2012 Late tiger comission build

- Steen Vøler

- Posts: 771

- Joined: Mon Nov 19, 2012 2:45 pm

- Location: Denmark

- Has liked: 62 times

- Been liked: 500 times

-

John Grima

- Posts: 250

- Joined: Sun Jul 15, 2007 2:54 pm

- Location: USA

- Been liked: 48 times

- Contact:

Re: 2012 Late tiger comission build

Thanks Steen, It feels like ages since I posted on this post, but now with the DML sherman out of the way I can focus my efforts on this build until completion.

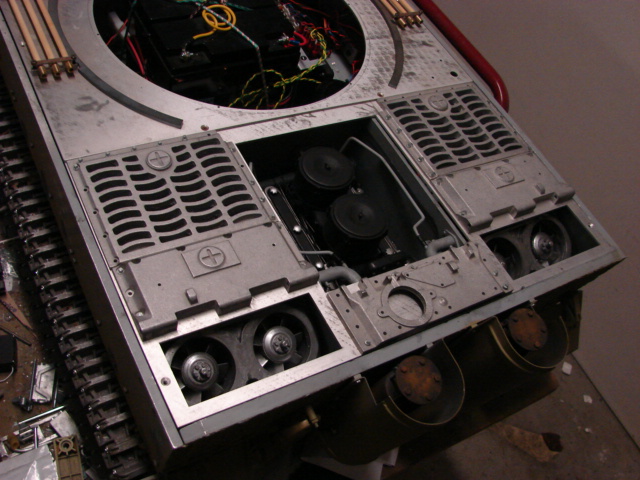

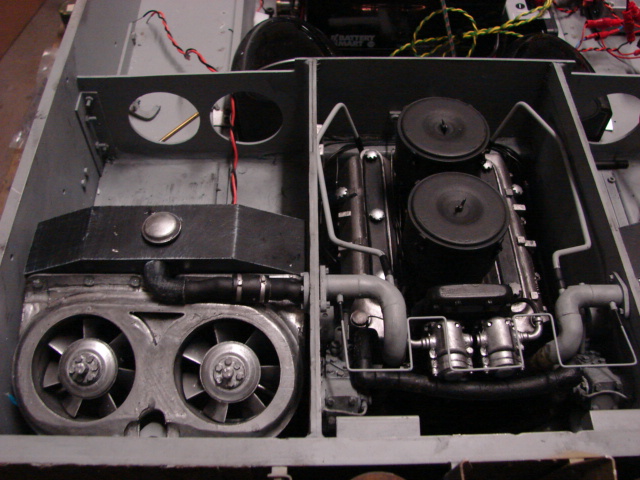

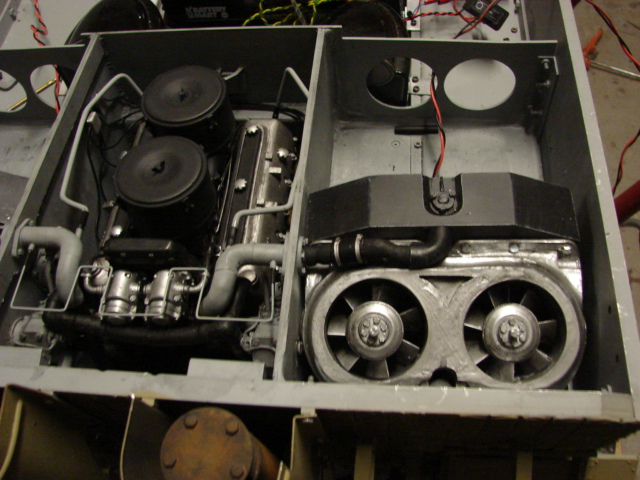

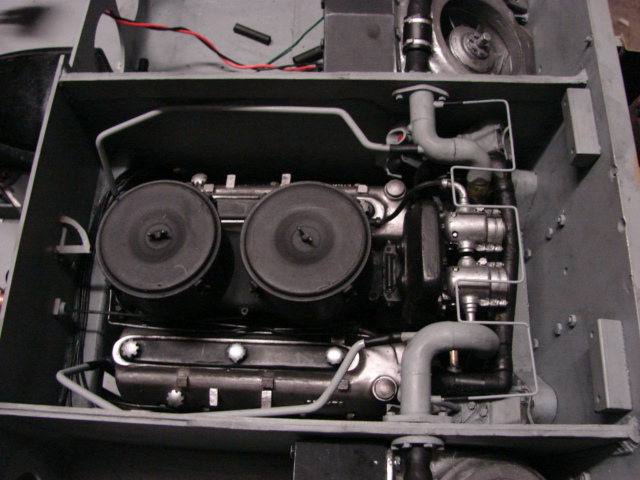

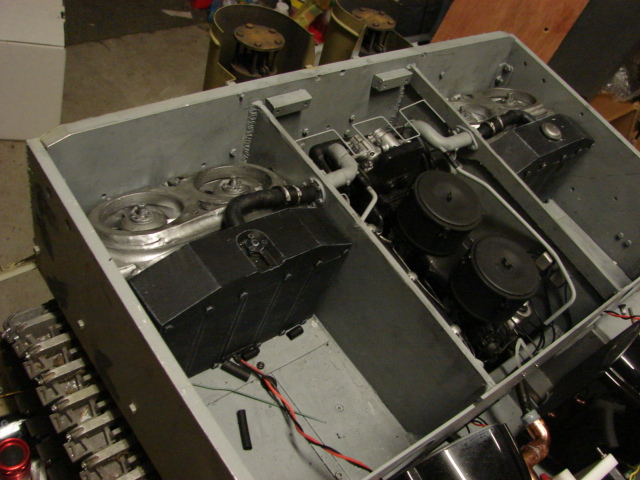

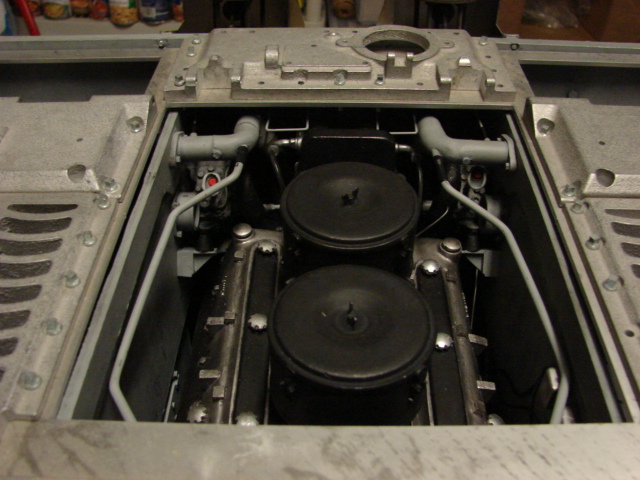

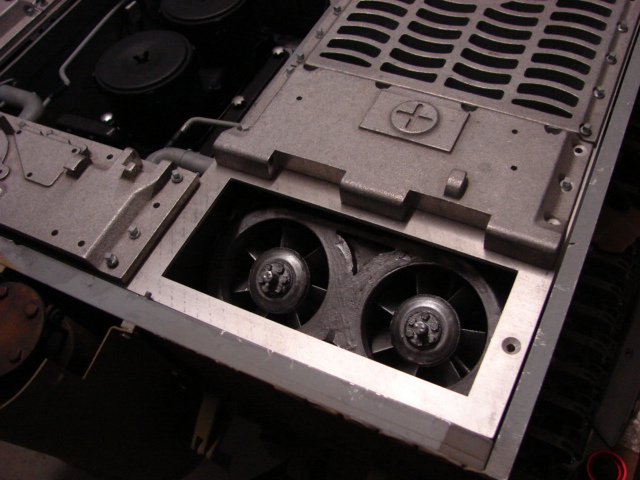

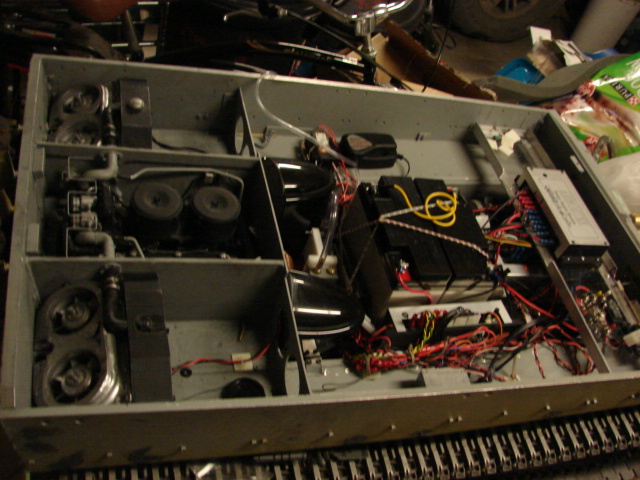

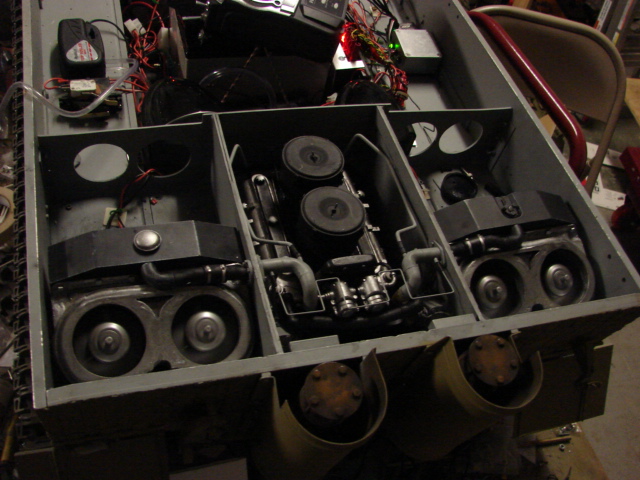

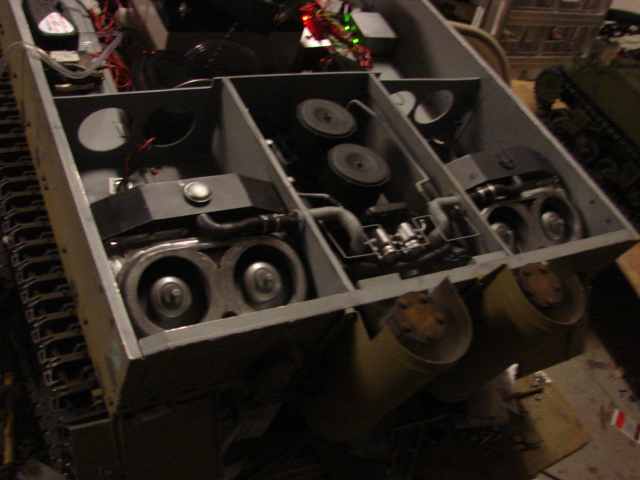

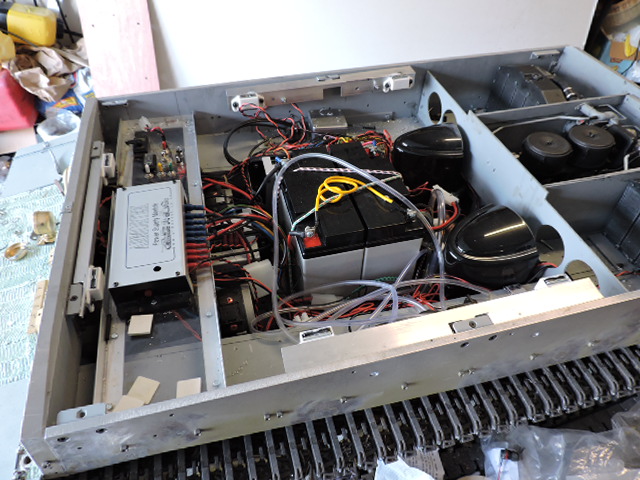

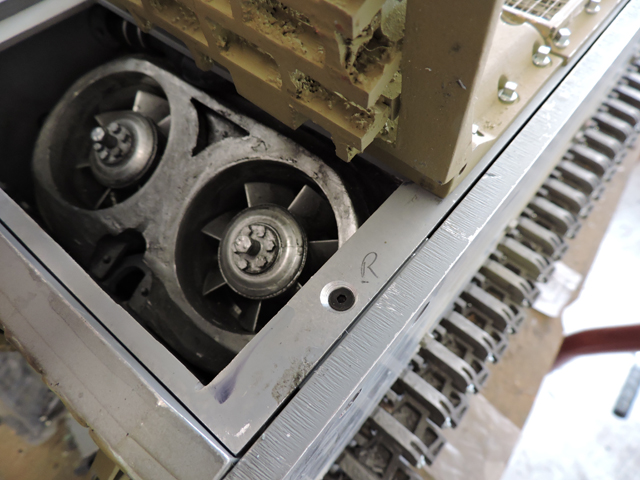

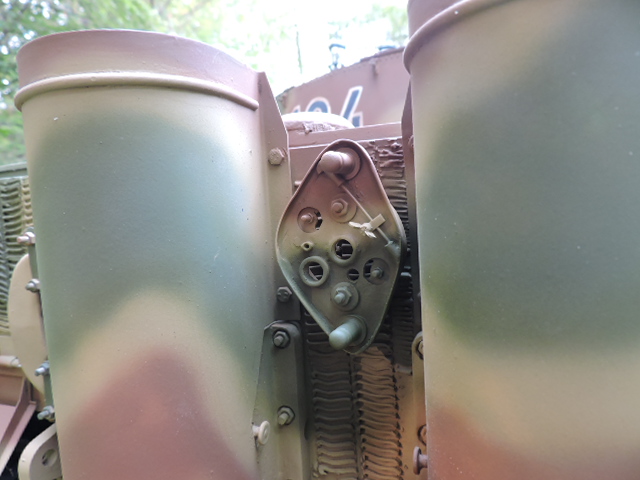

Since the other tank's completion I completed the engine compartment details, and installed the engine, fanwork, and all the rest of the compartment plumbing and other details

One design feature that I built into the tank is that all major components that are mounted in the rear can be removed in case of the emergency arises in which you need to get access to the rear idler wheels / torsion bars. However with the design mods I made earlier to these components this event should not happen, but it does help to have an insurance policy. The parts are mounted via fasteners, and silicone. The silicone gives a decent hold and, can be removed if needed that leaves little marks.

