Page 3 of 4

Re: Return rollers

Posted: Sat Dec 28, 2019 10:40 pm

by John Clarke

How about this then, forget the chain saw effect, all you'll need is a slitter wheel and a girly grinderette.

The tracks cut like hot butter. Just need to make up a cutting jig so there all the same length.

Centurion link is just for comparison.

Any takers?

- SAM_1943 (3).JPG (194.47 KiB) Viewed 2501 times

- SAM_1944.JPG (215.24 KiB) Viewed 2500 times

Even allows for a little wear and tear on the tyre

Re: Return rollers

Posted: Sat Dec 28, 2019 11:09 pm

by Richard Goodwin

Having just tried this using a dremmel 420 cut off blade and a Powerfile with 80 grit loaded, it took less than two minutes although watch out for the very hot off cut when it comes off. Not my ideal solution but having spent many hours cleaning and painting my tracks, I think it is the lessor of the evils plus no wear and tear on either the bushes, bearings or rollers.

Re: Return rollers

Posted: Sun Dec 29, 2019 12:21 am

by John Clarke

I can confirm that little blighter that comes off the horn is very hot.

Certainly away of personalizing your own track horn lengths depending on the cutting jig

I think a jig is necessary, other wise you could end up with horns looking like Albert Steptoes teeth.

Merry Xmas

- steptoe_328-1-640x389.jpg (49.22 KiB) Viewed 2483 times

Re: Return rollers

Posted: Mon Jan 06, 2020 11:44 am

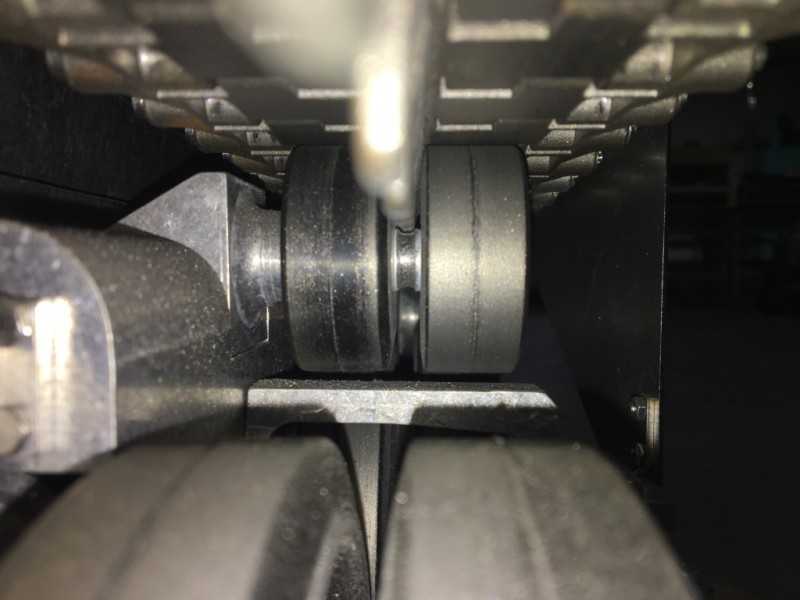

by Armortek

We have checked back to the models that we have here. The horns do not foul on the return rollers.

As zou can see in the pictures, the tracks sit on the rubber.

Re: Return rollers

Posted: Mon Jan 06, 2020 1:23 pm

by Greg Clement

Hello Kian

Your photo does show the track horn running clear of the rollers but there is definatley an issue, which is clearly demonstrated by the gap between the tyre and track link in the attached photo.

Greg

Re: Return rollers

Posted: Mon Jan 06, 2020 1:38 pm

by Richard Goodwin

Hi Kian,

I can confirm that mine is he same as Greg's and John's in that the horns are impacting on the roller wheels.

Re: Return rollers

Posted: Mon Jan 06, 2020 3:50 pm

by Charles A Stewart

Hi all

I concur with Greg, John,& Richard, the track horn fouls rtn roller.

Charles

Re: Return rollers

Posted: Mon Jan 06, 2020 5:35 pm

by simon_manning

just reduce the track horn length, i did both sets of my early Tiger Tracks, when there was a slight casting burr left on, no problem. regards simon manning.

Re: Return rollers

Posted: Mon Jan 06, 2020 7:22 pm

by John chamney

The horns on mine definitely hit the centre boss as well

Re: Return rollers

Posted: Mon Jan 06, 2020 7:28 pm

by John Clarke

I'm afraid there are only two options, allow the track horns to wear the return roller center bosses down, or reduce the horn length.

How much reduction, is debatable. 2mm the minimum I guess.

At least It's an easy if not a long winded fix.

I'm having a few choice words with the front armor plates at the moment, extra sandwich plates required me thinks. or not just had another look

Lots of shaping to do anyway on the gorgeous front end .....

Onwards and upwards.

Re: Return rollers

Posted: Thu Jan 09, 2020 9:48 am

by Armortek

Here is a photograph of our Chieftain in the factory.

As you can see, the tracks quickly cut a channel of about 0.5mm to 1mm. This is not an issue as there is still sufficient material left on the return rollers.

I would advise against cutting the track horns and instead let the running gear naturally bed in.

Worth pointing out that it is always good practice after assembly to run the tank and then get it back on the bench to check the running gear (taper locks, sprockets, idlers, roadwheels, etc) for wear and make any adjustments as needed. As you run the tank, this should be done on a periodic basis.

- CHANNEL CUT INTO THE RETURN ROLLERS

- CLOSE UP VIEW OF THE SAME THING

Re: Return rollers

Posted: Thu Jan 09, 2020 4:50 pm

by Manny Leung

I'm happy with that. If Armortek says go chainsaw then chainsaw it is!

Re: Return rollers

Posted: Thu Jan 09, 2020 5:14 pm

by John Clarke

Gosh, so you just have to wait for the clatterly clat to stop and it's bedded in.

If the clatterly clat doesn't stop, you've obviously haven't put enough grease in the gearbox.

It's just as well the tracks are made of steel and not aluminium.

I was thinking, what about adding small grind stones, fitted to each shaft between the return rollers, to grind the true depth of the track horn.

I'd be known as the "grind stone cowboy"

Re: Return rollers

Posted: Thu Jan 09, 2020 6:19 pm

by Mark Heaps

Thank you Armortek !

Now we know the true reason for the side-skirts or "bazooka plates" on Chieftain.

They were there to stop the crew getting worried whilst the tracks ground the top idler wheel hubs down to the correct operational size.

Mark

Re: Return rollers

Posted: Thu Jan 09, 2020 6:34 pm

by Phil Woollard

If the return rollers are gently contacting the track horns (or vice versa) making a nice clatter like the real thing, then I'm happy but I may just turn down the return rollers on the lathe as that would be the correct way to do it.