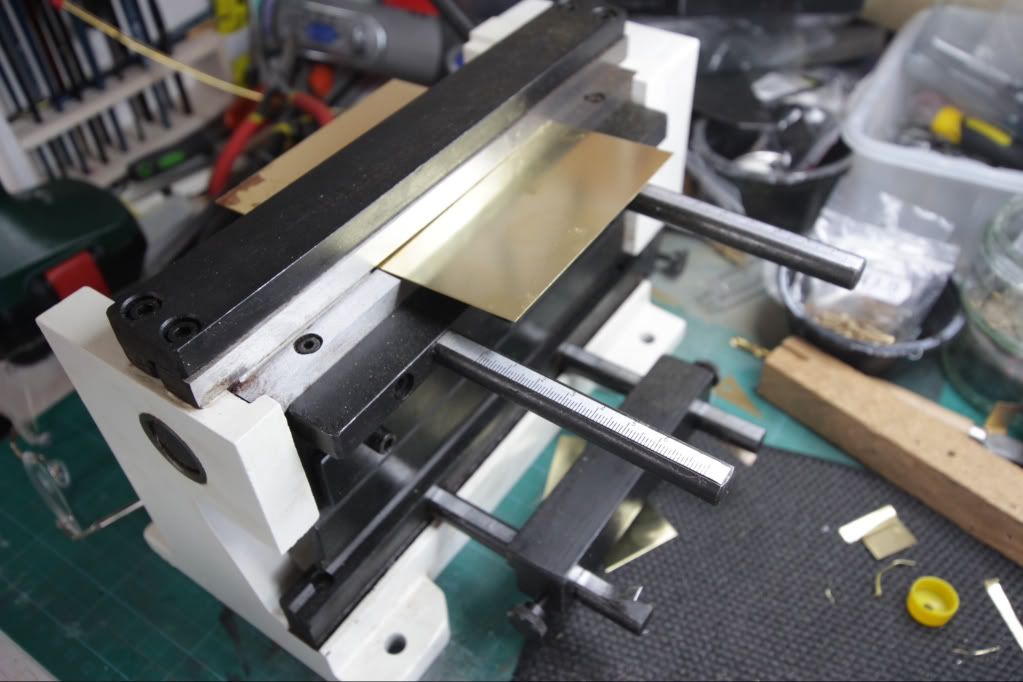

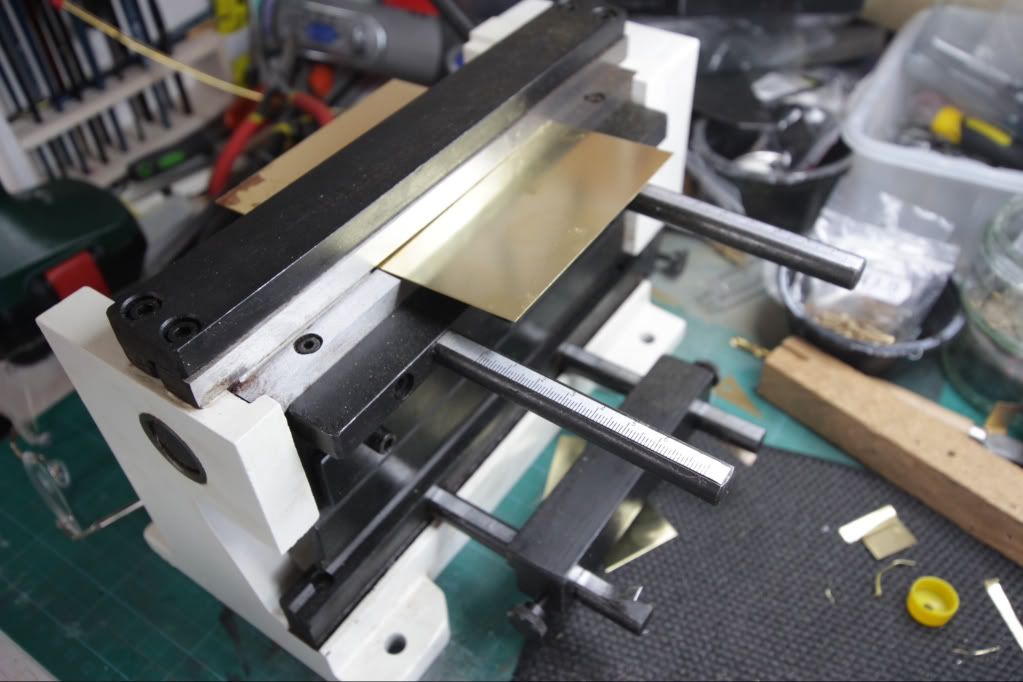

The build is back on....... With a new toy to play with!

