Rocky's Tiger

-

Dale jordan

- Posts: 1428

- Joined: Fri Jul 13, 2007 1:10 am

- Location: Port Macquarie Australia

- Been liked: 429 times

- Contact:

Re: Rocky's Tiger

Good job Rocky . Mike where are your photos of your mid tiger1 build ? I'm doing the same machine as yours , but I've lost your photos ...Dale

-

John Fitzsimons

- Posts: 1816

- Joined: Tue Dec 14, 2010 3:11 pm

- Location: IRELAND,Dublin/Meath

- Has liked: 5 times

- Been liked: 629 times

- Contact:

Re: Rocky's Tiger

Hi rocky, I was intending to use 3-48 hex heads for the idler caps. Interested to know what others recommend.

If interested in any parts used in my builds contact me at johnfitzsimons@msn.com for a price list.

http://www.armortek.co.uk/Forum3b/viewt ... f=4&t=4770

https://youtube.com/@16rctankworkshop-y ... TlMwTalnX5

http://www.armortek.co.uk/Forum3b/viewt ... f=4&t=4770

https://youtube.com/@16rctankworkshop-y ... TlMwTalnX5

-

Rocky Sembritzky

Re: Rocky's Tiger

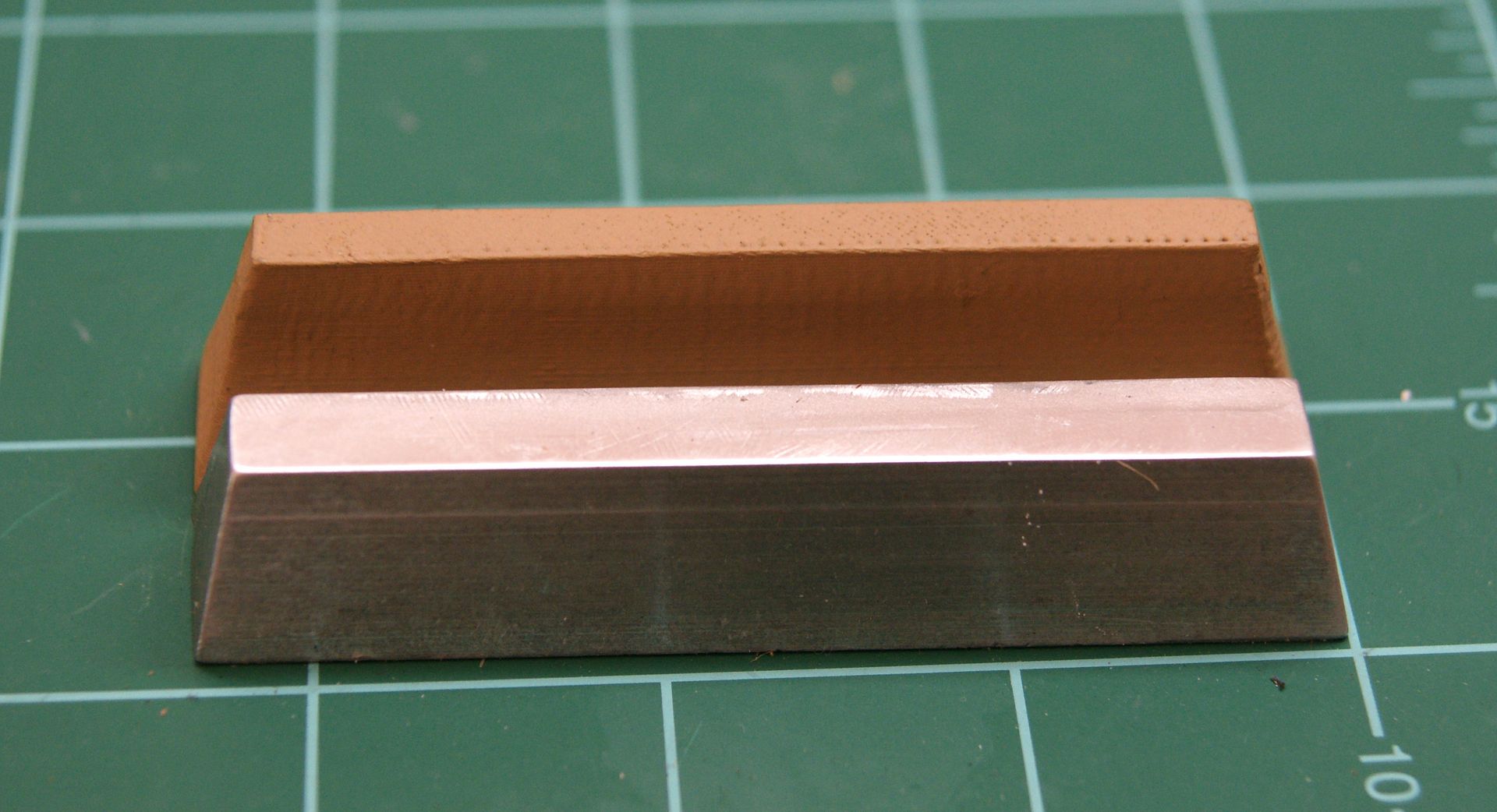

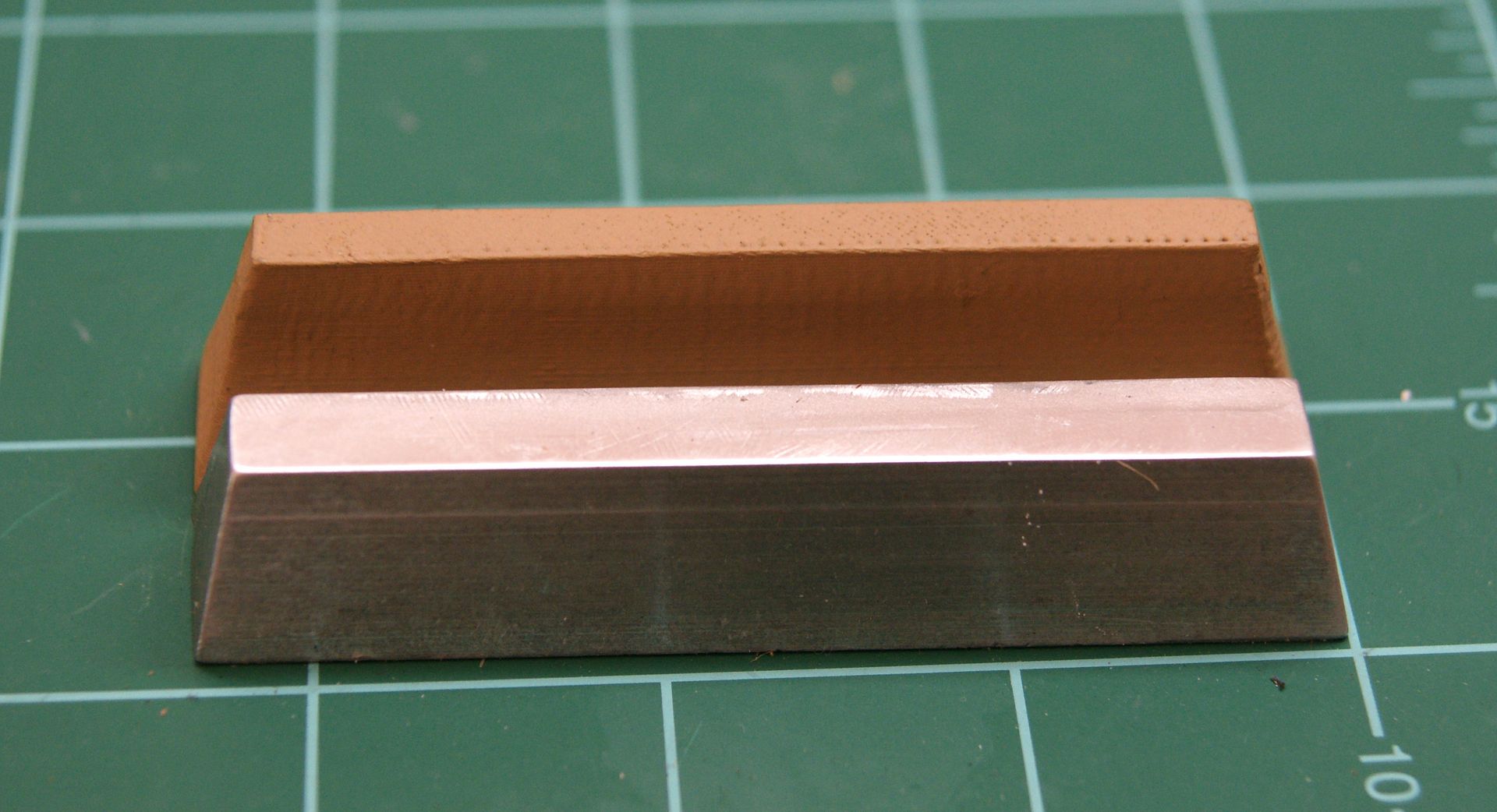

I noticed something while comparing parts from the early Tiger to the mid Tiger. The center armor cover sizes are different.....

