Feifel bracket

-

Dale jordan

- Posts: 1456

- Joined: Fri Jul 13, 2007 1:10 am

- Location: Port Macquarie Australia

- Been liked: 514 times

- Contact:

Feifel bracket

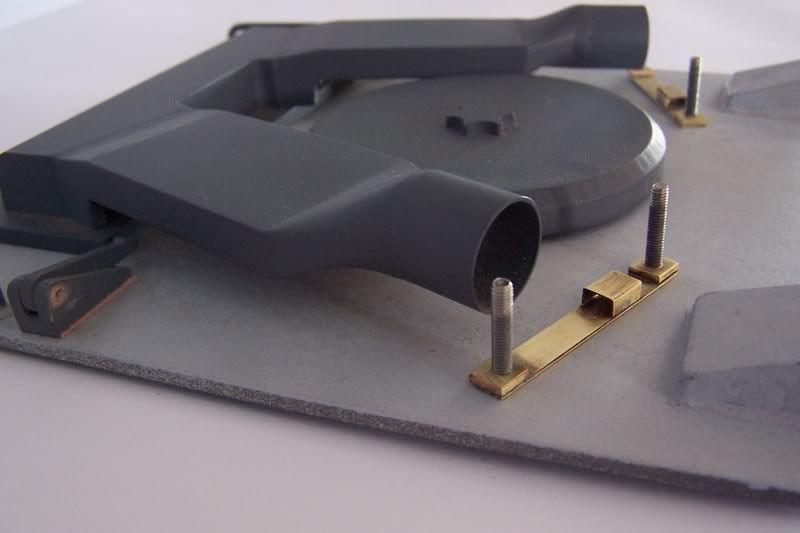

Here is a photo of my Feifel pipe hold down bracket that I'm working on . All I have to do now, is to add the top hold down bar , plus the correct bolts and nuts. Dale.

-

Dale jordan

- Posts: 1456

- Joined: Fri Jul 13, 2007 1:10 am

- Location: Port Macquarie Australia

- Been liked: 514 times

- Contact:

-

Joe Boylan

- Posts: 76

- Joined: Mon Jul 23, 2007 1:30 am

- Location: Crestview, Florida - USA

-

Allan Richards

- Posts: 743

- Joined: Thu Jul 12, 2007 10:34 am

- Location: Kent

- Been liked: 10 times

Dale,

Very nice looing work. The only problem with these fiffel pipes is that they prevent you opening the engine hatch if they are not easily remvable, and they also prevent you opening the rear grills to get at the switches. I made up some clamps like these but ended up fitting them to the tubes and not to the deck, so they hold the tubes together and come off with them.

Allan

Very nice looing work. The only problem with these fiffel pipes is that they prevent you opening the engine hatch if they are not easily remvable, and they also prevent you opening the rear grills to get at the switches. I made up some clamps like these but ended up fitting them to the tubes and not to the deck, so they hold the tubes together and come off with them.