While fitting in all the parts I was very careful in making the engine / components fit properly so that when the top deck / engine hatch are fitted everything fits snug and has the proper clearance.

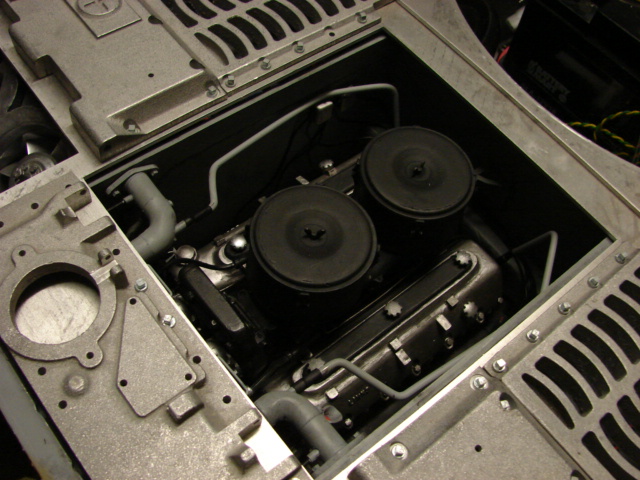

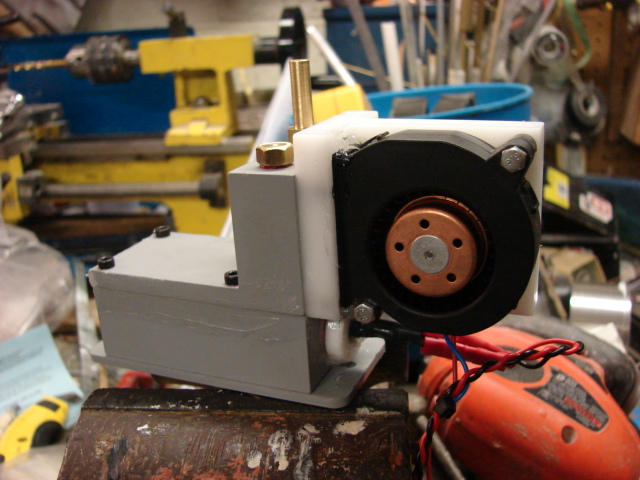

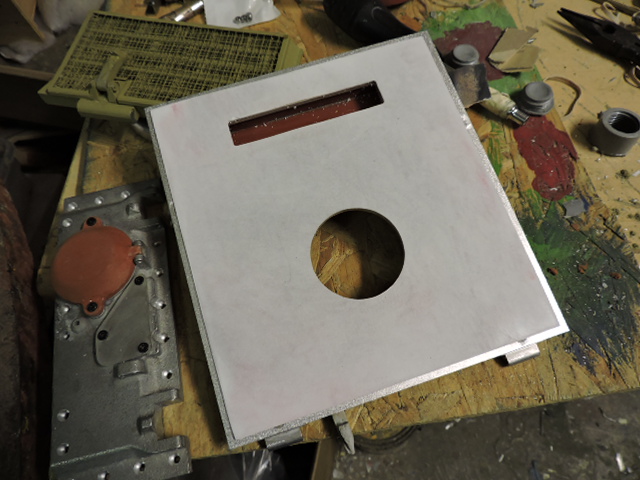

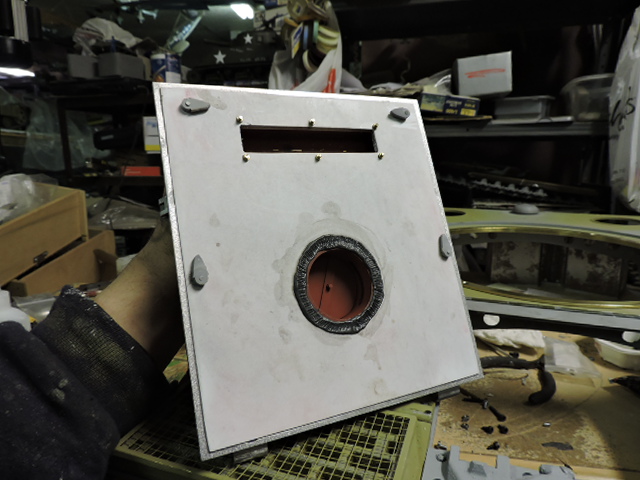

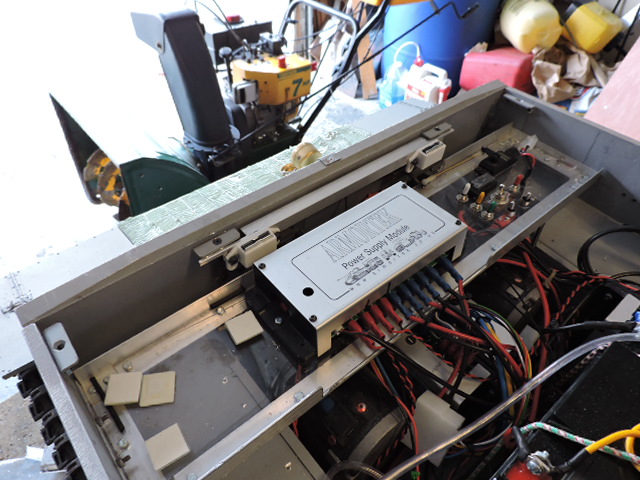

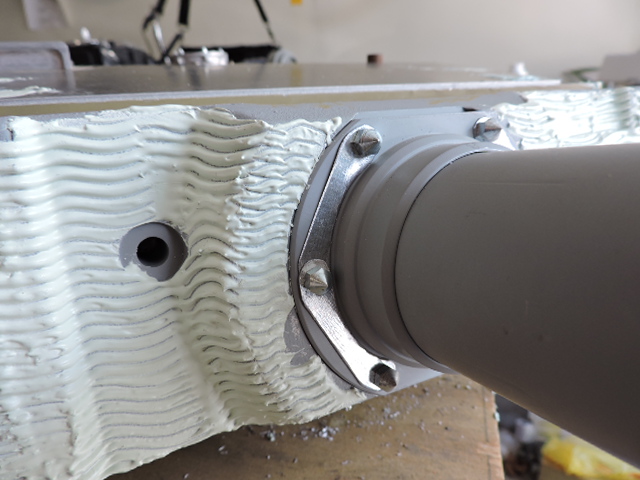

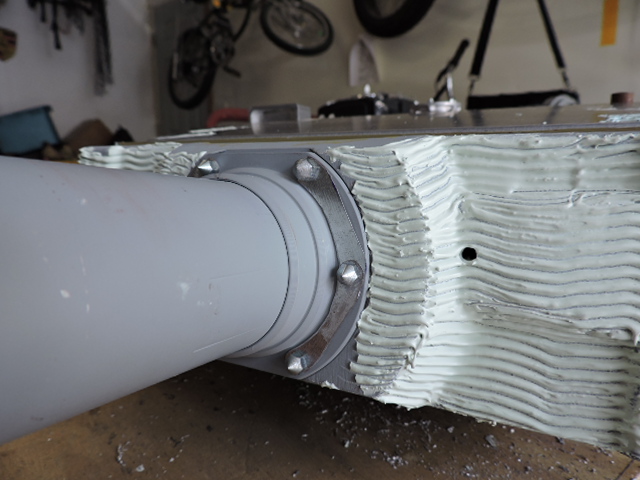

After the engine was fitted I then turned my attention to the smoke system. For the smoke system I used the Unit from armotek. This same unit was used in My M4A4 Sherman and works very well. The unit was assembled out of the box following the supplied instructions, which are very well laid out.

The only mod that was made to the system itself was I added a bead of silicone sealant around all gaps of the unit. The sealant helps in preventing smoke from seeping out of any gaps, and also funnel's more of the fan's air to expel the smoke from the desired location.

Before installing the top, I went and presoaked the element wick with the smoke fluid. Once soaking was complete access fluid was poured out / back into the bottle and the top was installed with it's silicone seal

Because of the engine compartment details I had to mount the generator just behind the firewall. The smoke is then runs through the engine's exhaust manifolds (which were casted hollow) and out the rear of the tank via the stacks, like the real tank.

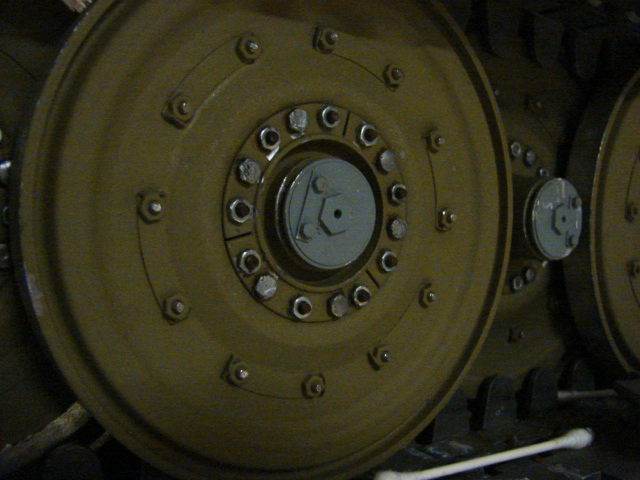

In addition to the engine and smoke work I also completed the tank's hub caps. The kit supplies you with CNCed allum. hub caps for the road wheels and the sprockets. The parts are correctly scaled and had some detailing present.

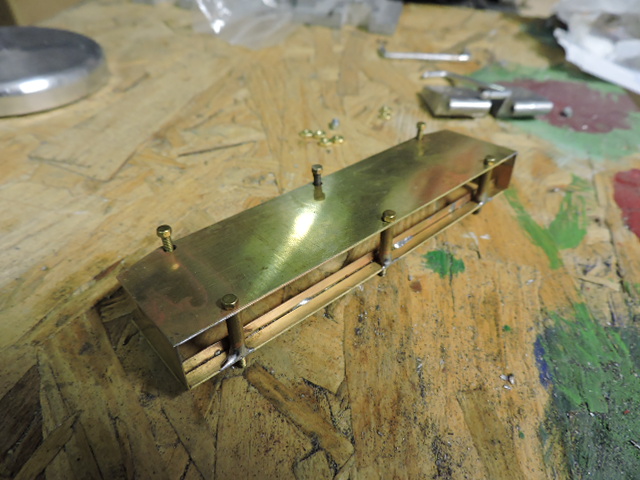

For the sprocket hubs the kit contains PE brass parts for the fastener locks. as well as the correct acorn style fasteners.

The only mod that I made to the sprockets was I bent up a portion of the kit PE to lock onto the fasteners. A zerk fitting bolt, and center brass fastener lock was also fabricated.

For the road wheel hubs, The real tiger has a small hole in the center of the hub, this hole was added via the lathe, by using the lathe the hole has a better chance of being dead center compared to using the drill press.

Also the hole is not all the way through. Because these hubs cover and seal the inner bearings and axles of the wheels a hole can allow moisture and other dirt into the space which can lead to issues. By drilling part way the detail is present, and the sealed off interior is retained

Also on the rear tiger A small retaining plate is found on the hubs. This detail was fabricated out of plastic strip and brass fasteners.

After the mods were made the parts were primed in gray and were then installed to the model.

the wheel hubs simply screw on, while the sprocket hubs are installed with silicone... Like with the engine compartment parts the hubs are on well, but can be easily removed if needed.

More pics were posted on the ECA Facebook page, https://www.facebook.com/EastCoastArmory

Currently I'm working on hooking up the new parts to the electronics. Once added I can then jump to the top deck, and side hull zemm / detailing, More to come!!

Since the other tank's completion I completed the engine compartment details, and installed the engine, fanwork, and all the rest of the compartment plumbing and other details

One design feature that I built into the tank is that all major components that are mounted in the rear can be removed in case of the emergency arises in which you need to get access to the rear idler wheels / torsion bars. However with the design mods I made earlier to these components this event should not happen, but it does help to have an insurance policy. The parts are mounted via fasteners, and silicone. The silicone gives a decent hold and, can be removed if needed that leaves little marks.

While fitting in all the parts I was very careful in making the engine / components fit properly so that when the top deck / engine hatch are fitted everything fits snug and has the proper clearance.

After the engine was fitted I then turned my attention to the smoke system. For the smoke system I used the Unit from armotek. This same unit was used in My M4A4 Sherman and works very well. The unit was assembled out of the box following the supplied instructions, which are very well laid out.

