Holes Not threaded

-

Ray Massa

- Posts: 139

- Joined: Wed Jan 18, 2023 9:44 pm

- Location: Michigan, USA

- Has liked: 18 times

- Been liked: 110 times

Holes Not threaded

On page 03 of the M26 assembly instructions...

On part EVO111 and EVO111M, the three vertical holes that are to attach to EVO102 and EVO113 (side plates), these holes on mine are not threaded, but are called out to use M4 x 16 CSK screws. Anybody else having this issue?

One more minor issue, when trying to attach Side brace EVO121 to the side plate EVO114 using M4 x 20 screws, the screws are too short to grab onto the nut. Only a couple threads make it through. Just need to source a few longer M4's.

Thanks.

-Ray

On part EVO111 and EVO111M, the three vertical holes that are to attach to EVO102 and EVO113 (side plates), these holes on mine are not threaded, but are called out to use M4 x 16 CSK screws. Anybody else having this issue?

One more minor issue, when trying to attach Side brace EVO121 to the side plate EVO114 using M4 x 20 screws, the screws are too short to grab onto the nut. Only a couple threads make it through. Just need to source a few longer M4's.

Thanks.

-Ray

Last edited by Ray Massa on Thu Apr 06, 2023 6:37 pm, edited 1 time in total.

-

Nick Chiocchio

- Posts: 40

- Joined: Wed May 04, 2022 11:15 pm

- Location: New Hampshire, USA

- Has liked: 34 times

- Been liked: 30 times

- Contact:

Re: Holes NOT threaded

I have the same issue with EVO111 and EVO111M, holes are not tapped and I can't find my M4 tap! Looks like a trip to the hardware store. I didn't have a problem with the brace, the screws come out of the nut. Maybe you picked up a 4 X 16 by mistake?

Nick C.

-

DaveMacri

- Posts: 62

- Joined: Thu May 23, 2019 1:04 am

- Location: Calhan, Colorado

- Has liked: 13 times

- Been liked: 114 times

Re: Holes NOT threaded

I had no issues with my sections being threaded-but on that note I have a full set of metric taps the I run through these pre tapped holes anyway-the threads notoriously need cleaning up-I have snapped off the steel fasteners while tightening several times-then its a bitch with an easy out or move the hole over and start a new. I recommend also to have a set of counter sink bits to improve the AT recessed holes. setting the fastener slightly below the surface makes it much easier to fill and cover.

You may want to use a 3mm tap on the drive cases EV0310 as I spun off a hex head and stripped out the threads on another hole. After that I retapped out every hole and there are 15 on each casing to facilitate the M3x16 hex's application.

You may want to use a 3mm tap on the drive cases EV0310 as I spun off a hex head and stripped out the threads on another hole. After that I retapped out every hole and there are 15 on each casing to facilitate the M3x16 hex's application.

King Tiger, Tiger Early, Tiger Mid,2-Sherman E8's, Stug III, Panzer III, Hetzer, Panther G, M26 Pershing, T34/85

-

Ray Massa

- Posts: 139

- Joined: Wed Jan 18, 2023 9:44 pm

- Location: Michigan, USA

- Has liked: 18 times

- Been liked: 110 times

Re: Holes NOT threaded

Nick, I see why you did not have the same issue with the braces. I mounted mine 180 degrees from the way you did. I looked at the drawings several times and looked at the braces on different pages, and it looks like they want the braces with the ridges toward the side hull. I did think about doing it as you did, but i figured since the drawing showed it the other way I would conform. Not a big deal, I just used a couple 8-32 x 1" screws, since I could not find a metric size handy.

Weird that some of the side plates were not threaded since they are CNC'ed programmatically I assume. I did tap them with an M4 tap. It was a fairly easy job.

-Ray

Weird that some of the side plates were not threaded since they are CNC'ed programmatically I assume. I did tap them with an M4 tap. It was a fairly easy job.

