G'day All. I've recently been researching 3d printers and found them to be limited in the number of companies producing them and bang for bucks if you know what I mean. So my questions are does anyone use a 3d printer, what type is it, what sort of quality product does it produce and are you satisfied/very satisfied/extremely satisfied with your 3d printer?

Also how much printing can you get with a 1kg spool of plastic?

Cheers & thanks

Ray

3 D Printers

-

Ray Brown

- Posts: 452

- Joined: Tue Jul 05, 2011 2:00 am

- Location: Penrith NSW

- Has liked: 26 times

- Been liked: 103 times

- Contact:

Re: 3 D Printers

G'day All. I see there have been 90 views. Unfortunately I can't tell how many were forum members. I was hoping someone knew something.

Cheers

Ray

Cheers

Ray

- Armortek

- Site Admin

- Posts: 2933

- Joined: Tue Jul 10, 2007 10:30 am

- Location: Winchester, England

- Been liked: 3689 times

Re: 3 D Printers

Hello Ray

We have a commercial 3D printer here. We have had it for about ten years, so its a little old now in terms of its technology. Its a Statasys Dimension, filament deposition machine. Pros. Accurate strong models, ideal for prototype parts. Cons. slow and limited fine detail. Step height large compared to more recent machines.

I would say its useful but not an answer to all problems.

Mark

We have a commercial 3D printer here. We have had it for about ten years, so its a little old now in terms of its technology. Its a Statasys Dimension, filament deposition machine. Pros. Accurate strong models, ideal for prototype parts. Cons. slow and limited fine detail. Step height large compared to more recent machines.

I would say its useful but not an answer to all problems.

Mark

Armortek

-

colin fairweather

- Posts: 253

- Joined: Fri Aug 17, 2007 4:34 pm

- Location: athlone rep of ireland

- Been liked: 9 times

Re: 3 D Printers

hi mark

would it make a breech block for the tiger nudge nudge

colin

would it make a breech block for the tiger nudge nudge

colin

2003 first batch tiger 1 mid still fiddling with it

2006 222 SOLD

2009 pzr111 046 SOLD

-

Fabrice Le Roux

- Posts: 394

- Joined: Thu Jul 12, 2007 8:57 pm

- Location: London UK

- Been liked: 14 times

Re: 3 D Printers

Hi Ray,

Keep prodding. A number or forum users in Europe and the US have made parts with 3d printing technology. Speak up people, don't be shy!

As you say the printers available are still very expensive or as in the case of the "MakerBoT" quite low resolution. The trade off is to get a low res part made cheaply by a 3d printing bureau, clean it up and then either use directly or as a pattern for casting in resin or metal. The advantage of making a decent pattern and mould is that you can recover the cost of the printing by making a production run and selling the parts to other model makers. Paying a bureau more for a hi res print would not only save you cleanup time, but might be justified where tolerances might get messed up by filling and sanding the master pattern.

Unless you are a real electro mechanical hobbyist who will get a serious buzz from building the MakerBot kit per se, then I would get a quote from a Bureau. Some of the Tech/Art colleges/Unis are getting grants to buy this kit too and some are offering printing services at reasonable rates. Worth a few emails/calls if you are near a campus.

The neat thing about this whole rapid prototyping revolution is that you don't need to own the printing device (which will be obsolete next year anyway), just an STL compatible sofware package and internet access. So it would be very useful given the global reach of this forum to build up a list of 3d printing bureaux round the world, so that anyone's model can be printed near to the intended recipient, saving shipping charges and delays. Just a thought...

Cheers, Fabrice

Keep prodding. A number or forum users in Europe and the US have made parts with 3d printing technology. Speak up people, don't be shy!

As you say the printers available are still very expensive or as in the case of the "MakerBoT" quite low resolution. The trade off is to get a low res part made cheaply by a 3d printing bureau, clean it up and then either use directly or as a pattern for casting in resin or metal. The advantage of making a decent pattern and mould is that you can recover the cost of the printing by making a production run and selling the parts to other model makers. Paying a bureau more for a hi res print would not only save you cleanup time, but might be justified where tolerances might get messed up by filling and sanding the master pattern.

Unless you are a real electro mechanical hobbyist who will get a serious buzz from building the MakerBot kit per se, then I would get a quote from a Bureau. Some of the Tech/Art colleges/Unis are getting grants to buy this kit too and some are offering printing services at reasonable rates. Worth a few emails/calls if you are near a campus.

The neat thing about this whole rapid prototyping revolution is that you don't need to own the printing device (which will be obsolete next year anyway), just an STL compatible sofware package and internet access. So it would be very useful given the global reach of this forum to build up a list of 3d printing bureaux round the world, so that anyone's model can be printed near to the intended recipient, saving shipping charges and delays. Just a thought...

Cheers, Fabrice

-

Tim Bowman

- Posts: 1762

- Joined: Fri Jul 13, 2007 4:53 am

- Location: Northern California

- Been liked: 177 times

- Contact:

Re: 3 D Printers

Hi Ray

Fabrice is spot on in regards to using a bureau in leu of purchasing your own machine for all the reasons he mentions. Initial cost, cost of maintenance/headaches etc. The only thing I would differ on is his comment regarding cost recuperation. Due to the cost of the process and my time involved(which I don't add into the cost), I have lost money on every art I have sold. We need to remember that this is a hobby and not a business. In my case, if I develop a part for one of my projects, I am happy to produce duplicates for others if they are interested and find the part useful. or supply the masters to Steve Winstone, Dave Dibb and Mike Stannard for casting if they can use them. These, I try to sell at my cost but that is not always the case...usually it's for less then I paid for the extra parts.

3D PRINTERS vs. SLA MACHINES

There is a misconception out there when it comes to "3D printers" and "printed parts". My company had a 3D printing machine several years ago that used the spooled material as you mention. These parts are NOT the same quality and NOT the same process as an SLA machine. I always use the analogy of a low-resolution photo vs. a hi-resolution photo. SLA parts are a much higher quality (and cost) part but maintain the fine details and require much less clean up before using them or molding them or whatever you plan on doing with them. A "3D printed" part requires a lot of clean up and does not maintain the fine details your 3D part file might have. These parts are OK though for a part that will receive a "cast texture" finish. My Panther idler wheel center detail piece for example....or even my very first prototype Panther cupola interior.(the later ones were SLA parts)

All the more recent parts I have shown on my builds are SLA parts done to "standard" finish.

