I finally have something to post on the Tiger forum! I've been wanting to try this for some time. I made a CNC program to machine the ice cleats into the early Tiger 1 links to try to convert them to late syle tracks. I tried two different machining styles. Style #1 machines off the three rectangular early recess's off the existing link, then machines the cleats. The second style #2 does not machine off the three recess, but machines the cleats in the link pretty much as is. There are trade offs with both methods. Style 1 had fully complete cleats, but lowers the height of the link the most -this style will look the best. Style 2 reduces the height the least, but two of cleats are interfered with by the early recess and are only partial height, not full depth- the benefit is the height of the link isn't reduced much.

I think both styles look good after painting. Style 1 takes 17 minutes to machine each link, Style 2 takes 11 minutes per link.

The next step is to try and machine the guide tooth square hole! More to follow soon.

Thanks for looking, enjoy -Bob

PS I'm not quite ready to go into business machining links for everyone, this is just to show what can be done.

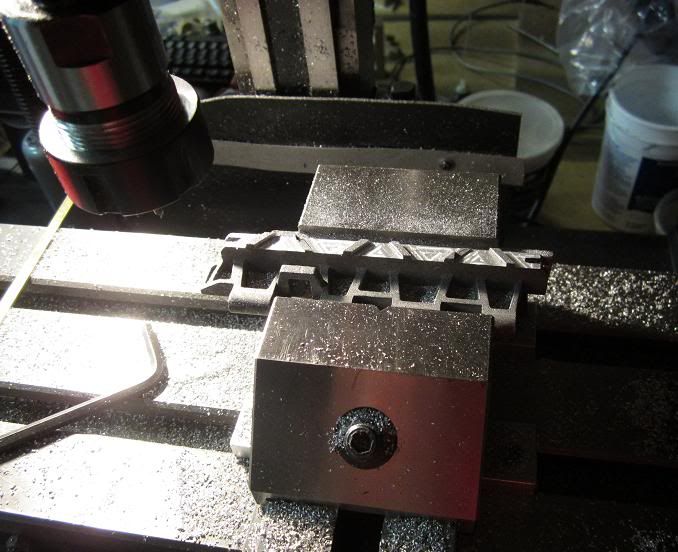

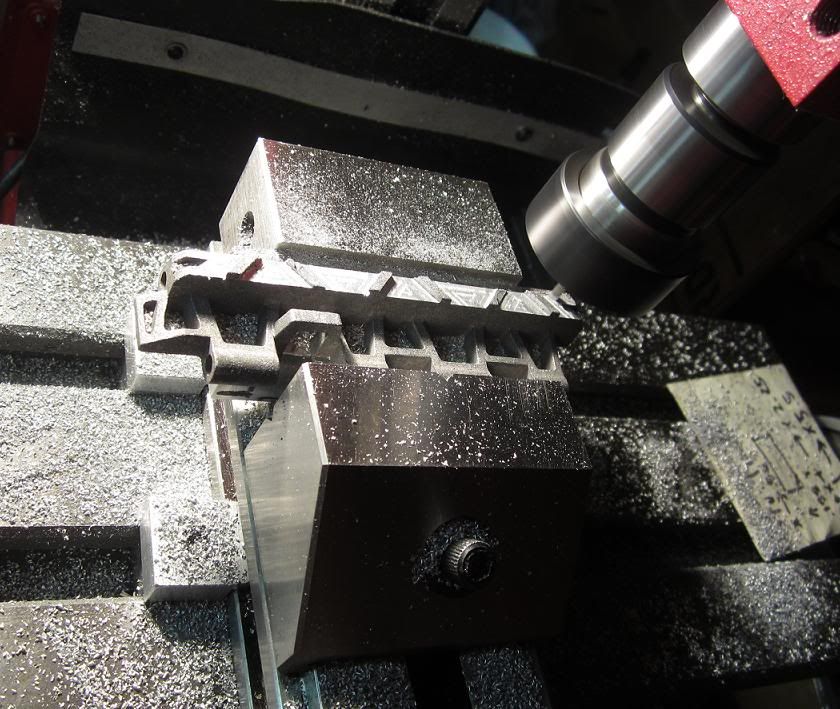

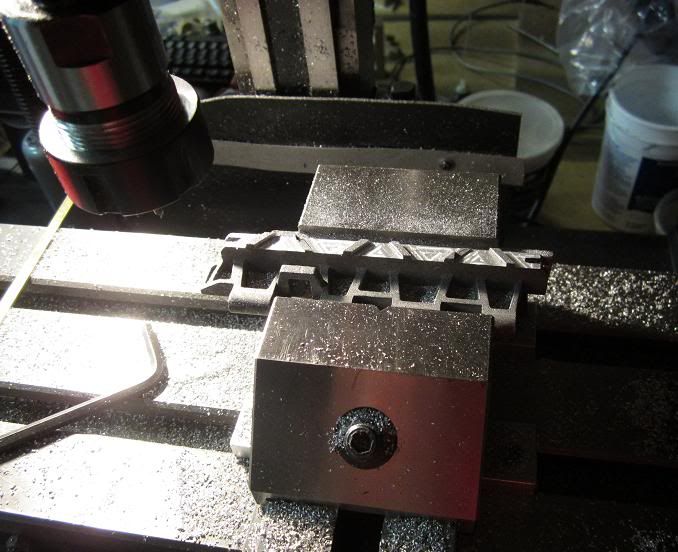

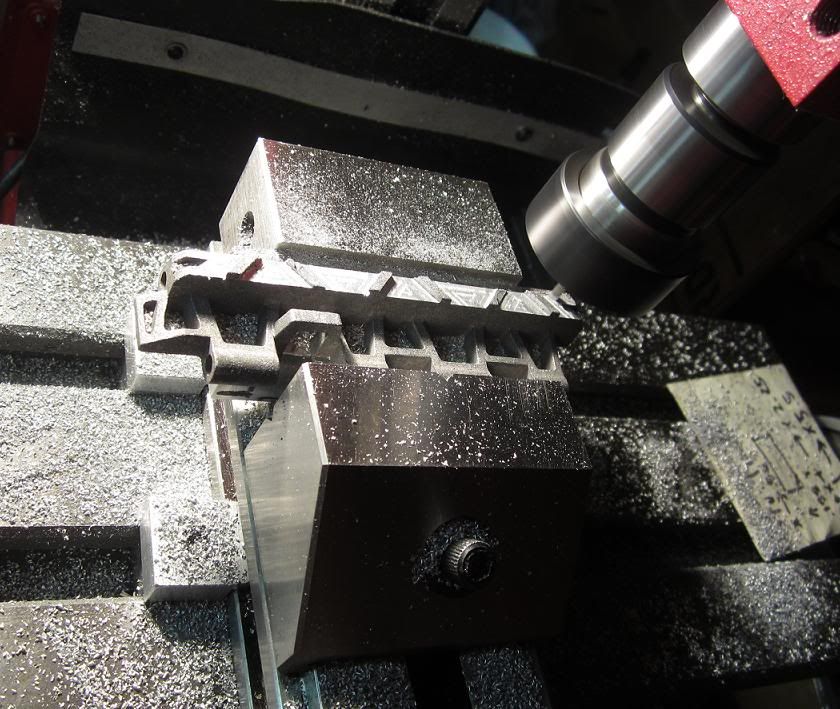

Style 2 link being machined:

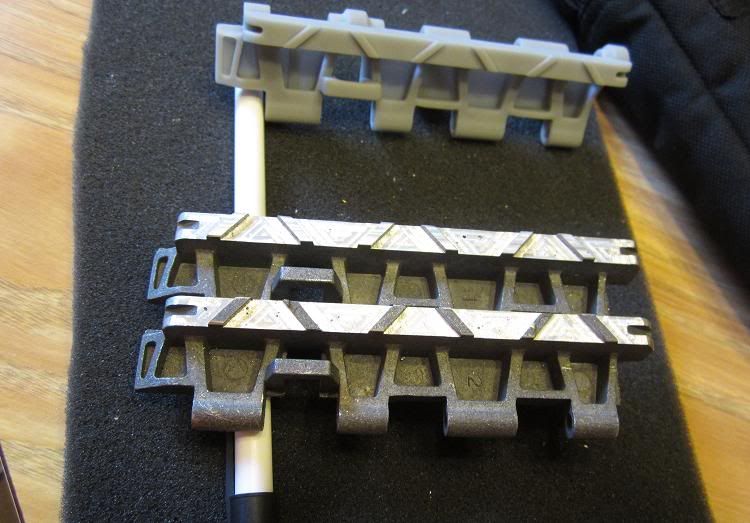

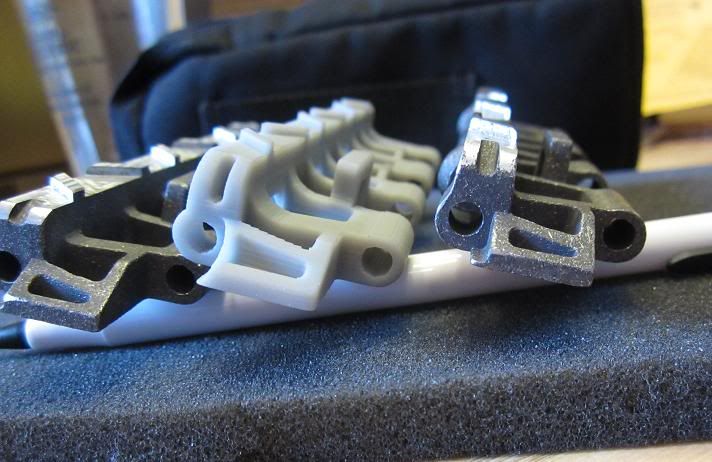

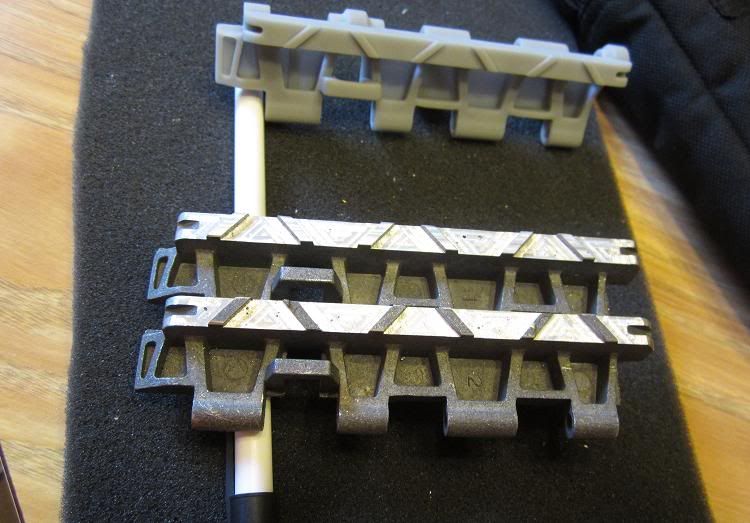

Style 1 after machining top, Style 2 bottom with Tim Bowmans excellent SLA

model in background

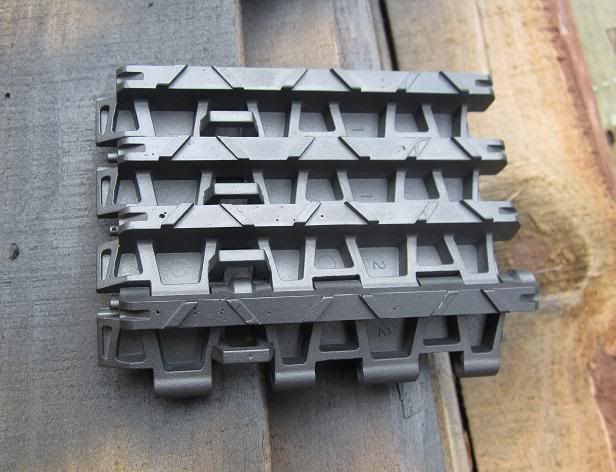

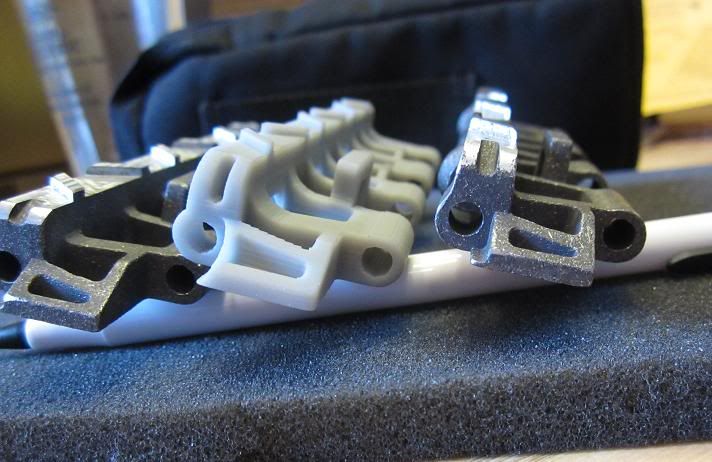

Height comparison, stock link, Style 1 on left, style 2 right

