Page 7 of 29

Posted: Sun Aug 16, 2009 6:40 pm

by Tim Bowman

Hi Mike

No problem. Email sent.

Tim

Posted: Sun Aug 16, 2009 8:26 pm

by Lionel Champ

I would like to thank Tim for his excellent drawing of the pannier gusset. That information can not be obtained from photo's alone. For anyone who is attempting this mod, I would like you to know that a "one euro"coin is almost perfect for getting the arched cutouts inscribed ( I am sure most people use a more technical method,but we neanderthals have to improvise).

Cheers again Tim,

Lionel

Posted: Sun Aug 23, 2009 5:59 pm

by Tim Bowman

Thanks everyone very much.

Here's two of the four bump stops. I am repositioning them on the hull slightly and will take some photos of them mounted later.

If any

rivet counters out there see glaring errors in the cast numbers/letters, now is the time to change them. Otherwise I plan on molding two like this, one plain and one with fewer letters and numbers.

regards

Tim

Posted: Sun Aug 23, 2009 6:57 pm

by Kent Wiik

Tim,

Look super! Don’t change a thing!

For everyone here is a photo to compare and comment Tim’s cast letter/numbers.

Wonderful work (as always!)

Cheers

Kent

Posted: Sun Aug 23, 2009 7:11 pm

by Adrian Harris

A superb looking piece of art

Who would have thought a hidden bump stop would prove to be so exciting

Adrian.

Posted: Sun Aug 23, 2009 10:40 pm

by simon_manning

very, very nice,put me down for a set if they become available,great detail tim.

simon manning

Posted: Wed Aug 26, 2009 7:07 am

by Per Sonnervik

Hi Tim,

Very nice work indeed and you asked for a rivet counter so here goes; the lettering should be upside down (compared to your part now) and the numbers are not correct. I have a photo but can´t make out the whole number but perhaps Kent´s photo can show the first numbers.

What I can make out is ???0/C27?2-1 DKR

In what material are planning to these details?

/Per

Posted: Wed Aug 26, 2009 9:19 pm

by Tim Bowman

Hi Per

Thank you!

I plan on casting these in metal. The rubber portion I will model, mold and then cast a suitable durometer silicone. This will then be bonded to the mounting plate(not shown above but visible in Kent's Bovington picture.

Kind regards

Tim

Posted: Tue Sep 01, 2009 3:05 am

by Tim Bowman

Hi Adrian,

They may be hidden but I've come to realize how much things I didn't do on the Panther bother me now just knowing I didn't do them. IE bump stops. Which will bring me to my next post under the Panther section.

I was finally able to finish the wheels and position the right side bump stops. These two masters will stay as they are, I have two more that will have numbers upside down as Per's comment recommends. Holes for the bumpers are not yet drilled and obviously the rubber bumpers are not in the pictures. Also, I used M3 fasteners but may change to M4s as the real ones appear to have had larger bolts then mine appear to be.

First two photos of the real thing on the factory floor courtesy of Alan Hamby.

http://www.alanhamby.com/tiger.html

Rear stop bracket with wheels removed

Rear stop bracket with wheels removed

The studs are threaded into the hull sides.

The studs are threaded into the hull sides.

Thank you again Roland, Kent and Per for the help and everyone who is interested in the parts. I will post progress updates as I have them.

Kind regards

Tim

Posted: Tue Sep 01, 2009 4:27 pm

by Robert E Morey

Awesome work Tim, the Tiger looks fantastic. Love the bump stop it looks real even if the numbers should go the other way! Great job.

Bob

Posted: Tue Sep 01, 2009 5:13 pm

by Steve Norris

Great work Tim.

A masterpiece in the making.

Steve

Posted: Tue Sep 01, 2009 7:57 pm

by simon_manning

bravo tim ,superb!as the time goes by parts and details are revaeled,its amazing what builders notice.

great posts simon manning

Posted: Wed Sep 02, 2009 12:00 am

by Adrian Harris

Those are great looking photos Tim.

Why have you gone for threaded holes rather than through holes and bolts

Is it to keep the internal clutter to a minimum

I know what you mean about missing things. I'm surrounded by Sherman parts but keep getting new ideas for ways of doing things or building new parts. I think I need to go on a Project Management course

If only I could win the lottery and not have to work to earn the money I need to feed this hobby

It's interesting to see how similar the ends of the swing arms are between Alan's photo and the model ones. The old advice on these was to file the end of the axle flat ad fill the void. From those factory shots it looks like they should have 10BA bolts inserted in the ends instead

Adrian.

Posted: Sun Sep 06, 2009 11:21 pm

by Tim Bowman

Thanks for the comments guys. Adrian, I don't really have a good answer for the threaded holes except that I wanted it to look like the real thing when the stops were removed (without the fasteners moving around).

