Hello Everyone again!

It has been a few weeks, I am sorry. I started in a new position and has been taking up a lot of my time.

I am mostly finished with the new foundry, the sheet metal and fire bricks are cut and fitted, I have drilled the holes for the new burner and the exhaust, added the handles. This week I expect to add the castable refractory this weekend for the lid and the bottom of the foundry. I will also be adding the legs and handles to the foundry before casting the refractory. So casting some brass should start the following weekend.

I bought a nice draft air burner and I have built myself a forced air burner, so I should have plenty of energy to fire the foundry. I will post some pictures of them in comparison this weekend too.

So, here is what I have done:

This is a view of the foundry showing it from the top with out the lid

This is a view of the foundry from the bottom with out any of bottom brick layer, The bars and ring are for support of the castable refractory

Here I am drilling out the hole for the burner. The screw clamps were only for support during construction.

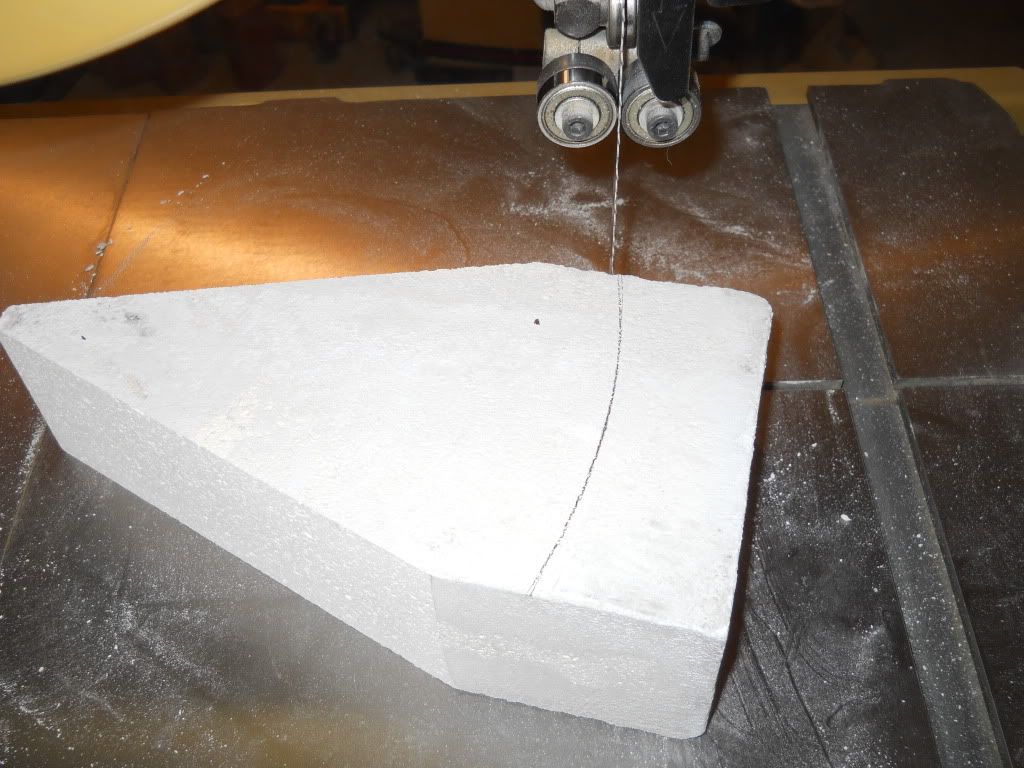

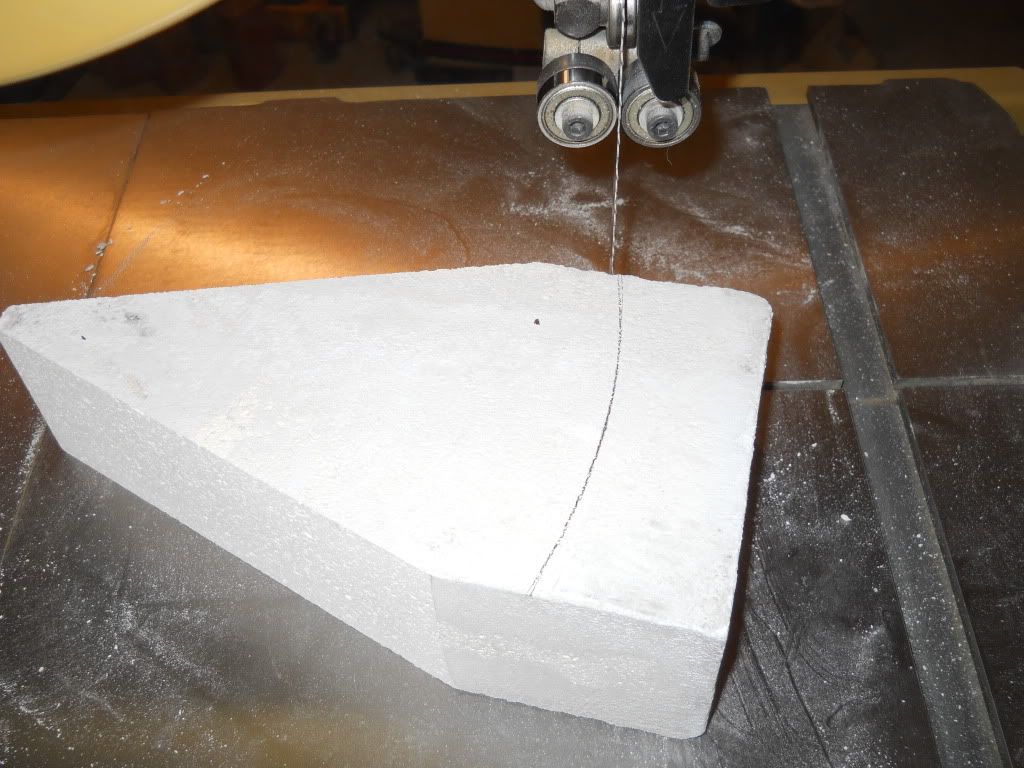

This is the fire brick for the bottom of the foundry. It is cut on the table saw, than the radius is cut on the bandsaw

Here the fire brick for the bottom is test fitted in the foundry. Once again this is a view of the fondry from the bottom

I have cut the sheet metal for the lid, screwed it togather, and attached the lifting handles. It is set on the bottom of the foundry just for a test fit as I formed it.

So. There we are. I apologize for the wait. It will all get done before we get too old.

(I am looking forward to getting some parts produced too)

Have a good day!