HI Roland. Sounds great. I'm making a list of fasteners for my deck details and will definately give those suppliers a try. The ones I've used so far are expensive and hard to get in bulk. Thanks again for the info.

Hi Bob,

Thanks. This stuff is so fun. I'm looking into three different ways to make the actual parts. Unfortunately, casting in metal would require more cost up front then I can absorb and I don't think I could sell enough to even cover my cost.

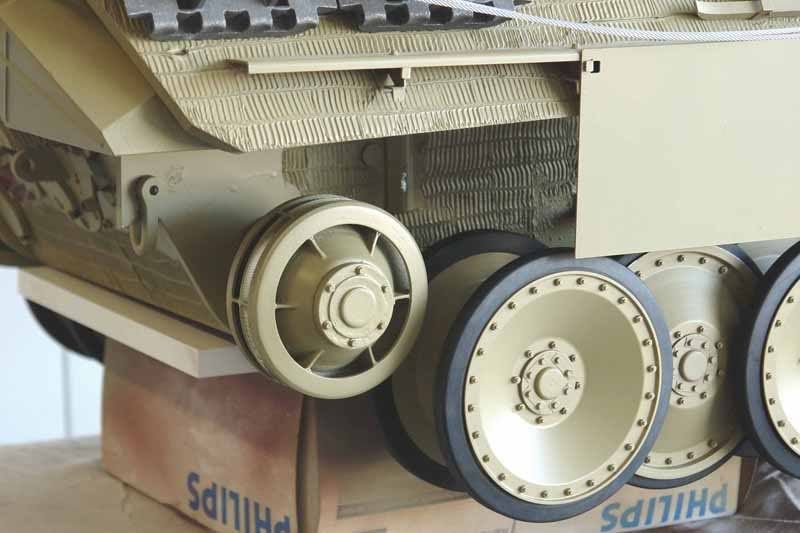

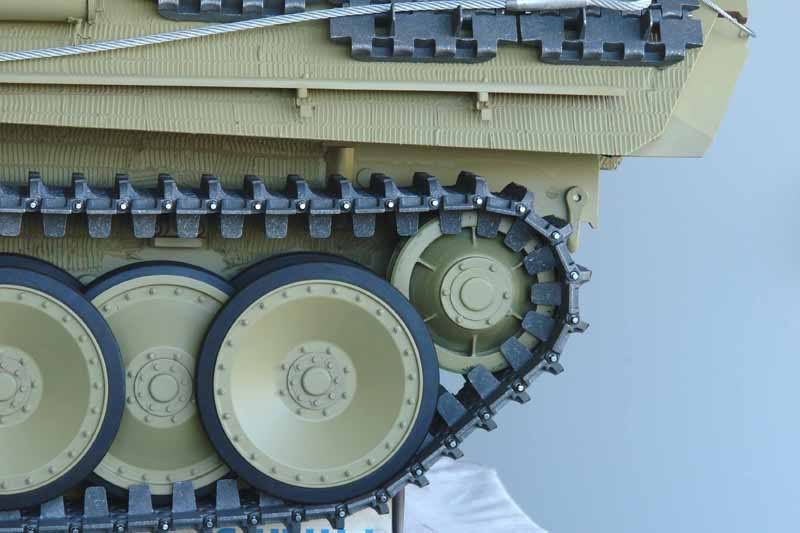

I also looked into 3D printed metal parts. They are done the same as SLA only in steel, at high resolution so super clean, functional, finished part with all the crazy, un-machinable undercuts this wheel has. This is the method I will probably use for my personal set.(also very expensive per wheel) If anyone is interested in spending the money I'll be happy to have more then my set run when I do them.

The last way is a very cost effective, do-able way that I will also be doing some prototypes in. It will sacrifice some accuracy but provide the look of the early wheels. These will be a combo of machined outer rings and hub(the functional structure) and an inner cast detail part which includes the spokes, grease fitting etc. I would supply them as kits so who ever wants to can detail them out to their personal standards when they assemble it.

So basically its a good, better, best plan with the best being beyond my budget. I do have to save something for that late Tiger I kit

I think the last option will be the way to go. It won't have the undercuts like the one in my photos but will look good. Once I have parts and prices I will let everyone know. I'm not looking to do this as a business so prices will be pretty much cost+shipping.

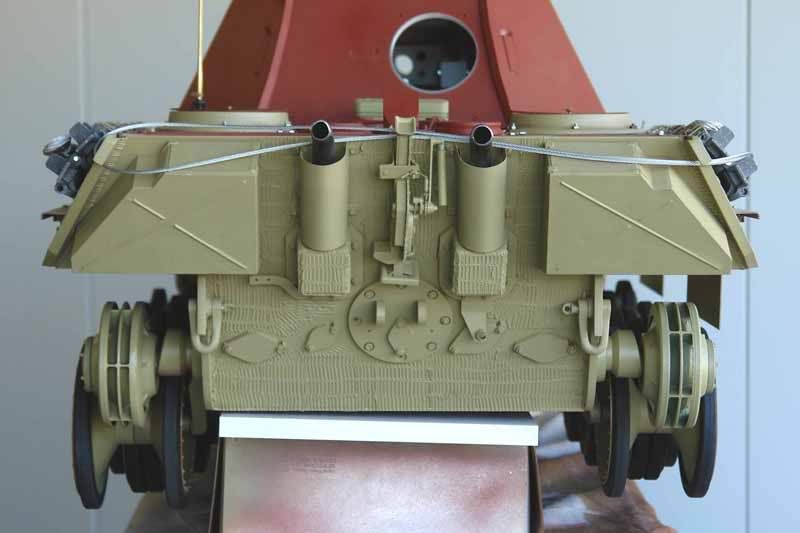

3D drawings are done for the exhaust guards and I am working on a VERY detailed, complete replacement deck, deck plates and deck components set as well.

PHEW..that was wordy. sorry about that.

Happy Panthering

Tim

That's my cost just for the 3D part. There's no price break at quantities either due to the nature of the process.

so I'm guessing somwhere just over $1,000/set with caps fasteners etc..again