Thanks to who ever posted the tutorial on soldering brass, I would never have managed without it!

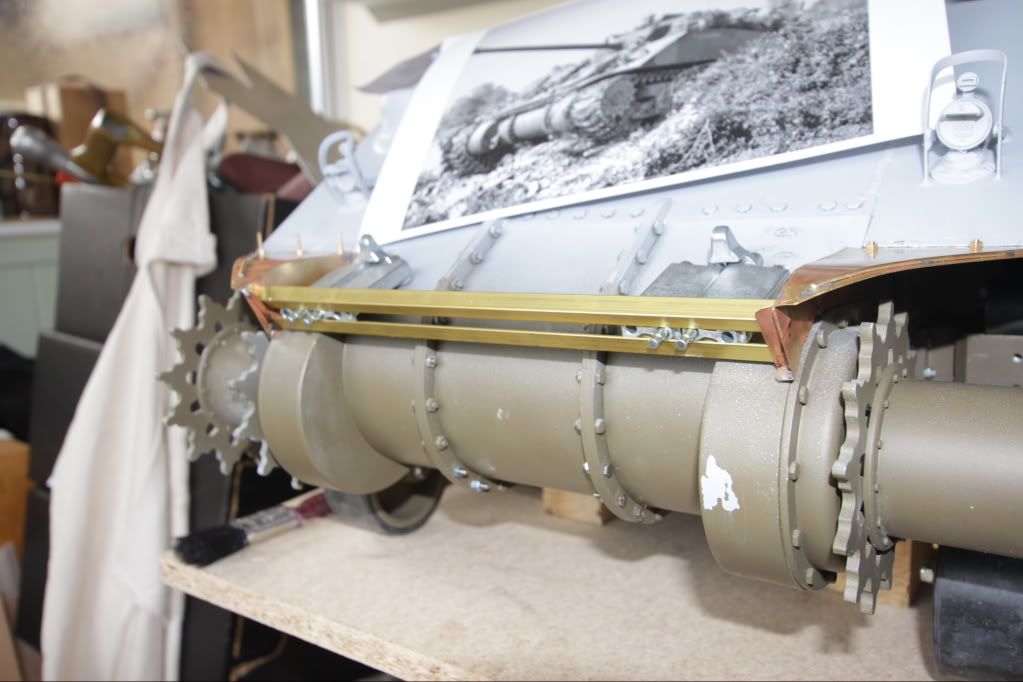

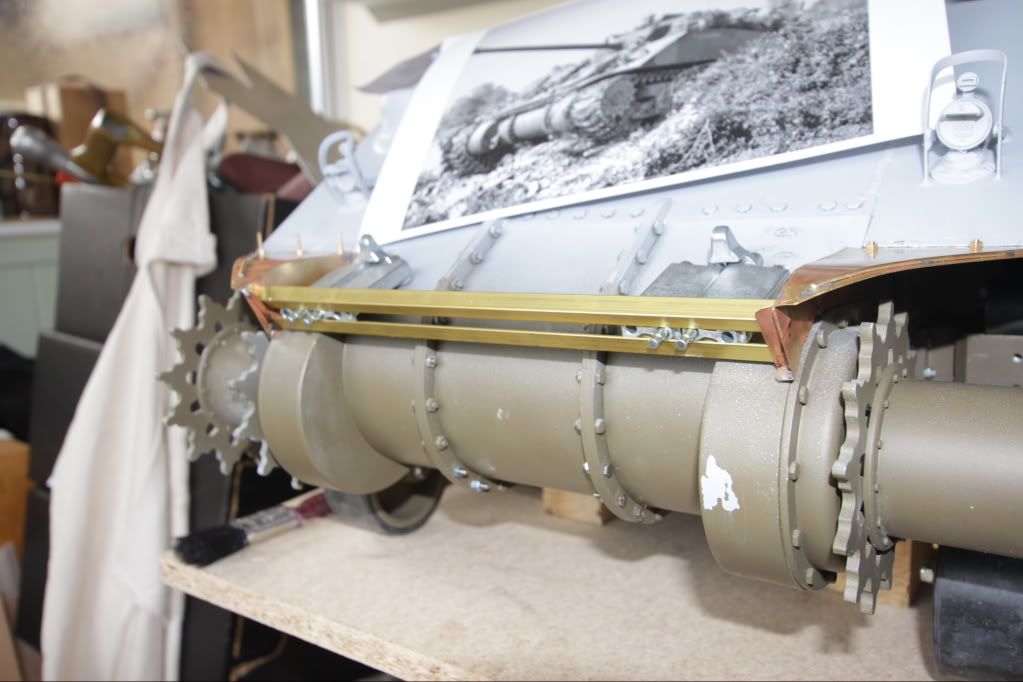

I have started to make the mud guards and storage rack, for the front of Belvedere. The rack is not complete, I still have to solder the angle iron in position, and then clean the flux of the parts before painting. Any suggestions on cleaning flux off brass would be most useful!

