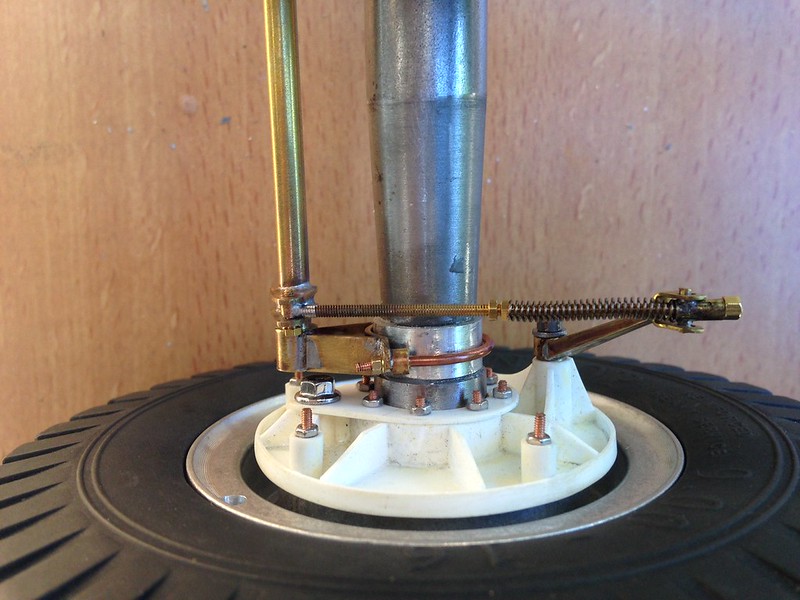

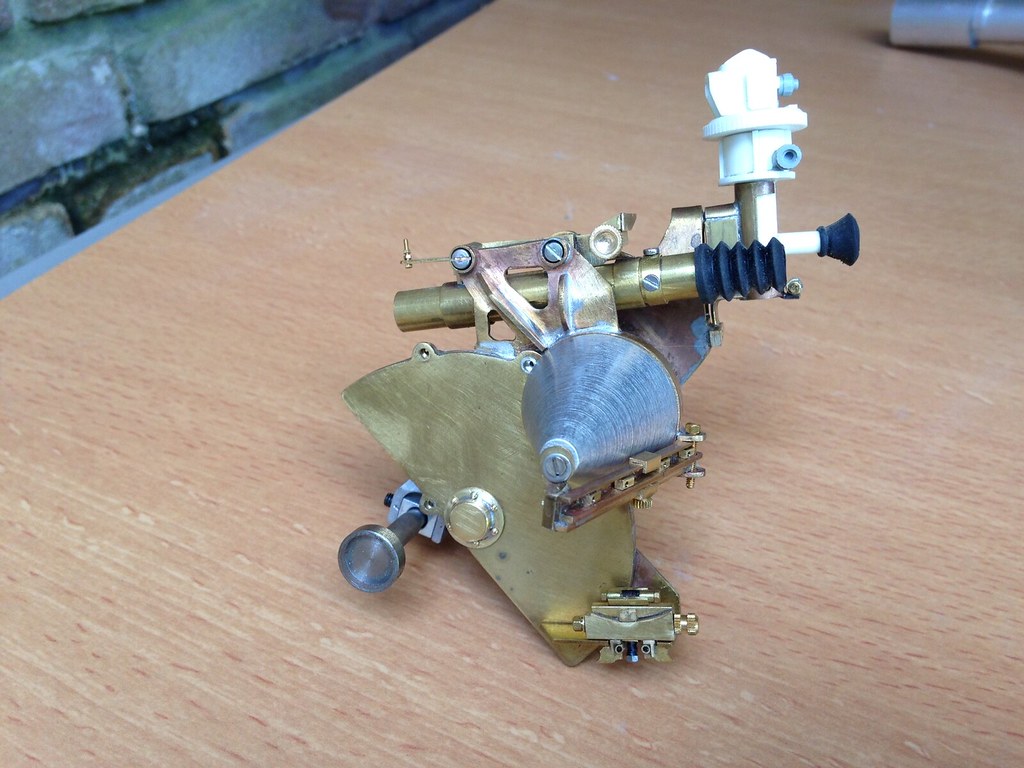

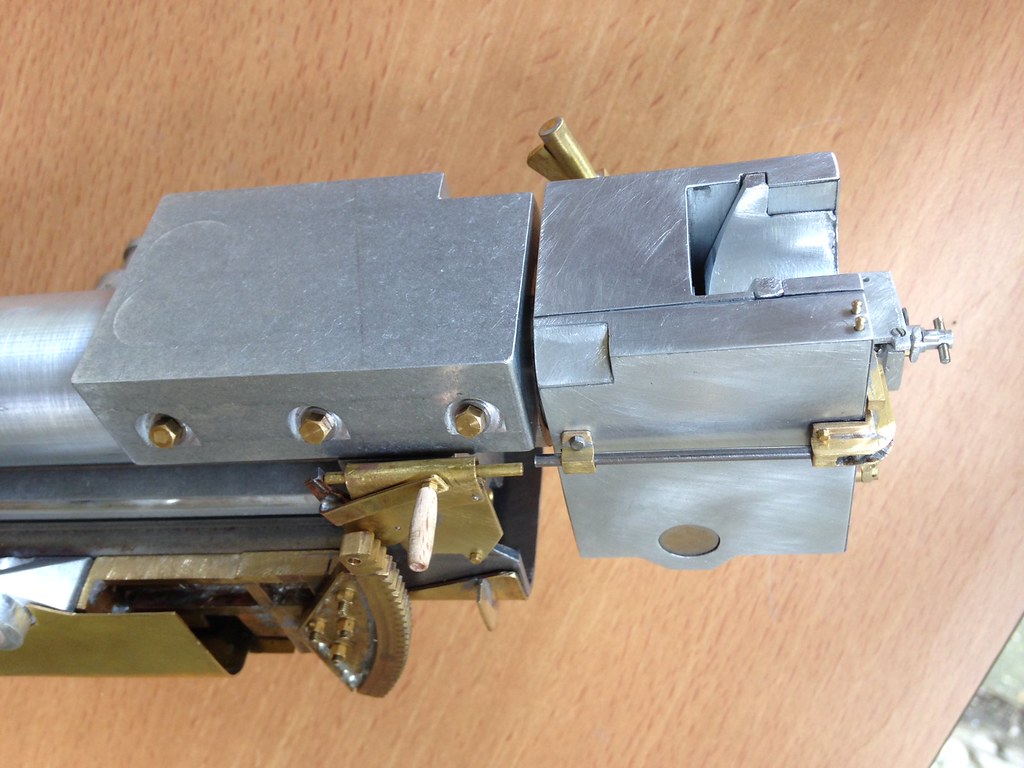

Parallel to the sight system I tackled the barrel and breech block. The kit barrel is about 25mm to short, this is most notable on the part of the barrel protruding past the gun cradle. The muzzle brake was initially almost in line with the cap on the gun cradle. A piece of aluminium tube of 20mm was added to the barrel and ground flush:

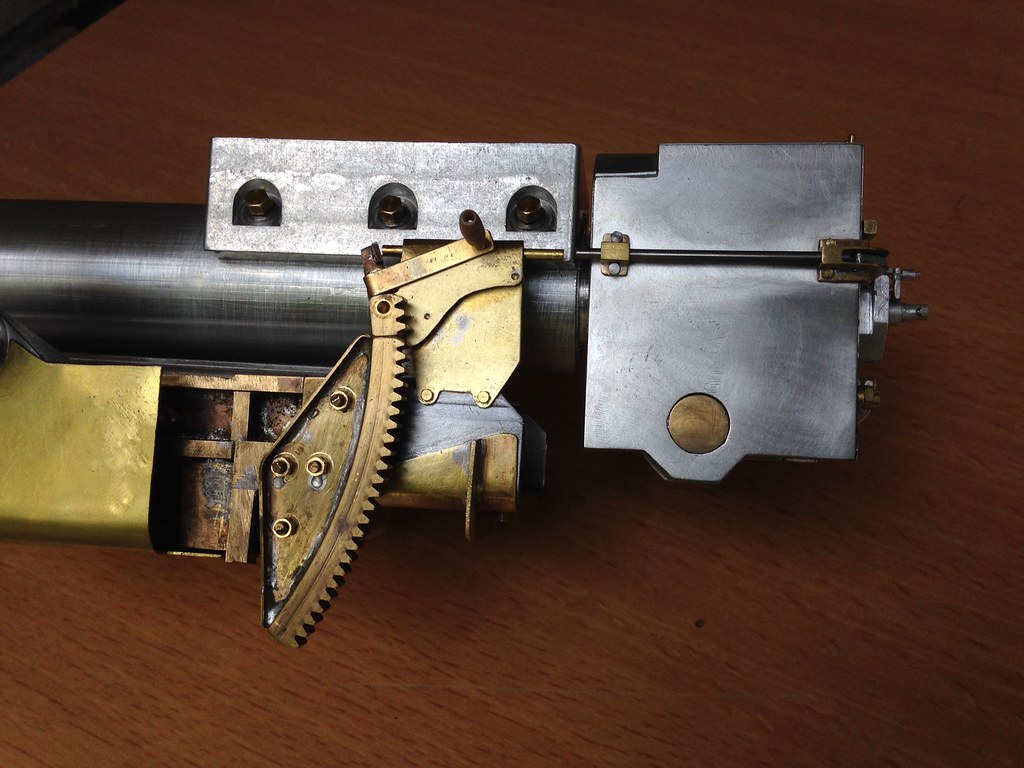

The last 5mm was added to the breech side of the barrel, actually I replaced a large part of the rear of the barrel with a 32mm aluminium tube. Not only to lengthen the barrel but also to accommodate the breech insert with enlarged chamber to be able to feed Dave's shells and my own shell casings. Incidentally the brass plug supplied in the kit has the correct outer dimensions of the shell casing.

New holes were drilled and tapped to fit the counter weight. The splice will be hidden under the barrel clamp.

