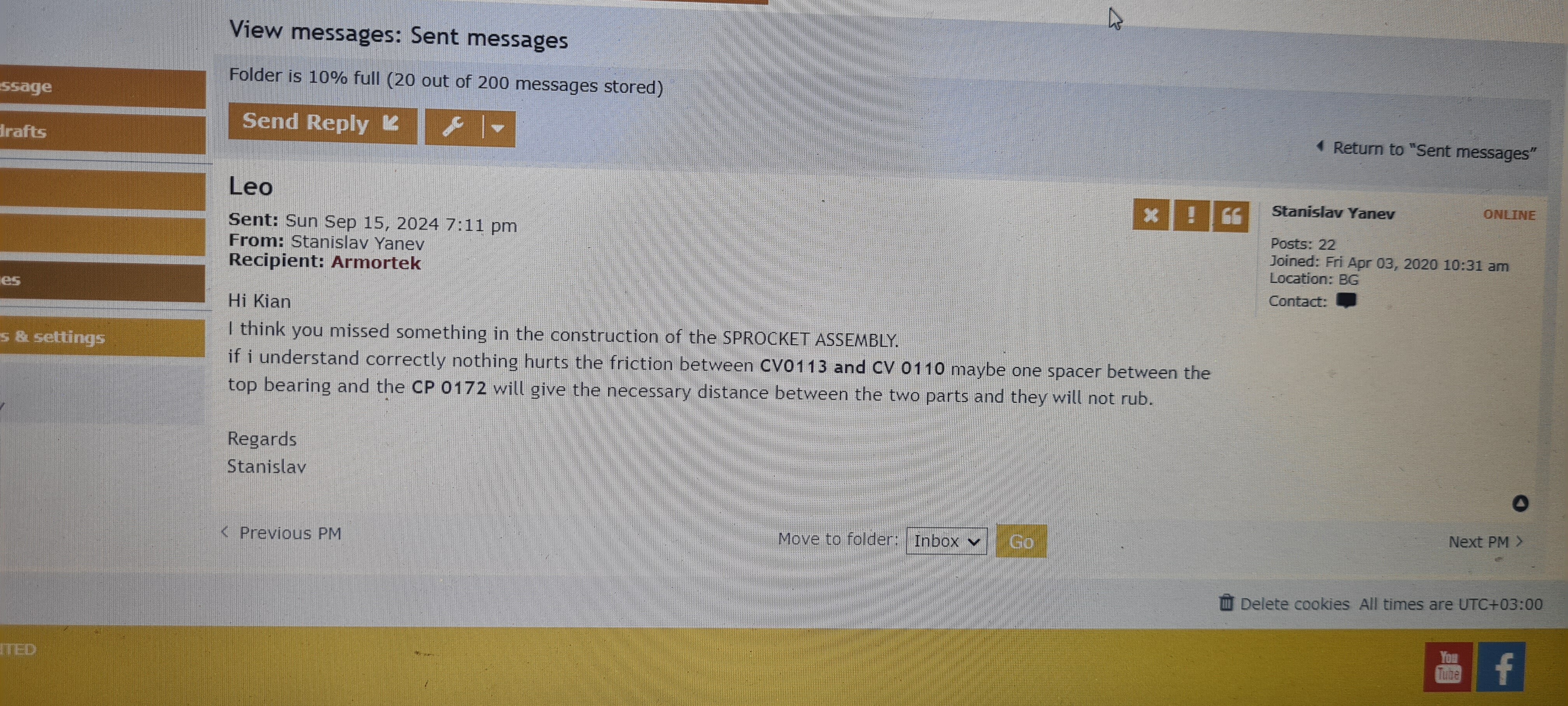

Stanislav,

Enjoy the hobby, it's personal journey to build the best model you can knowing every model will be an individual model, A one of a kind.

On the forum I sometimes make informal observations, possible remedies, but let other owners decide if they want to take any advice.

Of course any alterations I design or suggest won't be covered by the warranty on the model sold by Armortek.

Armortek will stand by their product and its build design and that's that. If you did find a fatal flaw and report it. I'm sure Armortek would be the first to acknowledge it. They've been doing this for a great many years.