The angle iron storage on the front of Belvedere is representative of tanks from 27th Armoured Brigade. Belvedere was from B Squadron Staffordshire Yeomanry, who landed on D Day and saw action against 21 Panzer Div, in the afternoon of the 6th of June.

Regards

John

Thanks to who ever posted the tutorial on soldering brass, I would never have managed without it!

I have started to make the mud guards and storage rack, for the front of Belvedere. The rack is not complete, I still have to solder the angle iron in position, and then clean the flux of the parts before painting. Any suggestions on cleaning flux off brass would be most useful!

The angle iron storage on the front of Belvedere is representative of tanks from 27th Armoured Brigade. Belvedere was from B Squadron Staffordshire Yeomanry, who landed on D Day and saw action against 21 Panzer Div, in the afternoon of the 6th of June.

Regards

John

- Adrian Harris

- Posts: 5130

- Joined: Thu Jul 12, 2007 10:46 pm

- Location: Berkshire (UK)

- Has liked: 1481 times

- Been liked: 1687 times

Re: Firefly 008 build

Hi John.

> cleaning flux off brass

It depends what flux you used. I use Easy-Flo for silver soldering and it washes off with hot water.

Good to see your build progressing.

I've been working on updating the return roller brackets and will post some pictures shortly.

Adrian.

> cleaning flux off brass

It depends what flux you used. I use Easy-Flo for silver soldering and it washes off with hot water.

Good to see your build progressing.

I've been working on updating the return roller brackets and will post some pictures shortly.

Adrian.

Contact me at sales@armortekaddict.uk for details of my smoker fan control module

-

John Wiggins

- Posts: 292

- Joined: Fri Jun 03, 2011 2:49 pm

- Location: North Staffordshire

- Has liked: 257 times

- Been liked: 147 times

Re: Firefly 008 build

Adrian, thanks for the quick reply!

I will try hot water, I'm usually in it

It would be good to see photos of other Firefly builds, it's a bit lonely, on here, especially when I'm new to this metalwork game!

Best

John

I will try hot water, I'm usually in it

It would be good to see photos of other Firefly builds, it's a bit lonely, on here, especially when I'm new to this metalwork game!

Best

John

-

Derek Attree

- Posts: 1307

- Joined: Thu Jul 12, 2007 12:44 pm

- Location: london

- Has liked: 219 times

- Been liked: 200 times

Re: Firefly 008 build

Hi John

I boil up soldered items in water with washing powder (surf ) in the water that kills the

acid effect of all fluxes.

It also degreases ready for painting after a rinse in fresh water.

Derek

I boil up soldered items in water with washing powder (surf ) in the water that kills the

acid effect of all fluxes.

It also degreases ready for painting after a rinse in fresh water.

Derek

we must stop making stupid predictions

- Robert E Morey

- Posts: 2349

- Joined: Wed Jul 18, 2007 12:59 am

- Location: Seattle, WA USA

- Has liked: 161 times

- Been liked: 830 times

Re: Firefly 008 build

John,

Great looking fenders and track mounting rack! For an alledged beginner your work looks professional. The 3 piece tranny and casting lettering also looks really good!

One can also use a solution of baking soda and water to neutralize flux. Its very inexpensive and the water to soda ratio is not critical. And old toothbrush to scrub in the soda solution is ideal. Hot water rinse. It is important to clean parts after solder, I'm seeing some pieces on my Panther with white fluffy residue coming through the paint. This is from flux acid still present and reacting with the brass and copper.

I have a little shear bender like that too. For cutting brass, alum and tin its pretty handy. Its a bit limited when bending, but not bad for the price.

Keep posting, even you are the only one. I enjoy seeing Sherman/firefly progress!

best regards,

Bob

Great looking fenders and track mounting rack! For an alledged beginner your work looks professional. The 3 piece tranny and casting lettering also looks really good!

One can also use a solution of baking soda and water to neutralize flux. Its very inexpensive and the water to soda ratio is not critical. And old toothbrush to scrub in the soda solution is ideal. Hot water rinse. It is important to clean parts after solder, I'm seeing some pieces on my Panther with white fluffy residue coming through the paint. This is from flux acid still present and reacting with the brass and copper.

