25 pdr recoil mechanism

-

John M. Lyle

- Posts: 17

- Joined: Wed Oct 22, 2014 11:59 am

- Been liked: 1 time

25 pdr recoil mechanism

My 25 pdr is coming along fine.my problem is the recoil slide. When the gun is elevated it slides back. I do not want to glue it in place and want to keep it operational. I read in one post about installing springs in the recoils slide. If someone has done this could you please supply pictures and information on how it was done?

-

Dave Backway

- Posts: 105

- Joined: Mon Oct 06, 2014 6:27 pm

- Location: Exeter, Devon

- Has liked: 12 times

- Been liked: 64 times

Re: 25 pdr recoil mechanism

Good evening John,

I have just read the above post and your post relating to the customer support from Armortek. I am starting my build of the 25pdr and will no doubt have many questions, however would it be possible if you could share some of the advice you have received from the Armortek team.

As my build progresses I hope to post a build log showing some additional details I'm planning to include within my build.

I wish you the best with your build

Regards

Dave

I have just read the above post and your post relating to the customer support from Armortek. I am starting my build of the 25pdr and will no doubt have many questions, however would it be possible if you could share some of the advice you have received from the Armortek team.

As my build progresses I hope to post a build log showing some additional details I'm planning to include within my build.

I wish you the best with your build

Regards

Dave

-

John M. Lyle

- Posts: 17

- Joined: Wed Oct 22, 2014 11:59 am

- Been liked: 1 time

Re: 25 pdr recoil mechanism

Hi Dave

First thing I would do is to degrease everthing first before "dry fitting" I didn't do that first and now have to partially dismantle the gun to degrease it and paint the primer coat. The "grease" I am talking about is the oil left over from the machining process and mold release. The paint won't stick otherwise. "Dry fitting" first lets you see how everything goes together first and lers you find any problem areas where a little filing maybe required and what assemblies are best to do first before final assembly.

For the rear top and bottom tail plates leave the bolts slack until you have all the rivets in place then tighten the bolts. On the gun shield there are two l shaped strips of metal. Rivet them from one end to the other sequentially. Don't do what I did and rivet the ends before doing the middle. My way made fitting the middle rivets a pain in the butt. Doing it sequentially gives you the other end as a lever to line up the rivet holes nicely.

It is a great kit any problems I have had are down to me not assembling things in the correct sequence. That is what a "dry assembly" lets you figure out. You may find the wheel hubs do not appear fit correctly, just use a clamp to squeeze them together before applying the CA glue. Also make sure the treads on the tires both go in the same direction. Fortunately I noticed that before completing the wheel assembly. There is a minor amount of filing to do mainly to smooth some edges. Check out the Kompact Kit forum for various building logs for more tips.

I bought the detail set from Armorpax. So that is another reason to dismantle the kit again. The Armorpax detail kit really makes this model shine as there are a lot more small derails to add. Until you complete the final assembly keep all the parts bags. When you disassemble the kit for painting after the dry fit you can keep track of the part numbers. I at least remembered to do that.

Ask customer support for help as well. They have been very helpful to me.

First thing I would do is to degrease everthing first before "dry fitting" I didn't do that first and now have to partially dismantle the gun to degrease it and paint the primer coat. The "grease" I am talking about is the oil left over from the machining process and mold release. The paint won't stick otherwise. "Dry fitting" first lets you see how everything goes together first and lers you find any problem areas where a little filing maybe required and what assemblies are best to do first before final assembly.

For the rear top and bottom tail plates leave the bolts slack until you have all the rivets in place then tighten the bolts. On the gun shield there are two l shaped strips of metal. Rivet them from one end to the other sequentially. Don't do what I did and rivet the ends before doing the middle. My way made fitting the middle rivets a pain in the butt. Doing it sequentially gives you the other end as a lever to line up the rivet holes nicely.

It is a great kit any problems I have had are down to me not assembling things in the correct sequence. That is what a "dry assembly" lets you figure out. You may find the wheel hubs do not appear fit correctly, just use a clamp to squeeze them together before applying the CA glue. Also make sure the treads on the tires both go in the same direction. Fortunately I noticed that before completing the wheel assembly. There is a minor amount of filing to do mainly to smooth some edges. Check out the Kompact Kit forum for various building logs for more tips.

I bought the detail set from Armorpax. So that is another reason to dismantle the kit again. The Armorpax detail kit really makes this model shine as there are a lot more small derails to add. Until you complete the final assembly keep all the parts bags. When you disassemble the kit for painting after the dry fit you can keep track of the part numbers. I at least remembered to do that.

Ask customer support for help as well. They have been very helpful to me.

