Page 1 of 1

Piltz sockets and other additions

Posted: Sun Oct 19, 2008 6:57 pm

by Dave Dibb (Armorpax)

Posted: Sun Oct 19, 2008 8:03 pm

by Adrian Harris

I have to ask

What's a Piltz and where would its socket be mounted

Adrian.

Posted: Sun Oct 19, 2008 8:16 pm

by Dave Dibb (Armorpax)

Hi Adrian,

They are the sockets for the 2t tripod crane and were mounted on the top of the fighting compartment or turret of most late war German armour,

Cheers

Dave

PS I think someone on here was making the crane itself???

Posted: Sun Oct 19, 2008 8:25 pm

by Adrian Harris

Cheers Dave

Lots of interesting parts there...

Adrian.

Posted: Fri Oct 24, 2008 4:50 pm

by Paul Morris

Hello Dave.

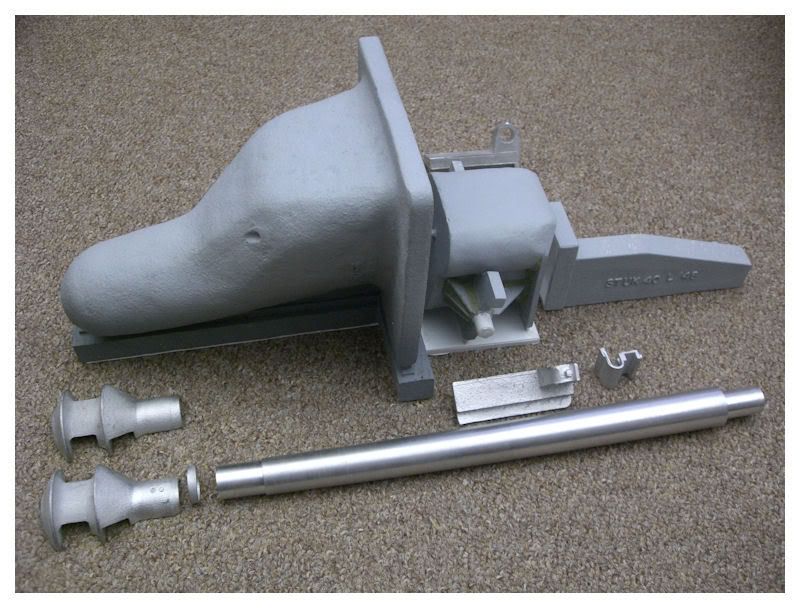

Thanks for the plug

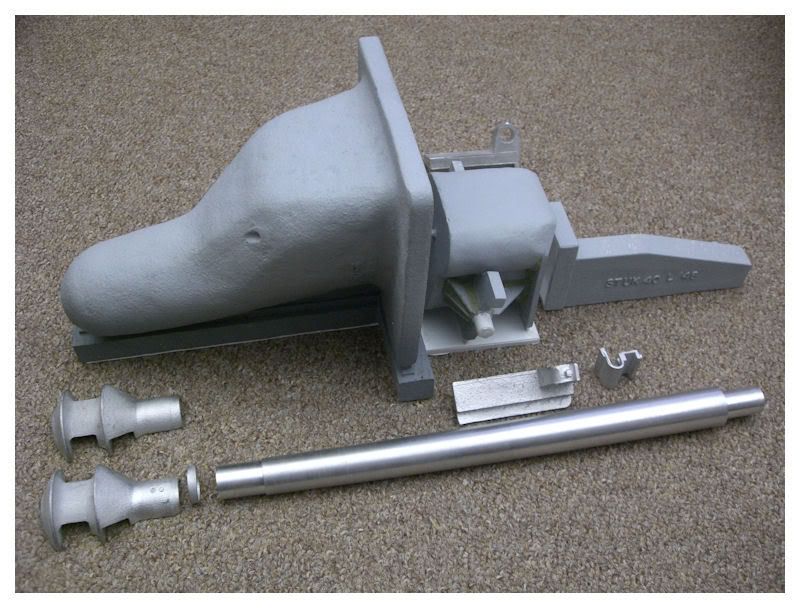

yes if anyone would like the crane to go with Daves excellent pilse sockets i can make them to order.

Cheers Paul

Posted: Fri Oct 24, 2008 5:10 pm

by Stewart Ashton

Hi Paul,

Have you got a picture and would one ever have been used with

the sdkfz7?

Regards Stewart

Posted: Fri Oct 24, 2008 5:25 pm

by Paul Morris

Hello Stewart.

