Page 1 of 1

Drive Gear Scraping Against Hull

Posted: Sat Mar 23, 2024 8:32 pm

by Peter Brown

Hi,

I have fitted the sproket to the drive shaft and secured via taper lock bush, on my Panther G.

Setting the distance between the hull and inner face of sproket at the recommened 34mm, (with the drive shaft pulled out). There is some play on the shaft and this leads to the drive gear moving and scraping the hull side.

Any ideas how to stop this would be appericated.

Thanks

Peter

Re: Drive Gear Scraping Against Hull

Posted: Sat Mar 23, 2024 9:58 pm

by Paul Sparkes

Did you have a brass bush to fit into the small hole on the hull side? This should stop the gear from moving inwards and hitting the hull side.

Re: Drive Gear Scraping Against Hull

Posted: Sat Mar 23, 2024 10:17 pm

by Adrian Harris

There's no bush as part of the 2022 Panther G kit.

The instructions call for the bearings to be loctited to the drive gear shaft (CH0212) and to the drive case (CH1208). This would prevent any movement of the shaft.

Looking at your picture, the marks seem to be from just the teeth, probably a burr from the hobbing process.

Running a file around them and giving them a slight chamfer may be all that's needed.

Adrian.

Re: Drive Gear Scraping Against Hull

Posted: Sat Mar 23, 2024 11:10 pm

by Peter Brown

Thank you Paul & Adrian for your replies.

I have loctited inner race to gear shaft, and outer race to drive case as per the instructions.

I am assuminig I will also need to loctite the shaft to the outer race as well?

Thanks

Re: Drive Gear Scraping Against Hull

Posted: Sat Mar 23, 2024 11:45 pm

by Adrian Harris

"Races" refers to the two halves of each bearing, not the two bearings themselves.

Adrian.

Re: Drive Gear Scraping Against Hull

Posted: Sun Mar 24, 2024 12:56 pm

by Peter Brown

Hi Sascha & Adrian, and thanks for your replies

I am not sure your C Clip solution will work on the Panther, as the bearing is not flush on the drive case.

Adrian, I did think the inner and outer races meant the bearings not the two halfs.

So it looks like I still need to loctite the shaft to the inner bearing race within the casing, and the outer race of the bearing nearest the gear to the casing. I can see now that this should stop any laterial play.

Once again thanks for all your help.

Re: Drive Gear Scraping Against Hull

Posted: Sun Mar 24, 2024 5:33 pm

by Malcolm.Plumb

Thanks for posting this and bringing it to my attention.

I had done exactly the same thing and only half Loctited the bearings in after not fully reading the instructions.

I have luckily not yet secured the main drive gears so have had both the gear cases off today and corrected it.

All good now.

Malcolm

Re: Drive Gear Scraping Against Hull

Posted: Mon Mar 25, 2024 12:57 am

by John Clarke

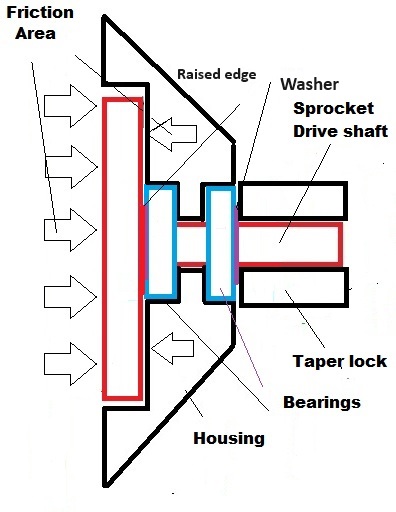

There is a simple solution which I now use on Centurion and Chieftain.

On Panther you'll need a thin metal sleeve (that will slide on the shaft and pass through the gearbox housing), due to the bearing being recessed inside the final drive cowling. Centurion and Chieftain only needs a thick washer/spacer butted up against the taper lock and the inner race of the outboard bearing. But it's essentially the same idea.

