Page 3 of 12

Posted: Sat Sep 20, 2008 4:06 pm

by Tim Bowman

Hi Bob

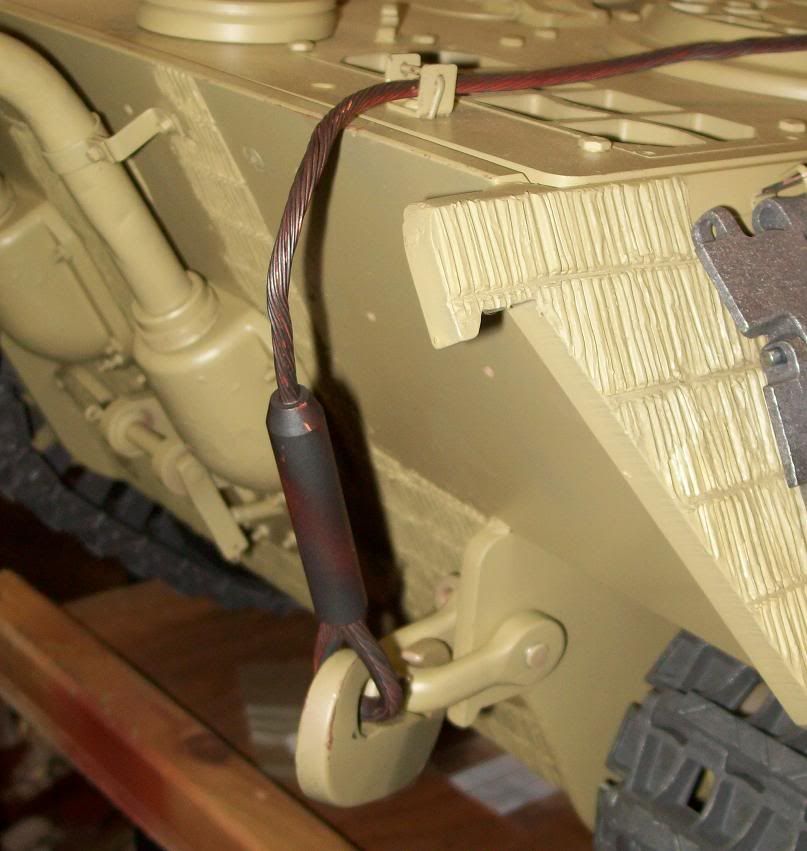

Super work! As always. That metal technique really looks like bare metal.

Tim

Posted: Sun Sep 28, 2008 9:35 pm

by Robert E Morey

Posted: Tue Sep 30, 2008 3:52 pm

by Tim Bowman

Hi Bob

Sweet !

Battered but still very much in the fight.

Tim

Posted: Sun Oct 12, 2008 4:20 am

by Robert E Morey

Posted: Sun Oct 12, 2008 9:04 am

by Adrian Harris

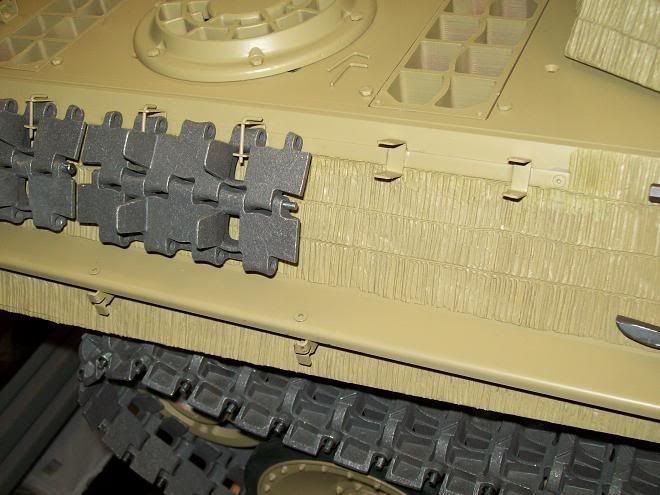

Nice rack

(It's not often you get to say that without the risk of a slap

)

Adrian.

Posted: Sun Oct 12, 2008 5:44 pm

by Robert E Morey

Ha ha Adrian

You're right! Thanks!

Posted: Sun Oct 12, 2008 7:15 pm

by Allan Richards

Nice work altogether - really nice work!