-

Dave Dibb (Armorpax)

- Posts: 1158

- Joined: Thu Jul 12, 2007 6:03 pm

- Location: Hampshire

- Has liked: 116 times

- Been liked: 1106 times

- Contact:

Re: 25 pdr recoil mechanism

Hi John,

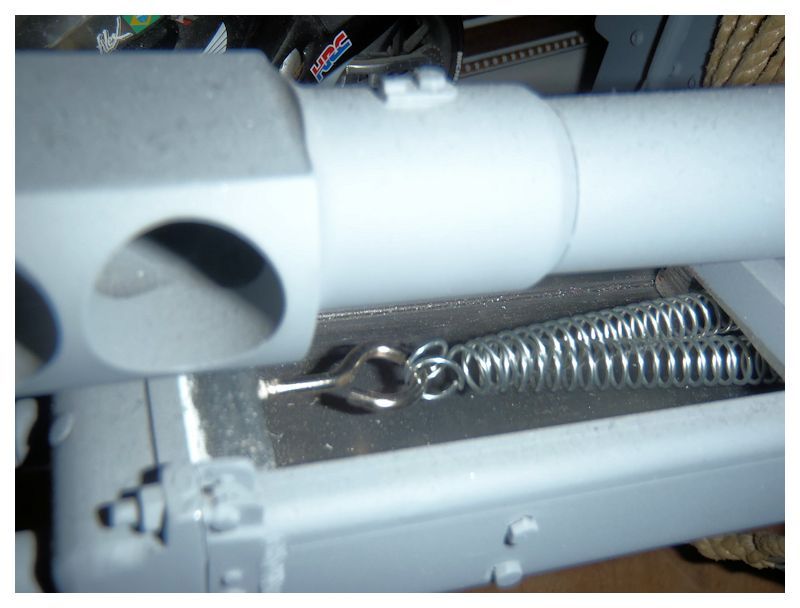

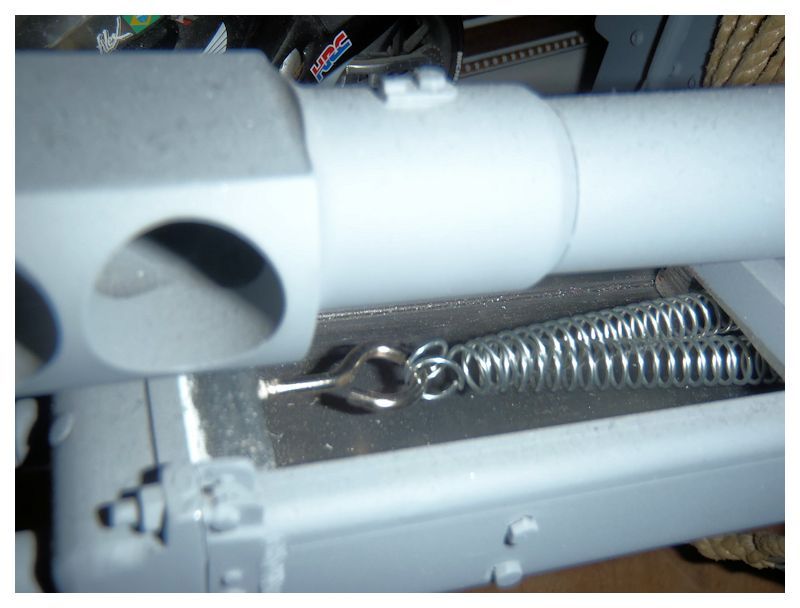

I thought I'd shown this in my original build but obviously haven't. I used two springs connected to a small net curtain ring. The other ends hook over two of the rivets supplied in the kit and drilled into the underside (I think from memory) of the sliding section of the gun carriage. It was a bit fiddly to connect but works OK and keeps the gun nicely forward when elevated. You will need to ensure the rivets are far enough down to overcome the initial extension of the spring caused by the weight of the gun assembly.

Best regards

Dave

I thought I'd shown this in my original build but obviously haven't. I used two springs connected to a small net curtain ring. The other ends hook over two of the rivets supplied in the kit and drilled into the underside (I think from memory) of the sliding section of the gun carriage. It was a bit fiddly to connect but works OK and keeps the gun nicely forward when elevated. You will need to ensure the rivets are far enough down to overcome the initial extension of the spring caused by the weight of the gun assembly.

Best regards

Dave

www.armorpax.net

There used to be a nice banner here till Photobucket lost everything.............................

There used to be a nice banner here till Photobucket lost everything.............................

-

John M. Lyle

- Posts: 17

- Joined: Wed Oct 22, 2014 11:59 am

- Been liked: 1 time

Re: 25 pdr recoil mechanism

Hi Dave

your photo looks pretty clear with what I have to do. Thanks

John

your photo looks pretty clear with what I have to do. Thanks

John

-

Marcus Kwa

- Posts: 176

- Joined: Wed Nov 13, 2013 6:22 pm

- Been liked: 39 times

Re: 25 pdr recoil mechanism

Hi John,

I like to share my recoil system. I tried to duplicate the actual system as much as possible (without the hydraulics).

The system consists of 2 threaded rods (m3) bolted to the end cap of the gun cradle. In my case, since I already had connected the front cap to the cradle, I glued to flanged nuts to the front cap. If I would build another I would drill holes in the front cap and tap threads to fit the rods into.

