Page 2 of 7

Re: Chieftain MK3 Build

Posted: Fri Sep 17, 2021 10:20 am

by John Clarke

David, (My opinion)

Agree, always love to see the suspension in action. but

I'm not a fan of missing bits either unless it's period, Tiger's with purposely missing front road wheels for the Russian winter or the perfect example, Stephen White's Cent adapted to historical harsh environment.

Missing bits or heavy battle damage models, I always think they are reserved for the Static Brigade.

Who wants to see a limping model tank traveling around and coming back after that, abused

I haven't fitted my bogies due to the weight, knowing I'd have to move the hull round several times on the bench, it sits on a little wheeled dolly trolley which allows with a little effort a 180 degree spin.

I don't know if the Bogie geometry is correct or not, probably wouldn't understand if it was explained to me either.

Early on, other modelers tried to get more "correct" travel by hollowing out the bogie frame tunnel, I did a couple of simple things including extending the tie rods about 10 mm, that helps prevent the springs from falling out when the bogie is not under tension. (Track removal)

Not sure what the final outcome will be.

On a serious note, I believe some Chieftain builders have experience scrubbing on the inside of the road tyres from the bolt heads on the shirt brackets.

Beware.

Another one for Adrian

Re: Chieftain MK3 Build

Posted: Fri Sep 17, 2021 8:31 pm

by Adrian Harris

Re: Chieftain MK3 Build

Posted: Wed Sep 22, 2021 9:41 pm

by David Battson

Re: Chieftain MK3 Build

Posted: Wed Sep 22, 2021 10:09 pm

by Charles A Stewart

Attention to detail, David, brilliant.

Now wishing I could put mine back in the box and start again, say five years later. Obviously that's not going to happen, too far in; Totem program could be a possibility in the future.

Great insight to the build.

Cheers Charles

Re: Chieftain MK3 Build

Posted: Wed Sep 29, 2021 11:40 pm

by David Battson

Re: Chieftain MK3 Build

Posted: Sat Oct 02, 2021 2:12 pm

by John Clarke

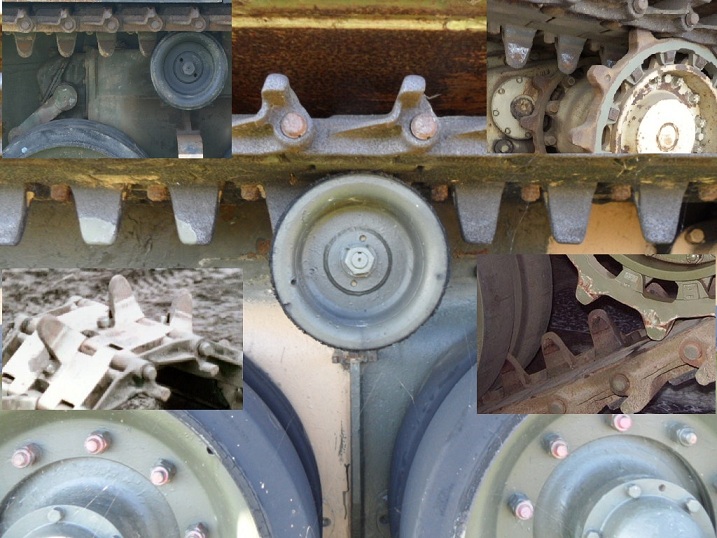

Awesome work David, at first when I saw the initial pictures of the bogie frame I thought you'd cut too much off top flange, not allowing enough space for the bolt heads, but the later post picture shows the chamfer along the top of the spring housing allowing the flange to "grow" back again. The detail is truly amazing. Changing the idler bearing mount and addressing the support webs for the shirt brackets. If you were to paint the changes there'd be very little left of the original model bogie frame surface.

Not sure how you do it. Would you dial in and make the six same machined cuts, one frame after another?

Or will you make each one independently?

Keep it up, I'll be eagerly waiting for the next installment on this most excellent build.

This sort of work on my model will be left as "Model Warranty Standard"

.

Something the next owner could possibly improve on, "To make it his own".

(Car salesman speak, on an unfinished project)

Re: Chieftain MK3 Build

Posted: Sat Oct 02, 2021 11:35 pm

by David Battson

Hi John,

Many thanks for your comments and interest.

I find that the most time consuming part of machining is more often than not, setting up a cut rather than actually making it. So wherever possible work is done in batches to minimise set ups, rather than make one item start to finish and then move onto the next. I don't have CNC, so things like the rollover curve between the front and upper surface was created by cutting steps at 1.0mm or 0.5mm vertical intervals and then filing the surface smooth.

