Page 3 of 20

Re: Churchill Mk3 number 67

Posted: Sat Feb 25, 2023 2:46 pm

by Andy Cameron

Thanks all for advice, certainly gives me a better start point. FYI not sure if it’s of interest but I did some experiments with a 3D photo app on my iPad which worked surprisingly well on a complex item just using sequenced photos on x y z planes and no LiDAR required. Could be of interest when visiting museums to get 3D walk arounds on components etc to compliment technical diagrams. There are quite a few apps available for this.

Regards

Andy

Re: Churchill Mk3 number 67

Posted: Sun Feb 26, 2023 8:24 pm

by Andy Cameron

Apologies Gary for hijacking your build thread, I will start a new topic tomorrow when I have my kit number to progress my build etc.

Looking forward to seeing any additional work performed on your build especially extra detailing.

Regards

Andy

Re: Churchill Mk3 number 67

Posted: Mon Feb 27, 2023 8:42 am

by Gary Richardson

Andy Cameron wrote: ↑Sun Feb 26, 2023 8:24 pm

Apologies Gary for hijacking your build thread, I will start a new topic tomorrow when I have my kit number to progress my build etc.

Looking forward to seeing any additional work performed on your build especially extra detailing.

Regards

Andy

Hi Andy

No apology required, I know what a steep leaning curve your first build is and am happy to help.

I look forward to following your build.

Regards

Gary

Re: Churchill Mk3 number 67

Posted: Mon Feb 27, 2023 10:04 am

by Gary Richardson

Good morning all

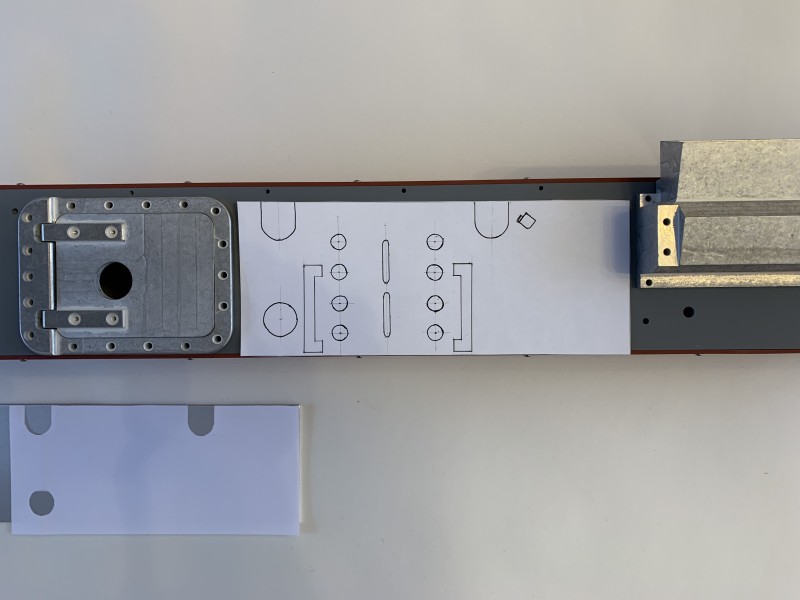

Today I did the dry fit of the left pannier to allow me to plan the cutting and installation of the applique armour. I spent many hours and four trips to the Tank Museum making sure I had accurate measurement of the applique armour. I then reduced the measurements to 1/6th scale and made my technical drawings. Its been over 50 years since I did technical drawing but I managed to find my old drawing sets in the loft which made life easier.

I made a basic paper template with just the outline shape and cone bolt cut outs and ran into a problem

, the scale applique armour is to high by 5mm.

I am sure my measurements are correct as I had forgotten a few vital ones and went back to Bovington on two occasions and rechecked them all. So, where does this leave me. I know the bottom edges of the applique armour sits flush with the bottom of the pannier so that is my datum line to work from. It may be model measurements on the pannier height are wrong, but to be fair to Armortek, I would think that is unlikely and no criticism is intended, I am really enjoying this build and it is a great model. My measurements were taken from the Mk3 AVRE built in 1942 and used as a range target at Otterburn before being restored. Perhaps Armortek took their measurements from the Tank Museums other Mk3 currently having a new clutch fitted and there are differences in the pannier sizes due to the restorations. I am not sure I would be able to get access to the Mk3 being repaired to check the applique armour measurements and I am probably just being too fussy.