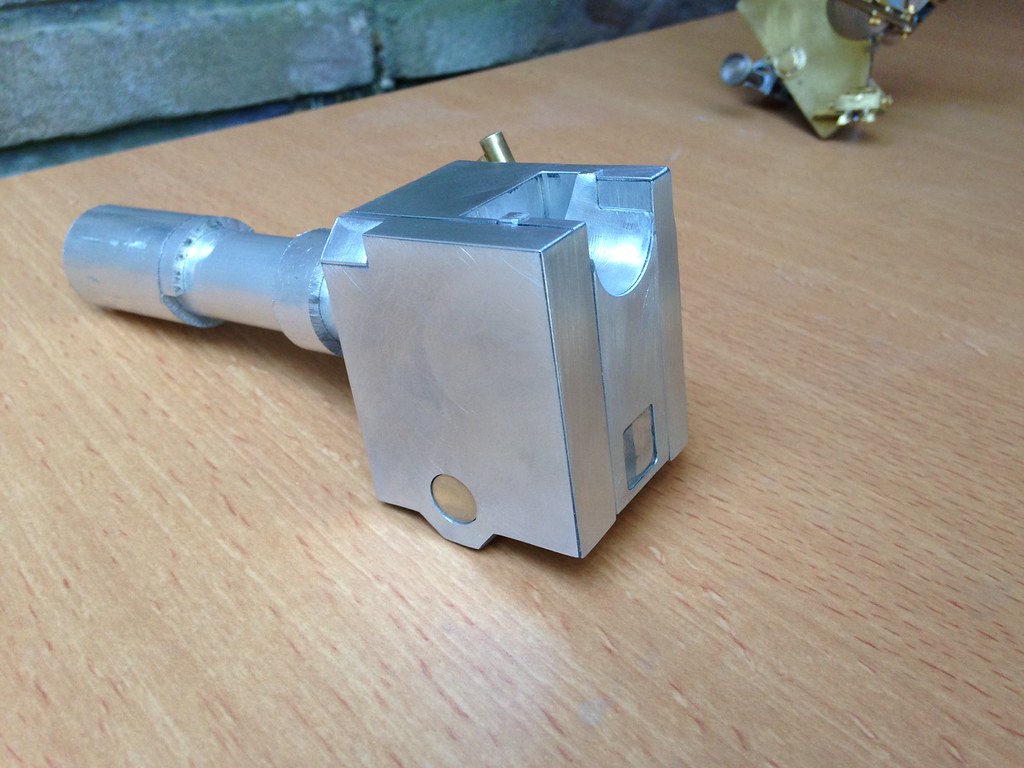

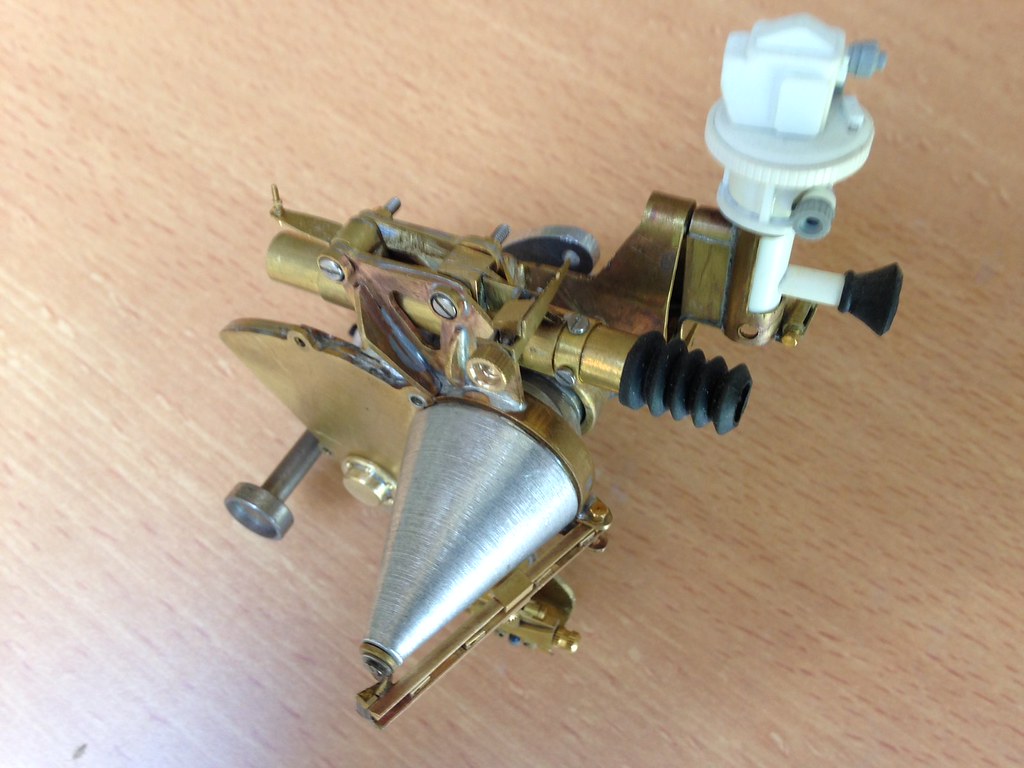

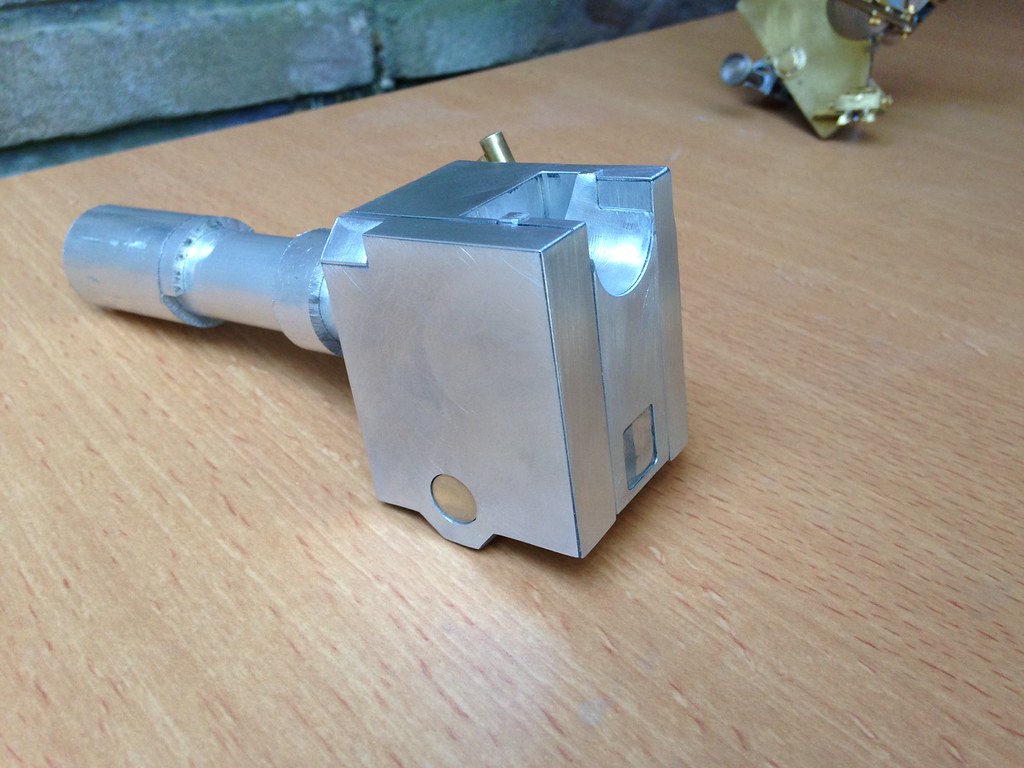