-Ray

-

Ray Massa

- Posts: 139

- Joined: Wed Jan 18, 2023 9:44 pm

- Location: Michigan, USA

- Has liked: 18 times

- Been liked: 110 times

Re: Holes NOT threaded

Dave,

Thanks for the heads up on the threads. You are ahead of me. I spent two weeks priming before I turned one screw.

I did just order a set of taps that are coming tomorrow. Sounds like I will need them. Good idea about the countersinks. I didn't think about that.

Sounds like another trip to the store or Amazon! Thanks.

I made a modification to the exhaust, as I tried to make it look a bit softer like pictures I have seen of the real tank. Not perfect, but not has hard edged, as I did not want to push my luck with the Dremel tool.

-Ray

Thanks for the heads up on the threads. You are ahead of me. I spent two weeks priming before I turned one screw.

I did just order a set of taps that are coming tomorrow. Sounds like I will need them. Good idea about the countersinks. I didn't think about that.

Sounds like another trip to the store or Amazon! Thanks.

I made a modification to the exhaust, as I tried to make it look a bit softer like pictures I have seen of the real tank. Not perfect, but not has hard edged, as I did not want to push my luck with the Dremel tool.

-Ray

- Armortek

- Site Admin

- Posts: 2810

- Joined: Tue Jul 10, 2007 10:30 am

- Location: Winchester, England

- Been liked: 3058 times

Re: Holes NOT threaded

Those holes should be tapped M4 - will look into why this may not be the case on some parts.

Looks like you found the solution to this.

All our parts (apart from steel) go through a surface deburring process to remove sharp corners. Sometimes this can cause material to fold over a threaded home.DaveMacri wrote: ↑Sat Apr 01, 2023 3:51 amI had no issues with my sections being threaded-but on that note I have a full set of metric taps the I run through these pre tapped holes anyway-the threads notoriously need cleaning up-I have snapped off the steel fasteners while tightening several times-then its a bitch with an easy out or move the hole over and start a new. I recommend also to have a set of counter sink bits to improve the AT recessed holes. setting the fastener slightly below the surface makes it much easier to fill and cover.

You may want to use a 3mm tap on the drive cases EV0310 as I spun off a hex head and stripped out the threads on another hole. After that I retapped out every hole and there are 15 on each casing to facilitate the M3x16 hex's application.

In addition, parts that are threaded on a CNC machine before a surface is milled, turned or parted off may have material folded over the threads. This can most commonly be found on the German tank's suspension arms.