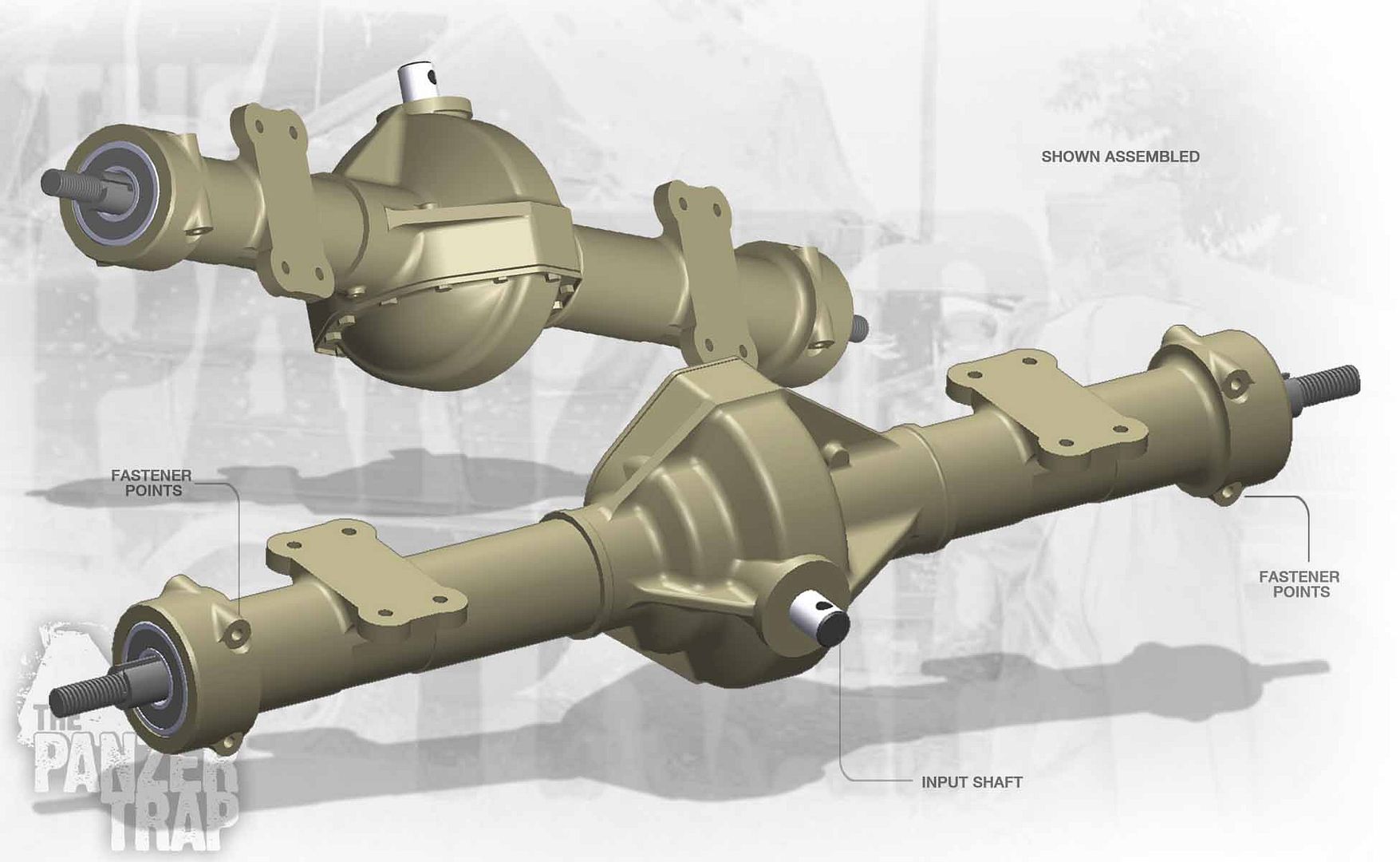

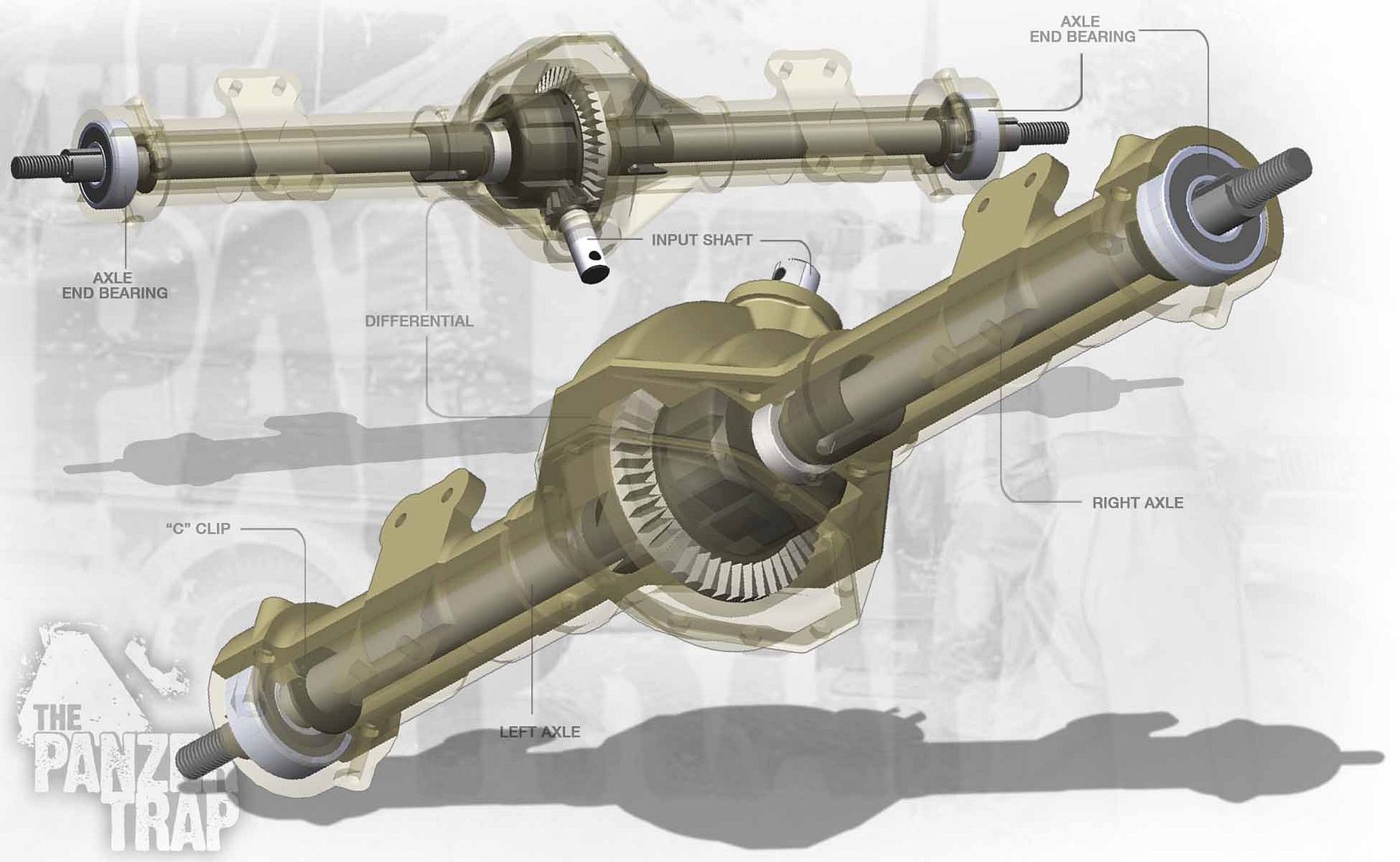

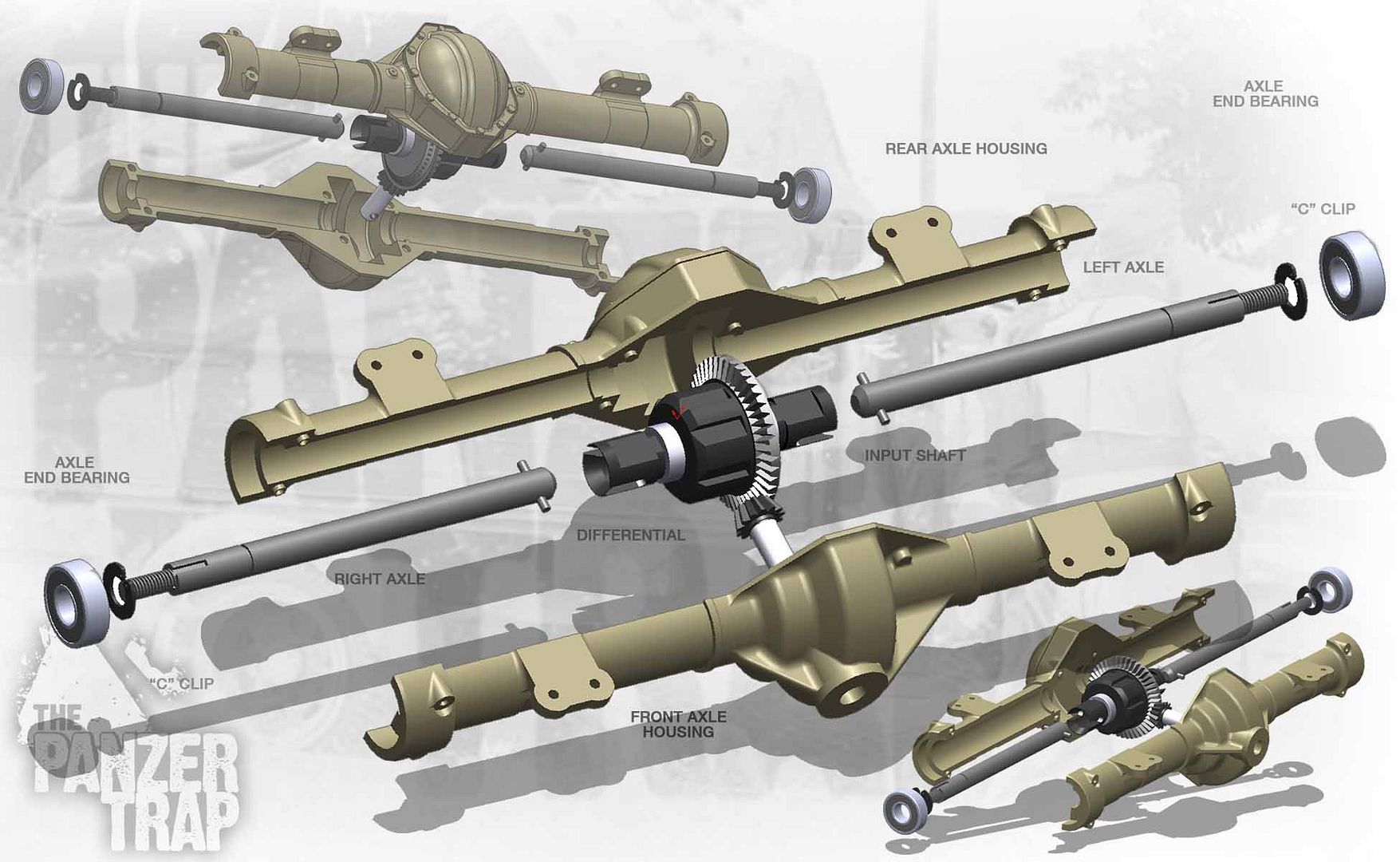

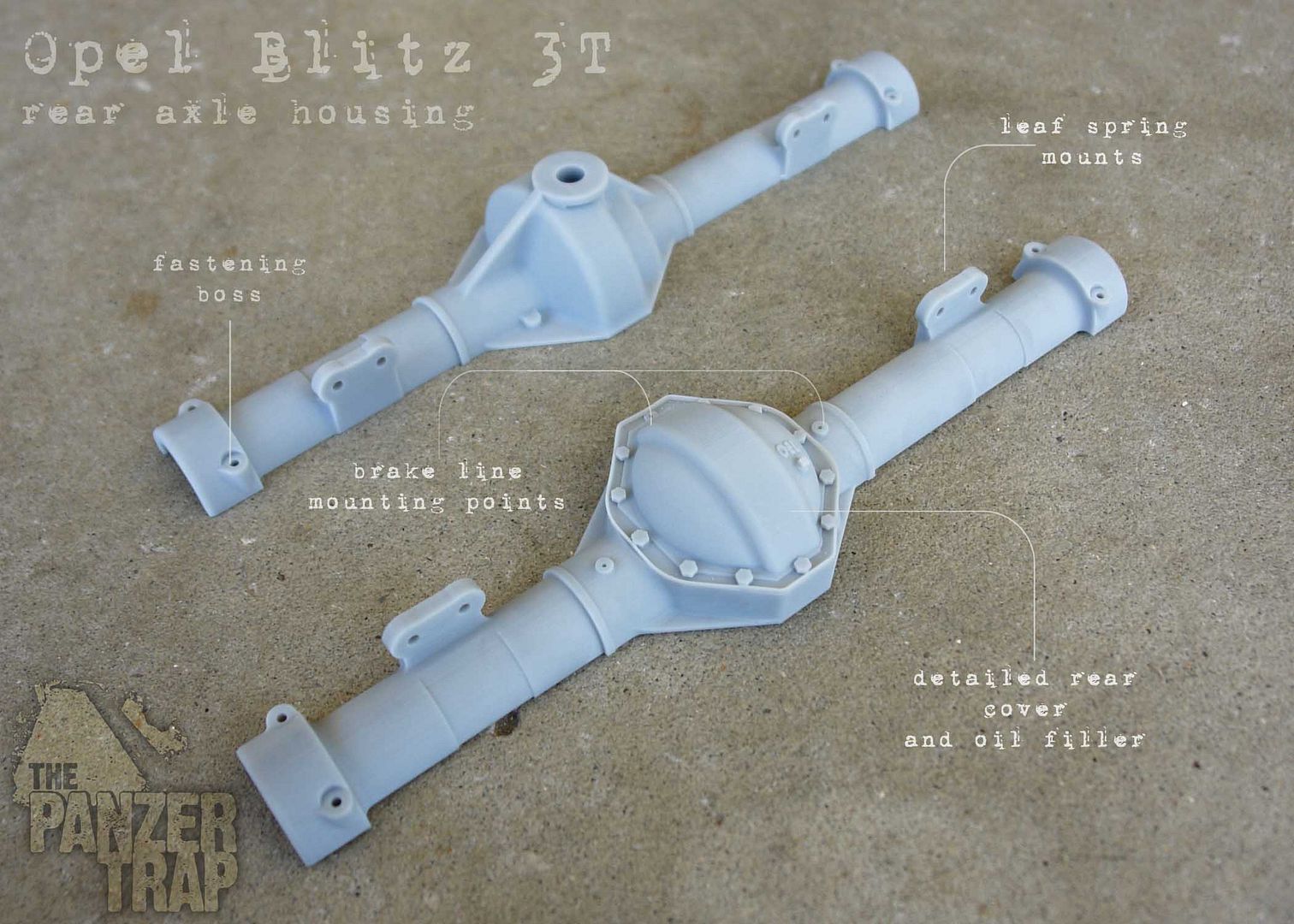

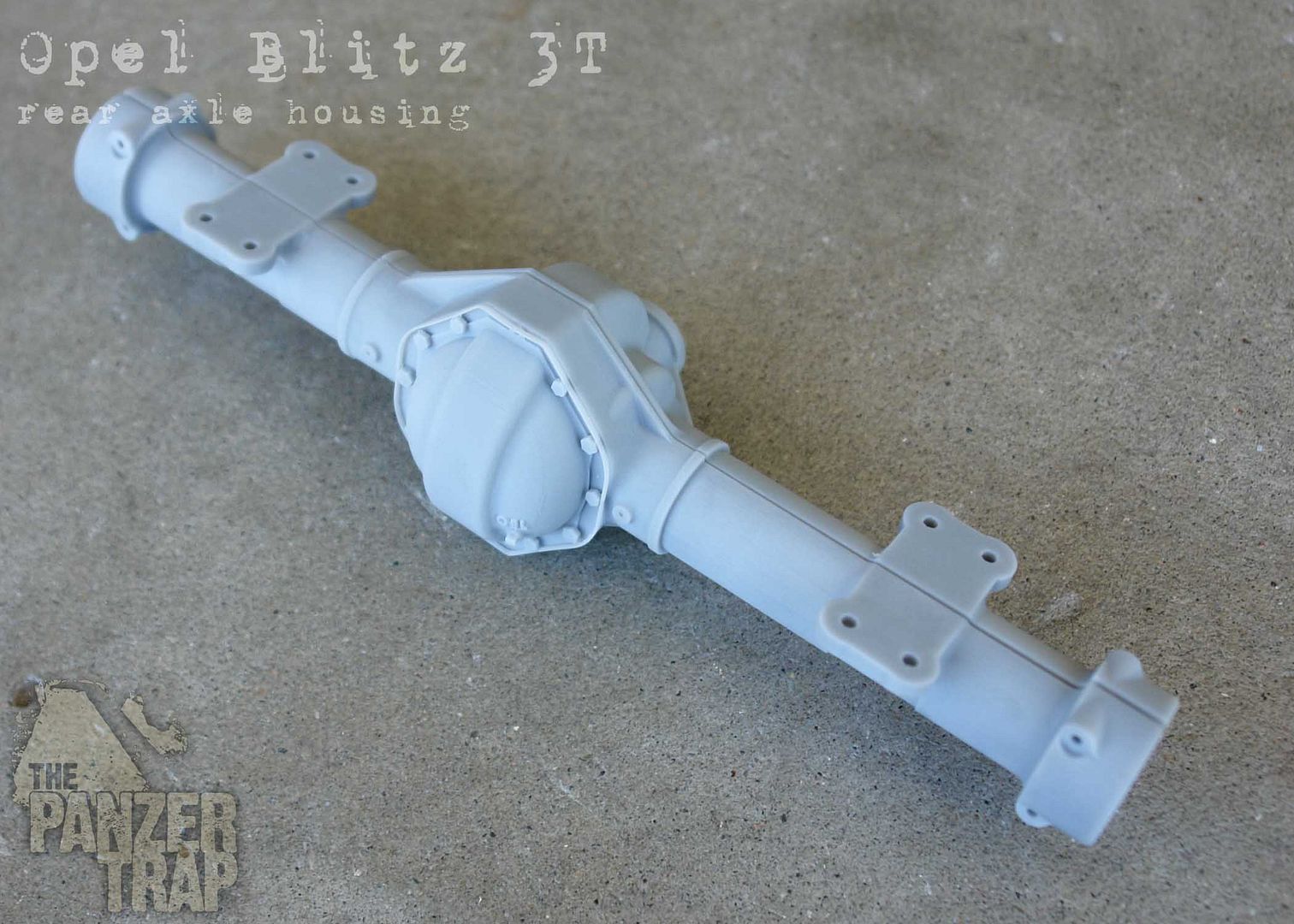

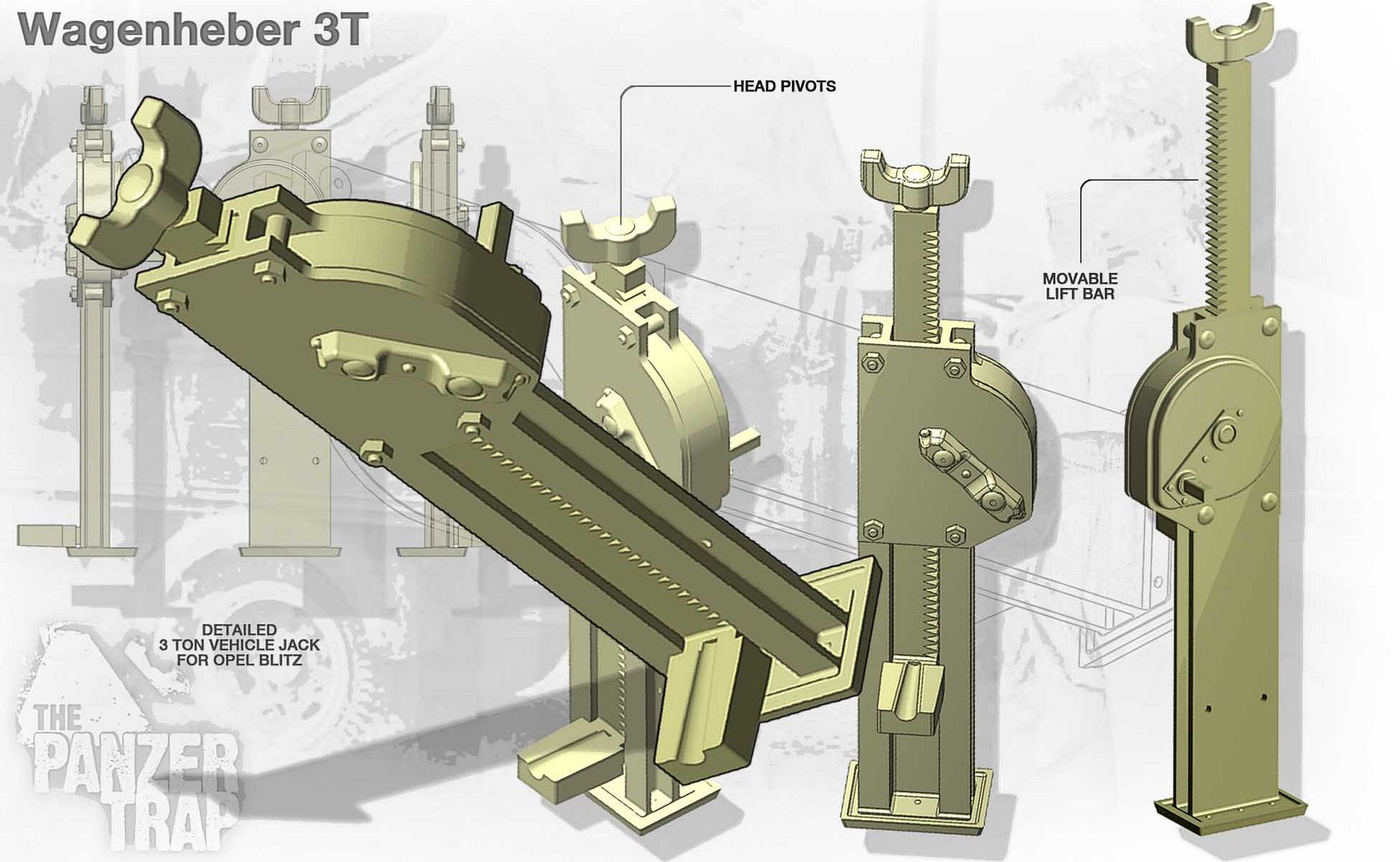

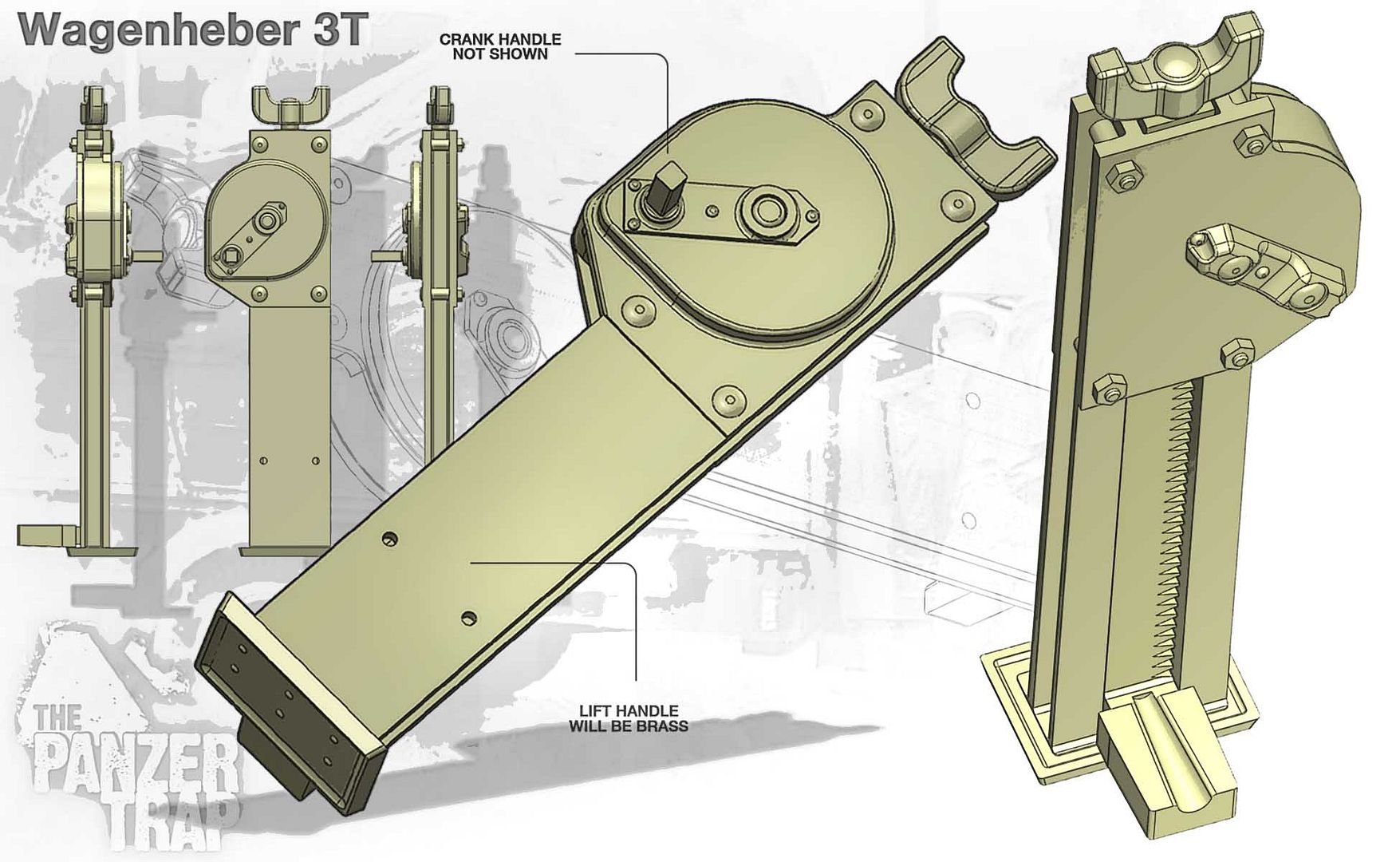

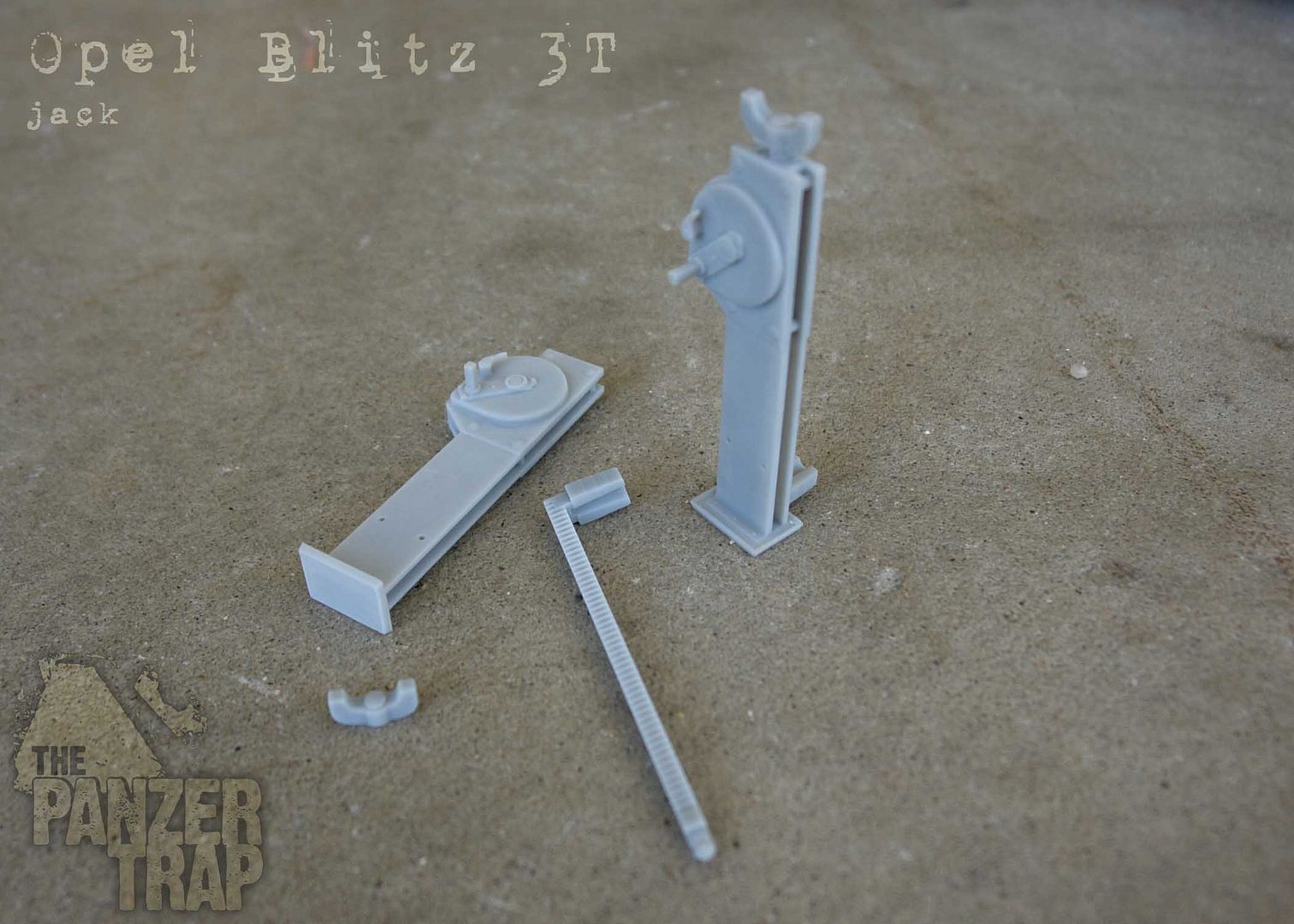

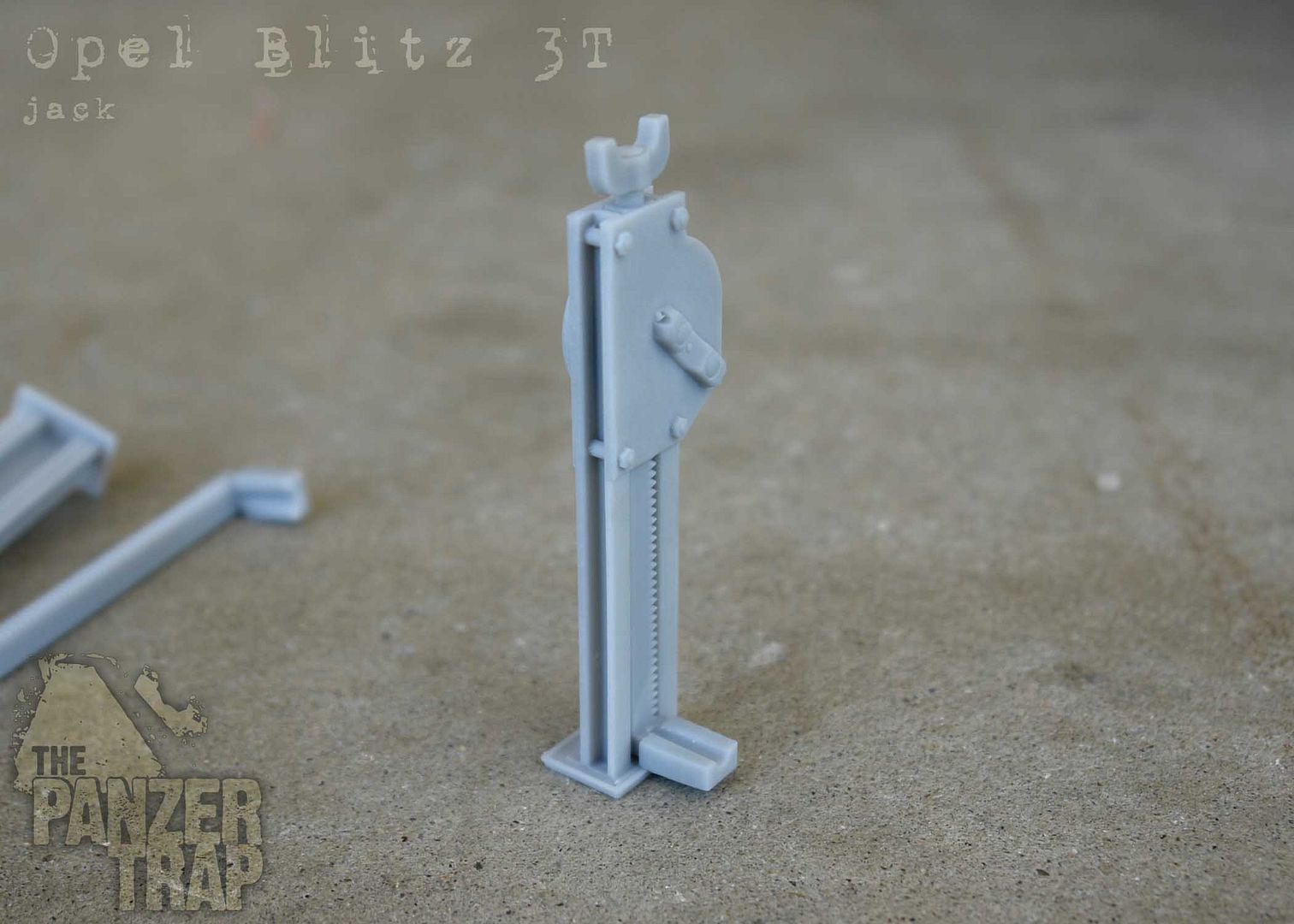

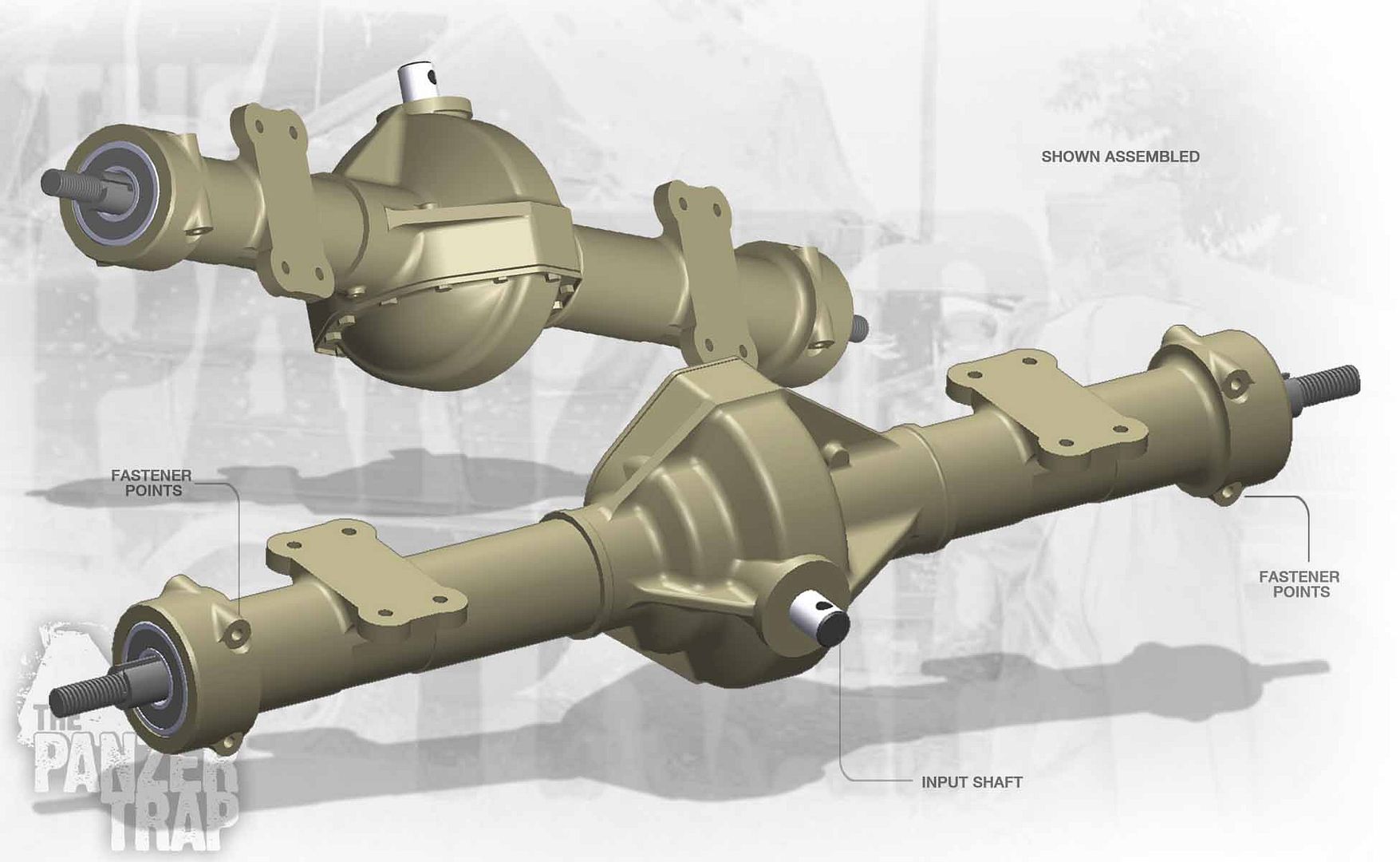

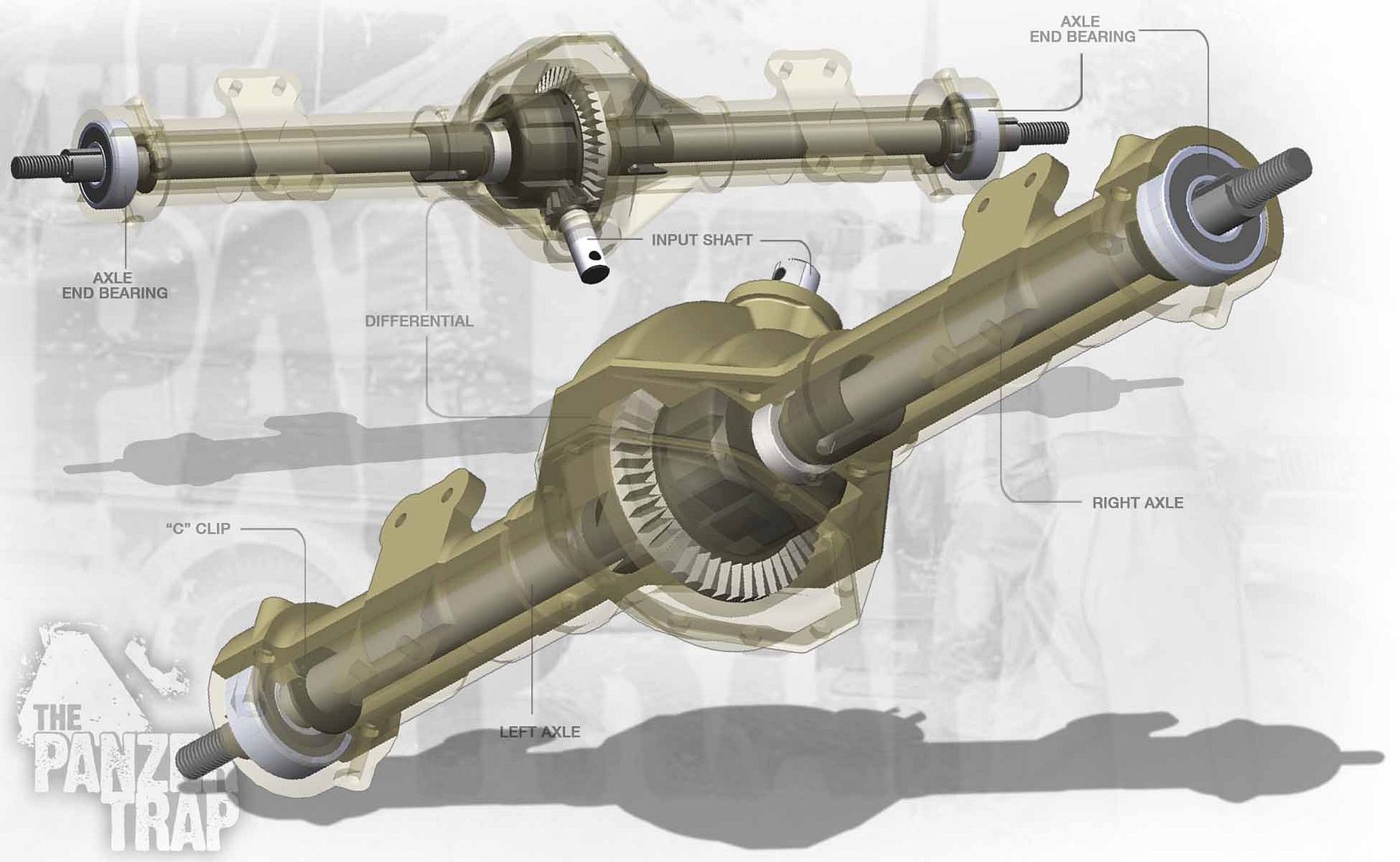

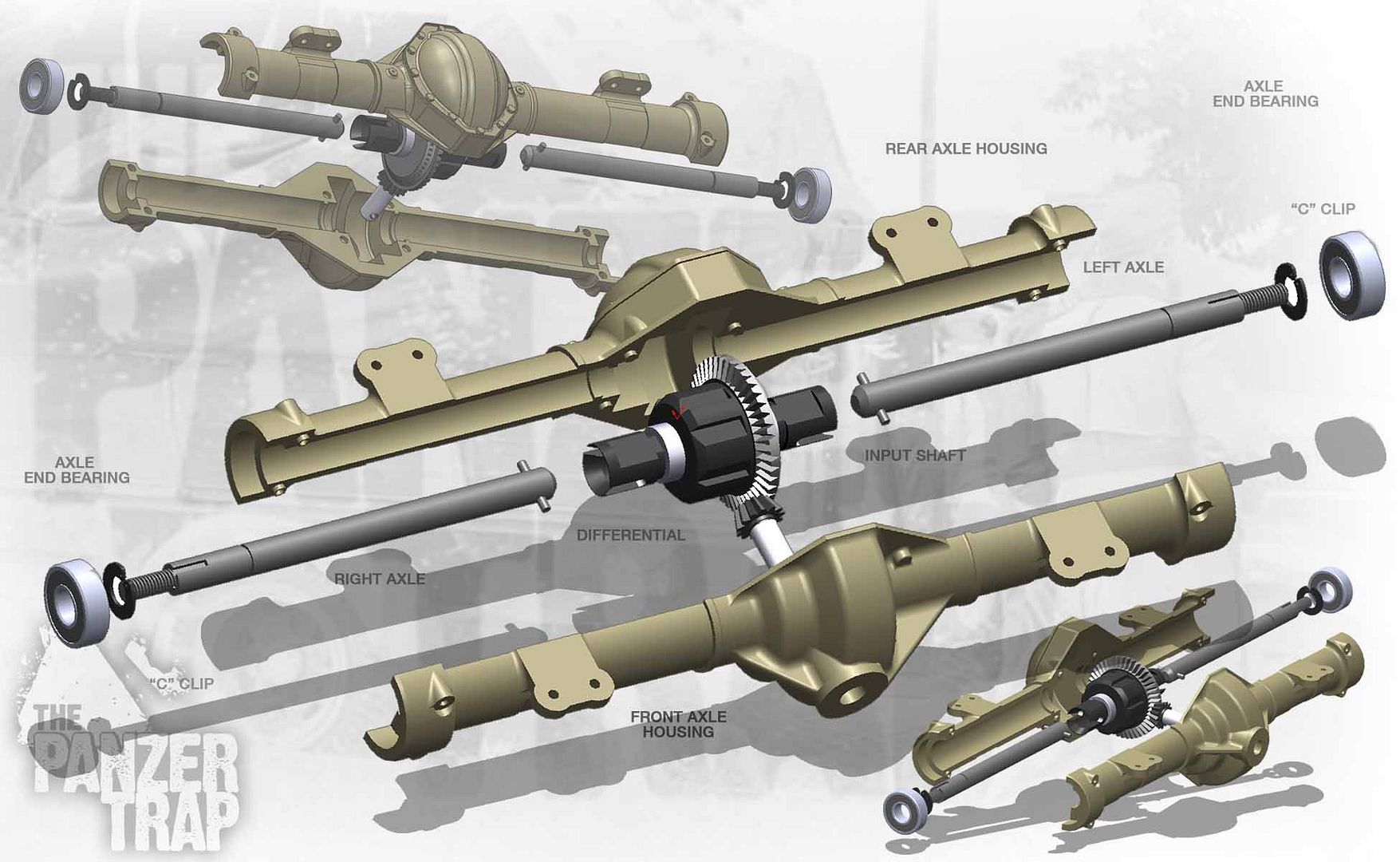

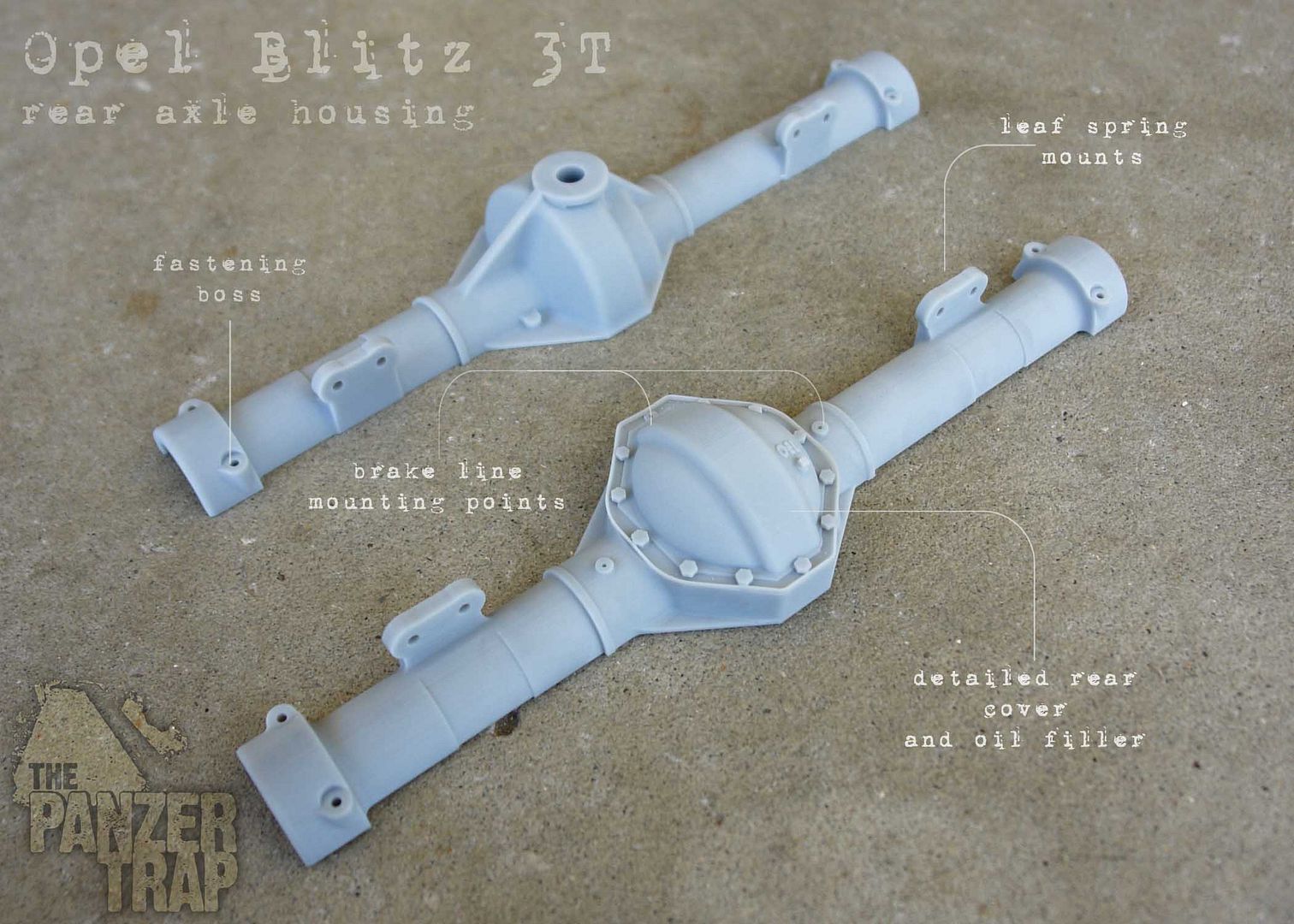

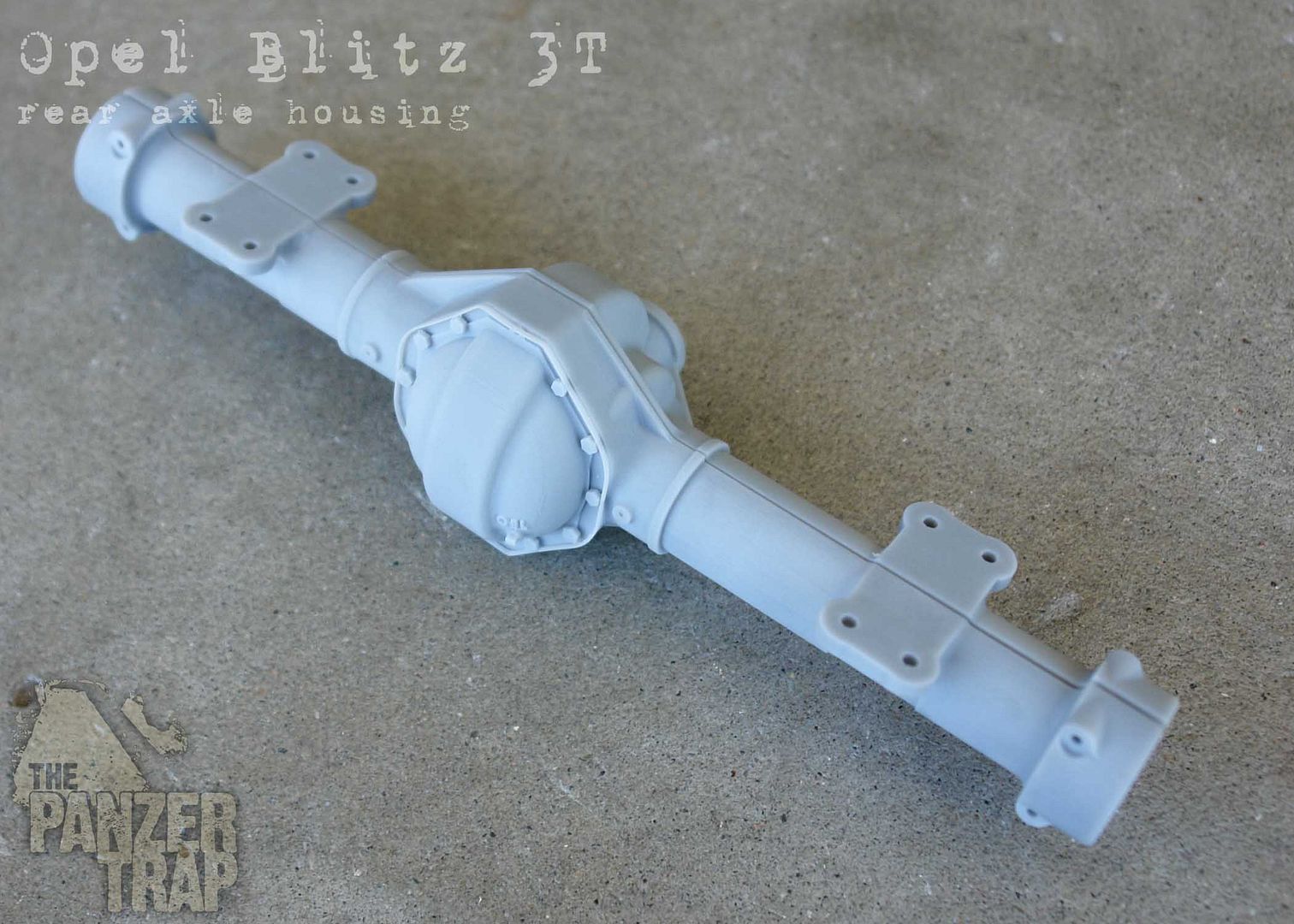

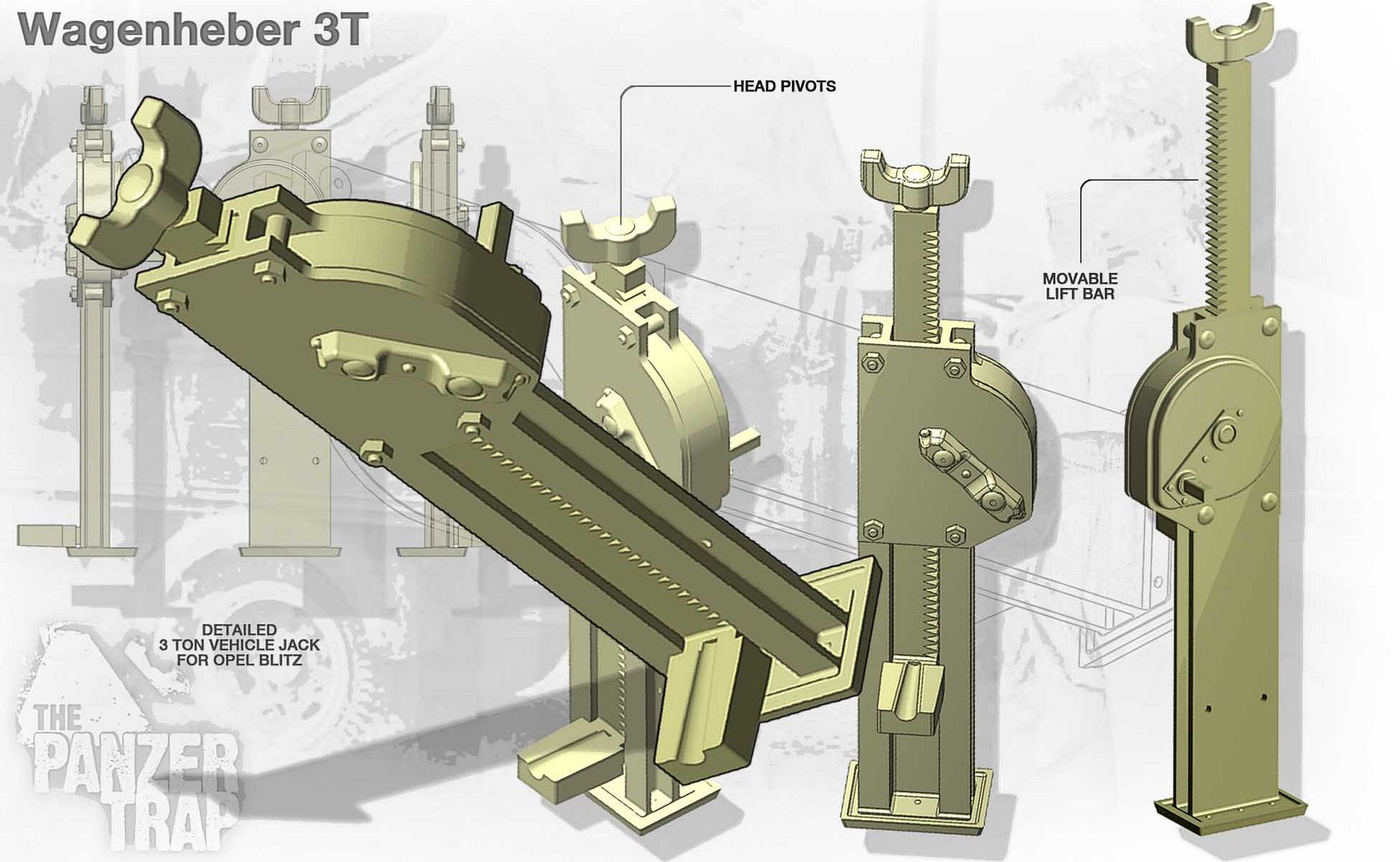

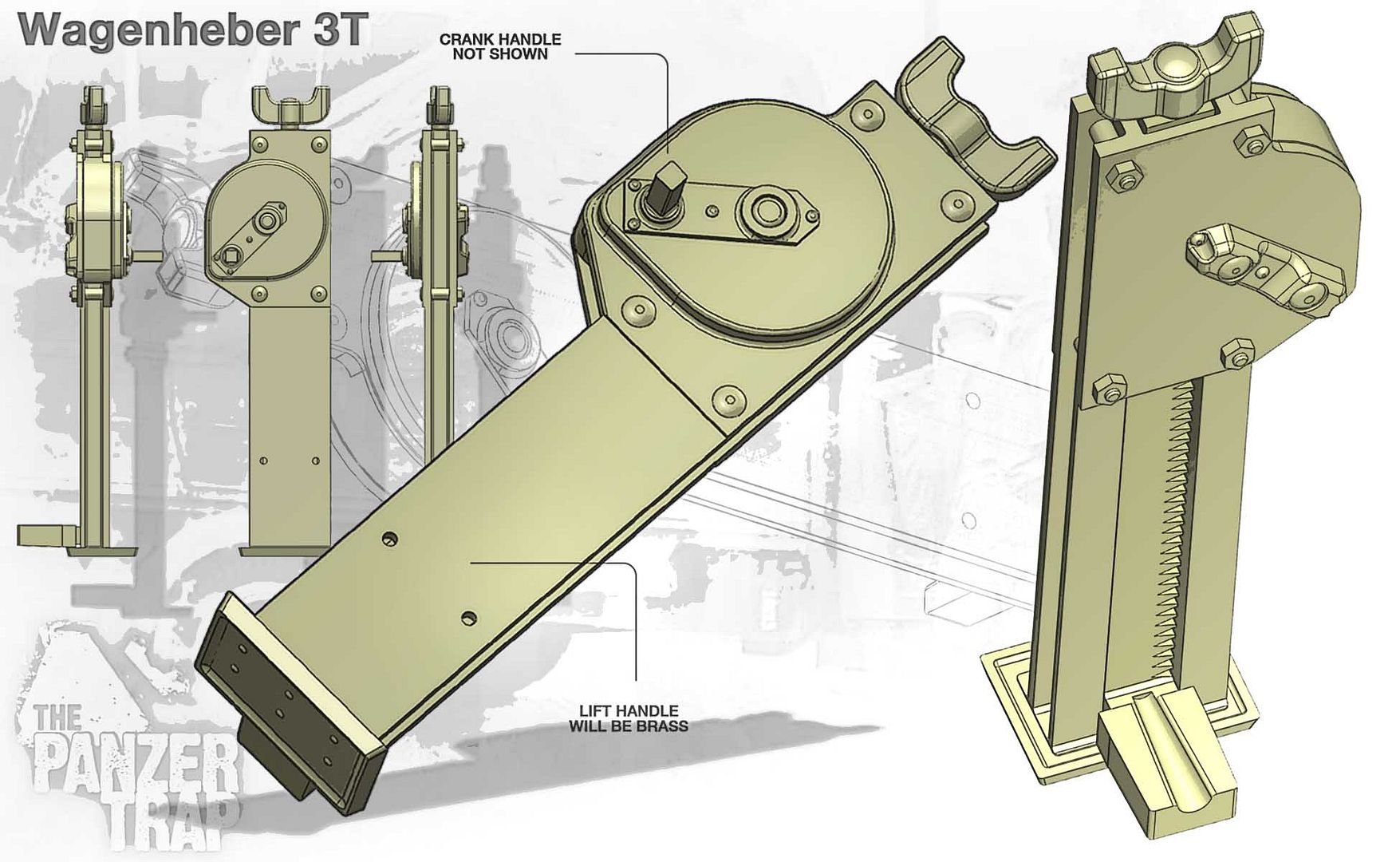

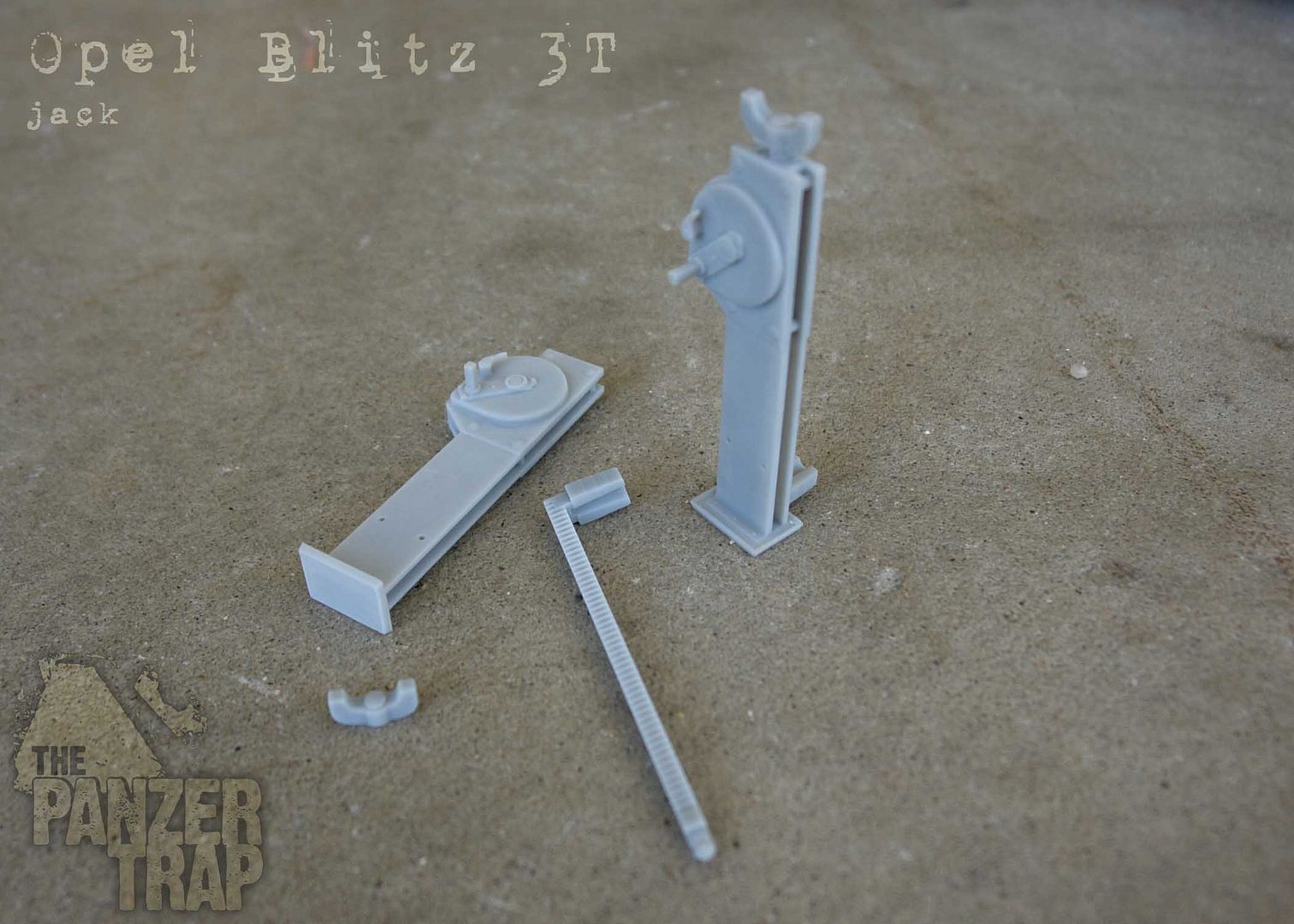