The only mod that was made to the system itself was I added a bead of silicone sealant around all gaps of the unit. The sealant helps in preventing smoke from seeping out of any gaps, and also funnel's more of the fan's air to expel the smoke from the desired location.

Before installing the top, I went and presoaked the element wick with the smoke fluid. Once soaking was complete access fluid was poured out / back into the bottle and the top was installed with it's silicone seal

Because of the engine compartment details I had to mount the generator just behind the firewall. The smoke is then runs through the engine's exhaust manifolds (which were casted hollow) and out the rear of the tank via the stacks, like the real tank.

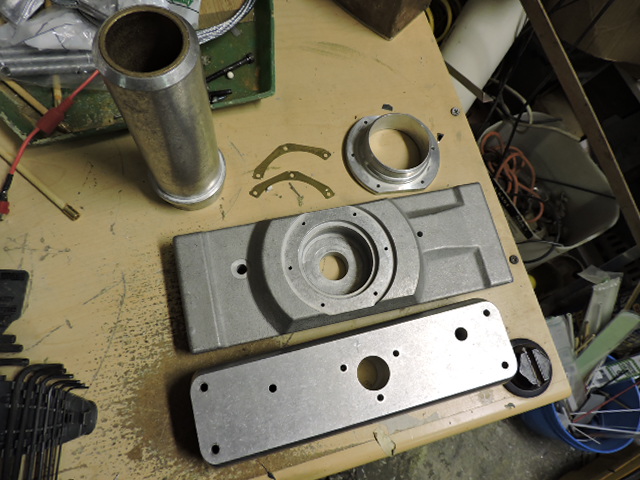

In addition to the engine and smoke work I also completed the tank's hub caps. The kit supplies you with CNCed allum. hub caps for the road wheels and the sprockets. The parts are correctly scaled and had some detailing present.

For the sprocket hubs the kit contains PE brass parts for the fastener locks. as well as the correct acorn style fasteners.

The only mod that I made to the sprockets was I bent up a portion of the kit PE to lock onto the fasteners. A zerk fitting bolt, and center brass fastener lock was also fabricated.

For the road wheel hubs, The real tiger has a small hole in the center of the hub, this hole was added via the lathe, by using the lathe the hole has a better chance of being dead center compared to using the drill press.

Also the hole is not all the way through. Because these hubs cover and seal the inner bearings and axles of the wheels a hole can allow moisture and other dirt into the space which can lead to issues. By drilling part way the detail is present, and the sealed off interior is retained

Also on the rear tiger A small retaining plate is found on the hubs. This detail was fabricated out of plastic strip and brass fasteners.

After the mods were made the parts were primed in gray and were then installed to the model.

the wheel hubs simply screw on, while the sprocket hubs are installed with silicone... Like with the engine compartment parts the hubs are on well, but can be easily removed if needed.

More pics were posted on the ECA Facebook page, https://www.facebook.com/EastCoastArmory

Currently I'm working on hooking up the new parts to the electronics. Once added I can then jump to the top deck, and side hull zemm / detailing, More to come!!

-

John Grima

- Posts: 250

- Joined: Sun Jul 15, 2007 2:54 pm

- Location: USA

- Been liked: 48 times

- Contact:

Re: 2012 Late tiger comission build

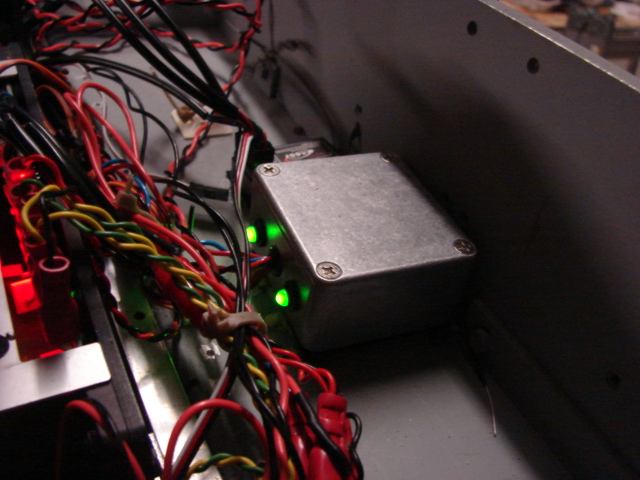

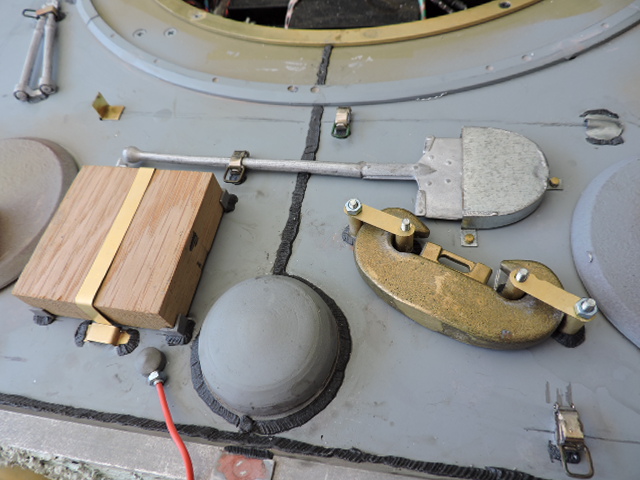

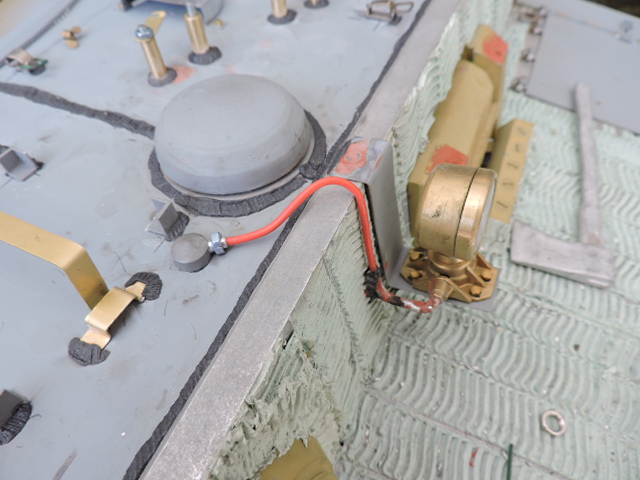

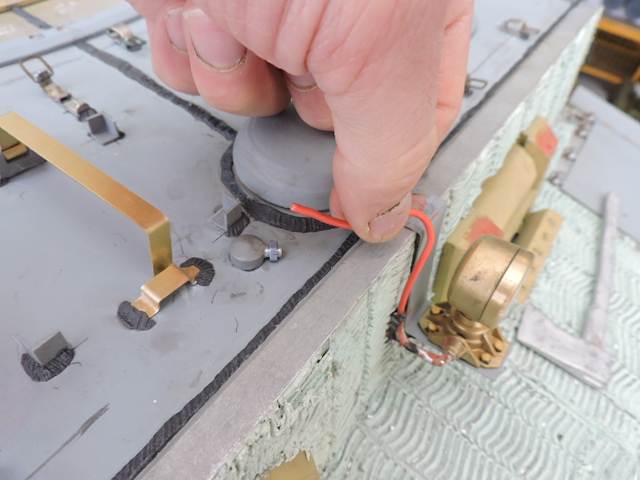

More progress has been made to the model, and all of the hull functions have been wired and completed.

All functions controls were added and mounted below the radio operator hatch

The remote lighting trigger was fabricated and added, The system has a cut off at the hatch so that if the operator doesn't want to run with lights the lights won't activate if the toggle on the radio is accidentally hit. Directly next to the remote lighting is the smoke system refueling pump. The pluming for the refueler will be connected to the grill work fuel fillers, which is to follow.

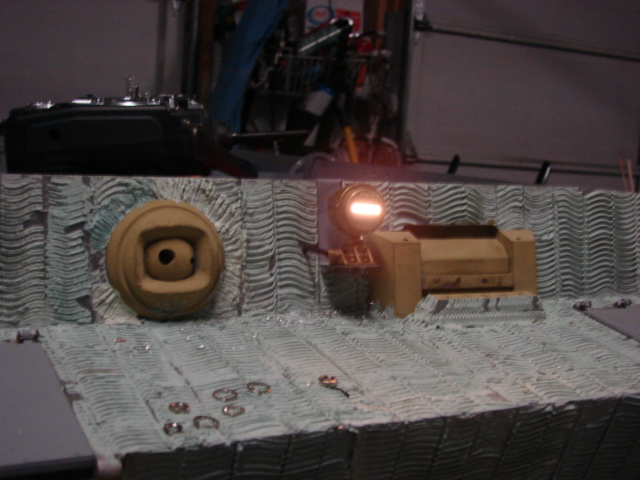

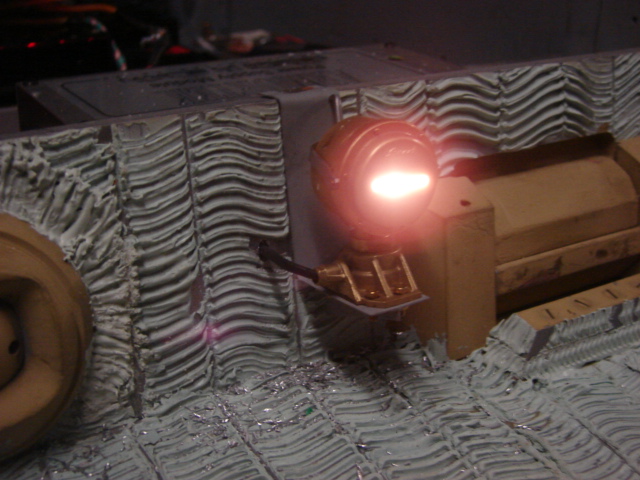

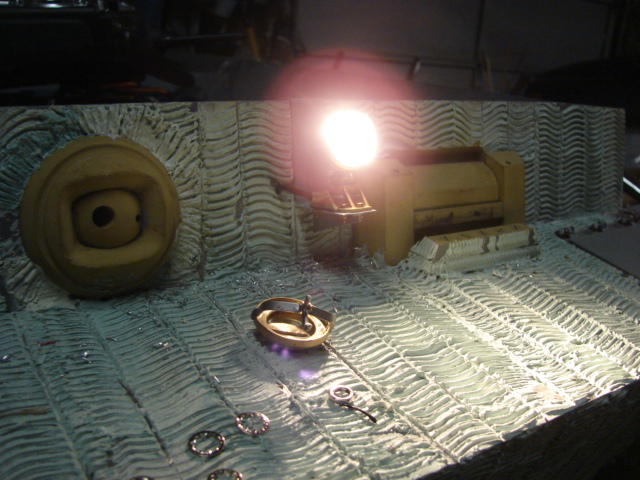

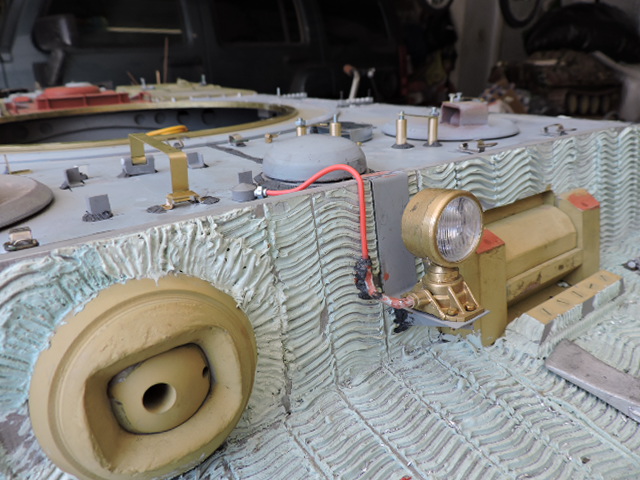

The lights themselves were wired together and the front headlight was mounted.

Because of the top deck's removal the headlight power cord enters the tank from the front, a dummy cable will be fabricated and mounted next to give the illusion that the cable runs to the top deck as it does on the real tank

The sound system was also calibrated, along with the smoke Adrian's smoke system throttle control was also mounted. The system works very well and is highly recommended. With it the appropriate amount of smoke is emitted when the throttle is revving up or down

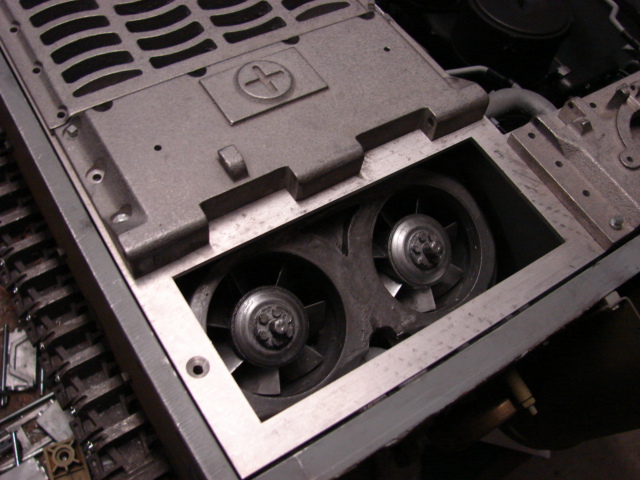

The engine animations were also wired. This includes the fans, the engine flywheel and the fan clutches.

Unfortunately photographing the engine animations is very difficult, but are visible in the youtube video update.