Filling in the space between sprocket taper lock and outer bearing or reducing the possible shaft end float to a minimum should it become loose on the bearings.

You'd have to mark up where the taper lock normally sits on the shaft, with the sprocket on and the track aligned. Then remove track and sprocket, refitting taper lock to it's correct position so you can then measure the gap between the taper lock inner edge to the outer inner ball race edge, Using this measurement measure up a sleeve that will fit between bearing and taper lock. The sleeve wall thickness should not rub on the housing passing freely though to the outer bearing inner ball race.

Now it can be put back together checking the taper lock is back in it's original position.

Tighten taper lock and sprocket up against new sleeve and you won't have to rely on just the loctite to hold the shaft in place. The sleeve (or washer/spacer in my case) rotates with the shaft locked in place by the taper lock itself so no damage can occur.

I would advise NOT to loctite the sleeve on the shaft, as you might want to strip it down in the future sometime.

Heating up the shaft to loosen the loctite won't do the bearings any good.

I drew something like this out for Mick Hilton on his Stug when it was thought his final drive shaft was moving rubbing on the hull side.

On later Armortek models I've seen have brass buffer stop on the hull side to stop shaft moving on to the hull side (a delaying measure). But my solution just stops any excess end float using loctite on the bearings with the taper lock and sleeve/washer/spacer holding everything in place.

Disclaimer, Don't do it if you don't like it or know what I'm on about. Stick with the loctite

- bearings2.jpg (52.02 KiB) Viewed 2712 times

Re: Drive Gear Scraping Against Hull

Posted: Wed Apr 03, 2024 3:08 pm

by Peter Brown

John Clarke wrote: ↑Mon Mar 25, 2024 12:57 am

There is a simple solution which I now use on Centurion and Chieftain.

On Panther you'll need a thin metal sleeve (that will slide on the shaft and pass through the gearbox housing), due to the bearing being recessed inside the final drive cowling. Centurion and Chieftain only needs a thick washer/spacer butted up against the taper lock and the inner race of the outboard bearing. But it's essentially the same idea.

Filling in the space between sprocket taper lock and outer bearing or reducing the possible shaft end float to a minimum should it become loose on the bearings.

You'd have to mark up where the taper lock normally sits on the shaft, with the sprocket on and the track aligned. Then remove track and sprocket, refitting taper lock to it's correct position so you can then measure the gap between the taper lock inner edge to the outer inner ball race edge, Using this measurement measure up a sleeve that will fit between bearing and taper lock. The sleeve wall thickness should not rub on the housing passing freely though to the outer bearing inner ball race.

Now it can be put back together checking the taper lock is back in it's original position.

Tighten taper lock and sprocket up against new sleeve and you won't have to rely on just the loctite to hold the shaft in place. The sleeve (or washer/spacer in my case) rotates with the shaft locked in place by the taper lock itself so no damage can occur.

I would advise NOT to loctite the sleeve on the shaft, as you might want to strip it down in the future sometime.

Heating up the shaft to loosen the loctite won't do the bearings any good.

I drew something like this out for Mick Hilton on his Stug when it was thought his final drive shaft was moving rubbing on the hull side.

On later Armortek models I've seen have brass buffer stop on the hull side to stop shaft moving on to the hull side (a delaying measure). But my solution just stops any excess end float using loctite on the bearings with the taper lock and sleeve/washer/spacer holding everything in place.

Disclaimer, Don't do it if you don't like it or know what I'm on about. Stick with the loctite

bearings2.jpg

Hello John,

Thanks for your help, and sorry for late reply.

I will give that a try.

Re: Drive Gear Scraping Against Hull

Posted: Wed Apr 03, 2024 5:15 pm

by John Clarke

I was in B&Q the other day and they had some thin walled steel tubing in their trim department that might be ideal for the Panther to prevent any bearing slippage.

They have all sorts of shaped materials in aluminium brass and steel at reasonable prices, which is ideal in some cases for our modeling needs.