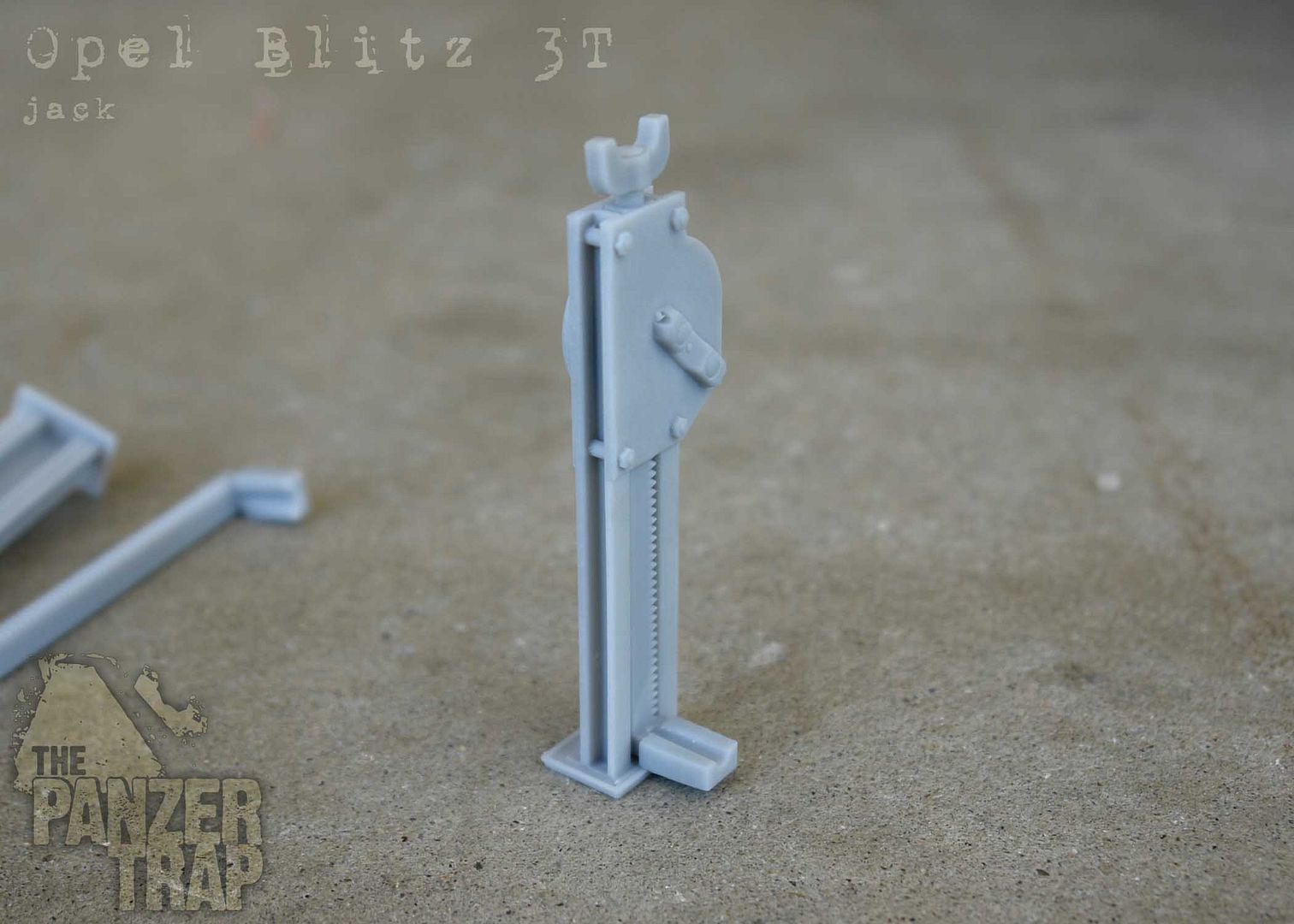

Opel parts for example. Sorry if this is a repeat.

So, bottom, line in my opinion is if you have the 3D drawing capability, take the money you would spend on a low cost machine and put it towards the parts you really want to do through a rapid prototype service bureau. Fees vary so have your parts quoted at various places.

Just my 2 cents worth...you get what you pay for LOL

All the best Ray

Tim

Fabrice is spot on in regards to using a bureau in leu of purchasing your own machine for all the reasons he mentions. Initial cost, cost of maintenance/headaches etc. The only thing I would differ on is his comment regarding cost recuperation. Due to the cost of the