More pics were posted on the ECA facebook page,

http://www.facebook.com/EastCoastArmory

I'm now working on the top deck mounting system / details. Once completed I'll post more pics... More to come!

All functions controls were added and mounted below the radio operator hatch

The remote lighting trigger was fabricated and added, The system has a cut off at the hatch so that if the operator doesn't want to run with lights the lights won't activate if the toggle on the radio is accidentally hit. Directly next to the remote lighting is the smoke system refueling pump. The pluming for the refueler will be connected to the grill work fuel fillers, which is to follow.

The lights themselves were wired together and the front headlight was mounted.

Because of the top deck's removal the headlight power cord enters the tank from the front, a dummy cable will be fabricated and mounted next to give the illusion that the cable runs to the top deck as it does on the real tank

The sound system was also calibrated, along with the smoke Adrian's smoke system throttle control was also mounted. The system works very well and is highly recommended. With it the appropriate amount of smoke is emitted when the throttle is revving up or down

The engine animations were also wired. This includes the fans, the engine flywheel and the fan clutches.

Unfortunately photographing the engine animations is very difficult, but are visible in the youtube video update.

More pics were posted on the ECA facebook page,

http://www.facebook.com/EastCoastArmory

I'm now working on the top deck mounting system / details. Once completed I'll post more pics... More to come!

-

John Grima

- Posts: 250

- Joined: Sun Jul 15, 2007 2:54 pm

- Location: USA

- Been liked: 48 times

- Contact:

Re: 2012 Late tiger comission build

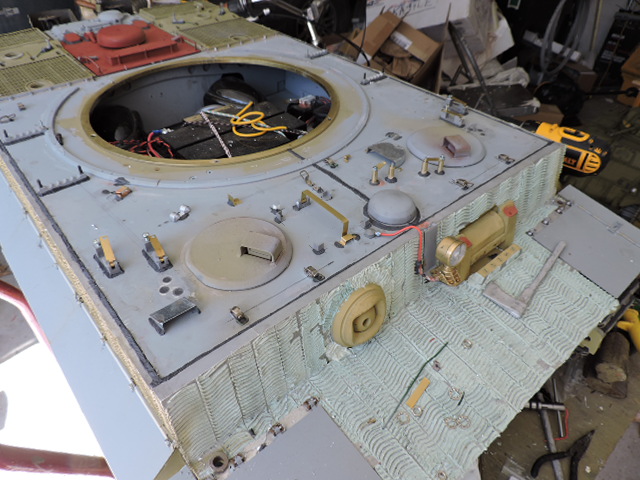

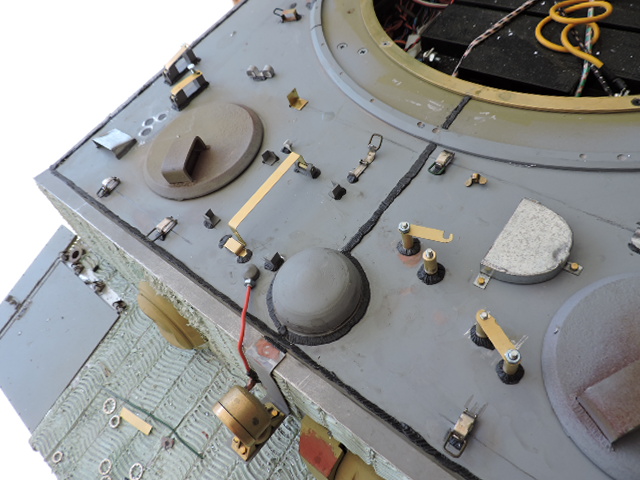

The hinges themselves were also slightly tweaked, Their shape was adjusted and had cast texture added after installation. All that needs to be added now are some weld beads... which will be added momentarily.

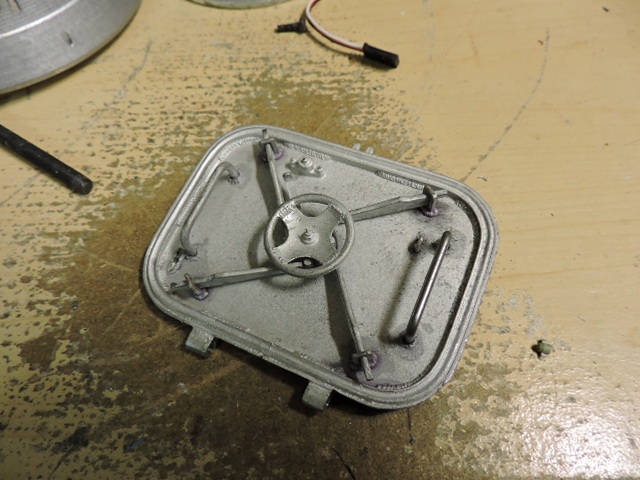

As for the Hatch because of the detailed engine compartment the interior of the engine hatch needed to be detailed. What was added to the kit the the addition of the secondary lip, and hatch locks, and new air intakes

The main air intake was replaced with a Sixth Scale Icons set, Like all of Mike's work it is an amazing add on and really makes the hatch pop,

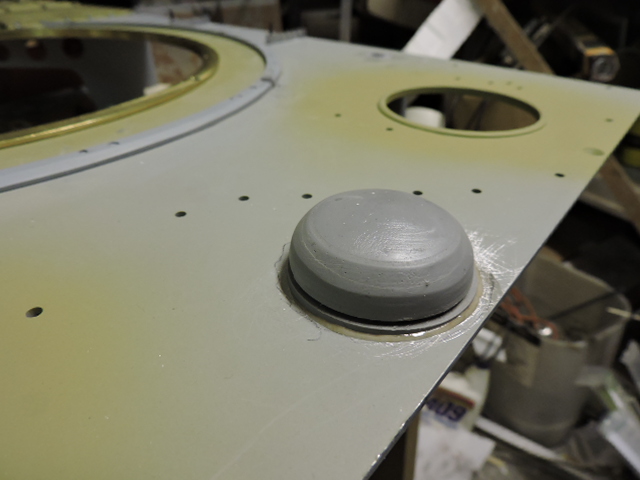

As for the dome intake this is a new part that I tooled up and added to the the ECA catalog.

East Coast Armory -- 1/6th Scale Tiger I Detail Upgrades

This version of the dome intake is the later style one. It differs from the earlier style that I have in that this is the style that would be seen on mid / late production tanks.

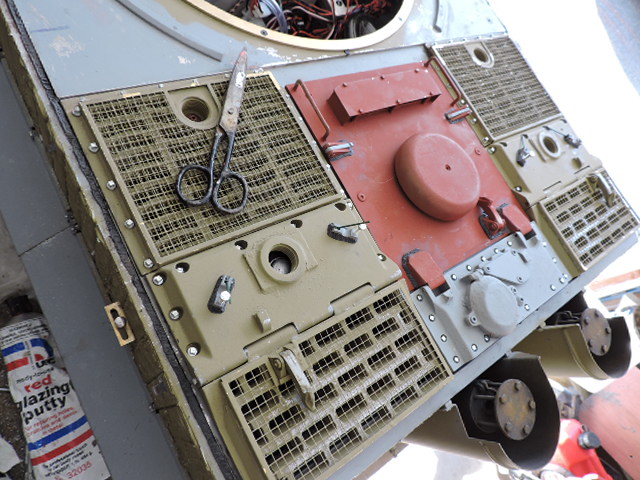

Once the hatch was completed all grill work was mounted to the rear deck.

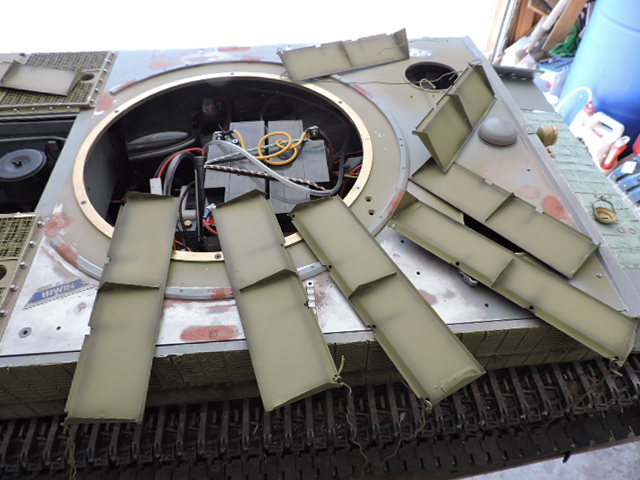

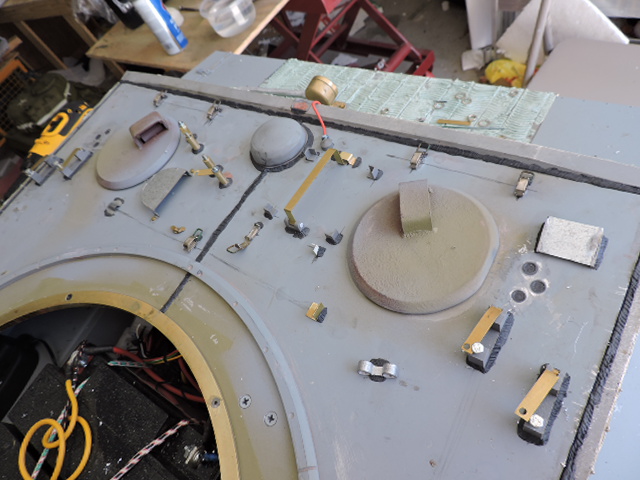

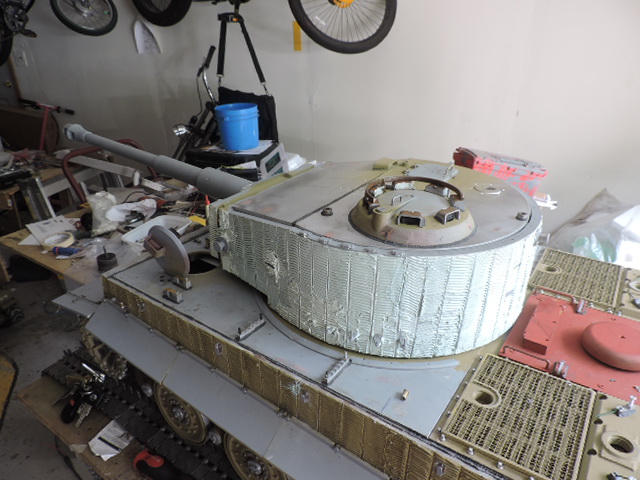

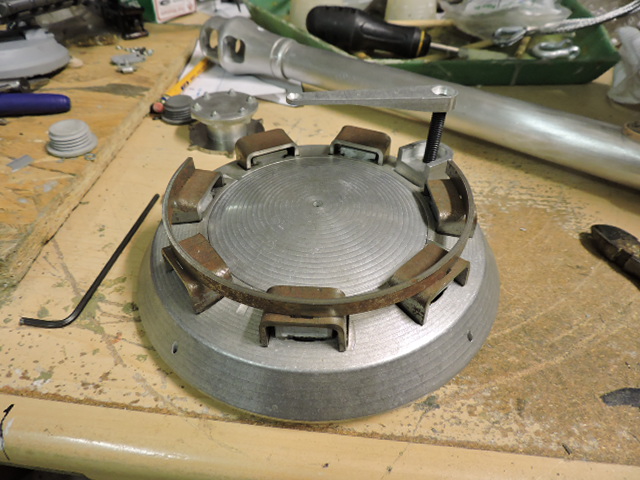

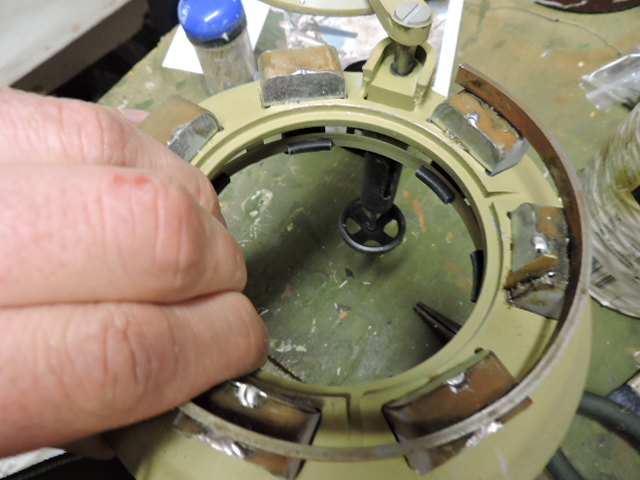

After the grillwork I turned my attention to the main deck. The Brass turret bushing was added. Like on all armortek builds I used counter Sunk fasteners to mount the ring to the deck. Also added was the late tiger turret joint guard and hatch ring bosses.

All parts were included with the kit. On the joint guard I modded the laser cut steel ring to have a bevel, segment and fastener detail. On the real tank the ring was not welded and was bolted to the tank from the inside.

On the front portion I replaced the basic kit original intake dome with one of my own resin ones. This part is not on the catalog as one is listed on Panzerwerk.

The Bow hatches were also painted / weathered. Not sure if they are the kit original, or were acquired by the previous builder, but the hatches are all white metal, and are very detailed... perhaps armorpax? Either way no mods were made and detail wise were left as is.