Whatever the reason I will have to modify my measurements for the applique armour accordingly. The length of the side plate actually needs extending by 5mm so I cannot just rescale the drawing as a whole, plus the hole and bolt sizes and bracket fittings need to remain accurate.

I will make very small adjustments to a few areas, maybe losing 1mm between each bracket bolt hole and shaving some from the top of the plate. The front left applique armour also needs a slight adjustment but that is easier to do. I will probably move/redrill the conehead bolt holes to match the applique armour.

On the plus side I now have a wealth of measurements and some applique armour drawings from the Tank Museum archive who also found me a parts list so I know all the correct sizes of bolts, washers, etc used for the brackets. Many thanks to Sheldon at the archive for his time and effort finding these for me.

Sorry if the above is a bit long but I thought it might be of interest to anyone else adding applique armour.

Regards

Gary

- Paper template of scale applique armour

- This will need adjusting as too high and not wide enough

Re: Churchill Mk3 number 67

Posted: Mon Feb 27, 2023 5:31 pm

by Gary Richardson

Hi all

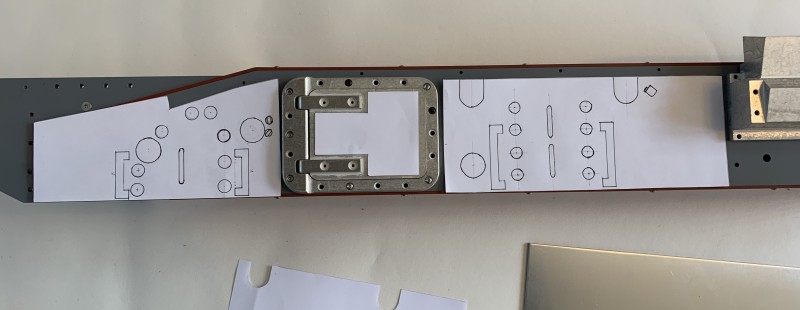

I have modified the applique armour dimensions at 1/6 scale to better fit the model. In total I had to reduce the height by 8mm and extend the length by 7mm. This will allow for scale size welds which I also have measurements for and they are surprisingly large. It also allows for more simple measurements by rounding out the sizes. Luckily the aluminium plate I bought for the applique armour is the right height but I will need to order some new plates for the front side applique armour. Metals 4 u are very good for aluminium plate and will cut to size for free, even on quite small plates.

I am using 3mm for the side armour and 5mm for the front turret armour which is pretty close to the scale thickness and readily available. The front side armour will need a thin aluminium plate behind it where the horn attaches to the main pannier to allow for the recess.

I have taken a photo to show the new template on the pannier side. I will be redrilling the cone head bolt holes to align with the template.

Regards

Gary

- Revised applique armour template, kept as close to scale as possible.

Re: Churchill Mk3 number 67

Posted: Tue Feb 28, 2023 4:05 pm

by Gary Richardson

Hi all

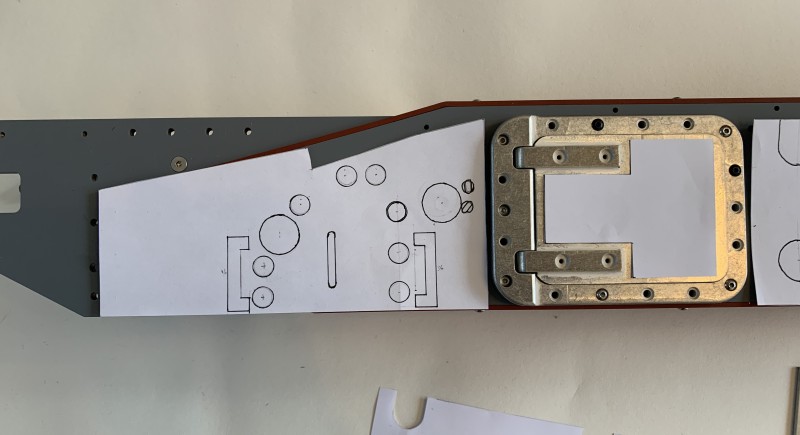

Just a quick update on the applique armour. As with the centre plate I have modified the scale measurements for the front side applique armour to suit the model. It will mean losing the Armortek cable holders but I will make scale ones fixed to the applique armour and above the hatch door frame. Other small changes will be required to attach some of the models steel parts near the horn/pannier joint.