process and my time involved(which I don't add into the cost), I have lost money on every art I have sold. We need to remember that this is a hobby and not a business. In my case, if I develop a part for one of my projects, I am happy to produce duplicates for others if they are interested and find the part useful. or supply the masters to Steve Winstone, Dave Dibb and Mike Stannard for casting if they can use them. These, I try to sell at my cost but that is not always the case...usually it's for less then I paid for the extra parts.

3D PRINTERS vs. SLA MACHINES

There is a misconception out there when it comes to "3D printers" and "printed parts". My company had a 3D printing machine several years ago that used the spooled material as you mention. These parts are NOT the same quality and NOT the same process as an SLA machine. I always use the analogy of a low-resolution photo vs. a hi-resolution photo. SLA parts are a much higher quality (and cost) part but maintain the fine details and require much less clean up before using them or molding them or whatever you plan on doing with them. A "3D printed" part requires a lot of clean up and does not maintain the fine details your 3D part file might have. These parts are OK though for a part that will receive a "cast texture" finish. My Panther idler wheel center detail piece for example....or even my very first prototype Panther cupola interior.(the later ones were SLA parts)

All the more recent parts I have shown on my builds are SLA parts done to "standard" finish.

Opel parts for example. Sorry if this is a repeat.

So, bottom, line in my opinion is if you have the 3D drawing capability, take the money you would spend on a low cost machine and put it towards the parts you really want to do through a rapid prototype service bureau. Fees vary so have your parts quoted at various places.

Just my 2 cents worth...you get what you pay for LOL

All the best Ray

Tim

"So long as one isn't carrying one's head under one's arm, things aren't too bad." – Erwin Rommel

-

Fabrice Le Roux

- Posts: 394

- Joined: Thu Jul 12, 2007 8:57 pm

- Location: London UK