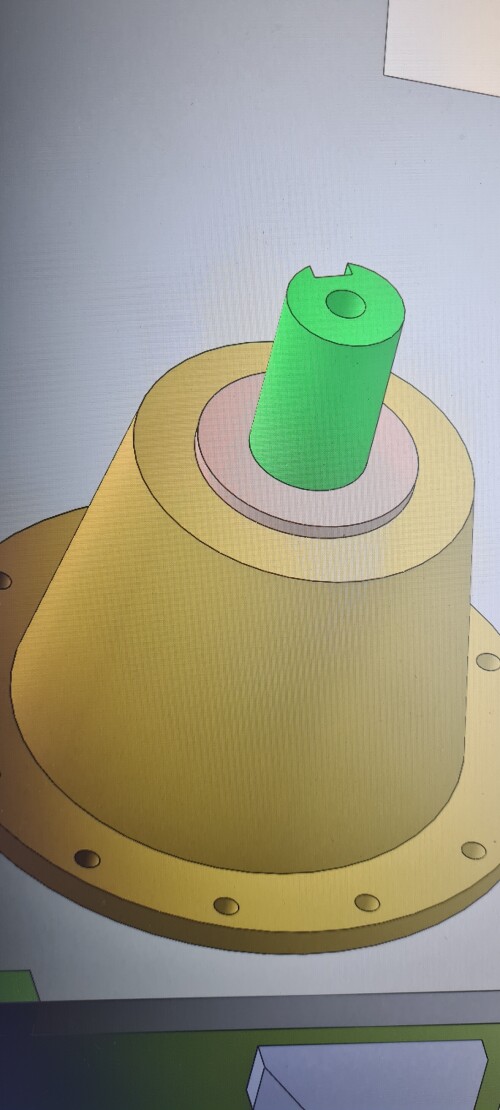

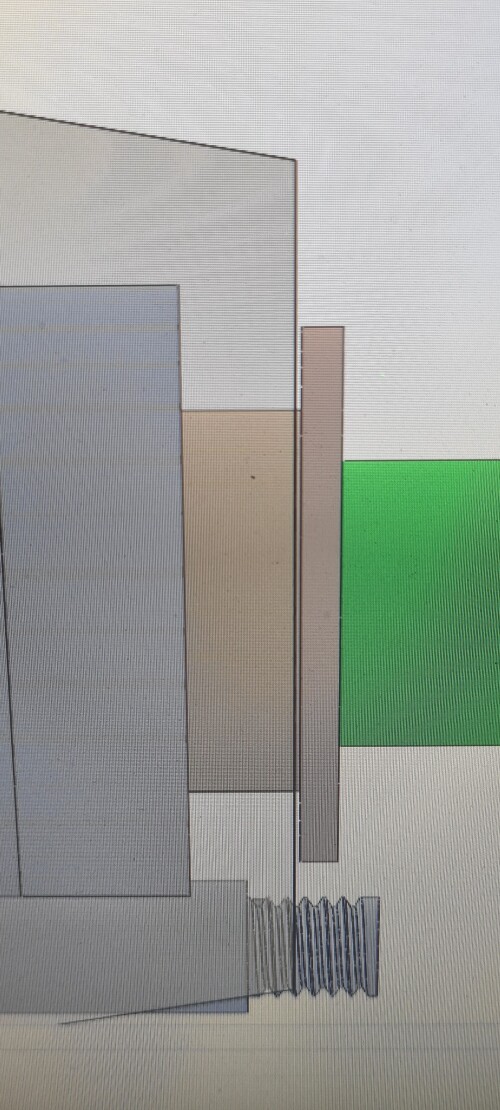

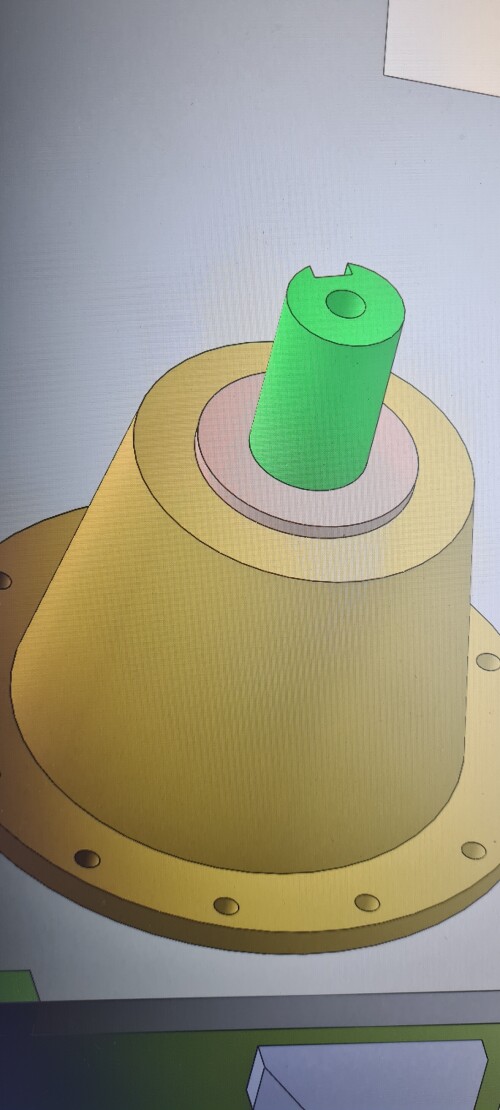

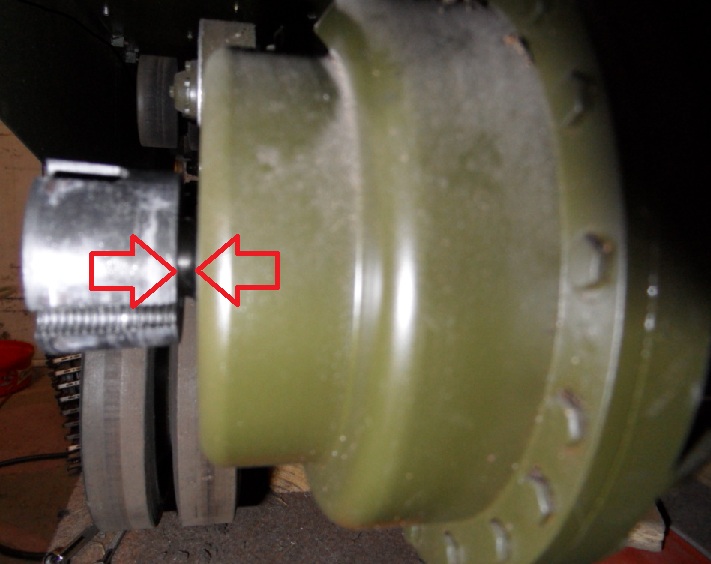

I suggested a similar idea on the sprocket of the Centurion, a measured spacer (brass washer) between sprocket taper lock and bearing. But not for the reason you suggested, it was to prevent any slippage on the final drive shaft if the bearings inside the bearing housing start to slip. It (spacer) allows shaft and bearings to be locked in place via the taper lock, and while the taper lock is locked in position on the final drive shaft nothing should go out of alinement. (Sprocket, track, bearings and none of that rubbing on the inner final drive gearbox wall).

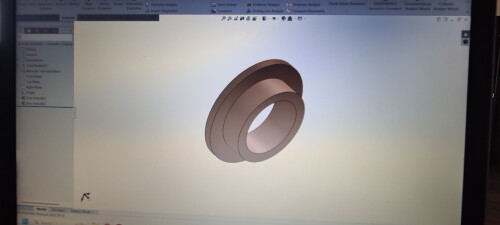

As I said every model is different, so the spacer gap will be tailored to your model. A flat spacer works well with Centurion, but your spacer would need to be a top hat design similar to the WW2 German tank models as you have shown.

Later Armortek models have a (brass?) bumper stop inside the housing to reduce any possible shift of the final drive shaft and gear and possibly centering the final drive gear .

The spacer idea would still be a good belt and braces idea, preventing bumper stop wear too if there was any shift in the final drive shaft position.

Ps, its a good idea to check the taper lock every now and then if the model is used regularly.

Have fun, make an observation and leave it like that.

- SAM_1849.JPG (154.71 KiB) Viewed 1063 times