David

Re: Chieftain MK3 Build

Posted: Sun Oct 17, 2021 11:52 am

by David Battson

Re: Chieftain MK3 Build

Posted: Mon Oct 18, 2021 8:46 am

by John Clarke

Nice detailing Expecially enjoying the pictures, looking forward to see how you deal with the spring units

Re: Chieftain MK3 Build

Posted: Sun Oct 24, 2021 9:21 pm

by David Battson

Re: Chieftain MK3 Build

Posted: Mon Oct 25, 2021 1:11 pm

by John Clarke

Beautiful workmanship. I might just say "wow" from now on.

But I do worry.

I worry, do you have a big enough box for the discarded items, if not, send them to me

There's another obvious question, but I dare not ask

And the Tracks, no biggy, once you get into it. I think the horns are too tall/wide anyway and there were different shaped horns on the originals too.

Re: Chieftain MK3 Build

Posted: Wed Oct 27, 2021 6:11 pm

by David Battson

Hi John, thank you for the comments.

I can’t find the measurement I took, but seem to remember that the height of the kit track horn was actually very close to the real thing. From the return roller drawing it is evident that the diameter of the axle shaft on the real thing was quite small. Rather than grind the track horns down or wait for things to wear in over time, I thinned the walls of the return roller sleeves down as much as I dare (to about 0.8mm) to give some clearance to the track horns. Hopefully there’s still enough strength remaining.

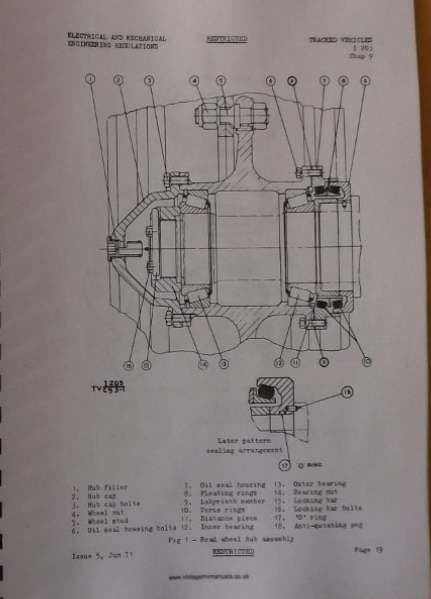

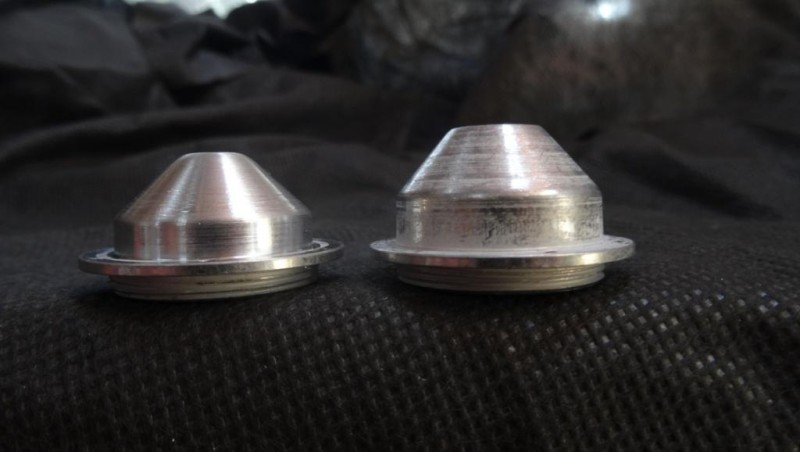

Road wheel hubs - Comparing the kit piece against the drawing, there were two areas of the road wheel hub I wanted to improve.

Firstly, the ‘nose’ of the hubcap should be in line with the outer wheel rim, whereas on the kit the hubcap protrudes by about 8mm beyond the wheel rim. To improve the look, I re-profiled the hubcap cone angle to 45degrees and slightly reduced the height and diameter of it’s base. This reduced the effective ‘height’ of the hubcap by 4mm. To complete the job and bring the nose of the hub cap flush with the rim, a 4mm spacer was added to the front face of the wheel mounting flange and blended in with filler. Hopefully the extra thick wheel mountings won’t be too visible from underneath. A corresponding 4mm was taken off the axle shafts to bring the road wheel positions back into their original line,. The oil filler cap was made by trimming down the head of an m3 countersunk hex screw.

