Page 3 of 81

Re: Vince's Tiger 1 late variant 2017

Posted: Fri Feb 09, 2018 2:12 pm

by Vince Cutajar

Robert

The rubber stops were made from a sheet of 12mm rubber. I used a Stanley knife to cut them out. I used 2mm studs to fix the rubber to the main body. Drilled two 1.5mm holes in the rubber so that the studs could be threaded in.

I do not know if the rear deck has been lowered in this version. I hope it is. Guess I will find out eventually.

Vince

Re: Vince's Tiger 1 late variant 2017

Posted: Sun Feb 11, 2018 5:22 pm

by Vince Cutajar

It feels like I am faffing around a lot and not doing anything constructive (pun intended) on the Tiger. The only real thing I did was Loctite the brass bushes in the suspension bars and also drill and tap the new 6mm holes in the suspension bars.

What I noticed is that the head of the bolts which fix the suspension bars to the side of the lower hull and are also used to lock the torsion bars remain proud of the side of the hull by 0.7mm.

I wonder if this is by design? I think I will ask Kian about it.

Vince

Re: Vince's Tiger 1 late variant 2017

Posted: Sun Feb 11, 2018 8:36 pm

by Vince Cutajar

So I sent Kian an email hoping that he will read it tomorrow (Monday).

Half an hour later he responded saying that it was by design and that the bolt heads will be hidden behind the wheels. That put my mind at rest.

Thanks Kian.

Vince

Re: Vince's Tiger 1 late variant 2017

Posted: Tue Feb 13, 2018 4:06 pm

by Vince Cutajar

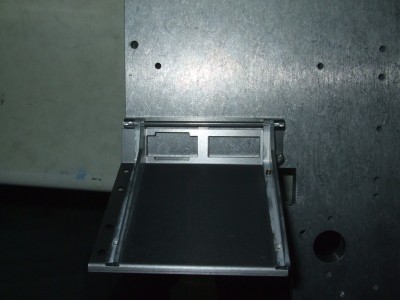

Started "butchering" the floor panel countersinking some of the holes and drilling holes for the rectangular access panel. Don't laugh but the setup in the following photo is a bit iffy.

- Set-up for countersinking the edge holes

That is the only way I could hold the plate to countersink the holes on the bent part of the plate. Fortunately it worked.

Now in the process of plugging up the unwanted holes. At the moment using JB Weld especially for the larger holes.

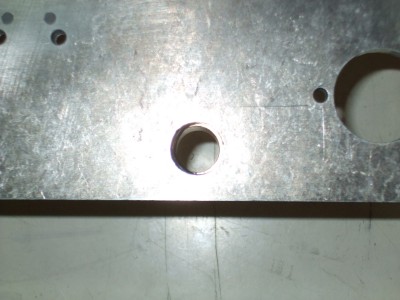

I have a question for anybody who has built a Tiger before. The following photo is of the holes for the round access panel.

- Holes for round access panel

Does the hole in the centre serve any particular purpose? I suspect it is part of the manufacturing process of the kit floor plate but am not sure about this.

Vince

Re: Vince's Tiger 1 late variant 2017

Posted: Wed Feb 14, 2018 4:39 pm

by Vince Cutajar

Finished plugging the unused holes in the floor plate and will give it 24 hours curing time before sanding flush.

In the meantime had a look at the axle assemblies and as the suspension arm mates with two shafts which are threaded and glued I thought that a good clean of the suspension arms was required. So, I cleaned them in an ultrasonic bath to remove all the muck from the female thread.

Vince

Re: Vince's Tiger 1 late variant 2017

Posted: Wed Feb 14, 2018 7:45 pm

by Christoffer Ahlfors

In the old days, a lot of people (myself included..) cross drilled the swing arms through the torsion bar holder and put a rolled pin through to prevent the thread from giving way. With the adjustable suspension, there is no need for this as you can simply readjust if necessary. The second reason this is not needed, is that it was never the threads giving way - it was the grub screws eating their way into the torsion bars, causing sag. With the preground torsion bars and adjustable suspension these days, I would say there is no need to glue this assembly. Also, the way the swing arms are oriented on a Tiger, the torsional load on the threads acts to tighten them - they won't fall apart.