I have taken a photo with the paper templates in place. As with the centre template the height of the front had to be reduced by 8mm and I have moved all the holes down by a few millimetres to try and keep the scale appearance. An extra 3mm shaped plate will be required under the front quarter of the applique armour where the horn joins the pannier body. The dog leg in the top of the front applique armour is a bit superfluous as it doesn't exist on the model but does on the full size. I will try it with and without and see which version looks best.

Just purchased a Sieg SX2PG milling machine to help with all the mods, being delivered Friday and I cannot wait to start on the applique armour.

Regards

Gary

- Pannier applique armour templates

- Pannier front applique armour templates

Re: Churchill Mk3 number 67

Posted: Tue Feb 28, 2023 7:03 pm

by Vince Cutajar

Just purchased a Sieg SX2PG milling machine to help with all the mods

Have fun. Hopefully it will come with some tooling to get you started. Word of warning; don't use a milling cutter in a drill chuck.

Vince

Re: Churchill Mk3 number 67

Posted: Wed Mar 01, 2023 10:17 am

by Gary Richardson

Vince Cutajar wrote: ↑Tue Feb 28, 2023 7:03 pm

Just purchased a Sieg SX2PG milling machine to help with all the mods

Have fun. Hopefully it will come with some tooling to get you started. Word of warning; don't use a milling cutter in a drill chuck.

Vince

Hi Vince

Thanks for the tip. The mill comes with a free bundle of accessories, including a milling vice, clamping set, 4 x R8 collets and 3 x mill bits plus I bought a book on milling for beginners

. It is a new version that has two gas struts and a 500w output brushless motor with belt drive. Arc are going to do a check and set up on it today prior to shipping it to me for Friday. I am looking forward to learning how to use it, I think the applique armour will be the ideal parts to learn on and I will have some decent size scrap aluminium plates to practice on.

Regards

Gary

Re: Churchill Mk3 number 67

Posted: Wed Mar 01, 2023 11:28 am

by Vince Cutajar

As you will be working mostly with aluminium, get some WD40. Great coolant for aluminium.

