Hi all,

Just finished some mod's to the gun shield. Actually I only intended to take the gun shield off, remove the rust and refit the shield to the gun..... I got carried away....

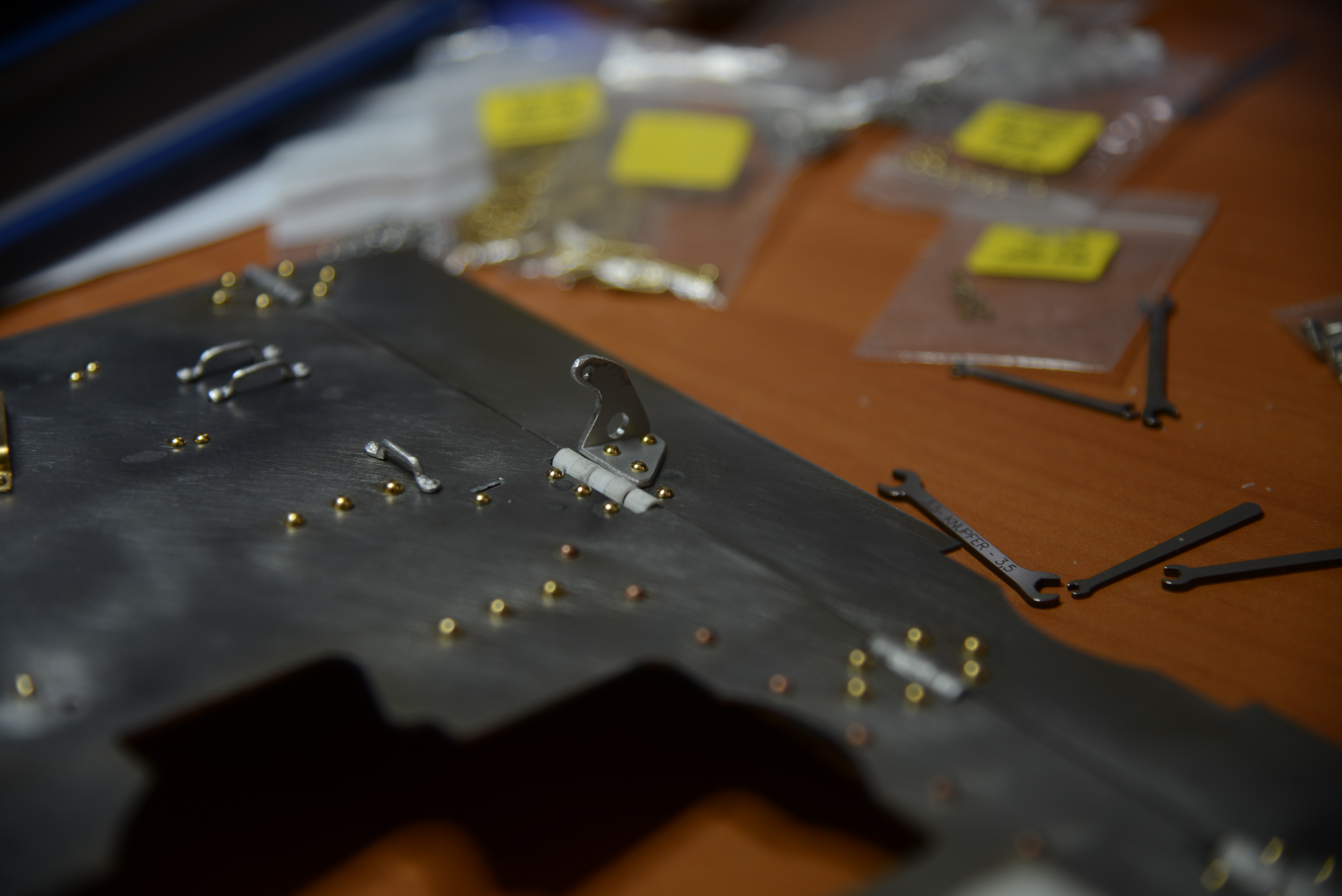

The major mod's were the replacement of the 2nd and 4th hinge of the gun shield top. The 2 hinges have a different shape on the actual gun and incorporate the locking mechanism for the gun shield top in both folded down and extended positions. More on these hinges later!