I have a little shear bender like that too. For cutting brass, alum and tin its pretty handy. Its a bit limited when bending, but not bad for the price.

Keep posting, even you are the only one. I enjoy seeing Sherman/firefly progress!

best regards,

Bob

-

John Grima

- Posts: 250

- Joined: Sun Jul 15, 2007 2:54 pm

- Location: USA

- Been liked: 48 times

- Contact:

Re: Firefly 008 build

It depends on which type of flux you use. Some are water soluble, others can be removed with rubbing alcohol, or paint thinner.

-

John Wiggins

- Posts: 292

- Joined: Fri Jun 03, 2011 2:49 pm

- Location: North Staffordshire

- Has liked: 257 times

- Been liked: 147 times

Re: Firefly 008 build

Hi

Thanks, everyone for the help and advice, it's much appreciated!

Bob I am use to soldering electronic components, but brass is a whole new board game. I've just looked at Adrian's silver soldering and metal working on his post, wow the skill is incredible . But I have to start somewhere, never going to reach the dizzy heights of all the builds on the forum. Really enjoying acquiring new skills and applying them to 'Belvedere'. Originally I was going to make the tank out of the box, but now I understand that, what you add to the model makes it your own!

I just hope my lack of knowledge and skill does not detract from this excellent kit produced by Armortek.

Thanks for the positive comments

John

Thanks, everyone for the help and advice, it's much appreciated!

Bob I am use to soldering electronic components, but brass is a whole new board game. I've just looked at Adrian's silver soldering and metal working on his post, wow the skill is incredible . But I have to start somewhere, never going to reach the dizzy heights of all the builds on the forum. Really enjoying acquiring new skills and applying them to 'Belvedere'. Originally I was going to make the tank out of the box, but now I understand that, what you add to the model makes it your own!

I just hope my lack of knowledge and skill does not detract from this excellent kit produced by Armortek.

Thanks for the positive comments

John

- Adrian Harris

- Posts: 5130

- Joined: Thu Jul 12, 2007 10:46 pm

- Location: Berkshire (UK)

- Has liked: 1481 times

- Been liked: 1687 times

Re: Firefly 008 build

> I've just looked at Adrian's silver soldering and metal working on his post, wow the skill is incredible .

I'm flattered you think so but you really should see me wielding a blow torch

but you really should see me wielding a blow torch

For a first attempt, I'd be more than happy with the mudguards and rails you have made.

I've been planning these brackets for probably three years, though these parts are only the second set which have made it into metal.

The more you work with these models, and see what others are up to, the more ideas you get of where and how to do your own thing. And nothing is cast in stone, so if you come up with what you think is a better way to make the mudguards for instance, then you just go ahead and swap them out.

You have to learn what is achievable and where to make compromises. For example, to be truly accurate, these brackets should have a 1.5mm thick top and 3mm thick sides. But that makes it incredibly difficult to heat the sides to the correct temperature without distorting the tops (BTDT ), so for these ones I went with 2mm throughout. I know it's "wrong" but I'm pretty sure no-one else would have spotted it, especially once they are fitted in place and surrounded by tracks, rollers, mud etc.

), so for these ones I went with 2mm throughout. I know it's "wrong" but I'm pretty sure no-one else would have spotted it, especially once they are fitted in place and surrounded by tracks, rollers, mud etc.

I still have to add the side braces, but I have another cunning plan for them

Adrian.

I'm flattered you think so

For a first attempt, I'd be more than happy with the mudguards and rails you have made.

I've been planning these brackets for probably three years, though these parts are only the second set which have made it into metal.

The more you work with these models, and see what others are up to, the more ideas you get of where and how to do your own thing. And nothing is cast in stone, so if you come up with what you think is a better way to make the mudguards for instance, then you just go ahead and swap them out.

You have to learn what is achievable and where to make compromises. For example, to be truly accurate, these brackets should have a 1.5mm thick top and 3mm thick sides. But that makes it incredibly difficult to heat the sides to the correct temperature without distorting the tops (BTDT

I still have to add the side braces, but I have another cunning plan for them

Adrian.

Contact me at sales@armortekaddict.uk for details of my smoker fan control module

- Adrian Harris

- Posts: 5130

- Joined: Thu Jul 12, 2007 10:46 pm

- Location: Berkshire (UK)

- Has liked: 1481 times

- Been liked: 1687 times

Re: Firefly 008 build

Another observation on the soldering.