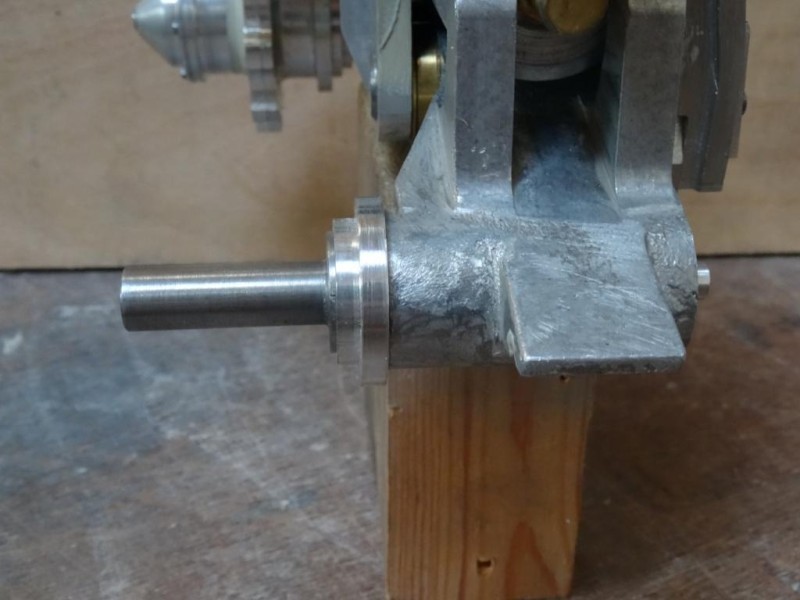

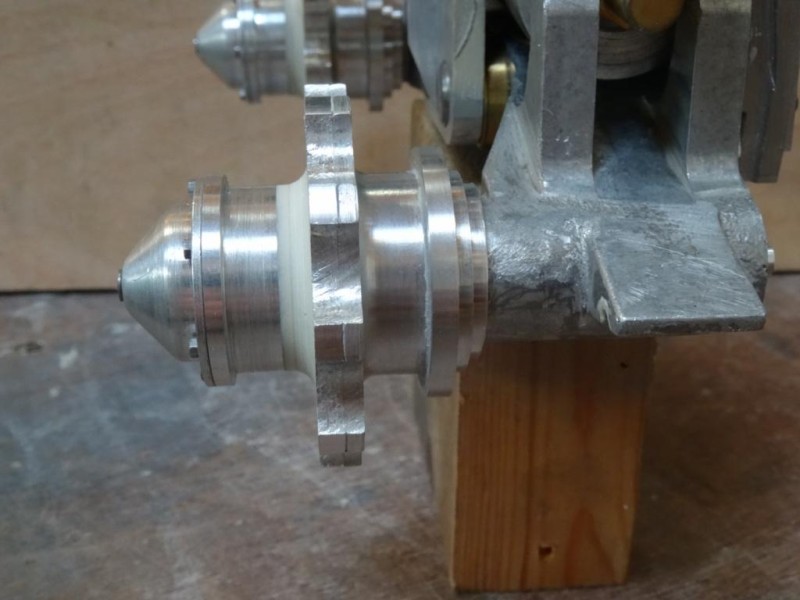

The second area for improvement was the back of the wheel hubs which are surprisingly on show with Chieftain, for the front wheels at least. To improve the look, the RS bearing was hidden by the addition of the sealing ring and back plate detail. The overlap between the wheel hub and back plate is kept to an absolute minimum to stop anything from getting caught between the two surfaces.

David

- Drawing

- Wheel hub.PNG (347.33 KiB) Viewed 5690 times

- Hubcap comparison

- Original kit piece

- original wheel hub 1.JPG (79.41 KiB) Viewed 5690 times

- Axle back plate

- Completed wheel hub

Re: Chieftain MK3 Build

Posted: Wed Oct 27, 2021 8:01 pm

by Charles A Stewart

David, all I can say is that I am very impressed by what you are doing and I will pre-empt John:- WOW

Cheers Charles

Re: Chieftain MK3 Build

Posted: Thu Oct 28, 2021 11:43 am

by John Clarke

Wow, brilliant workmanship David.

Hey Charles that Kylie's and my saying you've used there.

Now complete, that suspension unit just needs a nice varnished mahogany plinth.

I'll have to agree to disagree on the track horns, the shape and size varies from what I've seen. With the most common being the sharper rounded type. My tracks came with horns that have a flattened top, which were rounded after clipping and shaping.

Scale wise, the model track I have is about 1mm wider than scale, which is a good thing.

Less ground pressure

They'll only be one winner between steel track and alloy idler

Will you be hollowing out the horn roots?

I'm tempted to do just the spare track pieces.

- SAM_149511.jpg (220.72 KiB) Viewed 5607 times

Re: Chieftain MK3 Build

Posted: Wed Nov 10, 2021 8:23 pm

by David Battson