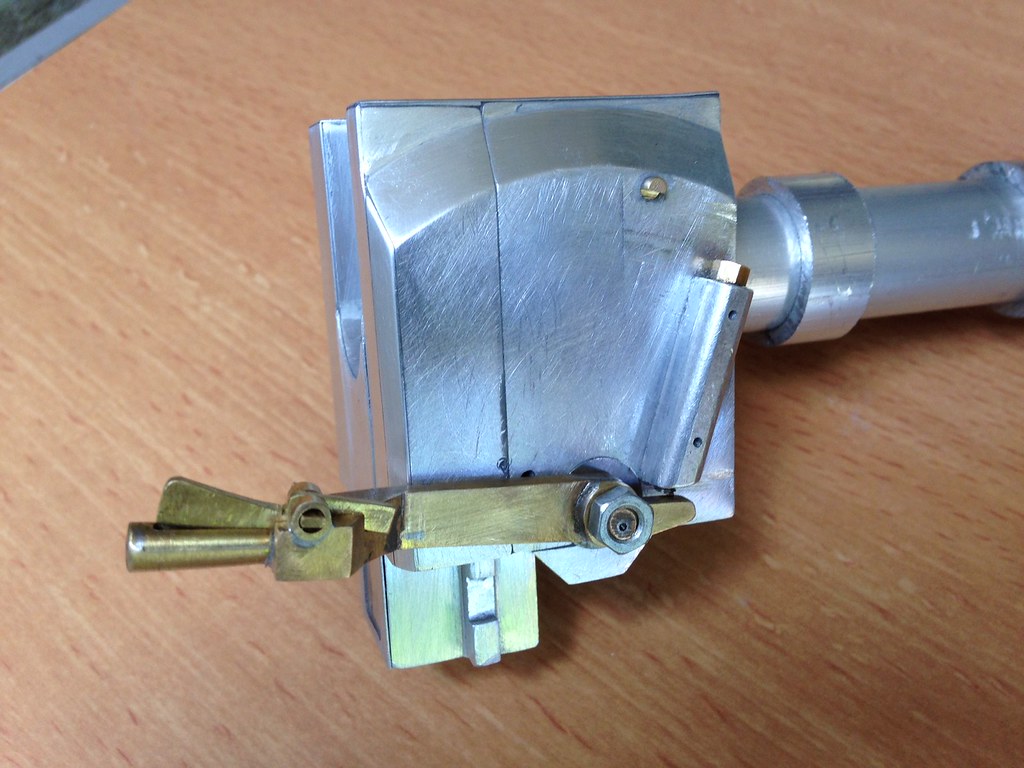

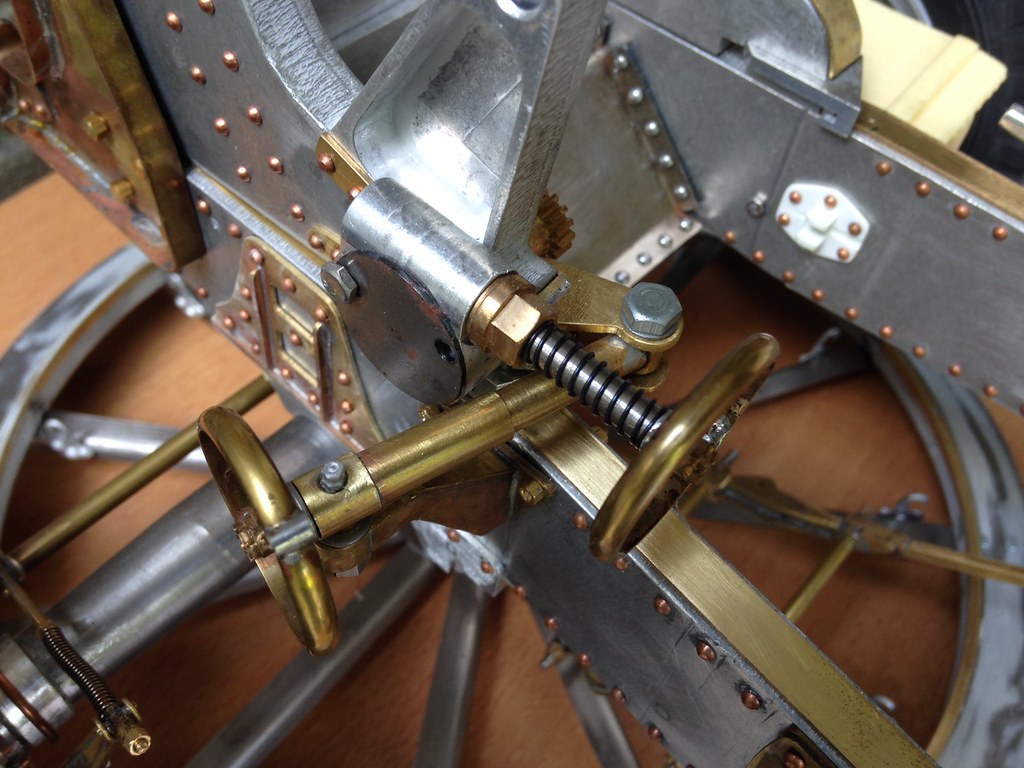