I bought a Dremel VersaFlame specifically for doing these parts, but I found it wasn't beefy enough to heat the parts, so I used my BernzOMatic torch instead. That happened to have a MAPP gas cylinder attached, which proved a little too hot, so now I've ordered some propane cylinders to try with them.

I would guess this sort of process happens to most of us who enjoy customising these kits, it's just the viewing public only ever gets to see the parts posted of which we're most proud

Adrian.

I bought a Dremel VersaFlame specifically for doing these parts, but I found it wasn't beefy enough to heat the parts, so I used my BernzOMatic torch instead. That happened to have a MAPP gas cylinder attached, which proved a little too hot, so now I've ordered some propane cylinders to try with them.

I would guess this sort of process happens to most of us who enjoy customising these kits, it's just the viewing public only ever gets to see the parts posted of which we're most proud

Adrian.

Contact me at sales@armortekaddict.uk for details of my smoker fan control module

-

John Wiggins

- Posts: 292

- Joined: Fri Jun 03, 2011 2:49 pm

- Location: North Staffordshire

- Has liked: 257 times

- Been liked: 147 times

Re: Firefly 008 build

Hi Adrian

I bought a small blow torch from the local DIY store. I found it difficult to fill and use, I was getting so frustrated I thought I would do some research (finally !) , on the Internet. On hearing this the beloved one said, we've got a blow torch in the kitchen, (used for melting sugar on crem caramel, I think). Brilliant, plenty of heat, good sized tank, ignition, just don't try to pick it up by the nozzle when it's alight!

. Thankfully I am left handed, I burnt the right one

. Thankfully I am left handed, I burnt the right one  !

!

I think the forum is great, the ideas and techniques displayed provide great inspiration to all who study them.

I only wished I had sat down, calmly, before I commenced the build and decided what I would like, and was capable of doing to personalise the kit! I have now done that (2 months into the build). .So now I am taking Mick Hilton's advice and taking my time. Hopefully by the time 'Blevedere' is up and running, and my skill set has improved, and the beloved has saved her pennies

.So now I am taking Mick Hilton's advice and taking my time. Hopefully by the time 'Blevedere' is up and running, and my skill set has improved, and the beloved has saved her pennies  , the dynamic duo in Devon will have produced a Centurion kit

, the dynamic duo in Devon will have produced a Centurion kit

.

.

Regards

John

I bought a small blow torch from the local DIY store. I found it difficult to fill and use, I was getting so frustrated I thought I would do some research (finally !) , on the Internet. On hearing this the beloved one said, we've got a blow torch in the kitchen, (used for melting sugar on crem caramel, I think). Brilliant, plenty of heat, good sized tank, ignition, just don't try to pick it up by the nozzle when it's alight!

I think the forum is great, the ideas and techniques displayed provide great inspiration to all who study them.

I only wished I had sat down, calmly, before I commenced the build and decided what I would like, and was capable of doing to personalise the kit! I have now done that (2 months into the build).

Regards

John

-

John Wiggins

- Posts: 292

- Joined: Fri Jun 03, 2011 2:49 pm

- Location: North Staffordshire

- Has liked: 257 times

- Been liked: 147 times

-

Ray Brown

- Posts: 452

- Joined: Tue Jul 05, 2011 2:00 am

- Location: Penrith NSW

- Has liked: 26 times

- Been liked: 103 times

- Contact:

Re: Firefly 008 build

g'day john. i'm with you. the p4 is my first 1/6 r/c anything. like you i'm learning to cut, bend, twist and join metal and brass. brought a roller, guilotine & bender which has helped inmeasureably. the more i do the bettermy skjills have become. with the help of the guys on this forum many obstacles have been overcome. i'm enjoiying your sherman build and i wish there were more with you posting pictures. even though i'm nowhere near the skill level of others here but they still appreciate seeing your build. my skill will be better for the tiger 1.

-

Steve Stuart

- Posts: 779

- Joined: Fri Apr 18, 2008 11:34 pm

- Location: Oxford

- Has liked: 264 times

- Been liked: 195 times

Re: Firefly 008 build

Apologies if this is the wrong place to ask this question, but I was going to ask this question elsewhere but it seems to fit in here.

What do you recommend for priming brass before painting? I used red oxide and the paint came off very quickly with just a little contact with a tow rope!

Does Acid Etch Primer work on brass as well as alumnium?

Many thanks in advance for any advice.

Steve

What do you recommend for priming brass before painting? I used red oxide and the paint came off very quickly with just a little contact with a tow rope!

Does Acid Etch Primer work on brass as well as alumnium?

Many thanks in advance for any advice.

Steve