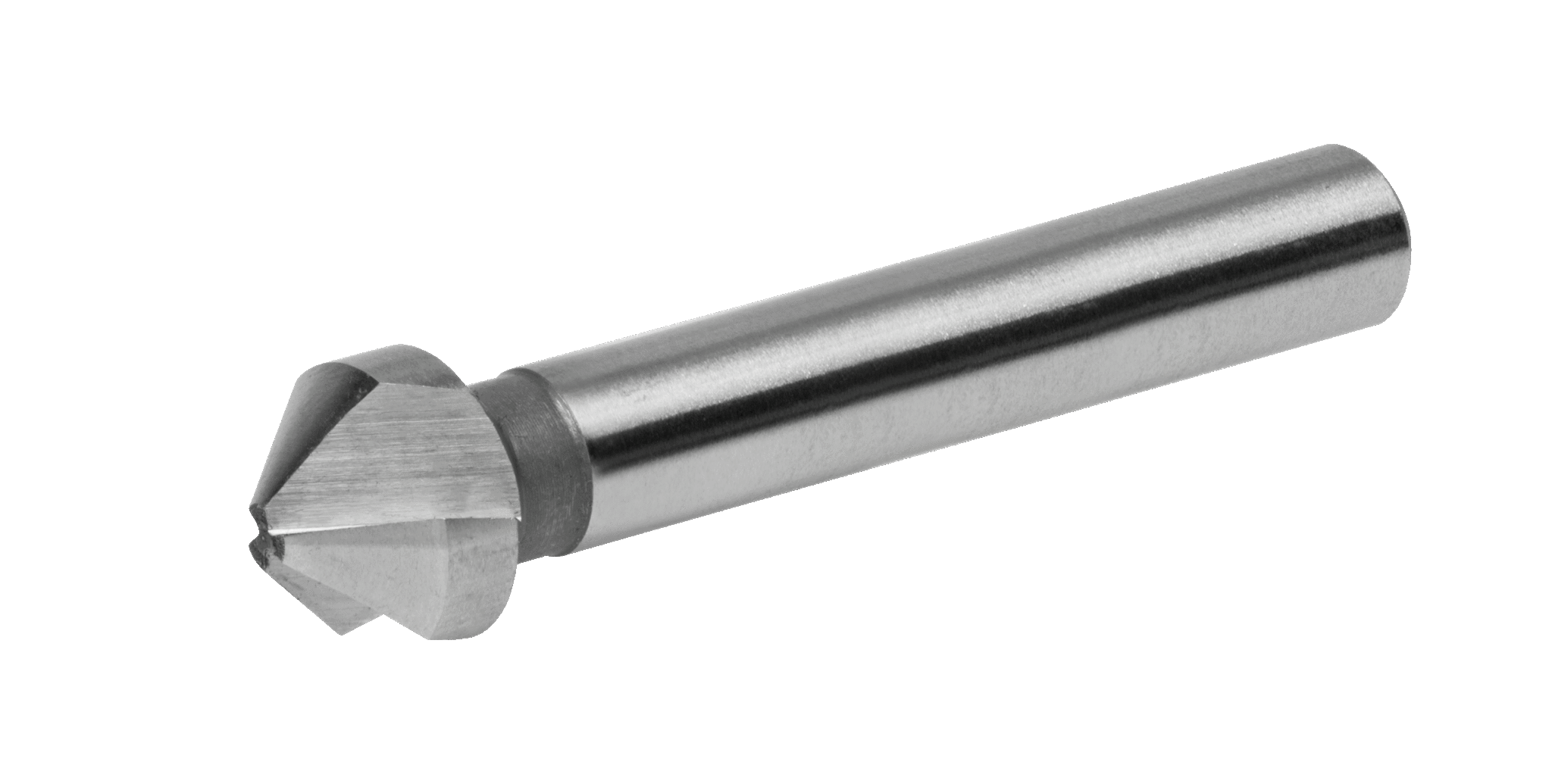

The easiest way to get around this is to use a hole deburring tool. Of course a tap can be used as well.

Or you can get a countersink bit and use it in your power tools:

Armortek

-

Ray Massa

- Posts: 139

- Joined: Wed Jan 18, 2023 9:44 pm

- Location: Michigan, USA

- Has liked: 18 times

- Been liked: 110 times

Re: Holes NOT threaded

Thanks Amortek for the reply. I just tapped the holes with an M4, but just wanted to alert you of the issue for future parts.

-

DaveMacri

- Posts: 62

- Joined: Thu May 23, 2019 1:04 am

- Location: Calhan, Colorado

- Has liked: 13 times

- Been liked: 114 times

Re: Holes NOT threaded

Full set of taps and countersinks...have multiples on the taps cause ur gonna break them!

King Tiger, Tiger Early, Tiger Mid,2-Sherman E8's, Stug III, Panzer III, Hetzer, Panther G, M26 Pershing, T34/85

-

DaveMacri

- Posts: 62

- Joined: Thu May 23, 2019 1:04 am

- Location: Calhan, Colorado

- Has liked: 13 times

- Been liked: 114 times

Re: Holes NOT threaded

Good work on the exhaust clean up-did you use Mr Surfacer on it for texture?Ray Massa wrote: ↑Sat Apr 01, 2023 4:27 amDave,

Thanks for the heads up on the threads. You are ahead of me. I spent two weeks priming before I turned one screw.

I did just order a set of taps that are coming tomorrow. Sounds like I will need them. Good idea about the countersinks. I didn't think about that.

Sounds like another trip to the store or Amazon! Thanks.

I made a modification to the exhaust, as I tried to make it look a bit softer like pictures I have seen of the real tank. Not perfect, but not has hard edged, as I did not want to push my luck with the Dremel tool.