[

img]

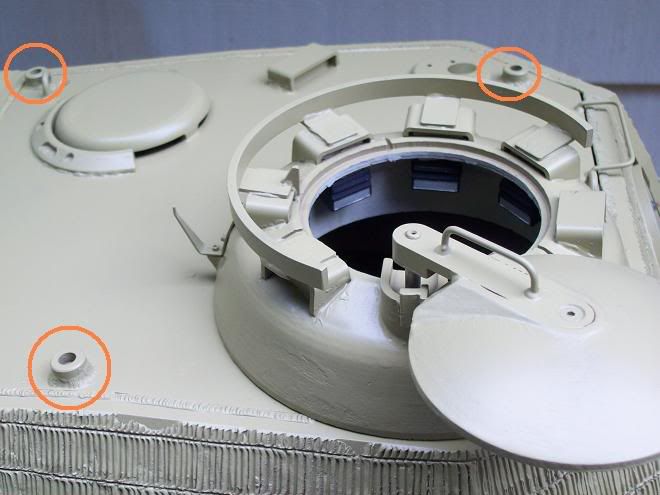

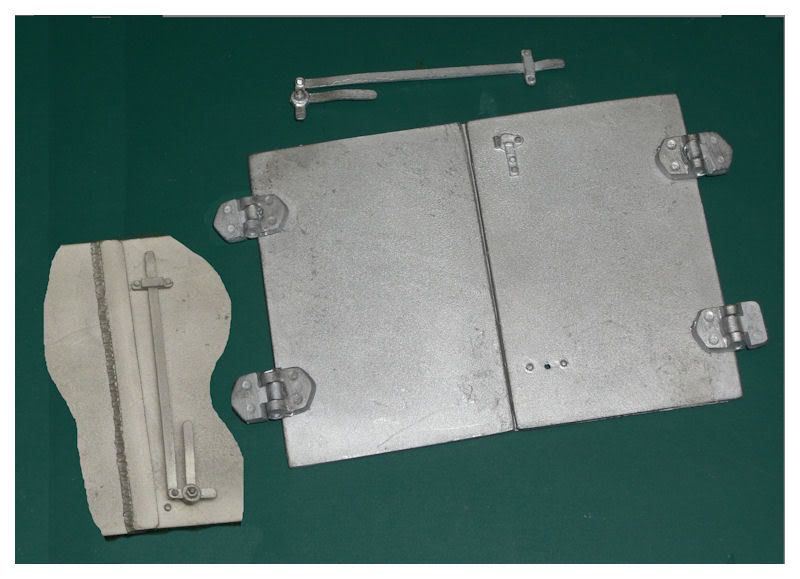

Here is a pic of one fitted on one of my Tigers, i had better pics but lost the hard drive on my computer and so...

i do not have one now to take photo's of for you unfortunately as i have sold them all but i still have my drawings

.

As for wether or not they wer used on the SDKFZ 7 i would tend to say no? but... i could be wrong there so lets Google it and see who gets the answer unless someone else can tell us?

Cheers Paul

Posted: Fri Oct 24, 2008 5:30 pm

by Stewart Ashton

Excellent pic Paul.