Vince

Re: Churchill Mk3 number 67

Posted: Sun Mar 12, 2023 10:01 am

by Gary Richardson

Good morning all

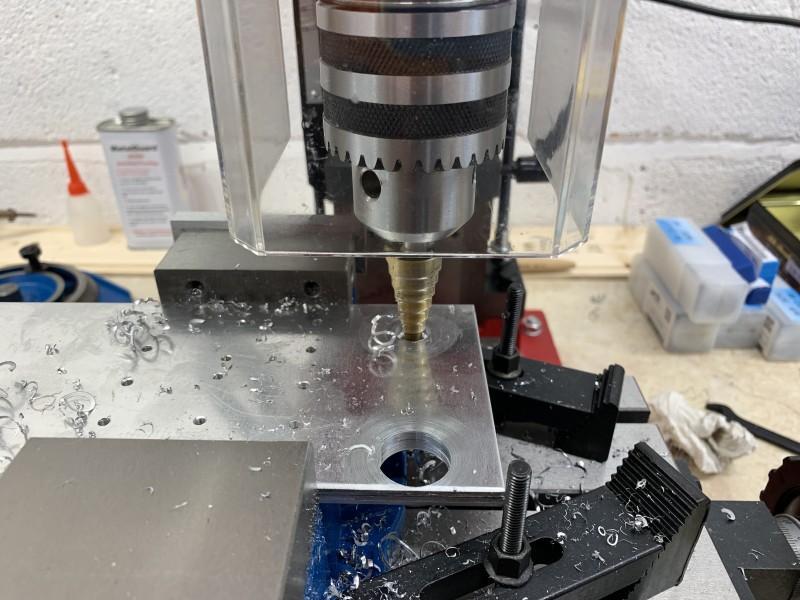

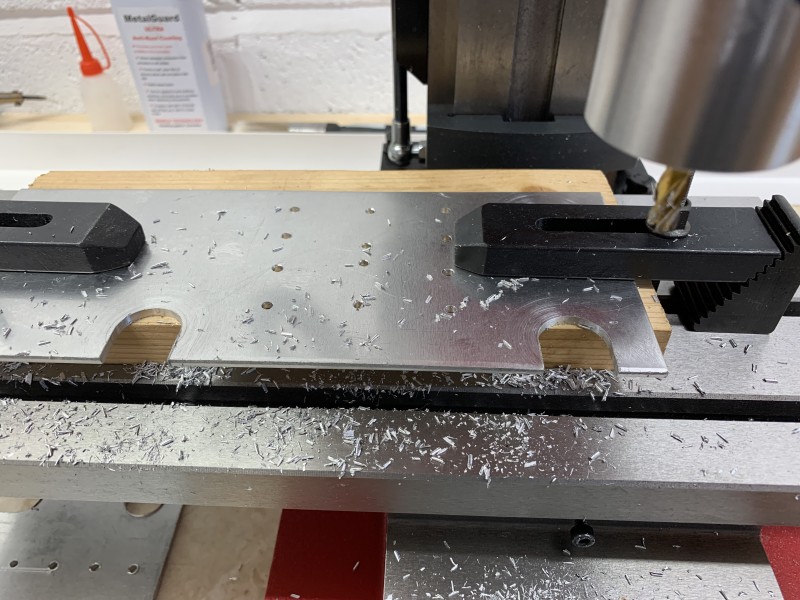

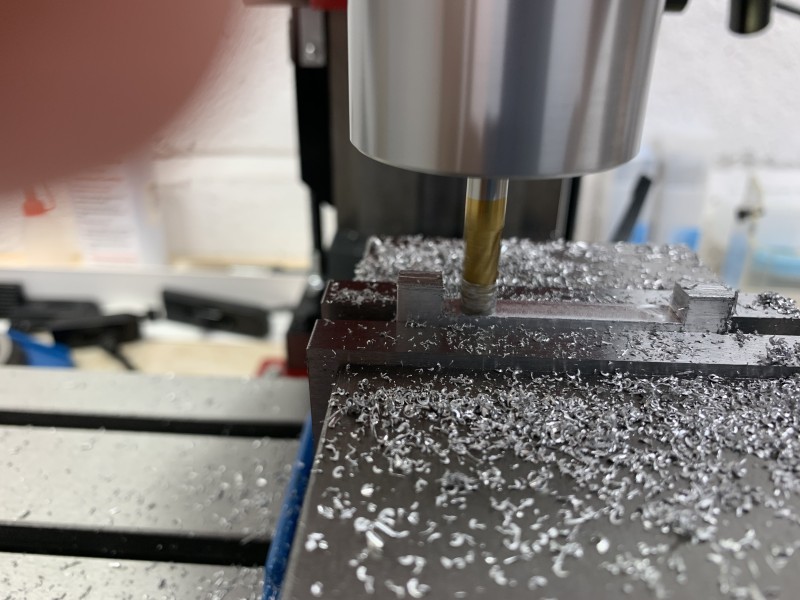

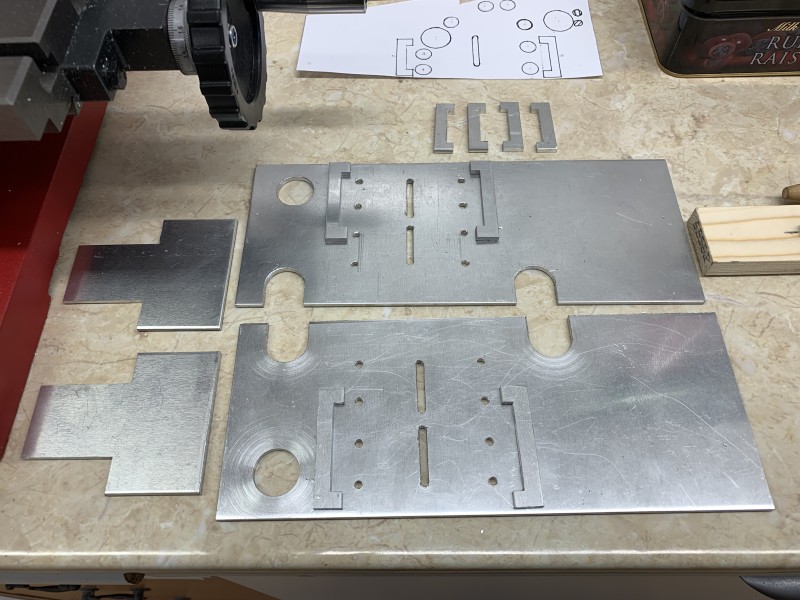

I feel like a kid in a sweet shop as I have set up my new milling machine and started fabricating the applique armour. Drilling the holes is so much easier than using my old pillar drill and a lot more accurate. At present I have drilled all the pilot holes and tapping holes for the bracket bolts. The holes for the cone head bolt positions will be expanded to the correct size and the mill used to do the two top cut outs and the central bracket slots.