-Ray

IMG_8519.jpeg

IMG_8518.jpeg

King Tiger, Tiger Early, Tiger Mid,2-Sherman E8's, Stug III, Panzer III, Hetzer, Panther G, M26 Pershing, T34/85

-

DaveMacri

- Posts: 62

- Joined: Thu May 23, 2019 1:04 am

- Location: Calhan, Colorado

- Has liked: 13 times

- Been liked: 114 times

Re: Holes NOT threaded

Nick Chiocchio wrote: ↑Sat Apr 01, 2023 12:26 amI have the same issue with EVO111 and EVO111M, holes are not tapped and I can't find my M4 tap! Looks like a trip to the hardware store. I didn't have a problem with the brace, the screws come out of the nut. Maybe you picked up a 4 X 16 by mistake?

IMG_6101.JPG

IMG_6100.JPG

King Tiger, Tiger Early, Tiger Mid,2-Sherman E8's, Stug III, Panzer III, Hetzer, Panther G, M26 Pershing, T34/85

-

Ray Massa

- Posts: 139

- Joined: Wed Jan 18, 2023 9:44 pm

- Location: Michigan, USA

- Has liked: 18 times

- Been liked: 110 times

Re: Holes NOT threaded

Dave,

I have not used and surfacer material on it yet. This is just using a Dremel with a routing bit, a honing bit, hand filed, and sanded for now.

-Ray

I have not used and surfacer material on it yet. This is just using a Dremel with a routing bit, a honing bit, hand filed, and sanded for now.

-Ray

-

Ray Massa

- Posts: 139

- Joined: Wed Jan 18, 2023 9:44 pm

- Location: Michigan, USA

- Has liked: 18 times

- Been liked: 110 times

Re: Holes NOT threaded

Dave,

I am starting to accumulate a lot more tools for this project and I have a lot now!

On the bracket install, I don't know if it makes a difference, but looking at the instruction pics, it clearly shows (to me) the bracket goes 180 degrees from what you have. Maybe it does not matter, and maybe Armortek can chime in to let us know if it makes a difference, or if you have it correct, then the instruction pics should be changed. Your install seems more logical, but I just went according to the pictures. This is my first Armortek, so I am still learning.

-Ray

I am starting to accumulate a lot more tools for this project and I have a lot now!

On the bracket install, I don't know if it makes a difference, but looking at the instruction pics, it clearly shows (to me) the bracket goes 180 degrees from what you have. Maybe it does not matter, and maybe Armortek can chime in to let us know if it makes a difference, or if you have it correct, then the instruction pics should be changed. Your install seems more logical, but I just went according to the pictures. This is my first Armortek, so I am still learning.

-Ray

-

DaveMacri

- Posts: 62

- Joined: Thu May 23, 2019 1:04 am

- Location: Calhan, Colorado

- Has liked: 13 times

- Been liked: 114 times

Re: Holes NOT threaded

I too tried with it 180 on the rear brackets and saw that there was not enough thread for the 4 mm nut but the CAD shows the front bracket the other direction. This is build #10 for me and I can see that this directional issue is moot point-the brackets with flat side up against the hull section vs the ridges against are not going to make any difference. I used two nuts on mine as the fastener stripped on tightening. The exterior will be getting a miliput weld applied also then you will not see the vertical split.

King Tiger, Tiger Early, Tiger Mid,2-Sherman E8's, Stug III, Panzer III, Hetzer, Panther G, M26 Pershing, T34/85

-

Ray Massa

- Posts: 139

- Joined: Wed Jan 18, 2023 9:44 pm

- Location: Michigan, USA

- Has liked: 18 times

- Been liked: 110 times

Re: Holes NOT threaded

Dave,

I agree, probably makes no difference. I will check the CAD on the front bracket. I thought they looked the same to me.

Build #10? WOW. I hope I make it to #2 next year.

Regards.

I agree, probably makes no difference. I will check the CAD on the front bracket. I thought they looked the same to me.

Build #10? WOW. I hope I make it to #2 next year.

Regards.