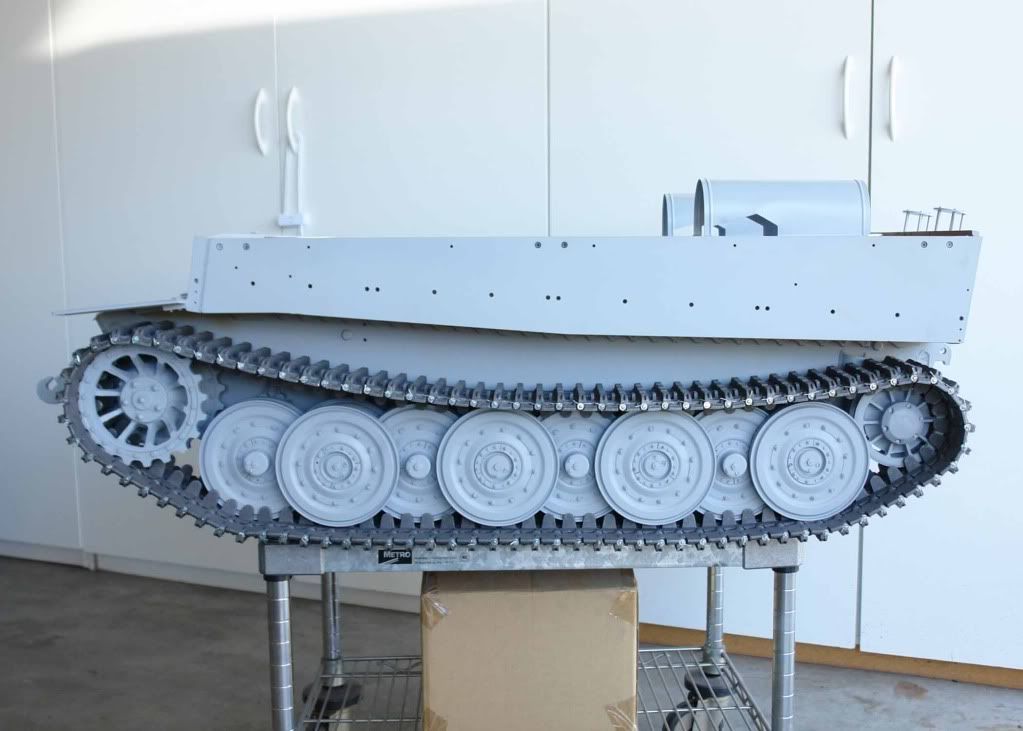

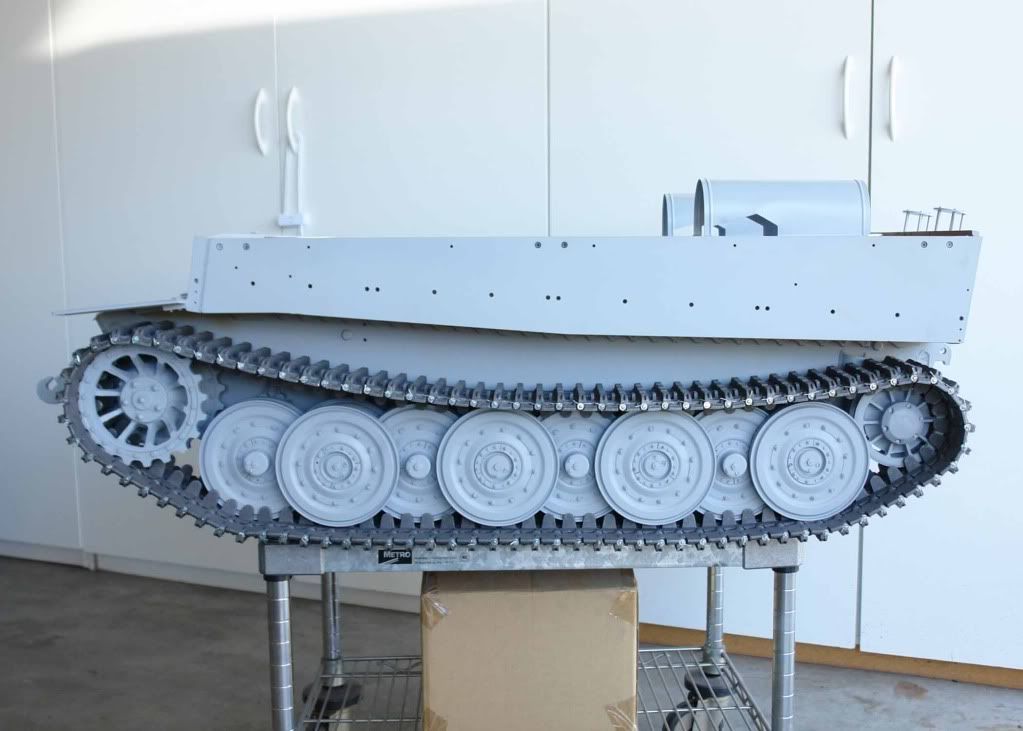

With the wheels and their hubs finally detailed and all four bump stops located, I could not resist the urge to assemble and mount the tracks. The Tiger amazes me in that every time I add the next part it just keeps getting bigger and bigger. The Panther was sort of big to start with.

I stayed up late and assemble both tracks rather hastily as can be seen by the untidy cotter pins. I'll clean those up.

regards

Tim

Posted: Sun Sep 06, 2009 11:26 pm

by Dale jordan

Tim I remember when I first put my tracks on my Tiger and Sherman You just go woooo . And you keep on walking in and out of your work shop just to have another look at your machine and yes it does look much bigger ....Dale