I have ordered a variety of mill cutting/drilling tools to add to the ones that came with the mill, these will be used to do other modifications I have in mind such as recessing the bolts for the cooling vents on the rear plate.

I am redrilling the conehead bolt holes in the panniers to match my applique armour templates, this will keep the scale appearance. I am also hoping to make the brackets removeable as per full size, but, may need to bring forward a lathe purchase

as there are some fiddly components required that would be too time consuming to do by hand.

Its too cold in the garage for spraying the top coat on the bogies prior to assembly, hence this build will jump around a bit as I find other areas I can progress. Apologies is this makes following the build tiresome.

Regards

Gary

- New toy to play with

- first phase of applique armour fabrication

- Enlarging the cone head bolt recesses

Re: Churchill Mk3 number 67

Posted: Tue Mar 14, 2023 8:39 am

by Gary Richardson

Good morning all

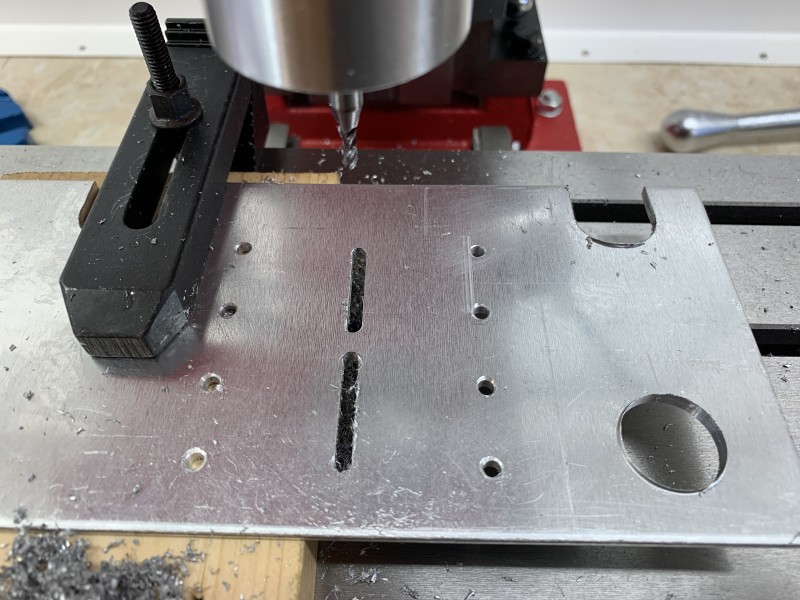

The fabrication of the applique armour continued yesterday, progress has been reasonably quick thanks to the mill. I am still learning how to get the best out of it and only wish I had bought one when I was building my Tiger. It would have saved me many hours of filing and hacksawing and I would recommend getting one if you intend to make modifications to your own tanks.

I have made the four C shaped bracket holders that keep the brackets aligned and today I will make the two hatch armour plates which are quite straight forward.

The applique armour for the front side plates will take a bit more work as a shaped fillet needs to go where the horn plate and main pannier side plate meet to take up the 3mm difference in depth. I also have to order some more 3mm plate as I didn't allow for the horn section originally as it was before I went to Bovington to measure up

. Still it is a minor irritation.