Re: Vince's Tiger 1 late variant 2017

Posted: Wed Feb 14, 2018 8:45 pm

by Vince Cutajar

Thank you Christoffer for your thoughts and comments. Food for thought.

Christoffer Ahlfors wrote: ↑Wed Feb 14, 2018 7:45 pm

Also, the way the swing arms are oriented on a Tiger, the torsional load on the threads acts to tighten them - they won't fall apart.

I already suspected what you said, but when I see everybody cross-pinning the swing arms, I start to think that it might have happened to somebody. As it is with the kit that I have, the swing arms come pre-tapped for grub screws (set screws) to lock the two shafts so it is not easy to cross pin in the usual way.

Vince

Re: Vince's Tiger 1 late variant 2017

Posted: Thu Feb 15, 2018 4:45 pm

by Vince Cutajar

The saga of the pannier gussets

It started last week. I collected the laser cut pannier gussets and the rectangular access panel last week. I brought them to the workshop and put the pannier gussets to one side as at that time I was more interested in the access panel. A couple of days later I had a closer look at the gussets and to my dismay noticed that that they were 10mm wider than what I wanted.

As it was made from 2mm 304 stainless, I did not even consider trying to fix it myself. I went back to the laser cutter in the hope that he still had kept the laser cutting file so that I could make two new ones. As luck would have it he still had the file and after correcting the error in this file ordered two new gussets.

This is the first time that I gave him a .dxf file. On rare occasions there is a possibility that when transferring a .dxf file from one CAD system to another system, some dimensions might get corrupted. In fact we checked some of the dimensions on his system. After finding that the dimensions we checked were correct we did not bother to continue checking them all.

Whilst waiting for the new ones, I decided to try and salvage the old ones which to my surprise I managed to do. Patiently used a hacksaw to remove most of the waste material and then cleaned up with an endmill on the milling machine. After all this work, they got warped a little but still usable. I will keep these as spares just in case I make a boo-boo with the new ones.

Today I collected the new ones.

- Top two are the new ones. Bottom two are the reworked ones.

Vince

Re: Vince's Tiger 1 late variant 2017

Posted: Thu Feb 15, 2018 4:59 pm

by Vince Cutajar

Also today I assembled the axles.

I then sanded flat the JB Weld I had used to plug the unused holes in the floor plate. Trial fit with the countersunk screws was successful.

I was so happy about it. It felt like I'm on a roll. Turned the hull right way up and that's when I wished the earth would swallow me up. I put the rectangular access panel on the wrong side.

After some choice words I called it a day and came back home to check a particular photo on this forum.

It's my lucky day. This photo actually confirmed that I have put the access panel on the correct side. Happy days.

Vince

Re: Vince's Tiger 1 late variant 2017

Posted: Fri Feb 16, 2018 4:58 pm

by Vince Cutajar

Disassembled everything for the last time. Drilled holes for bump stops, shock absorber mounts and track deflector assembly. Plugged the unused holes.

Vince

Re: Vince's Tiger 1 late variant 2017

Posted: Mon Feb 19, 2018 4:06 pm

by Vince Cutajar

As I need the pillars for the battery tray to be tapped as opposed to having a through hole I made a new set from stainless.

- Battery tray pillars

I was also thinking about the interior colour of the tank. Is RAL 1001 good?

Vince

Re: Vince's Tiger 1 late variant 2017

Posted: Tue Feb 20, 2018 4:50 pm

by Vince Cutajar

This week it was planned to do the final assembly of the lower hull but a couple of days ago Steve Winstone told me that he was sending me the convoy light. So I put the assembly on hold as, if there are any holes to be drilled for the convoy light, it is better to do them whilst the rear plate is still not fixed to the lower hull.