Height comparison with Tim's model (center). Style 1 left, style 2 right

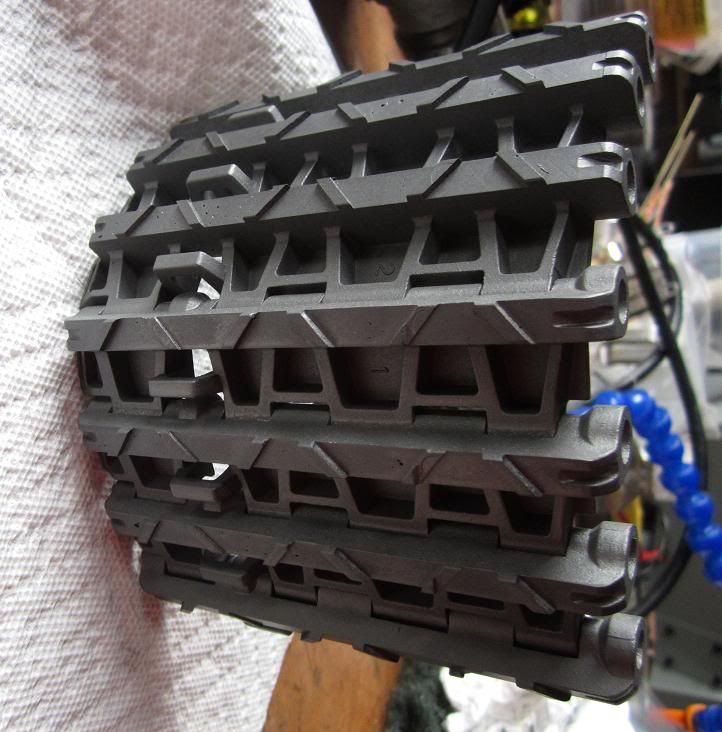

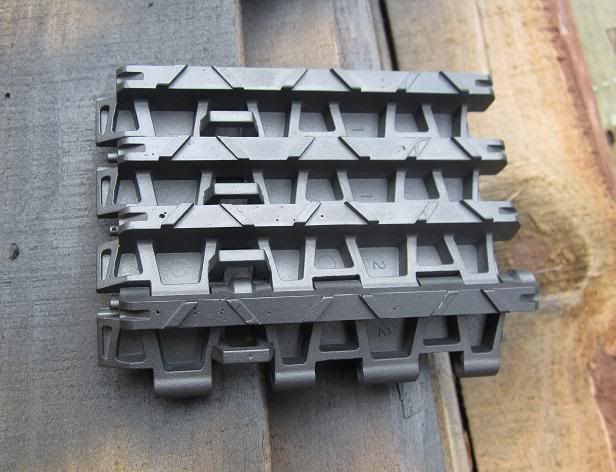

Style 2 painted

Style 1 painted

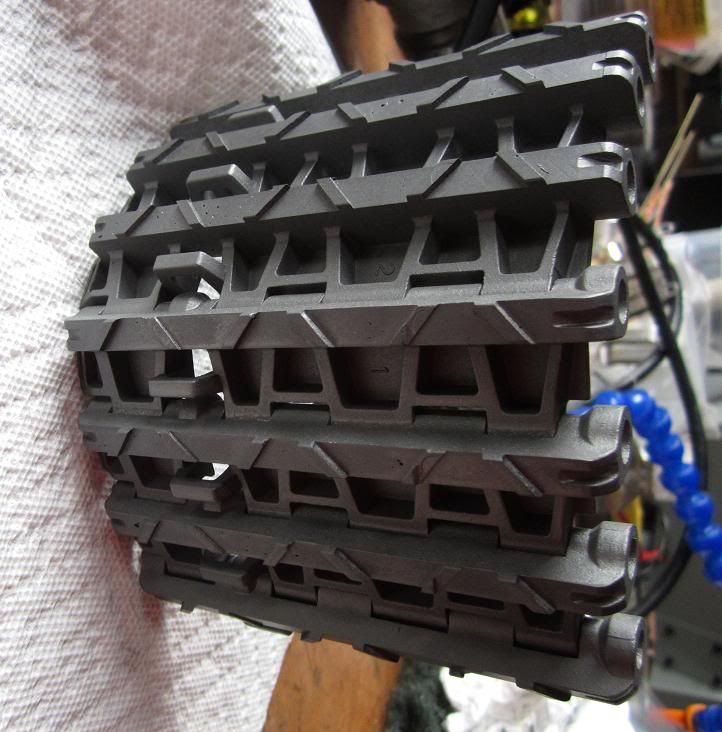

All together painted. Style 1 are the three links on left, Style 2 are the four to the right. Notice the partial second cleats on style 2 inboard from outer edges.