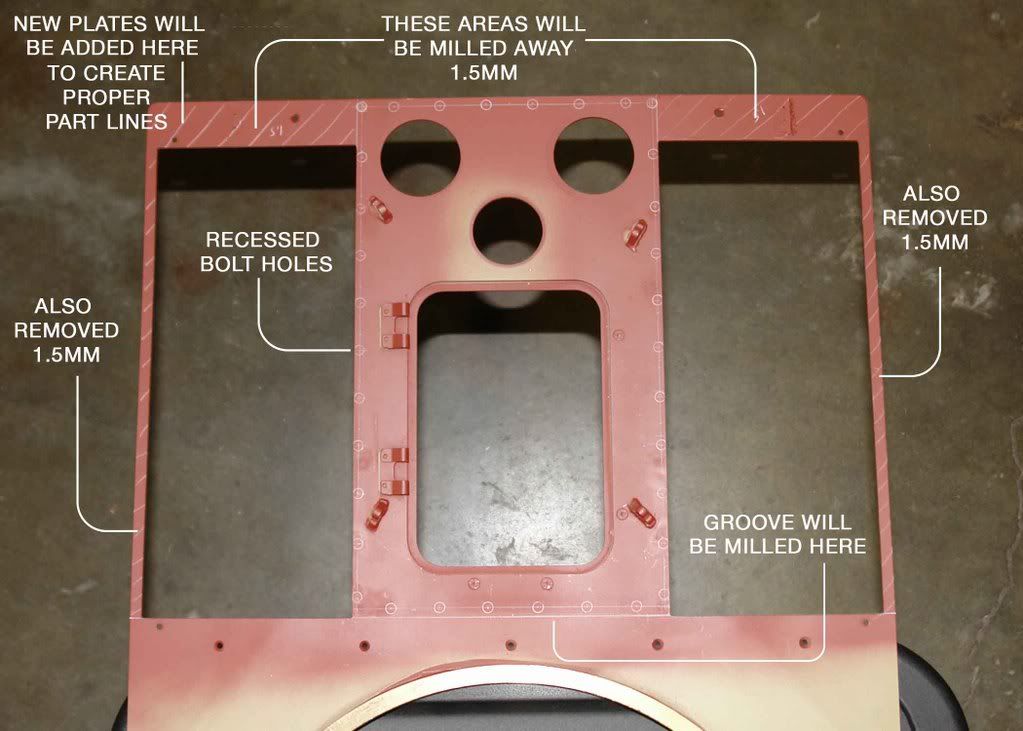

Well, I've procrastinated as long as I could on this part and was even thinking about skipping it all together because I'm so anxious to camo. But, I decided this past weekend to dive in and get it started. I'll be detailing out the deck on my Panther with part(plate) lines, recessed bolts around the engine compartment, new intake guards and fan shrouds etc.

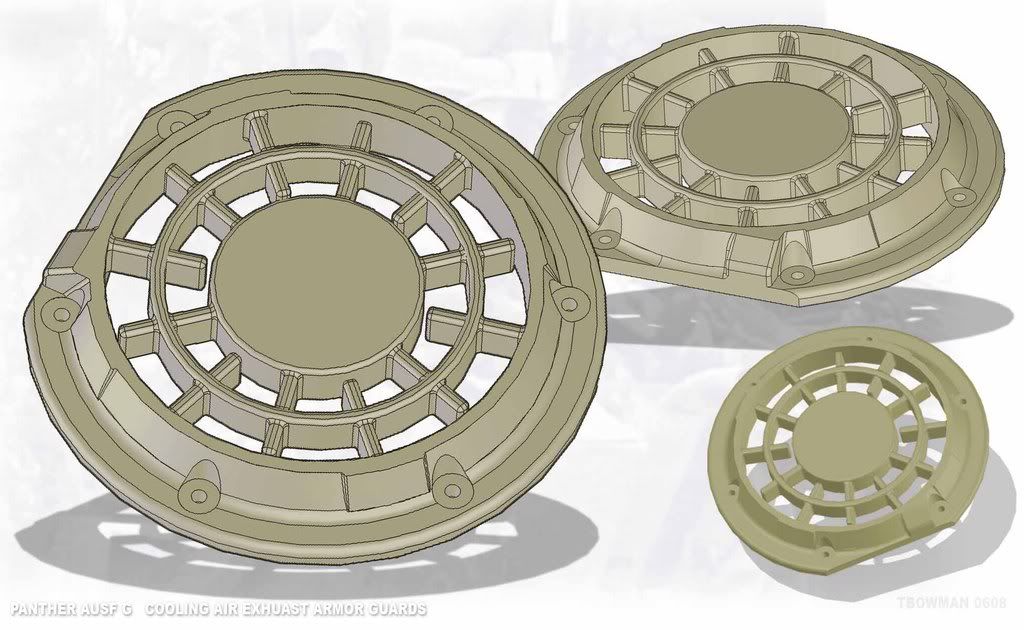

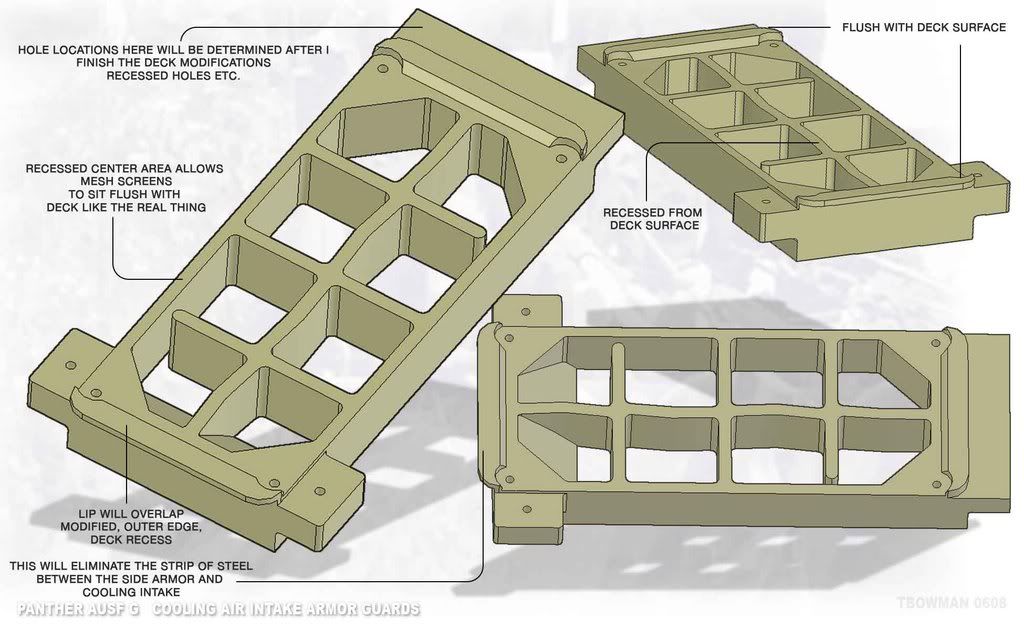

I don't have near the patience or the craftsman skills of Kent or Bob, so my fan shrouds and intake guards will be SLA parts.(similar to the idler parts I did) So far, just the intake guard computer model is done and I'll make SLAs when I have both complete. Then I'll detail them (casting texture) and mold them perhaps for metal castings.

Anyways, here's the rear deck before it goes under the cutter as well as the 3D file for my guards. I'll post more as I progress.

Thanks Derek, Bob and Kent for the kick in the pants I needed.

Kind regards

Tim