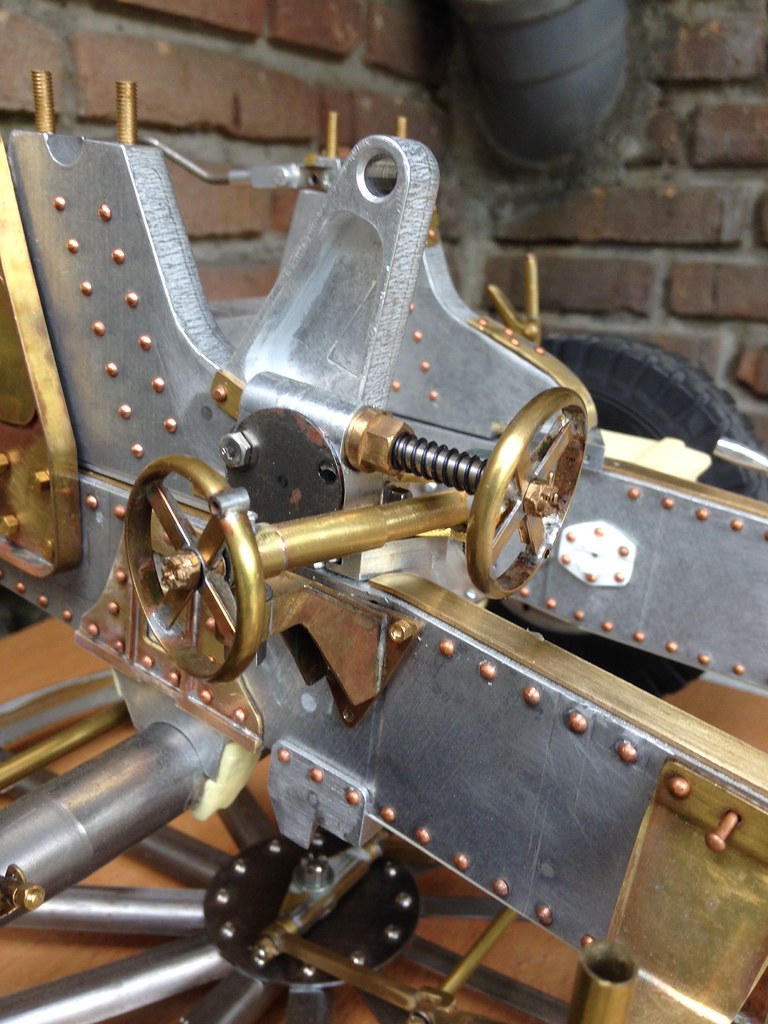

The breech block with the enlarge chamber, I had to add some spacers to have it fit inside the new barrel tube, the small square on the breech block is for the future cocking mechanism:

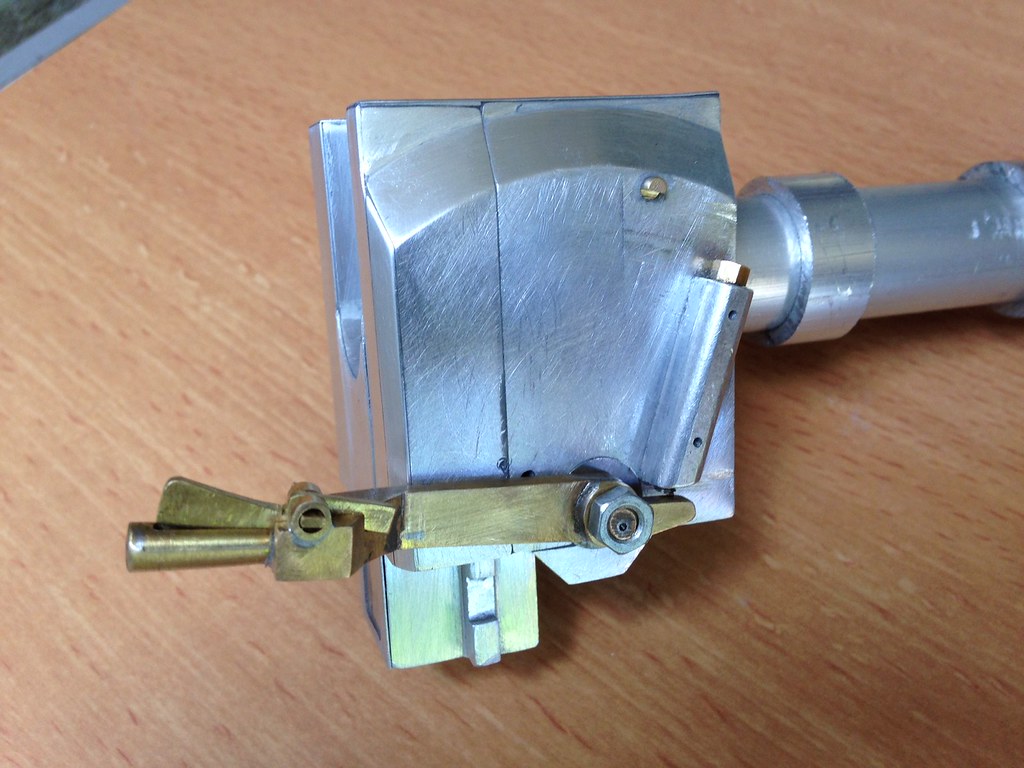

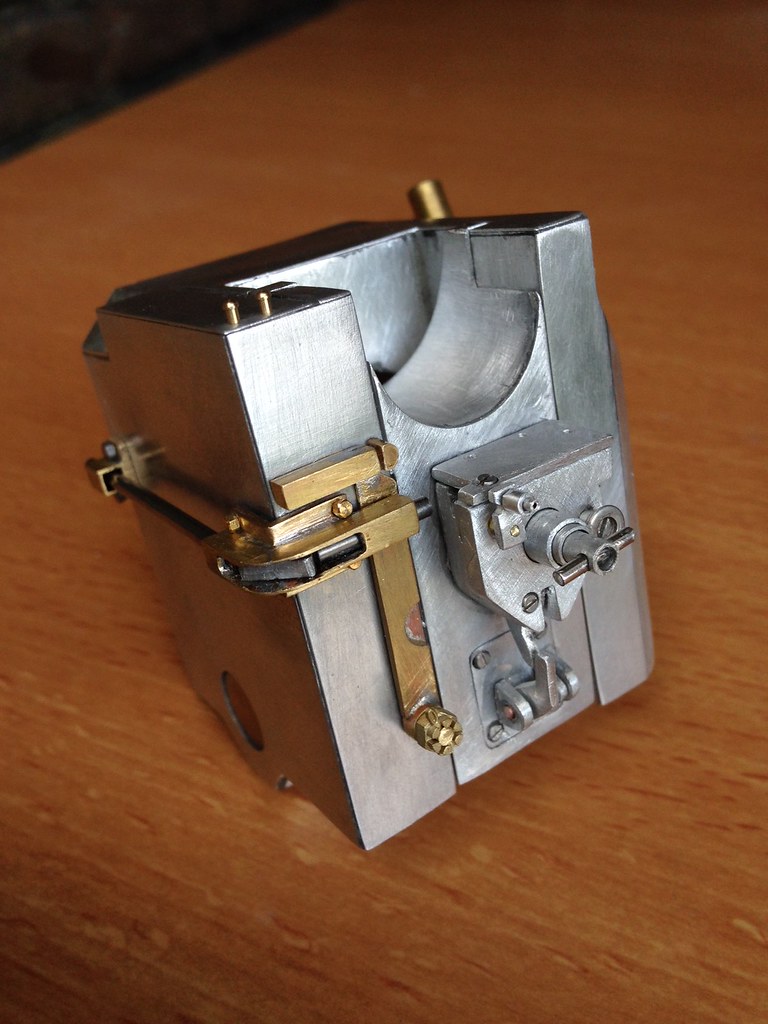

The breech was laminated with 0.3mm thick aluminium plate to eliminate the splices of the kit parts, the breech block axle was added and the breech reinforced where the axle pierced the lower part of the breech (bump just below the axle).

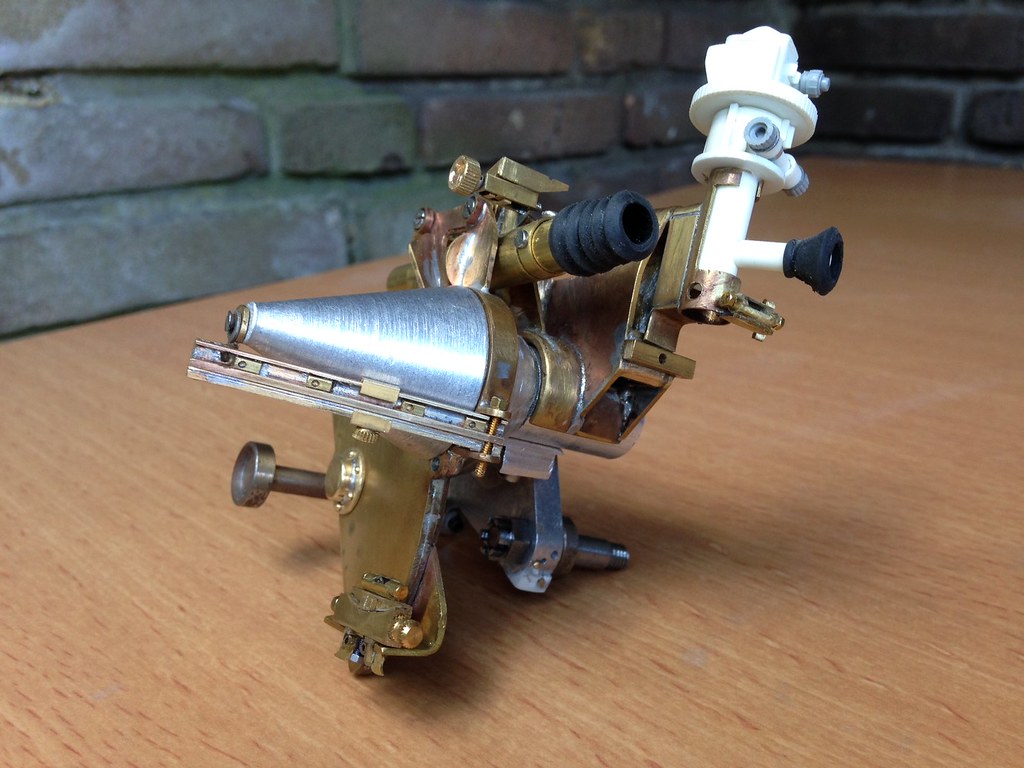

Breech handle:

Breech open, note handle locking boss:

The breech block was profiled/angled on the back and since I had to enlarge the breech block opening for the shell casing the front got the cut-out also present at most of the actual guns:

The slit visible on the back of the block is for the new breech actuation cam:

Cheers,

Marcus

.

.