Posted: Wed Nov 12, 2008 4:36 am

by Robert E Morey

Posted: Wed Nov 12, 2008 8:18 am

by Adrian Harris

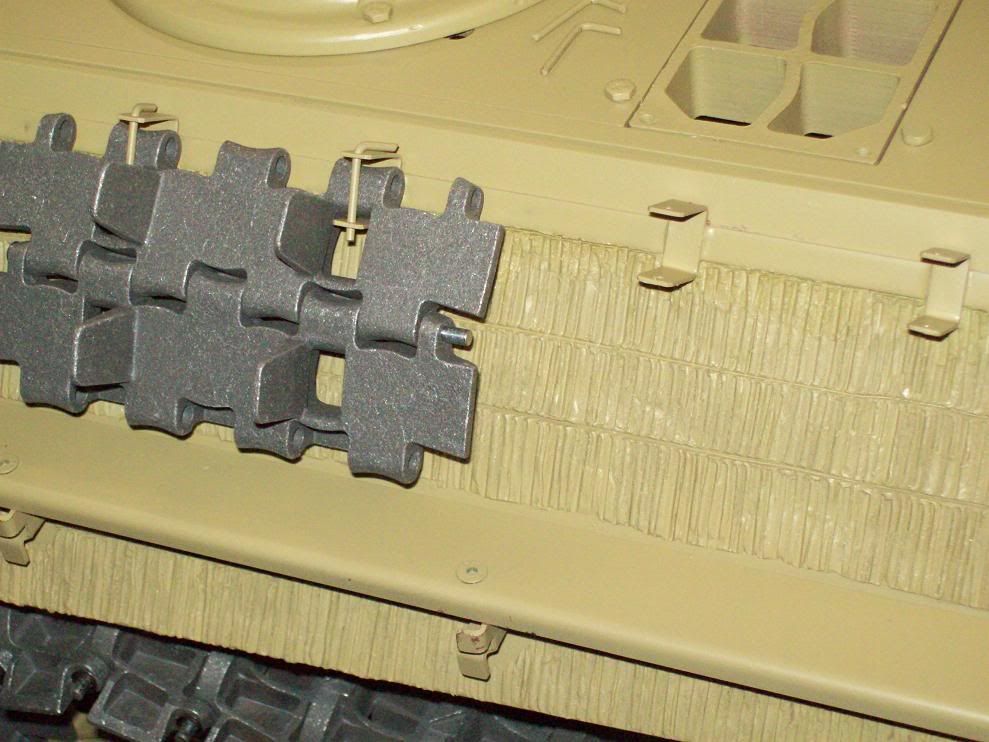

Excellent looking details Bob.

Some of those photos really could be of a 1:1 Panther

Adrian.

Posted: Thu Nov 13, 2008 3:26 am

by Robert E Morey

Thanks Adrian, I'm getting better with the camera up close. Some things look great from a distance, then at 8 megapixel magnification don't always look that great.

I've got a ways to go before my Panther is as detailed as Tim Bowman's though. That model is a masterpiece of detail. Its good Tim set the bar high a long time ago - gives us all something to strive for.

Bob

Posted: Thu Nov 13, 2008 9:42 am

by Kent Wiik

Excellent work Bob!

Yours and Tim’s work in progress postings are a pleasure to watch and when posted a source of pleasure and enjoy for me and I am sure a lot of others - thanks!

Your Panther looks awesome and I think you have got the "super detailing bug" now

Those tow cables when painted and weathered will look spot on the real thing as your C- and U-hooks do.

Noticed one thing at the rear that confirms my assumption regarding the lift boss for the U-hook.

It is placed to high and to far inwards compare with the real Panthers, and therefore the C-hook can’t work properly.

I have changed their position on my own Panther - did so before I assemble the hull as it was quite an easy conversion doing it that way.

Will post photos later.

Keep up the good work

Kent

Posted: Fri Nov 28, 2008 9:24 pm

by Robert E Morey

Posted: Sat Nov 29, 2008 12:35 pm

by Derek Attree

Hi Bob

That is a great extingusher.

Derek

Posted: Sat Nov 29, 2008 2:17 pm

by Kent Wiik

Nice one Bob!

Knowing how small it is in 1:6 that is almost a work of a goldsmith.

Kent

Posted: Sat Nov 29, 2008 4:19 pm

by Allan Richards

Excellent fire extinguisher, I can see that it must have been quite a fiddle to solder together. Altoether a superb addition to your tank.