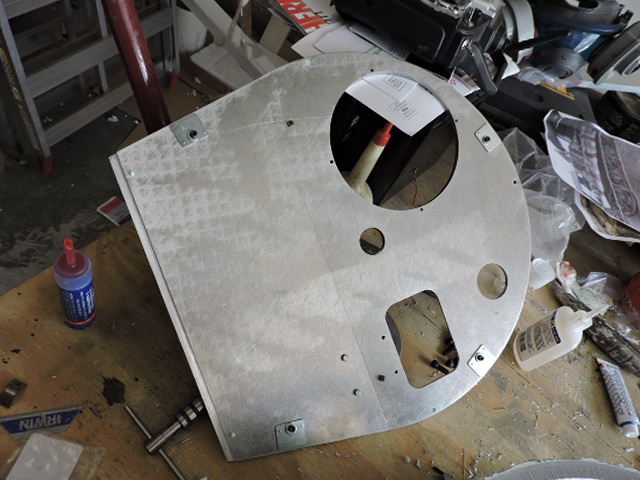

Finally the top deck mounts were fabricated. Because of the engine compartment and other RC access the top deck was modded to be removable. This was done with a combination of magnets and fasteners.

With the new setup the top deck locks on securely, but is removable in the off chance access is required.

More pics were posted on the facebook page

http://www.facebook.com/EastCoastArmory

and two videos were posted on youtube

https://youtu.be/fCYzL813tRo

https://youtu.be/XaFQxnIZ26c

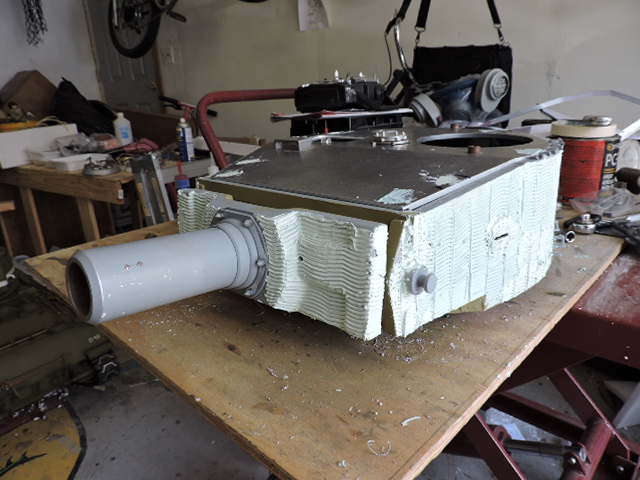

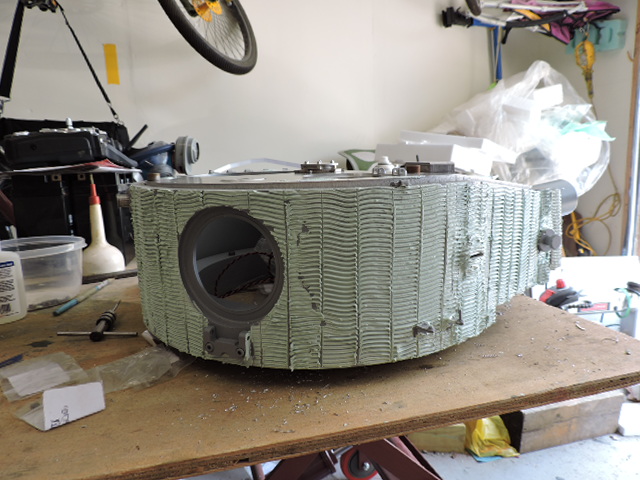

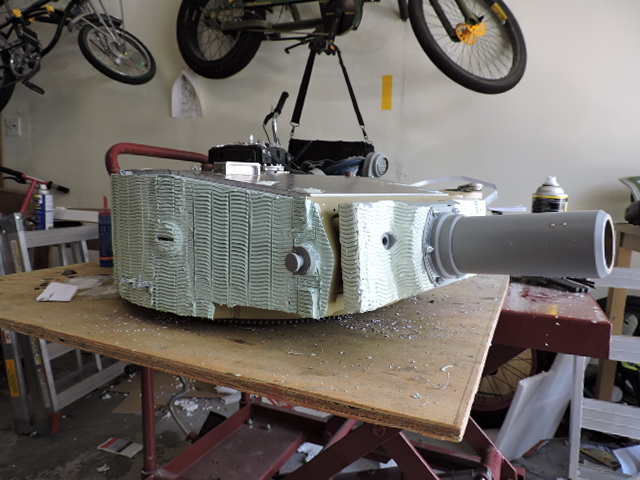

Currently I'm working on the hull zemmerite and side skirts. The turret was also started and once I have more progress I'll post another update... More to come!

As for the Hatch because of the detailed engine compartment the interior of the engine hatch needed to be detailed. What was added to the kit the the addition of the secondary lip, and hatch locks, and new air intakes

The main air intake was replaced with a Sixth Scale Icons set, Like all of Mike's work it is an amazing add on and really makes the hatch pop,

As for the dome intake this is a new part that I tooled up and added to the the ECA catalog.

East Coast Armory -- 1/6th Scale Tiger I Detail Upgrades

This version of the dome intake is the later style one. It differs from the earlier style that I have in that this is the style that would be seen on mid / late production tanks.

Once the hatch was completed all grill work was mounted to the rear deck.

After the grillwork I turned my attention to the main deck. The Brass turret bushing was added. Like on all armortek builds I used counter Sunk fasteners to mount the ring to the deck. Also added was the late tiger turret joint guard and hatch ring bosses.

All parts were included with the kit. On the joint guard I modded the laser cut steel ring to have a bevel, segment and fastener detail. On the real tank the ring was not welded and was bolted to the tank from the inside.

On the front portion I replaced the basic kit original intake dome with one of my own resin ones. This part is not on the catalog as one is listed on Panzerwerk.

The Bow hatches were also painted / weathered. Not sure if they are the kit original, or were acquired by the previous builder, but the hatches are all white metal, and are very detailed... perhaps armorpax? Either way no mods were made and detail wise were left as is.

Finally the top deck mounts were fabricated. Because of the engine compartment and other RC access the top deck was modded to be removable. This was done with a combination of magnets and fasteners.

With the new setup the top deck locks on securely, but is removable in the off chance access is required.

More pics were posted on the facebook page

http://www.facebook.com/EastCoastArmory

and two videos were posted on youtube

https://youtu.be/fCYzL813tRo

https://youtu.be/XaFQxnIZ26c

Currently I'm working on the hull zemmerite and side skirts. The turret was also started and once I have more progress I'll post another update... More to come!

-

John Grima

- Posts: 250

- Joined: Sun Jul 15, 2007 2:54 pm

- Location: USA

- Been liked: 48 times

- Contact:

Re: 2012 Late tiger comission build

More progress has been made to the model and it is now a step closer to completion!