I bolted an aluminium block on the inside of the gun slide and drilled holes to feed the 2 rods through. The spring will bear against the block on one side and the other side will be secured to the rod with a nut. The tube is just a distance keeper:

The black CSK bolts securing the block will be puttied over and will not be visible when the gun is finished:

When pulling the slide backwards the block will move with the slide and will tension the spring against the bolt at the end of the threaded rods. One of the springs was removed for the photographs.

During the whole recoil operation the threaded rods will be stationary only the block (and slide of course) will move. The nut visible in front of the block is to control the gap between the slide and the frontcap.

Hope it makes sense! Oh, and don't mind the rust on some parts, I just picked up the project after some time off.....

Best regards,

Marcus

I like to share my recoil system. I tried to duplicate the actual system as much as possible (without the hydraulics).

The system consists of 2 threaded rods (m3) bolted to the end cap of the gun cradle. In my case, since I already had connected the front cap to the cradle, I glued to flanged nuts to the front cap. If I would build another I would drill holes in the front cap and tap threads to fit the rods into.

I bolted an aluminium block on the inside of the gun slide and drilled holes to feed the 2 rods through. The spring will bear against the block on one side and the other side will be secured to the rod with a nut. The tube is just a distance keeper:

The black CSK bolts securing the block will be puttied over and will not be visible when the gun is finished:

When pulling the slide backwards the block will move with the slide and will tension the spring against the bolt at the end of the threaded rods. One of the springs was removed for the photographs.

During the whole recoil operation the threaded rods will be stationary only the block (and slide of course) will move. The nut visible in front of the block is to control the gap between the slide and the frontcap.

Hope it makes sense! Oh, and don't mind the rust on some parts, I just picked up the project after some time off.....

Best regards,

Marcus

Last edited by Marcus Kwa on Sat May 30, 2015 9:52 pm, edited 1 time in total.

-

John M. Lyle

- Posts: 17

- Joined: Wed Oct 22, 2014 11:59 am

- Been liked: 1 time

Re: 25 pdr recoil mechanism

Thanks Marcus

It looks like you have a good system there. I'll be rereading it a few times when it come time to complete my model.

It looks like you have a good system there. I'll be rereading it a few times when it come time to complete my model.

-

Ian Rodney

- Posts: 480

- Joined: Thu Jul 05, 2012 6:39 am

- Been liked: 53 times

Re: 25 pdr recoil mechanism

Hi Marcus,

That's great you shared your recoil system on the Forum. Looks a good system to add to the 25pdr

I have yet to start building my own 25 pdr gun, busy building the Limber first and adding all those Armorpax upgraded parts by Dave.

I down loaded your pics on how you went about making the recoil set up and noticed that the pictures when blown up gets to pixelated and blurred due to the small size of the images you down loaded on the Forum.

Is is possible that you could in increase the size of your pictures, and put them back on again, so that we can see all the fine details that have gone into set up!

Many Thanks

Cheers

Ian

That's great you shared your recoil system on the Forum. Looks a good system to add to the 25pdr

I have yet to start building my own 25 pdr gun, busy building the Limber first and adding all those Armorpax upgraded parts by Dave.

I down loaded your pics on how you went about making the recoil set up and noticed that the pictures when blown up gets to pixelated and blurred due to the small size of the images you down loaded on the Forum.

Is is possible that you could in increase the size of your pictures, and put them back on again, so that we can see all the fine details that have gone into set up!

Many Thanks

Cheers

Ian

-

Marcus Kwa

- Posts: 176

- Joined: Wed Nov 13, 2013 6:22 pm

- Been liked: 39 times

Re: 25 pdr recoil mechanism

Hi Ian,

I have some difficulties getting my pics into the forum lately. You can see the full size photo's on my photo stream while I try to figure out what is happening to my photo's on the forum!

https://www.flickr.com/photos/82214824@N03/

Best regards,

Marcus

I have some difficulties getting my pics into the forum lately. You can see the full size photo's on my photo stream while I try to figure out what is happening to my photo's on the forum!

https://www.flickr.com/photos/82214824@N03/

Best regards,

Marcus

-

Ian Rodney

- Posts: 480

- Joined: Thu Jul 05, 2012 6:39 am

- Been liked: 53 times

Re: 25 pdr recoil mechanism

Hi Marcus,

That's excellent now I can see your 25 pdr recoil mechanism pics on flickr, nice clear shots, and more interesting pics of the 25 pounder it's self.

I believe the Forum was being updated a few weeks ago, and some members where seeing their pics cropped on both sides. But is all sorted out now?

Hope you get your photo's sorted out on the Forum soon!

Thank you for putting these pics on via flickr on the Forum.

Best regards

Ian

That's excellent now I can see your 25 pdr recoil mechanism pics on flickr, nice clear shots, and more interesting pics of the 25 pounder it's self.

I believe the Forum was being updated a few weeks ago, and some members where seeing their pics cropped on both sides. But is all sorted out now?

Hope you get your photo's sorted out on the Forum soon!

Thank you for putting these pics on via flickr on the Forum.

Best regards

Ian