In the meantime, I have been passing the time cleaning and etch priming various parts of the running gear. Today I thought I would do a test assembly of the rear left mudguard where the convoy light fits.

At first I noticed a 4mm bolt would not fit in the threaded portion of all the mudguard hinge blocks (CE0327).

- Mudguard hinge blocks

After a measurement of the thread it was found to be oversize. Used a 4mm die to get the proper threads. As this part is made in aluminium, I took extra care that the die picks up the old thread.

- Test fit of the rear mudguard

Next thing I noticed was that the lower bolts in the frame might be a bit too large.

I can solve this by either using a 3mm bolt instead of the 4mm one or else use a 4mm bolt with what is called a one-size smaller head.

With this configuration, the convoy light is bolted to a small plate which is then bolted to the frame. What I am suspecting is that this configuration is for an early or mid Tiger. From the limited resources that I have, I think that on the late Tiger the frame is not used and the convoy light is bolted directly to the rear plate. I had a look at Tim Bowman's build, and it looks like he got an after-market rear mudguard and I cannot see the frame.

Could anybody kindly confirm this.

Vince

Re: Vince's Tiger 1 late variant 2017

Posted: Tue Feb 20, 2018 6:17 pm

by Stephen White

Vince, to quote Jentz and Doyle:

"In May 1943, the frames welded to the hull rear as a base for the rear track guards, were dropped. They were replaced by new hinged rear track guards (with cut-outs for the convoy light), supported by three hinge plates welded directly to the hull rear".

I haven't forgotten your reference for Dunkelgelb.

Best regards

Stephen

Re: Vince's Tiger 1 late variant 2017

Posted: Tue Feb 20, 2018 9:02 pm

by Vince Cutajar

Thank you Stephen for coming to my rescue. So, it is as I suspected. I have the book "Germany's Tiger Tanks" from those two authors but I could not find that page. Is that snapshot from some other book?

The kit mudguards are beautifully made and it is a pity not to use them. I will have to investigate the possibility of maybe modifying them. Failing that, I will have to see if after-market rear mudguards for a late Tiger are still available.

In this case I will start with the final assembly of the lower hull and take a decision on the mudguards later on.

Vince

Re: Vince's Tiger 1 late variant 2017

Posted: Sat Feb 24, 2018 9:05 am

by Vince Cutajar

Yesterday I finally started the final assembly of the lower hull but ran into a problem.

I decided to fit the O rings also when bolting the suspension bar to the side of the hull. Just by chance I thought I would try one of the assembled swing arms in the various holes to see how they fit. One side of the hull was not a problem but on the other side, the swing arm would not go in as much as the other side.

Had a look inside the holes with the problems and saw this:

- O ring sticking out on one side of the hole.

Dismantled everything and found the reason for this problem. The counterbore for the O ring was not concentric with the shaft hole. Discussed the situation with Kian and eventually he suggested two options:

- Leave the O ring out

- Counterbore the holes and use a different thickness of ring

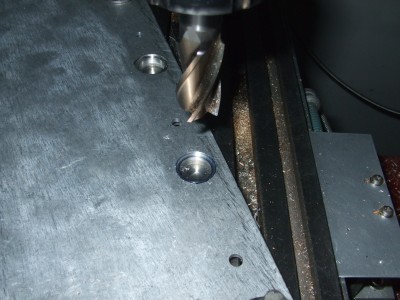

I advised him that prior to considering any of those two options I was going to try centering the counterbore with a boring head. This morning took the boring head out but was not looking forward to setting it up. I had a look in my box of milling cutters and there it was at the bootom of the box. A 19mm end mill. The diameter of the counterbore was measured to be around 19.5mm. No harm in trying 19mm with the cutter first and see how it goes.

- Centred shaft hole with a 16mm bar.

- Blued up the counterbore to see what is happening.

- Adjusting the position of the counterbore with 19mm endmill.

Another trial fit with the swing arm. Perfect. The other seven holes took less than 30 minutes to correct.

Vince