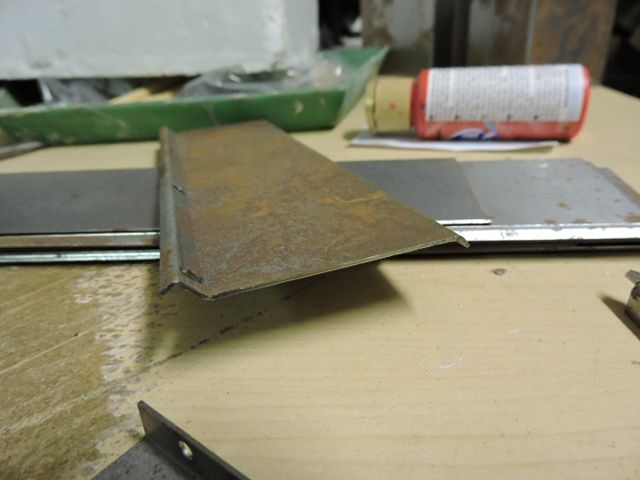

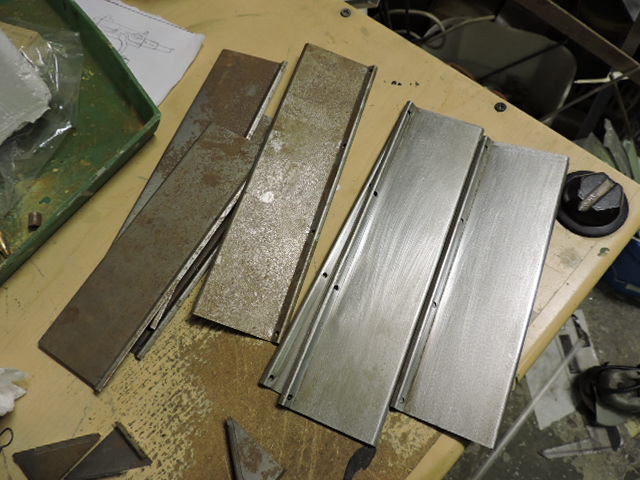

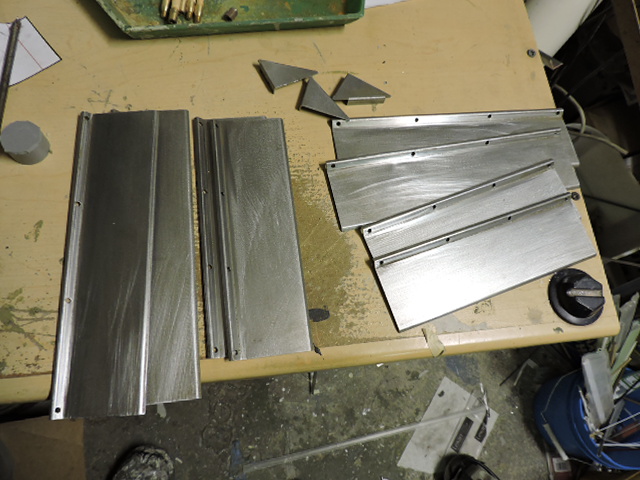

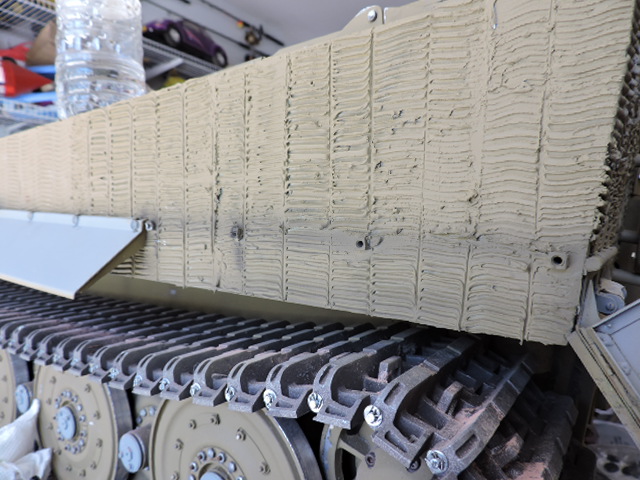

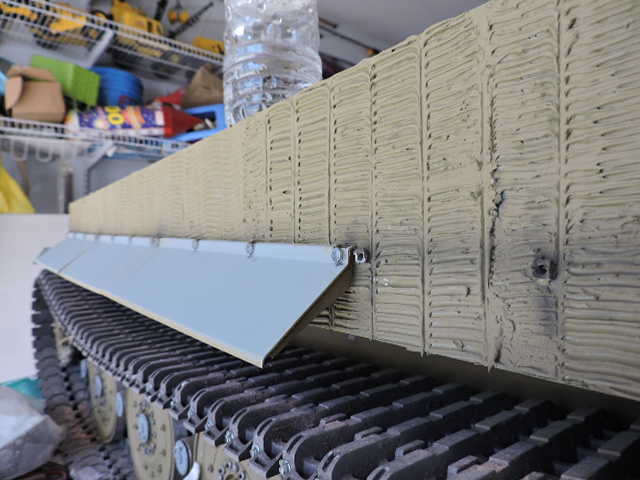

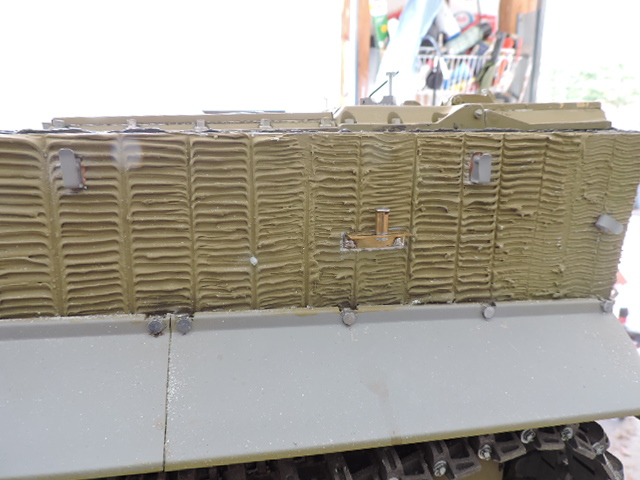

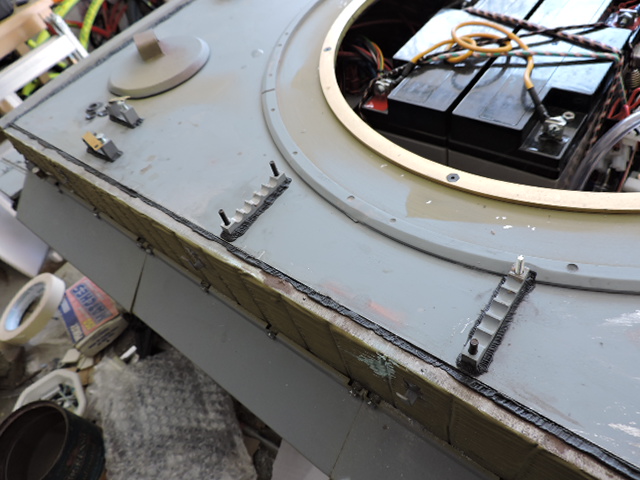

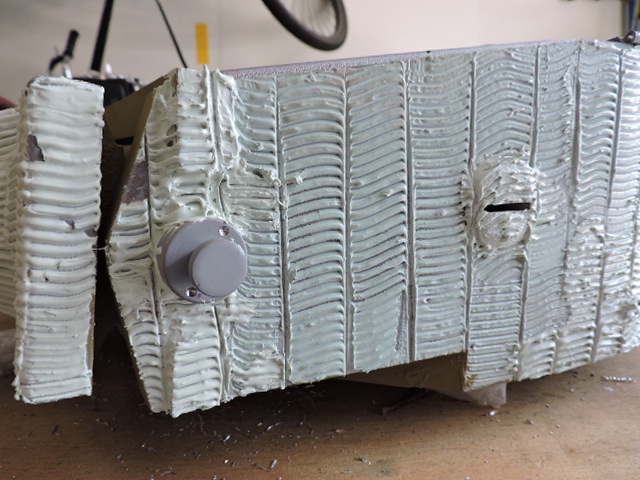

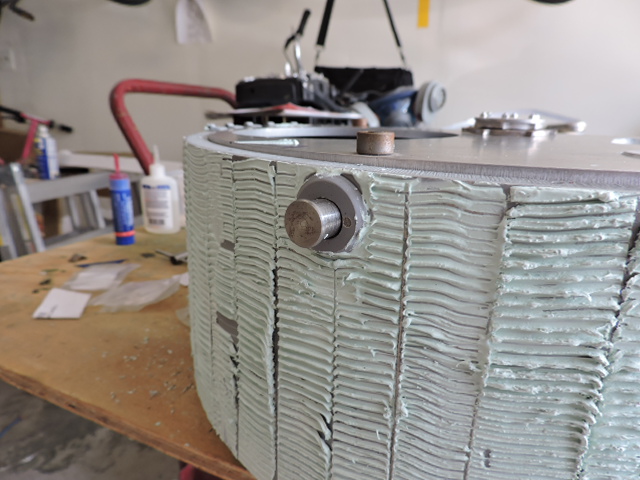

Since the last update I have focused on the upper hull detailing and in getting the hull now out of the way, first was to finish off the hull zemerite and the side skirts.

After the the zemm was sculpted the whole side plates were primed painted and weathered. This was done because of when the skirts get installed getting access to paint them will be difficult.

The skirts themselves were the armortek kit original ones. The kit always supplied very nice pre drilled and pressed steel skirt panels. Because they were left to the open air for a few years the exposed metal surface had some surface rust.

The rust was only superficial and was not an issue as it was quickly buffed away via a palm sander.

Once derusted I then was able to add the interior rib details. These reinforcement ribs are found on the real tanks, are not supplied with the kit

The ribs were all scratch built out of sheet steel and are affixed to the skirt panel via solder. The kit supplied end tips were also soldered on. The solder gives for a strong bond (stronger than adhesives) and replicate the weld which is found on the real counterpart.

Also added to the panel was the cutout notch for the mounting boss, this was added via a dremel and are also found on the real tanks.

After the ribs were affixed the panels were primed, painted and weathered. The paint and weather work was done for the same reason I mentioned above with the side hull.

The install was very smooth as the kit is well designed. One new addition that these newer gen armortek tiger kits have are the pre threaded mounting bosses.

In the past these would need to be scratch built and the skirt would be bolted to the tank via a nut. Once the tank was assembled installing the panel with the nut was very difficult. This is no longer the case with this newer style kit

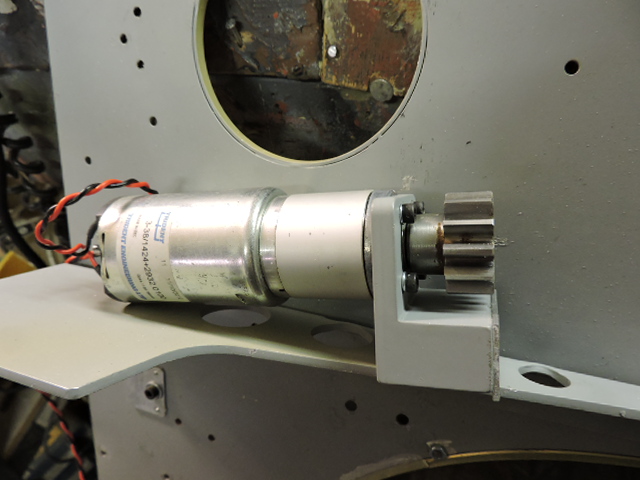

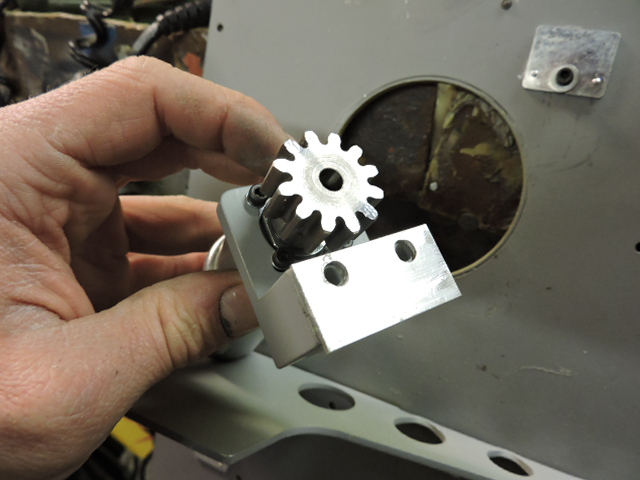

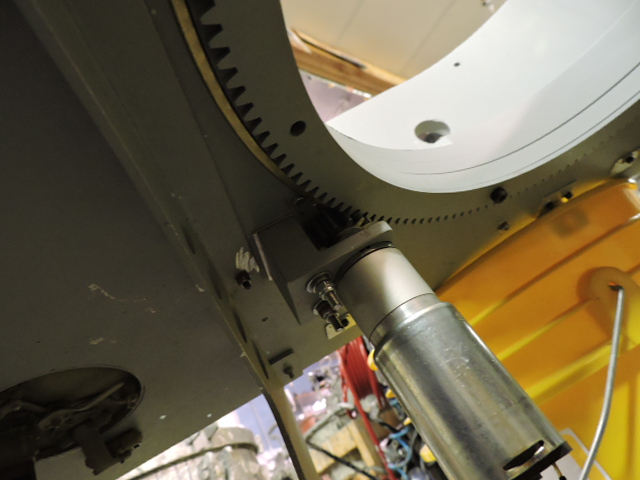

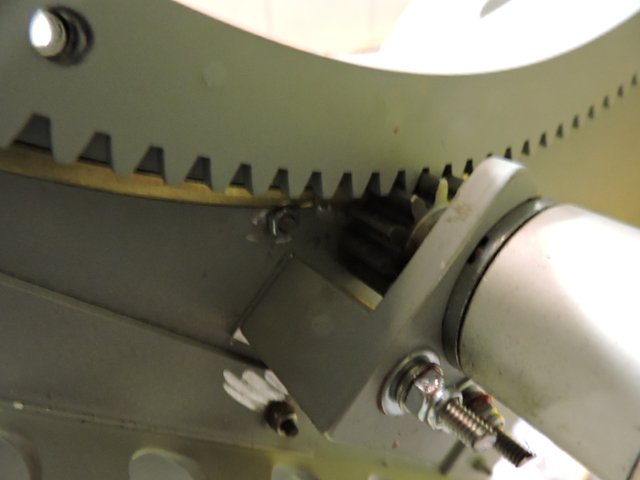

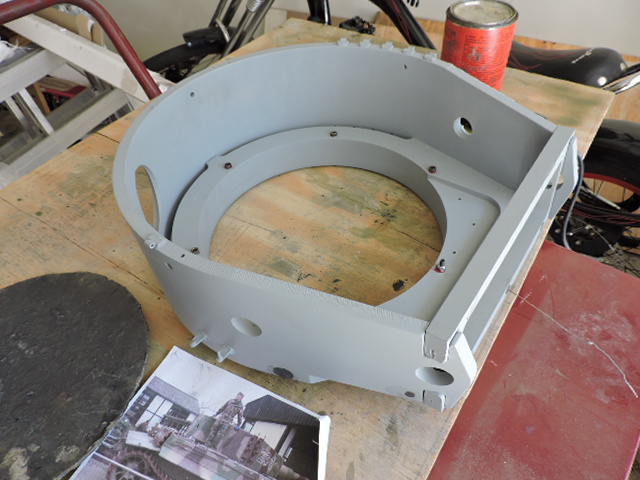

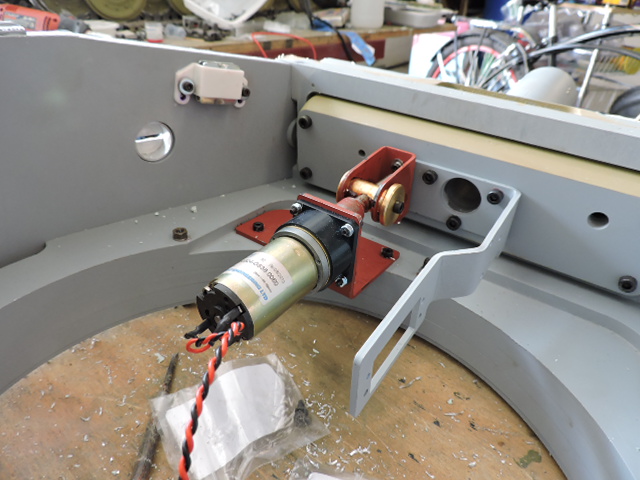

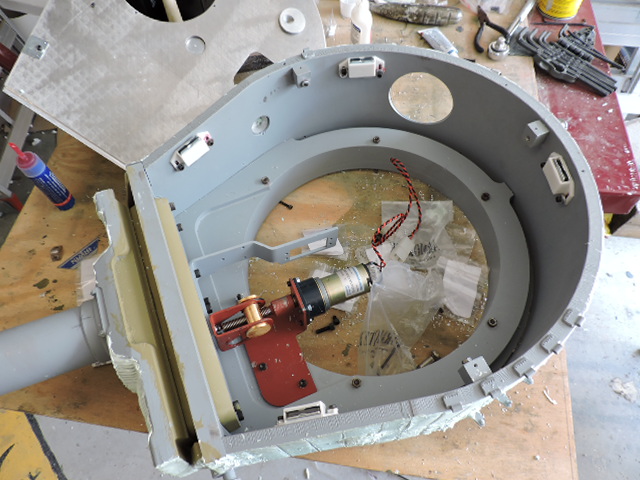

With the fenders done I was able to finish off the top deck, First was the assembly of the turret turning motor. The motor is the kit supplied unit and was assembled OOB.

To help mount the motor to the deck I added an aluminum spacer and cut away some of the material from the brass bushing so the gear has better clearance and runs smoothly

For the mounting I used my usual system of Lock washers, Locktite, and nylock fastners. This ensures that the motor is mounted rigidly and will have no play.

The system was tested and the turret rotation gear and gear box mesh properly.

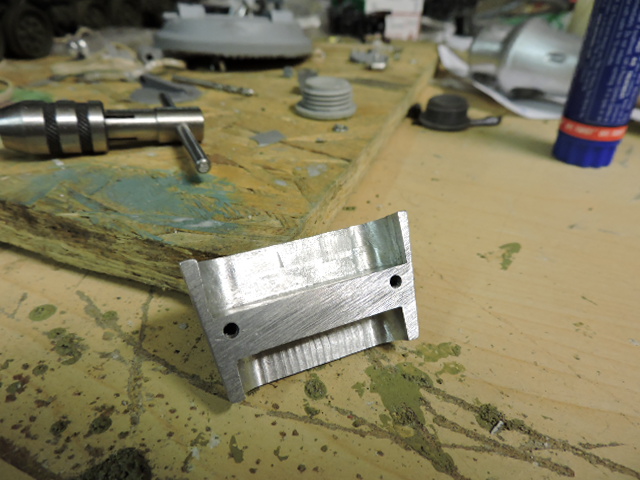

Once the motor was out of the way it was time to focus on the tank's tow cable mounts. To start I focused on the side mounted track removal cable mounts. The Kit does supply you with the cable and the mounting provisions, but the mounts are very basic and in their place I fabricated a new set out of metal

Similar to the design on the King tiger the cable is held in place via two capstands. the one in the front portion of the tank is mounted to a fixed stand,

while the one in the rear is adjustable and rides on a track.

After the parts were primed they were mounted to the tank

With the side mounts out of the way I then turned towards to the top deck tow cable mounts and tool posts.

Like with the transport cable mounts the kit supplied mounts are supplied but are very basic. I did utilize the cable / gun cleaning staves mounts, as for the other mounts I used my own resin variants in their place.

As for the rest of the tool post new functional ones were fabricated and mounted to the tank along with sculpted weld beads

Another important weld that I added was the center seam for the top plate. The tiger top deck was made out of two plates that were welded together in the center. This bead was a simple addition but helps with the look.

