"Beat it into submission" kind words Stephen.... and Richard, wouldn't dream of it "Read my lips".

Chieftain's belly plate seems to have mastered the almost flattest welds there are in the tank world, evidently to reduce friction when bottoming out on soft ground. Only spoiling it with oddly mounted inspection hatches and an ugly plug hole.

I thought long and hard for a couple of minutes, how can I do this very long and flat belly plate weld and came up with engraving.

Nope, bad idea, engraving removes metal and you need a steady hand, both no no's.

So on to plan B, I like plan B, It's easy.

Cut a thin strip of self adhesive aluminum tape and fix it to the center line of the belly plate and then scroll in the weld lines with a tooth pick. It's actually metal, it's raised,it's shaped and it's done.

Now if it's been done before, sorry I missed the memo.

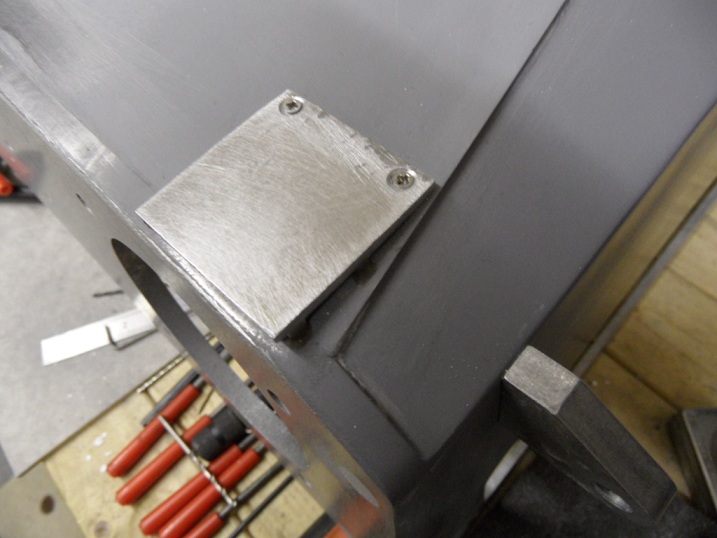

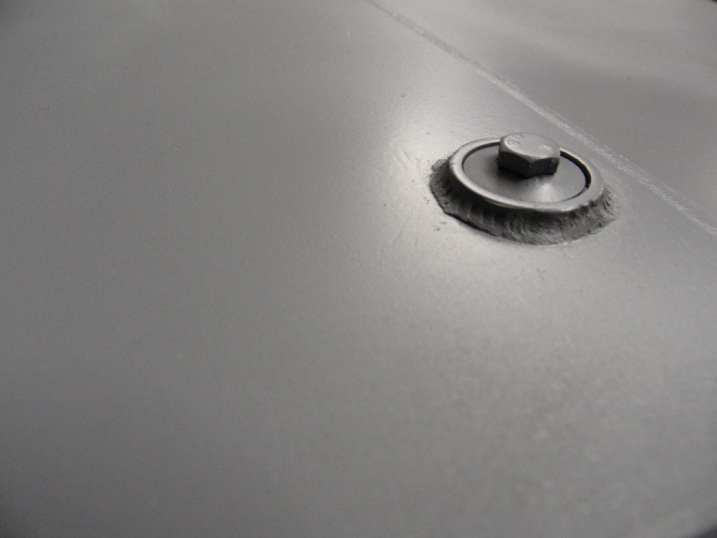

The jacking points have been fitted "Glued and Screwed" wouldn't want them to fall off and on the front end fitted the Plug/hole. To give it some shape like the original I squeezed a washer in a countersunk former giving it a conical shape.

Fake welds, When I took this close up picture of the plug/hole, first thought "laughing stock". Not one for having done this fake weld business before, so excuse the novice approach, there's all sorts techniques out there and I seem to be rubbish at most of them.I think I might have worked out one problem, I'm might be holding the shaping stick upside down. I'll have to do the plug/hole weld again, still you can see the conical washer effect, I hoping etching primer will smooth out a multitude of sins in the future.

- SAM_2202.JPG (126.58 KiB) Viewed 2832 times

- chieftan_mk11_15_of_831.jpg (131.31 KiB) Viewed 2832 times

- SAM_2138.JPG (133.95 KiB) Viewed 2832 times

- SAM_2139.JPG (161.09 KiB) Viewed 2832 times

- SAM_2212.JPG (129.14 KiB) Viewed 2832 times