Allan

Allan Richards

-

Allan Richards

- Posts: 743

- Joined: Thu Jul 12, 2007 10:34 am

- Location: Kent

- Been liked: 10 times

Dale

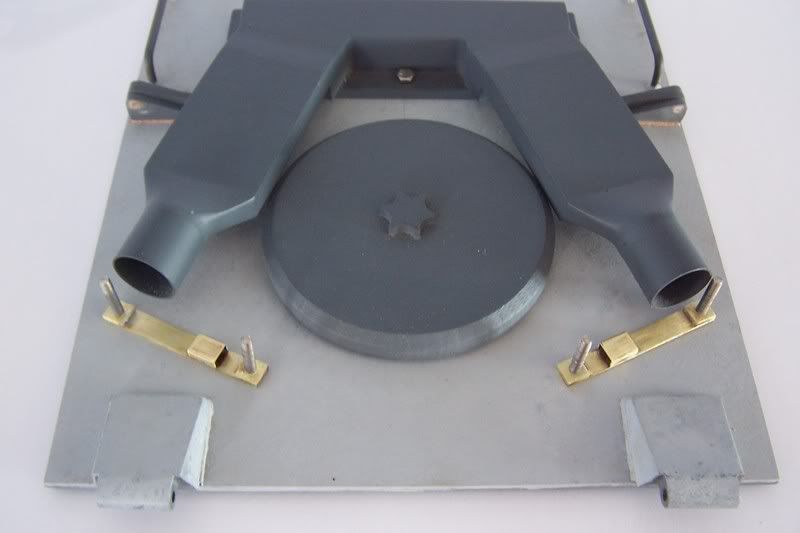

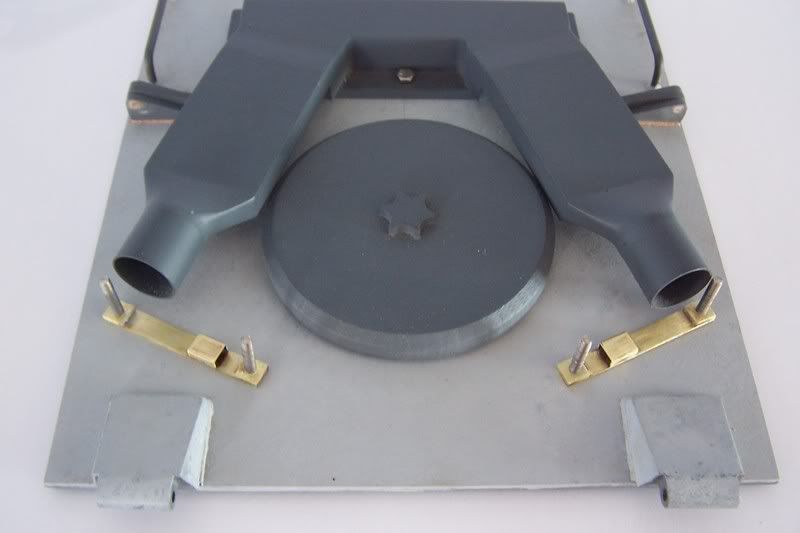

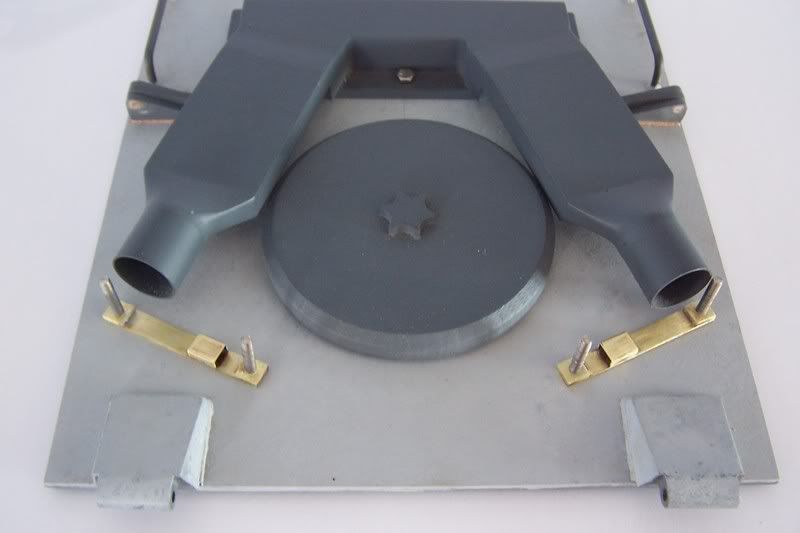

Here is a picture of the rear deck of my Tiger with the tubes and clamps fitted. I also use the Hunter systems remote switching unit with one master switch under the radio operators hatch at the front to avoid having to lift the rear grills ever time I want to switch something on or off. I use the four channels to switch the receiver and sound module on channel 1 smoker on channel 2 24v on channel 3 and animatronic man on channel 4. The smoker and 24v have automotive relays to switch the heavier currents. This means that the tank can be "running" to rev the engine etc without moving and also you can kill the 24v and any movement instantly should anything go wrong, like radio interferance.

If you have access to a lathe you could also make a new "star"nut for the engine cover plate. I found this quite easy to make by getting a disc of ally and drilling six holes on a PCD to form the cut outs then drilling and tapping a blind hole in the centre for a short length of stud then turning the nut to the correct diameter with a domed top, it only took about an hour to do and is a vast improvement on the moulded one - just a suggestion

Here is a picture of the rear deck of my Tiger with the tubes and clamps fitted. I also use the Hunter systems remote switching unit with one master switch under the radio operators hatch at the front to avoid having to lift the rear grills ever time I want to switch something on or off. I use the four channels to switch the receiver and sound module on channel 1 smoker on channel 2 24v on channel 3 and animatronic man on channel 4. The smoker and 24v have automotive relays to switch the heavier currents. This means that the tank can be "running" to rev the engine etc without moving and also you can kill the 24v and any movement instantly should anything go wrong, like radio interferance.

If you have access to a lathe you could also make a new "star"nut for the engine cover plate. I found this quite easy to make by getting a disc of ally and drilling six holes on a PCD to form the cut outs then drilling and tapping a blind hole in the centre for a short length of stud then turning the nut to the correct diameter with a domed top, it only took about an hour to do and is a vast improvement on the moulded one - just a suggestion

Allan Richards