As for the top deck welds they were sculpted in a way that covers up the seam, but still allows the top deck to be removed from the hull if need be, Along with the welds a similar feature was done with the head light.

The power cable for the light enters into the tank from the front plate, and a dummy cable runs along the plate and enters into the power box on the top deck, If the top needs to be removed the wire is pulled out of the box and is kept out of the way.

With the hull now done I have turned my attention towards the turret. Currently I have the turret primed and reassembled, and I'm now working on the mantlet and gun elevation.

Once I have more headway I will post another update,

Also more pics were posted on the facebook page,

http://www.facebook.com/EastCoastArmory

and a video update was posted on youtube,

More to come!

Since the last update I have focused on the upper hull detailing and in getting the hull now out of the way, first was to finish off the hull zemerite and the side skirts.

After the the zemm was sculpted the whole side plates were primed painted and weathered. This was done because of when the skirts get installed getting access to paint them will be difficult.

The skirts themselves were the armortek kit original ones. The kit always supplied very nice pre drilled and pressed steel skirt panels. Because they were left to the open air for a few years the exposed metal surface had some surface rust.

The rust was only superficial and was not an issue as it was quickly buffed away via a palm sander.

Once derusted I then was able to add the interior rib details. These reinforcement ribs are found on the real tanks, are not supplied with the kit

The ribs were all scratch built out of sheet steel and are affixed to the skirt panel via solder. The kit supplied end tips were also soldered on. The solder gives for a strong bond (stronger than adhesives) and replicate the weld which is found on the real counterpart.

Also added to the panel was the cutout notch for the mounting boss, this was added via a dremel and are also found on the real tanks.

After the ribs were affixed the panels were primed, painted and weathered. The paint and weather work was done for the same reason I mentioned above with the side hull.

The install was very smooth as the kit is well designed. One new addition that these newer gen armortek tiger kits have are the pre threaded mounting bosses.

In the past these would need to be scratch built and the skirt would be bolted to the tank via a nut. Once the tank was assembled installing the panel with the nut was very difficult. This is no longer the case with this newer style kit

With the fenders done I was able to finish off the top deck, First was the assembly of the turret turning motor. The motor is the kit supplied unit and was assembled OOB.

To help mount the motor to the deck I added an aluminum spacer and cut away some of the material from the brass bushing so the gear has better clearance and runs smoothly

For the mounting I used my usual system of Lock washers, Locktite, and nylock fastners. This ensures that the motor is mounted rigidly and will have no play.

The system was tested and the turret rotation gear and gear box mesh properly.

Once the motor was out of the way it was time to focus on the tank's tow cable mounts. To start I focused on the side mounted track removal cable mounts. The Kit does supply you with the cable and the mounting provisions, but the mounts are very basic and in their place I fabricated a new set out of metal

Similar to the design on the King tiger the cable is held in place via two capstands. the one in the front portion of the tank is mounted to a fixed stand,

while the one in the rear is adjustable and rides on a track.

After the parts were primed they were mounted to the tank

With the side mounts out of the way I then turned towards to the top deck tow cable mounts and tool posts.

Like with the transport cable mounts the kit supplied mounts are supplied but are very basic. I did utilize the cable / gun cleaning staves mounts, as for the other mounts I used my own resin variants in their place.

As for the rest of the tool post new functional ones were fabricated and mounted to the tank along with sculpted weld beads

Another important weld that I added was the center seam for the top plate. The tiger top deck was made out of two plates that were welded together in the center. This bead was a simple addition but helps with the look.

As for the top deck welds they were sculpted in a way that covers up the seam, but still allows the top deck to be removed from the hull if need be, Along with the welds a similar feature was done with the head light.

The power cable for the light enters into the tank from the front plate, and a dummy cable runs along the plate and enters into the power box on the top deck, If the top needs to be removed the wire is pulled out of the box and is kept out of the way.

With the hull now done I have turned my attention towards the turret. Currently I have the turret primed and reassembled, and I'm now working on the mantlet and gun elevation.

Once I have more headway I will post another update,

Also more pics were posted on the facebook page,

http://www.facebook.com/EastCoastArmory

and a video update was posted on youtube,

More to come!

-

Iacopo Di Giampietro

- Posts: 226

- Joined: Fri May 11, 2012 9:14 pm

- Been liked: 48 times

Re: 2012 Late tiger comission build

Hello John.

it is always a pleasure to follow your work and your explanations:

your research and the details are really well kept.

My most sincere congratulations.

Ciao,

Iacopo

it is always a pleasure to follow your work and your explanations:

your research and the details are really well kept.

My most sincere congratulations.

Ciao,

Iacopo

-

John Grima

- Posts: 250

- Joined: Sun Jul 15, 2007 2:54 pm

- Location: USA

- Been liked: 48 times

- Contact:

Re: 2012 Late tiger comission build

Thanks Iacopo,

It feels like forever since I posted an update, but with working on builds / and part orders free time has been very slim these days.

The turret detailing is about done with the exception of one or two components that are being installed now.

The last of the tank's zemmerite has been added, this includes the turret, mantlet and escape hatch.

Before installation the mantlet was disassembled in order to get all the parts into prime. Once primed the parts were reassembled and base color was painted to the areas which would be missed once installed.

Also like a few of the exposed bare steel parts the lift lugs had some surface rust on them, this was quickly sanded away and the parts went directly into prime, once primed they were installed to the tank.

After install the lugs had two small divots drilled into them. This was done after the install because these divots are in two specific locations and if done before the install there is a chance that they will be misaligned.

In addition to the two side lugs the rear lug was also fitted, the rear lug is kit supplied and is made out of CNC steel. The part is nice, but is missing the bottom base. For the bottom base I used one of my resin ones. The resin unit was simply fitted to the steel lug.

On the mantlet a few more more details were added, this would include the fastener straps. The kit supplies these parts as a single photo etch brass strip. They have the correct shape and are a nice addition. The real tank used four smaller straps as opposed to the kit supplied two, to make the tank more detailed I went and fabricated new straps out of steel.

Once complete they were added to the mantlet,

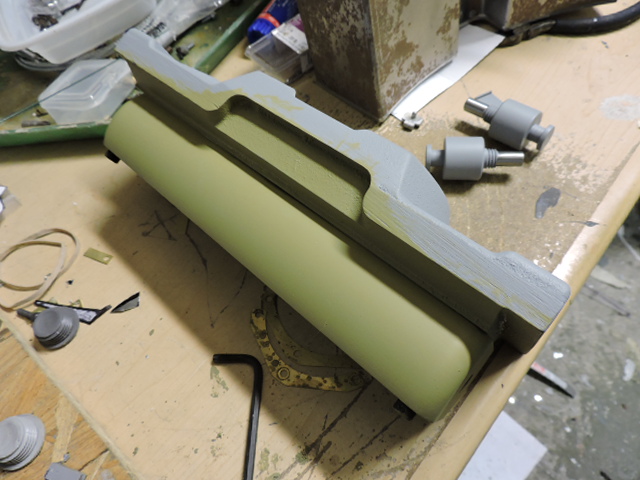

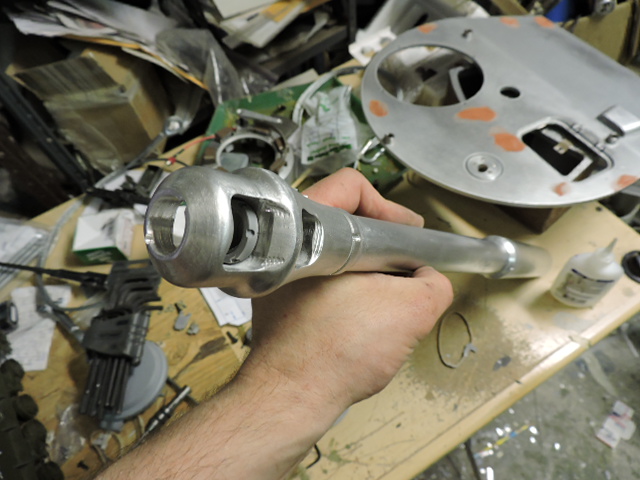

the tank's 88mm gun was also reworked, The stock gun and barrel are all CNC aluminium construction and have the correct shape, to further enhance the gun the barrel cnc marks were sanded away, and wrench slits were machined into the barrel nut.

The muzzle break also got some mods, here are some pics of the break while stock before the mods were conducted,

And here's the same muzzle with mods added. For the mods I added the wrench slits on retention nut, added the lock screw channel plate and fastener, cut away the baffle channels, widened the bore diameter, added the internal bushings, and milled in the front divots.

After the mantlet was mounted I installed the the elevation system, the system is all stock and was installed OOB after the metal parts were primed. The system works very well in the tiger, even with the heavy gun barrel attached. I did mod the limit switch set up, however during the build I didn't take any pics of the setup or the recoil system that has been installed :S, pics will be posted on that in the next update!

After the barrel was primed it was installed to the tank, which was then taken for a test run.

After the gun I turned my attention to the turret roof, to mount to the model the kit is designed to have the roof bolt on. It is a simple and effective way but because of the need to get access to the RC equipment I altered the design to use magnets. With the magnets the lid stays firmly on and can be removed if need be with no tools or fasteners

Once the roof mounts were completed I then began to add the roof details, starting with the loader's hatch the kit supplied armorpax hatch was installed as is, as it was an excellent part with no mods needed.

The escape hatch was also modded, the kit supplied hatch is all solid CNC aluminum. The basic hatch is absent any interior detailing,

For the hatch interior I modded one of my resin escape hatches, I casted the mold half way so only the interior portion of the hatch would be casted, I then bolted the resin detailing plug to the armortek hatch. The fasteners will prevent any chance of the resin dislodging from the metal hatch when the tank is running over time.

The fasteners were then deleted via the bodywork and were blended into the hatch seamlessly. After the hatch was primed / painted / weathered and installed to the turret.

I then turned my attention to the copula. The kit copula is a very basic set, it is full functional and does have the correct shape and some basic interior detailing.

The copula received lots of mods which would include, interior and exterior cast texture, periscope headrest ring and pads, revised opening system, interior opening mechanism detailing, bottom hatch head rest detailing, reshaped periscope guards, guard rear panels, sculpted welds, and resin fastener cover cap. Like with my other builds all MG rail and periscope rear plates are soldered together.

After the copula was fitted, I decided to retool the air intake. The new intake is listed on the product line, http://eastcoastarmory.com/tiger.htm

Also added were the roof divots, close quarter support weapon, and loader's scope box

For the scope box it is the armortek supplied part, but was modded to have more rounded sides, and a deeper inlet so I can add a strip of clear plastic to replicate the periscope lens.

The close quarter defense weapon was also kit supplied, but was modded to have fastener details, and was also modded to rotate via a servo. Better images of this part are found on the project update video.

More pics are also posted on the ECA facebook page,

http://www.facebook.com/EastCoastArmory

Currently I just completed the Sixth Scale Icons rear bustle bin, Once added I will add the last of the welds, and then this one is off to paint!!! More to come!

It feels like forever since I posted an update, but with working on builds / and part orders free time has been very slim these days.

The turret detailing is about done with the exception of one or two components that are being installed now.

The last of the tank's zemmerite has been added, this includes the turret, mantlet and escape hatch.

Before installation the mantlet was disassembled in order to get all the parts into prime. Once primed the parts were reassembled and base color was painted to the areas which would be missed once installed.

Also like a few of the exposed bare steel parts the lift lugs had some surface rust on them, this was quickly sanded away and the parts went directly into prime, once primed they were installed to the tank.

After install the lugs had two small divots drilled into them. This was done after the install because these divots are in two specific locations and if done before the install there is a chance that they will be misaligned.

In addition to the two side lugs the rear lug was also fitted, the rear lug is kit supplied and is made out of CNC steel. The part is nice, but is missing the bottom base. For the bottom base I used one of my resin ones. The resin unit was simply fitted to the steel lug.

On the mantlet a few more more details were added, this would include the fastener straps. The kit supplies these parts as a single photo etch brass strip. They have the correct shape and are a nice addition. The real tank used four smaller straps as opposed to the kit supplied two, to make the tank more detailed I went and fabricated new straps out of steel.

Once complete they were added to the mantlet,

the tank's 88mm gun was also reworked, The stock gun and barrel are all CNC aluminium construction and have the correct shape, to further enhance the gun the barrel cnc marks were sanded away, and wrench slits were machined into the barrel nut.

The muzzle break also got some mods, here are some pics of the break while stock before the mods were conducted,

And here's the same muzzle with mods added. For the mods I added the wrench slits on retention nut, added the lock screw channel plate and fastener, cut away the baffle channels, widened the bore diameter, added the internal bushings, and milled in the front divots.

After the mantlet was mounted I installed the the elevation system, the system is all stock and was installed OOB after the metal parts were primed. The system works very well in the tiger, even with the heavy gun barrel attached. I did mod the limit switch set up, however during the build I didn't take any pics of the setup or the recoil system that has been installed :S, pics will be posted on that in the next update!

After the barrel was primed it was installed to the tank, which was then taken for a test run.

After the gun I turned my attention to the turret roof, to mount to the model the kit is designed to have the roof bolt on. It is a simple and effective way but because of the need to get access to the RC equipment I altered the design to use magnets. With the magnets the lid stays firmly on and can be removed if need be with no tools or fasteners

Once the roof mounts were completed I then began to add the roof details, starting with the loader's hatch the kit supplied armorpax hatch was installed as is, as it was an excellent part with no mods needed.