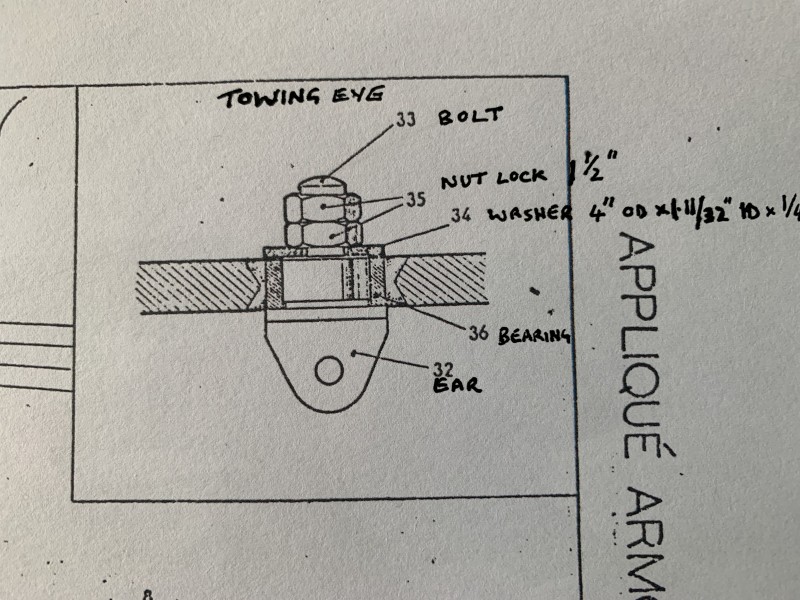

An important consideration for me when modifying the hull is to ensure the 8 tonne derrick I am building attaches to the tank as per full size. This will entail adding a phosphor bronze bush in the idler horn where the lifting eye goes. This bush was the SMS modification 7265 done on AVRE tanks that I was looking for earlier in the build, I checked the Mk3 AVRE at the tank museum which has had the mod done. It's nice when things fall into place

.I also have the diagram showing the lift eye and its components that shows the bush although it was not obvious until Sheldon found me the hull parts index in the archive and kindly sent it to me.

Regards

Gary

- Cone head positions milled out.

- Mid bracket slots cut out ( were used to weld centre of applique armour to the pannier

- Making the C bracket retainers

- Just the top hat stud retainers left to make

- Lift eye showing components and bush ( ignore towing eye on diagram, my error)

Re: Churchill Mk3 number 67

Posted: Tue Mar 14, 2023 6:12 pm

by Gary Richardson

Hi all

It feels like I have made a big step forward with the applique armour, I have found a supplier for M4 brass threaded inserts that are 4mm deep with a 3mm insertion depth, ideal for the stud retainers and a good scale match to the full size fittings. I will confirm my order with them tomorrow and see how they go.

The pannier hatch applique armour has been completed out of 3mm plate and all the C brackets have been milled, I will make the fillet for the front armour out of the excess remaining plate while I wait for the new 3mm plate to arrive.

Regards

Gary

- Just the front armour to complete and I can crack on with the hull.

Re: Churchill Mk3 number 67

Posted: Tue Mar 14, 2023 7:37 pm

by David Skeldon

Hi,

Your side plates look good but I think the RH side is different as the cone bolt is lower on the right

David

Re: Churchill Mk3 number 67

Posted: Wed Mar 15, 2023 7:58 am

by Gary Richardson

David Skeldon wrote: ↑Tue Mar 14, 2023 7:37 pm

Hi,

Your side plates look good but I think the RH side is different as the cone bolt is lower on the right

David

Hi David

Thanks for pointing that out, really appreciate you letting me know as I was about to redrill the pannier sides later today.

.I spent many hours measuring the MK3 AVRE applique armour at Bovington and it didn't even occur to me that the mid plates may have different layouts. Just shows how easy it is to miss something that obvious, I wrongly assumed the kit had the correct cone head layout and because the AVRE right hand side was close to the wall in the museum failed to notice it.

Now you have pointed it out it is so obvious from the photo I have of the AVRE using the derrick. Luckily I haven't placed my order for the extra plate I need, I will double check and make a new plate for the right hand side.

Regards

Gary

Re: Churchill Mk3 number 67

Posted: Fri Mar 17, 2023 6:23 pm

by Gary Richardson

Good evening

I received the aluminium plates and brass inserts today

, one of the aluminium plates for the front armour was missing

. After a quick call the supplier will get it out to me for tomorrow. I am still waiting for the Milling tools to arrive, so I decided to remake the right hand central applique armour plate and add the inserts to the left plate. The brass inserts are 8mm across the collar which is 1mm deep and the knurled insert is 3mm deep and 6.5mm diameter. As the inserts are intended to go into plastic fabrications I thought it best to do a test with some scrap 3mm aluminium. I used a 1/4" drill bit as it equals 6.35mm to get the interference fit I wanted, then gently pressed the inserts into the holes using a vice.

On the full size the inserts are held in place with a small welds at 3 & 9 o'clock which I will try to replicate. I will probably skim 0.3mm off the collars now they are in place to make them more realistic. The inserts will also allow me to bolt the applique armour in place with 4mm bolts through the pannier plates. The extra thread length from the bolts will become the exposed studs ready for the brackets which will be removable.

Regards

Gary

- M4 micro brass inserts

- More work to do, the bracket aligners need fixing in place next.