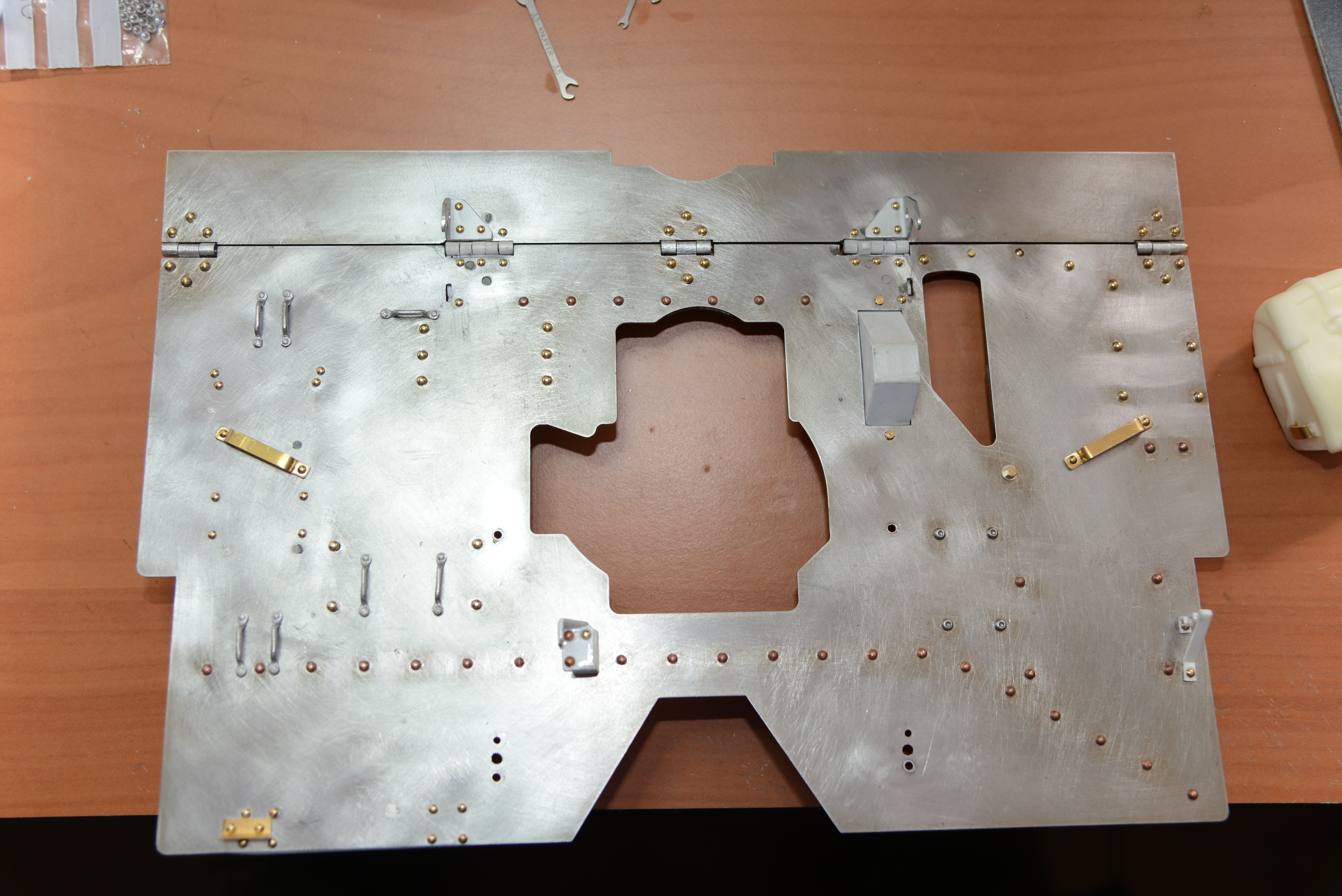

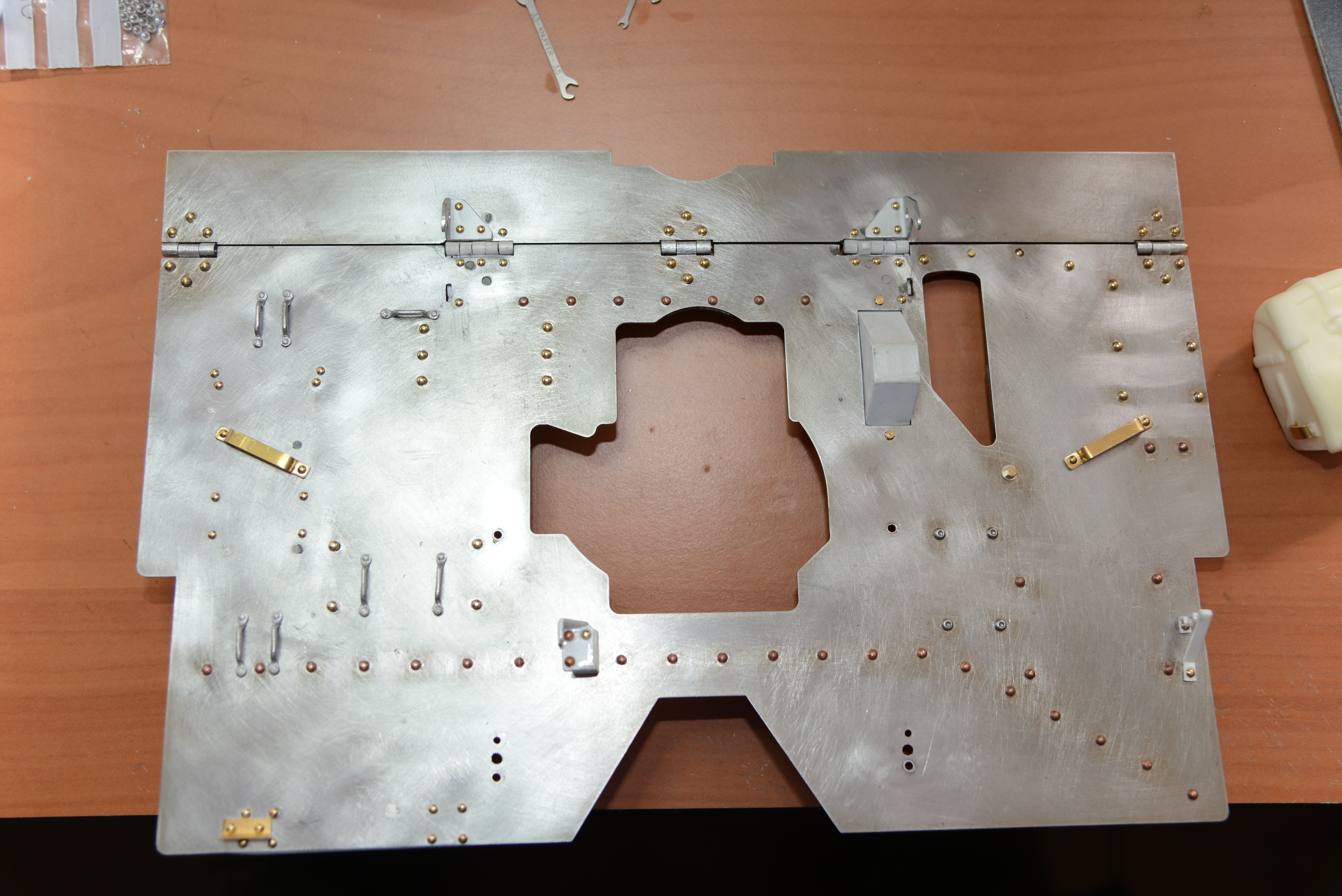

To the front of the shield 2 large handles were fitted, made of brass strip 4mm wide 0.6mm thick. In the lower left corner the stopper for the spade was added fitting neatly between the rivet clusters holding Dave's spares box to the gun shield. The stopper is a brass angle line 5.0x5.0x0.6mm.

Finishing touch are the tie-downs (Armorpax) for the spade and towing rope. For most of these fittings new holes were drilled in the gunshield. The original holes that were not used were soldered shut.