The escape hatch was also modded, the kit supplied hatch is all solid CNC aluminum. The basic hatch is absent any interior detailing,

For the hatch interior I modded one of my resin escape hatches, I casted the mold half way so only the interior portion of the hatch would be casted, I then bolted the resin detailing plug to the armortek hatch. The fasteners will prevent any chance of the resin dislodging from the metal hatch when the tank is running over time.

The fasteners were then deleted via the bodywork and were blended into the hatch seamlessly. After the hatch was primed / painted / weathered and installed to the turret.

I then turned my attention to the copula. The kit copula is a very basic set, it is full functional and does have the correct shape and some basic interior detailing.

The copula received lots of mods which would include, interior and exterior cast texture, periscope headrest ring and pads, revised opening system, interior opening mechanism detailing, bottom hatch head rest detailing, reshaped periscope guards, guard rear panels, sculpted welds, and resin fastener cover cap. Like with my other builds all MG rail and periscope rear plates are soldered together.

After the copula was fitted, I decided to retool the air intake. The new intake is listed on the product line, http://eastcoastarmory.com/tiger.htm

Also added were the roof divots, close quarter support weapon, and loader's scope box

For the scope box it is the armortek supplied part, but was modded to have more rounded sides, and a deeper inlet so I can add a strip of clear plastic to replicate the periscope lens.

The close quarter defense weapon was also kit supplied, but was modded to have fastener details, and was also modded to rotate via a servo. Better images of this part are found on the project update video.

More pics are also posted on the ECA facebook page,

http://www.facebook.com/EastCoastArmory

Currently I just completed the Sixth Scale Icons rear bustle bin, Once added I will add the last of the welds, and then this one is off to paint!!! More to come!

-

simon_manning

- Posts: 2061

- Joined: Fri Nov 02, 2007 8:51 pm

- Location: new forest,hampshire,u.k.

- Been liked: 1767 times

Re: 2012 Late tiger comission build

some nice building going on there john, i do enjoy your projects, regards simon manning.

-

Ian Rodney

- Posts: 480

- Joined: Thu Jul 05, 2012 6:39 am

- Been liked: 53 times

Re: 2012 Late tiger comission build

Me to John,

I enjoy your many projects, very well explained on your videos on how to go about the builds, excellent.

Cheers

Ian

I enjoy your many projects, very well explained on your videos on how to go about the builds, excellent.

Cheers

Ian

-

John Grima

- Posts: 250

- Joined: Sun Jul 15, 2007 2:54 pm

- Location: USA

- Been liked: 48 times

- Contact:

Re: 2012 Late tiger comission build

Thanks guys, the project is on the fast track now and it is now in pint and is almost done,

The last bit of detailing was added, this would include the top deck welds, and the rear bustle bin.

For the rear bin the Kit supplies you with a steel and aluminum bin. The bin is overall the correct shape and size, but is basic in detailing. Rather than re detailing the supplied bin, I replaced it with one from Sixth Scale Icons

The SSI bin is all Photoetch brass construction and is a very detailed / accurate and came unassembled and is all solder assembly. This is not a set for a novice / casual builder, If the builder has no experience with metal work, or metal working tools then this set will not be for them.

Once assembled however the bin is a work of art, and is sign to Mikes craftsmanship.

The bin was primed and mounted to the turret. Because of the RC nature of the model I designed the bin to be removable in case the turret needs to be removed for maintenance. With the bin removed the turret can be removed more easily without risk of the any damage to the bin or other turret details.

In addition to the bin, I replaced the fasteners on the escape hatch. The model was built with having allen bolts to bolt the hing to the turret, on the real tank this was done with hex bolts, I simply swapped out the allens for hex heads. I also added the third lower fastener, this is absent on the stock kit and was another simple addition that improves the look.

The tank also had the kit supplied spare track clips installed to the model. The model does come with these parts and on this release of the kit they are the sets form armorpax. They are also very nicely done.

When I acquired the tank the parts were pre installed by the first builder (who installed them very well) but some of these parts were bent and damaged. I repaired the bent portions and replaced the missing parts. Because of the material of the castings the replacement lugs were soldered directly to the castings.

The tank was taken out for one last pre paint test run, which it ran very well

After the run it went back on the lift, and into paint

then dunkelgelb basecoat, which was refreshing to see after seeing the tank all spot primed for as long as I have

The tank's pattern was then applied, for the pattern the tank is for SS-PZ.Abt.102 Normandy, 1944 .

A youtube video update for the tank was uploaded in addition to a video of the test drive,

Also more pics of the model were posted on the ECA facebook page,

https://www.facebook.com/EastCoastArmory

With the pattern now completed the tank will get it markings. The model will be getting some slight weathering shading, then the client will to do the rest of the weathering himself when the model is delivered. More to come!

The last bit of detailing was added, this would include the top deck welds, and the rear bustle bin.

For the rear bin the Kit supplies you with a steel and aluminum bin. The bin is overall the correct shape and size, but is basic in detailing. Rather than re detailing the supplied bin, I replaced it with one from Sixth Scale Icons

The SSI bin is all Photoetch brass construction and is a very detailed / accurate and came unassembled and is all solder assembly. This is not a set for a novice / casual builder, If the builder has no experience with metal work, or metal working tools then this set will not be for them.

Once assembled however the bin is a work of art, and is sign to Mikes craftsmanship.

The bin was primed and mounted to the turret. Because of the RC nature of the model I designed the bin to be removable in case the turret needs to be removed for maintenance. With the bin removed the turret can be removed more easily without risk of the any damage to the bin or other turret details.

In addition to the bin, I replaced the fasteners on the escape hatch. The model was built with having allen bolts to bolt the hing to the turret, on the real tank this was done with hex bolts, I simply swapped out the allens for hex heads. I also added the third lower fastener, this is absent on the stock kit and was another simple addition that improves the look.

The tank also had the kit supplied spare track clips installed to the model. The model does come with these parts and on this release of the kit they are the sets form armorpax. They are also very nicely done.

When I acquired the tank the parts were pre installed by the first builder (who installed them very well) but some of these parts were bent and damaged. I repaired the bent portions and replaced the missing parts. Because of the material of the castings the replacement lugs were soldered directly to the castings.

The tank was taken out for one last pre paint test run, which it ran very well

After the run it went back on the lift, and into paint

then dunkelgelb basecoat, which was refreshing to see after seeing the tank all spot primed for as long as I have

The tank's pattern was then applied, for the pattern the tank is for SS-PZ.Abt.102 Normandy, 1944 .

A youtube video update for the tank was uploaded in addition to a video of the test drive,

Also more pics of the model were posted on the ECA facebook page,

https://www.facebook.com/EastCoastArmory

With the pattern now completed the tank will get it markings. The model will be getting some slight weathering shading, then the client will to do the rest of the weathering himself when the model is delivered. More to come!

-

John Grima

- Posts: 250

- Joined: Sun Jul 15, 2007 2:54 pm

- Location: USA

- Been liked: 48 times

- Contact:

Re: 2012 Late tiger comission build

The project is now on it's last leg,

Normally on my builds this is the point where I would add the weathering, however on this build the customer opted to perform the weathering himself so I left it mostly clean. This also applies to the tools and the cables. I did however add some counter shading to the pattern along with exhaust sut / power fouling on the exhausts and barrel.

The tracks were also added, for the tracks they were pressure washed (to get any dirt or grass debris off from test drives) then they were painted and mounted to the model. Because the tracks are metal they will naturally weather themselves after the tank is driven. Unfortunately with the monsoons that we have been having here in the North East I have not had the weather to drive the tank in

More pics were posted on the facebook page,

https://www.facebook.com/EastCoastArmory

and a video update was also posted,

Currently the tank's tools and other final bits are getting installed, and the next time I post the tank will be DONE!!! More to come!!

Normally on my builds this is the point where I would add the weathering, however on this build the customer opted to perform the weathering himself so I left it mostly clean. This also applies to the tools and the cables. I did however add some counter shading to the pattern along with exhaust sut / power fouling on the exhausts and barrel.

The tracks were also added, for the tracks they were pressure washed (to get any dirt or grass debris off from test drives) then they were painted and mounted to the model. Because the tracks are metal they will naturally weather themselves after the tank is driven. Unfortunately with the monsoons that we have been having here in the North East I have not had the weather to drive the tank in

More pics were posted on the facebook page,

https://www.facebook.com/EastCoastArmory

and a video update was also posted,

Currently the tank's tools and other final bits are getting installed, and the next time I post the tank will be DONE!!! More to come!!

-

Iacopo Di Giampietro

- Posts: 226

- Joined: Fri May 11, 2012 9:14 pm

- Been liked: 48 times

- Robert E Morey

- Posts: 2349

- Joined: Wed Jul 18, 2007 12:59 am

- Location: Seattle, WA USA

- Has liked: 161 times

- Been liked: 830 times

Re: 2012 Late tiger comission build

John,

Fantastic paint job on an already fantastic build. A great inspiration for other late Tiger builds. The tank looks very "finished" with the tracks painted. Excellent work.

Best regards,

Bob

Fantastic paint job on an already fantastic build. A great inspiration for other late Tiger builds. The tank looks very "finished" with the tracks painted. Excellent work.

Best regards,

Bob

-

John Grima

- Posts: 250

- Joined: Sun Jul 15, 2007 2:54 pm

- Location: USA

- Been liked: 48 times

- Contact:

Re: 2012 Late tiger comission build

Thanks guys, The tank is now finished!

The last of the tools, and cables were mounted. For the tools the Armorpax kit supplied units were used, for added realism I replaced the metal handles with real wood ones.

The gun cleaning staves were also added. These too were kit supplied and the only mod I made was the addition of the swab brush.

Other misc. bits were also added like the bow MG34, turret roof periscope prism, antenna base, kit supplied armorpax resin fire extinguisher and AA gun mount

Another part that was added was the starter plate. For this model the kit supplies you with a basic plate made from CNC aluminum. Rather than upgrading the kit supplied unit I instead modded one of my early pattern plates, adding the late pattern detailing.

The new plate was molded and has been added to the catalog.

http://eastcoastarmory.com/tiger.htm

Some more markings were also added. this would include the divisional logos on the front and rear (easier seen in video), and black center on the bustle bin numbering

Once the tank was done it was taken for another final test run, which it ran well, and broke the in the track's new paint

The engine compartment was also checked and tested to see if the functions were operational, they too were working.

While filming I ran into a first when a bird laded on the tank, then flew off shortly after... guess he liked the paint job .

.

After he flew off the tank was driven some more then was placed into storage now awaiting delivery,

More pics were posted on the ECA facebook page, https://www.facebook.com/EastCoastArmory

and a final update video was posted on youtube, https://youtu.be/qSZ3pey_fZg

in addition to the new video, the entire project playlist has been rearranged in chronological order so watching the build from start to finish is now much more easier.

With the tank now officially completed, I have turned my attention back to the 222 armored car, and already have some more gun mount masters ready to mold. Once ready I will post more on that build.

I will also be starting another 1/6 armortek commission build project that I will also post in the coming weeks, and more will follow. stay tuned!!

The last of the tools, and cables were mounted. For the tools the Armorpax kit supplied units were used, for added realism I replaced the metal handles with real wood ones.

The gun cleaning staves were also added. These too were kit supplied and the only mod I made was the addition of the swab brush.

Other misc. bits were also added like the bow MG34, turret roof periscope prism, antenna base, kit supplied armorpax resin fire extinguisher and AA gun mount

Another part that was added was the starter plate. For this model the kit supplies you with a basic plate made from CNC aluminum. Rather than upgrading the kit supplied unit I instead modded one of my early pattern plates, adding the late pattern detailing.

The new plate was molded and has been added to the catalog.

http://eastcoastarmory.com/tiger.htm

Some more markings were also added. this would include the divisional logos on the front and rear (easier seen in video), and black center on the bustle bin numbering

Once the tank was done it was taken for another final test run, which it ran well, and broke the in the track's new paint

The engine compartment was also checked and tested to see if the functions were operational, they too were working.

While filming I ran into a first when a bird laded on the tank, then flew off shortly after... guess he liked the paint job

After he flew off the tank was driven some more then was placed into storage now awaiting delivery,

More pics were posted on the ECA facebook page, https://www.facebook.com/EastCoastArmory

and a final update video was posted on youtube, https://youtu.be/qSZ3pey_fZg

in addition to the new video, the entire project playlist has been rearranged in chronological order so watching the build from start to finish is now much more easier.

With the tank now officially completed, I have turned my attention back to the 222 armored car, and already have some more gun mount masters ready to mold. Once ready I will post more on that build.

I will also be starting another 1/6 armortek commission build project that I will also post in the coming weeks, and more will follow. stay tuned!!

-

John Heath

- Posts: 166

- Joined: Tue Jul 07, 2015 6:23 pm

- Has liked: 4 times

- Been liked: 102 times

Re: 2012 Late tiger comission build

Love the way it's turned out.

A real inspiration to anyone wanting to build a Tiger 1. Picked up a lot of ideas from the project. Now just have to wait until my Tiger 131 kit arrives.

John

A real inspiration to anyone wanting to build a Tiger 1. Picked up a lot of ideas from the project. Now just have to wait until my Tiger 131 kit arrives.

John