Looks a bit to hefty for use on a soft skin vehicle, but as you say

you never know

Regards Stewart

Posted: Sat Oct 25, 2008 6:47 pm

by Robert E Morey

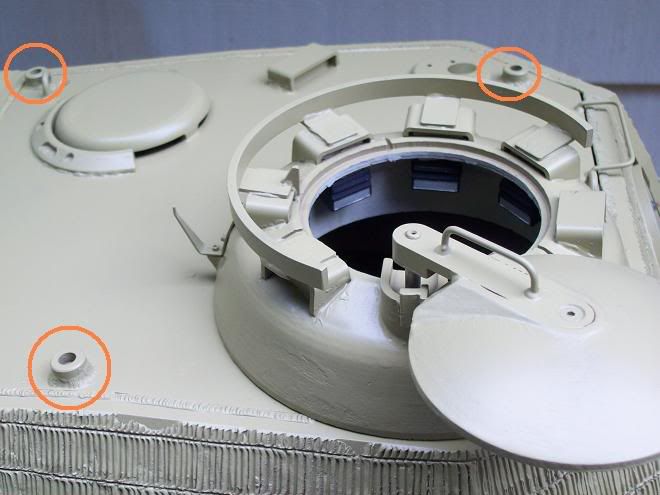

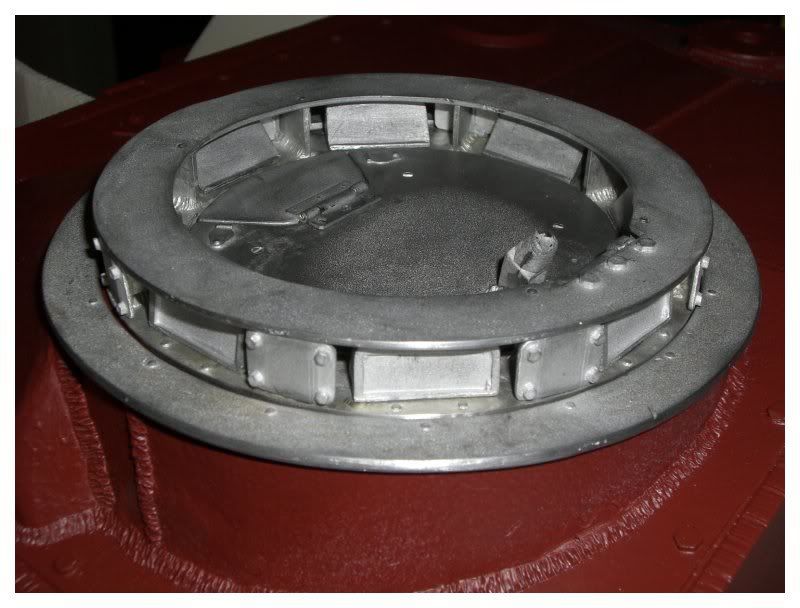

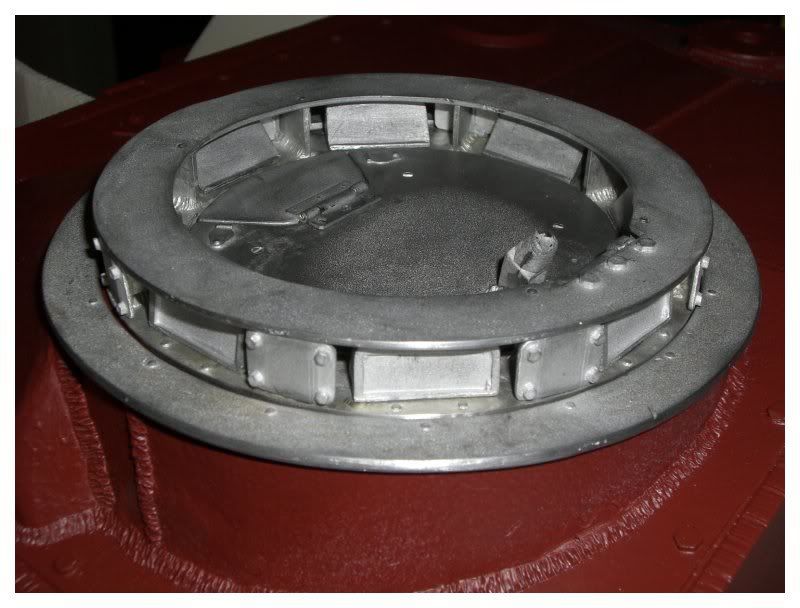

Heres the location of the pilse sockets on the Panther turret. The crane was used to remove the heavy engine grates and drivers hatches when replacing the rear engine or front transmission. Really cool crane Paul!

Pilzen details

Posted: Sun Nov 30, 2008 11:34 pm

by Fabrice Le Roux

Hi,

Have been trying to find snaps I took a couple of years ago of the Bov Hetzer sockets but without sucess. However I have a very clear recollecton that the sockets were:

a) welded with their top edges horizontal to the ground. This was confirmed visually on the Shriv KT in October.

b) Each socket had a small 5-8mm drain hole at the bottom to allow rainwater to run out.

c) Each socket had a coarse internal thread machined in hold the jib eyes in place in operation. Obvious really but no one else has mentioned it, and I only discovered it by reaching up and sticking my finger into the socket. Much the same way I discovered AC voltage at an early age

!

Cheers all and belated Happy Thanksgiving to my American friends.

Fabrice

Posted: Mon Dec 01, 2008 9:47 am

by Kent Wiik

Hi Fabrice,

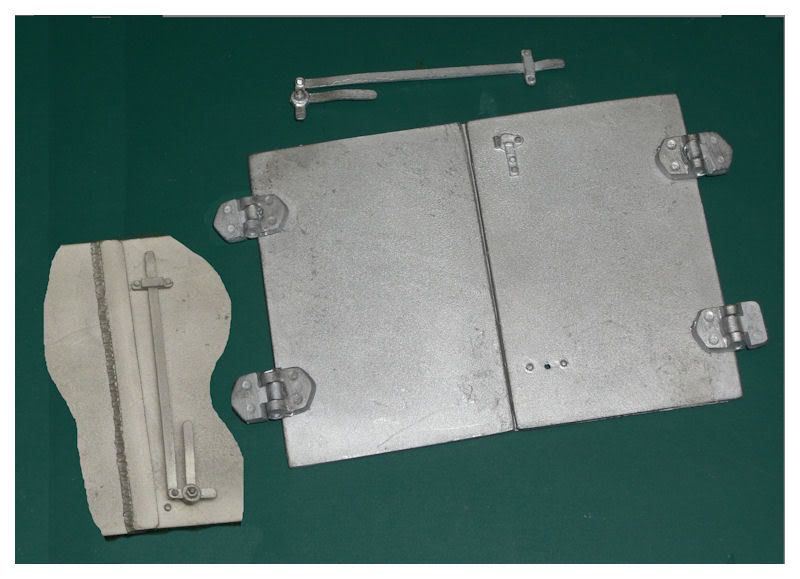

Good eyes (or fingers...), here are 2 photos of the Vimoutier Tiger I that shows the drainhole and thread. Also note how the hole end was sloped 45 degrees.

Cheers

Kent

img]

img]