Here is a photograph of our Chieftain in the factory.

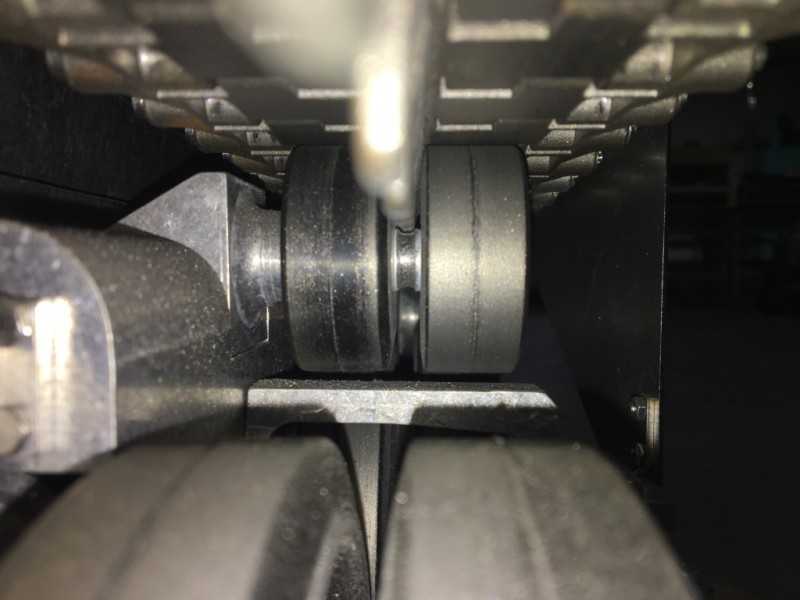

As you can see, the tracks quickly cut a channel of about 0.5mm to 1mm. This is not an issue as there is still sufficient material left on the return rollers.

I would advise against cutting the track horns and instead let the running gear naturally bed in.

Worth pointing out that it is always good practice after assembly to run the tank and then get it back on the bench to check the running gear (taper locks, sprockets, idlers, roadwheels, etc) for wear and make any adjustments as needed. As you run the tank, this should be done on a periodic basis.

- CHANNEL CUT INTO THE RETURN ROLLERS

- CLOSE UP VIEW OF THE SAME THING