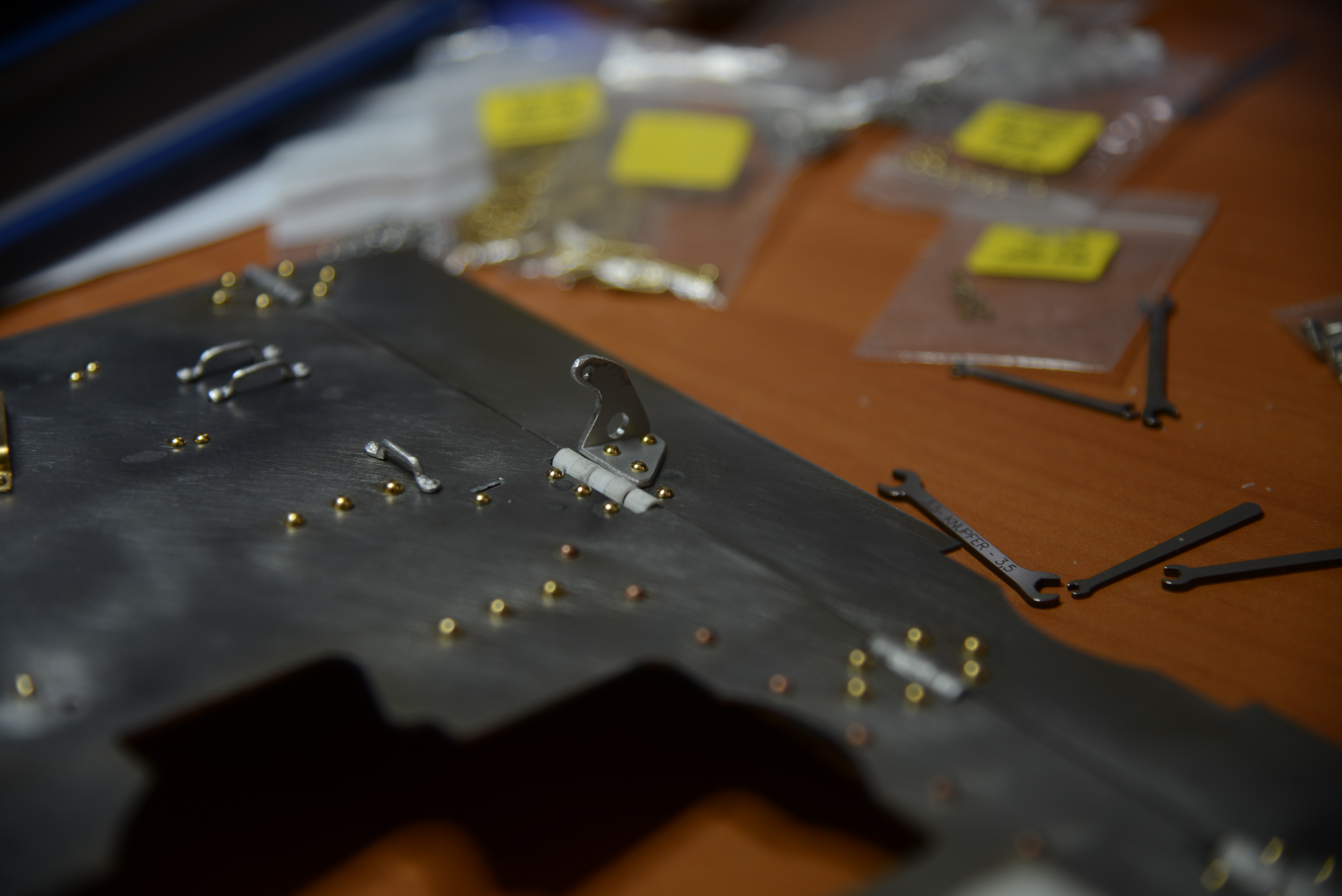

The two hooks just above the new hinges are the retaining hooks for the gun shield in the folded position and are part of the new hinge assembly. The hooks are cut and filed to shape from an aluminium angle line 1.0mm thick:

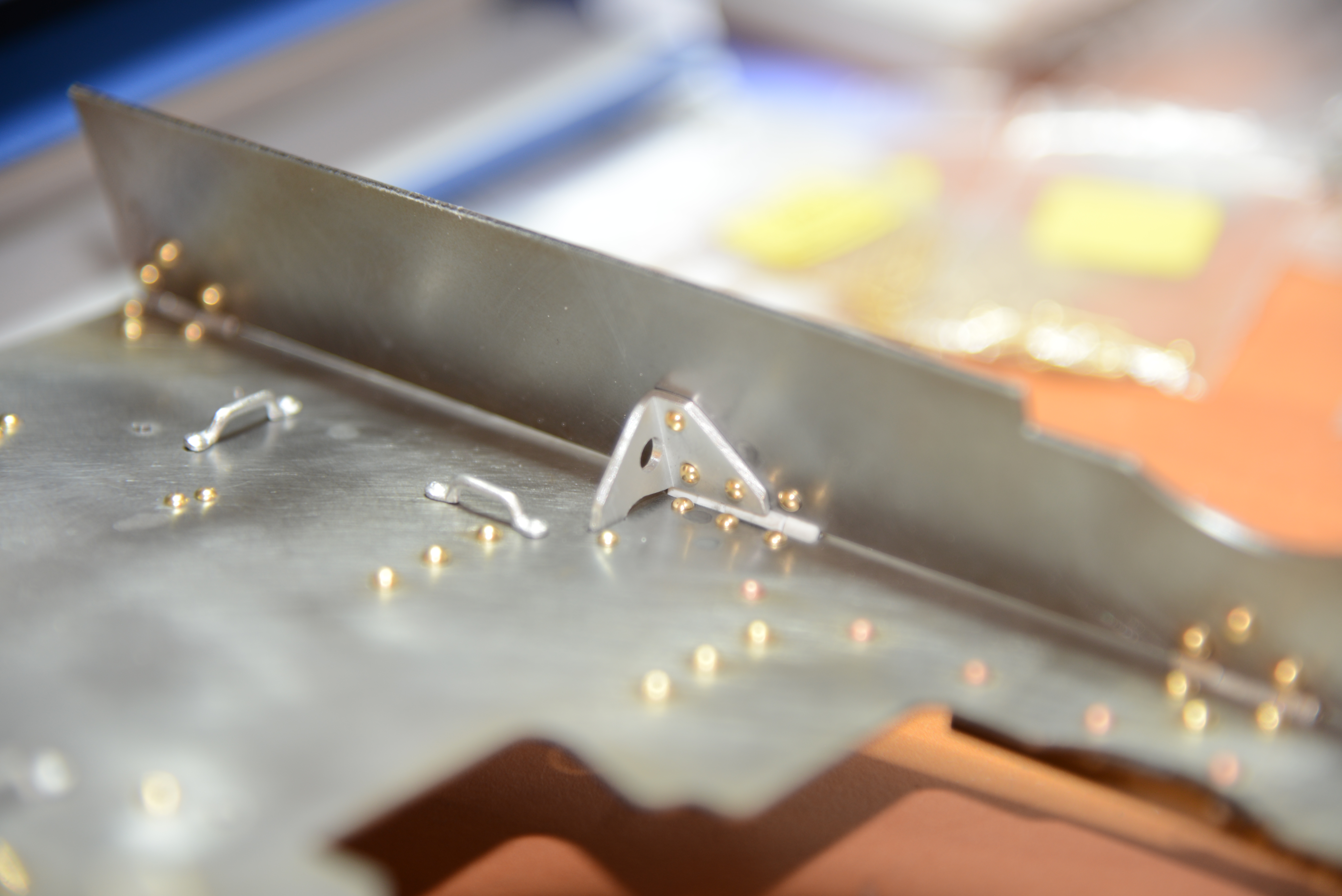

When folded down the tips of the hooks pass through slots in the gun shield so the locking bolt at the back of the gun shield can be engaged:

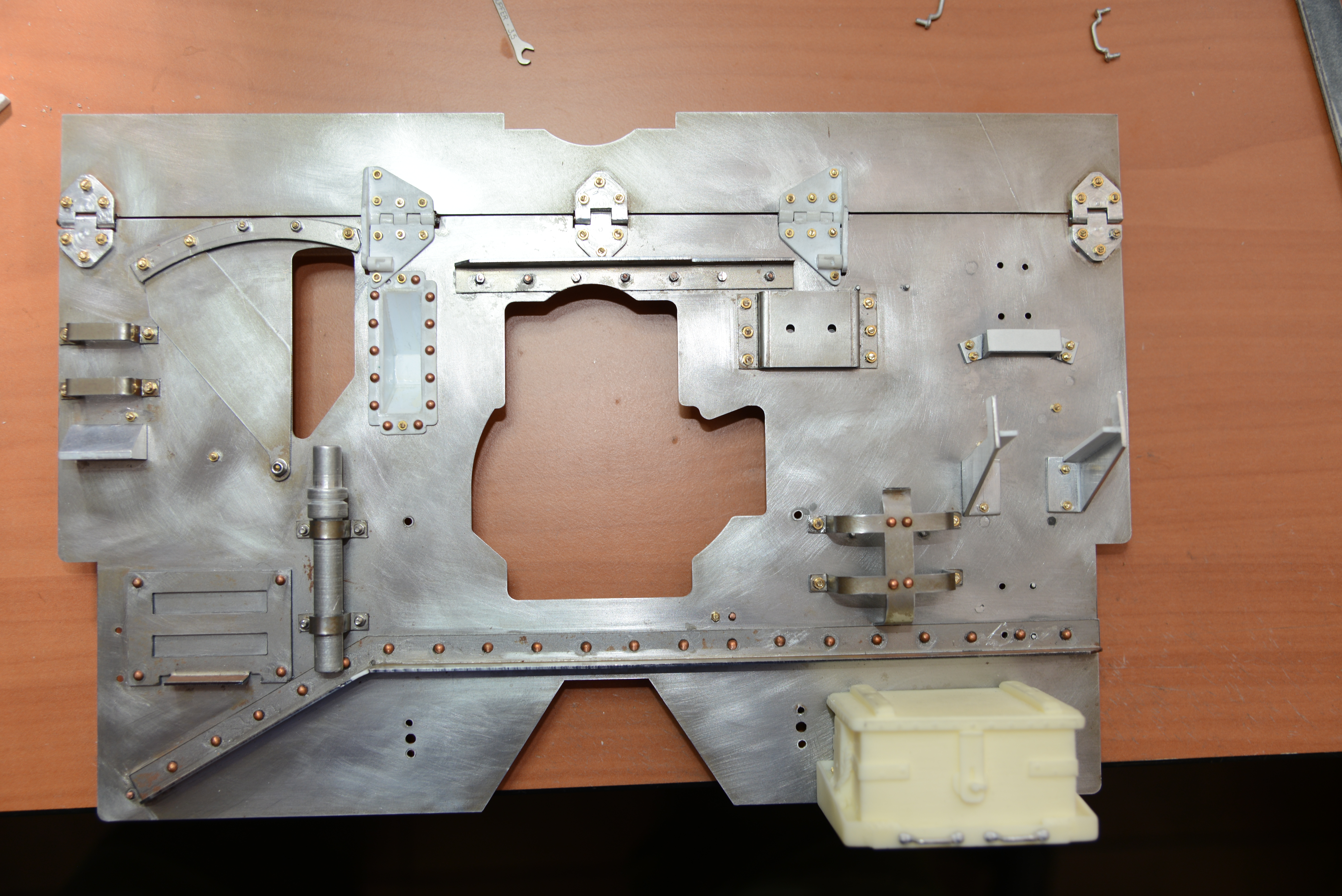

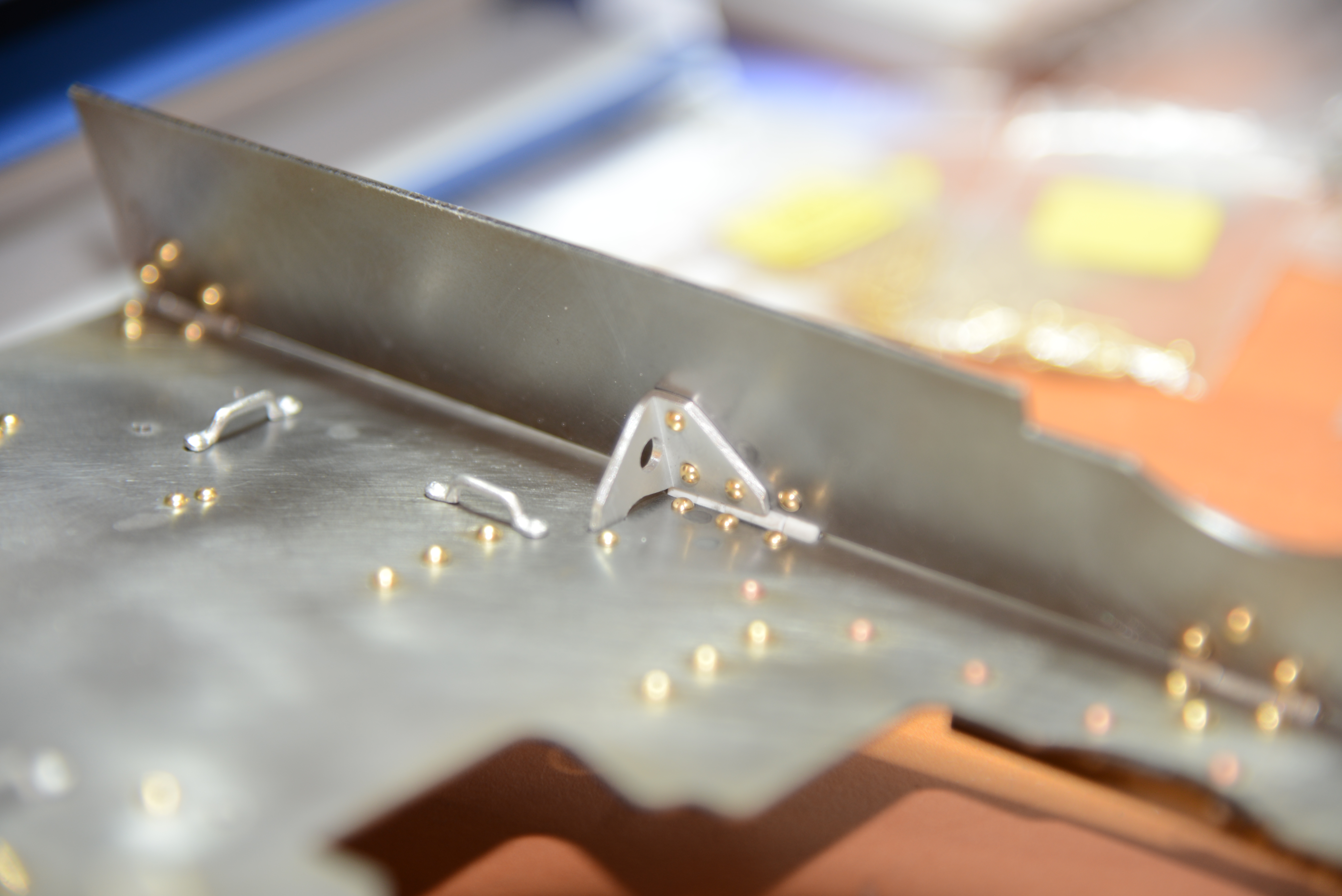

Looking at the back of the shield the tip of the hook is visible (actual locking bolt is missing in the photograph). Also visible is the locking arm for the gunshield in the extended position:

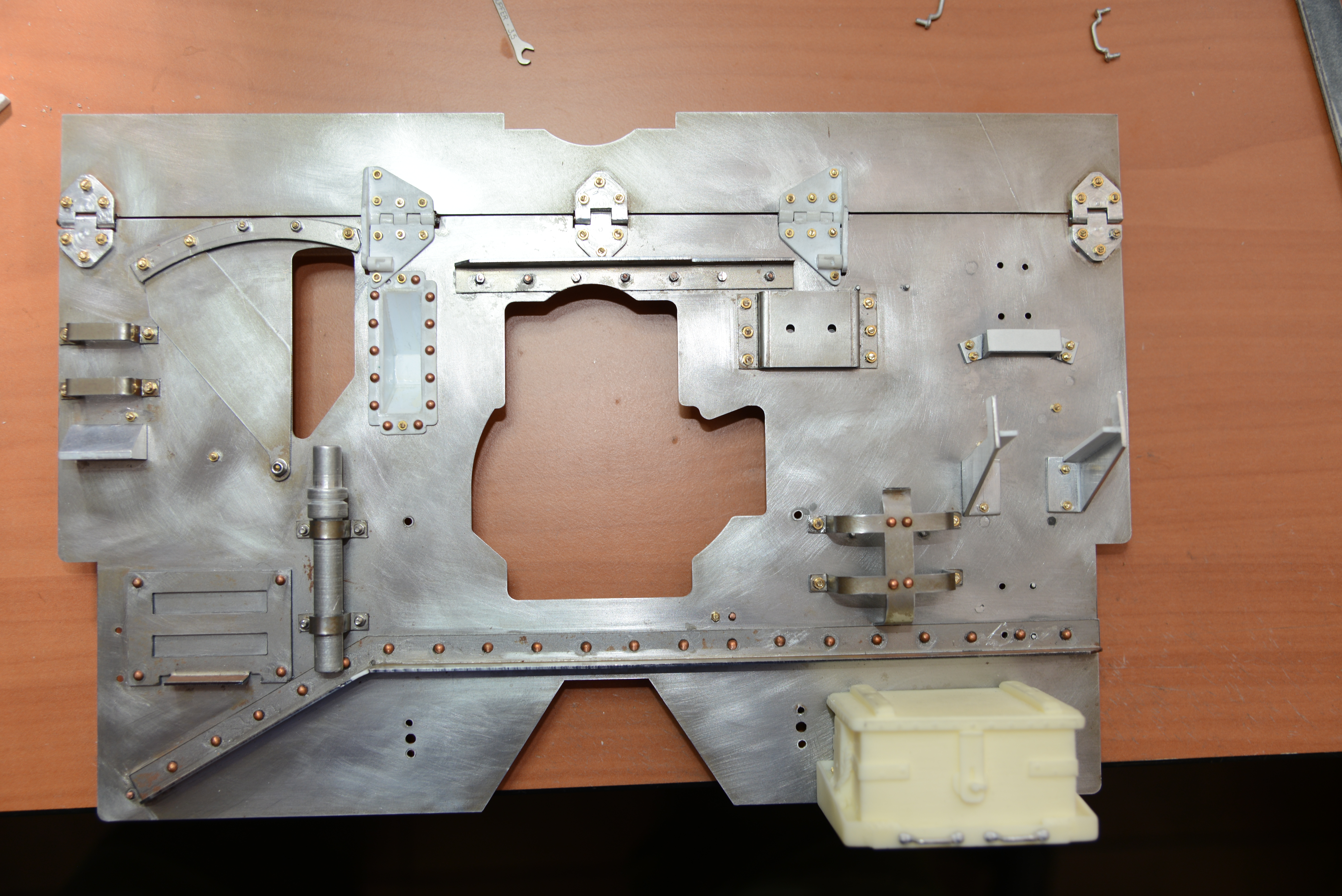

Now we are at the back of the shield let's look at the mod's here! Clearly visible are the new hinges and their distinctive shape. The hinges are in styrene but I am trying to make them from brass or aluminium since they are quite fragile.

I replaced the kit's one-piece sight carrying pouch/bag bracket EJ0237 with 2 separate brackets fitted with 2 bolts/rivets each. The whole bracket assembly was also moved a bit upwards. The position of these brackets differ slightly on the actual pieces I have examined, I just chose the position of an example in the collection of the 'Artillerie Museum'. I also replaced the upper bracket for the typically inclined bracket fastened by 4 rivets. All brackets were made (sawed and filed) from aluminium angle lines 1.5mm thick.

All gun shield fittings were fastened by brass roundhead rivets with a threaded shank (M2 and M1.6). I still have to trim them flush with their retaining nuts.

That's it for now! The work on the brake system has been delayed by these gun shield mod's but is next (promise....!!)

Cheers,

Marcus