- Been liked: 14 times

Re: 3 D Printers

Tim,

Many thanks for putting the record straight and sharing your considerable experience in this new craft.

Kind regards

Fabrice

Many thanks for putting the record straight and sharing your considerable experience in this new craft.

Kind regards

Fabrice

-

Pierluigi Patri

- Posts: 142

- Joined: Fri Jan 11, 2008 7:36 pm

- Location: Genoa

- Been liked: 1 time

- Contact:

Re: 3 D Printers

Hi Tim

I think I will never use neither 3D printer nor a SLA machine nevertheless I appreciated your post because it helps me in understanding something in a matter totally unknown to me.

Kind regards

I think I will never use neither 3D printer nor a SLA machine nevertheless I appreciated your post because it helps me in understanding something in a matter totally unknown to me.

Kind regards

Pierluigi

-

Ray Brown

- Posts: 452

- Joined: Tue Jul 05, 2011 2:00 am

- Location: Penrith NSW

- Has liked: 26 times

- Been liked: 103 times

- Contact:

Re: 3 D Printers

G'day All. Thanks for the feedback on all that. I can see a large number of personal applications as a hobbyist, not business which I'm not interested in. Especially as prototyping prior to laser cutting.

I'm sure this post has helped a few others. Anymore comments would be welcomed I'm sure.

Cheers

Ray

I'm sure this post has helped a few others. Anymore comments would be welcomed I'm sure.

Cheers

Ray