I checked my reference books, but I could not find any information regarding the size or if there was a change made to the cover.

Any help would be greatly appreciated.

Rocky

I checked my reference books, but I could not find any information regarding the size or if there was a change made to the cover.

Any help would be greatly appreciated.

Rocky

-

Rocky Sembritzky

Re: Rocky's Tiger

In the words of Pink Floyd, is anybody out there?

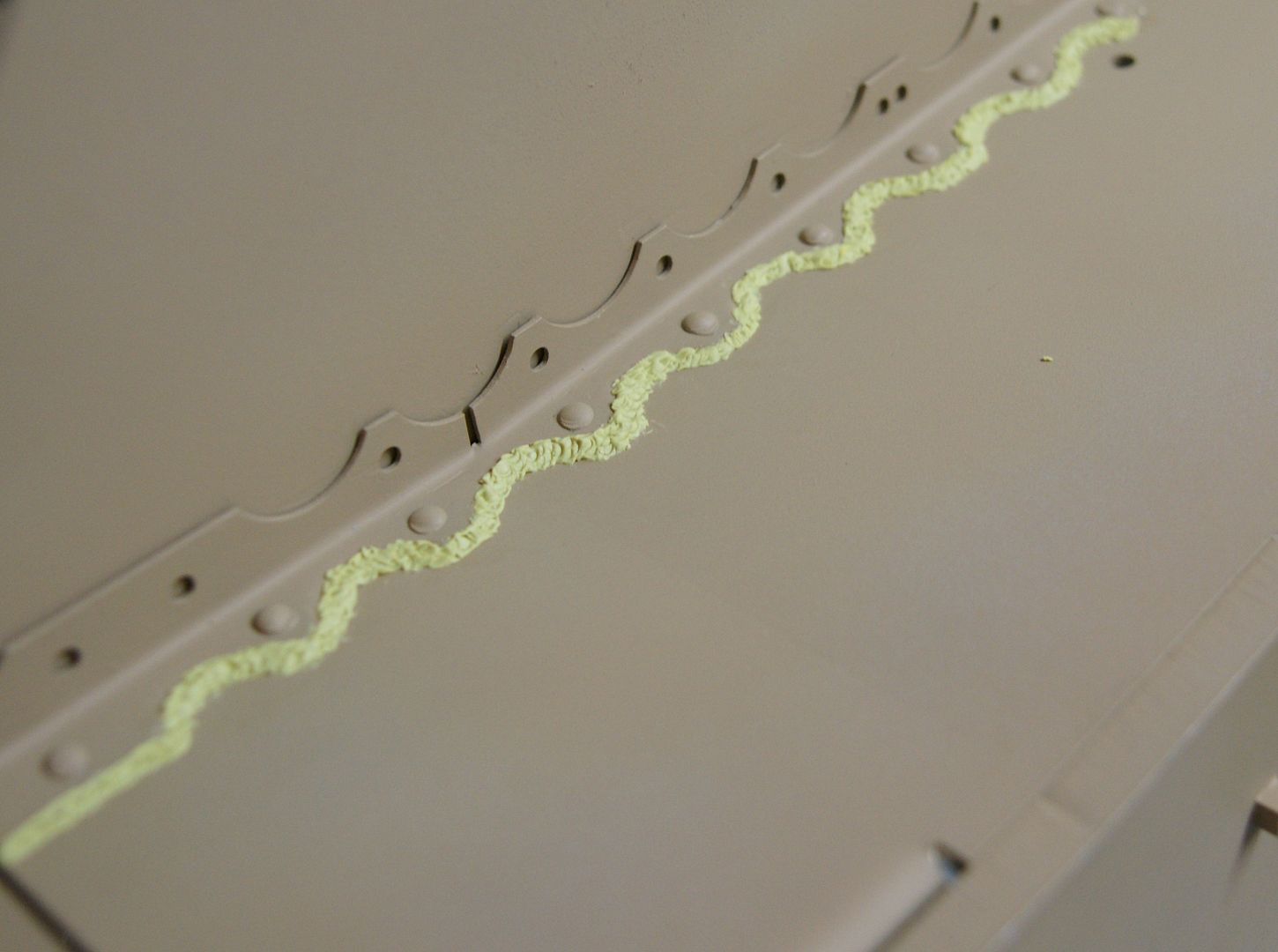

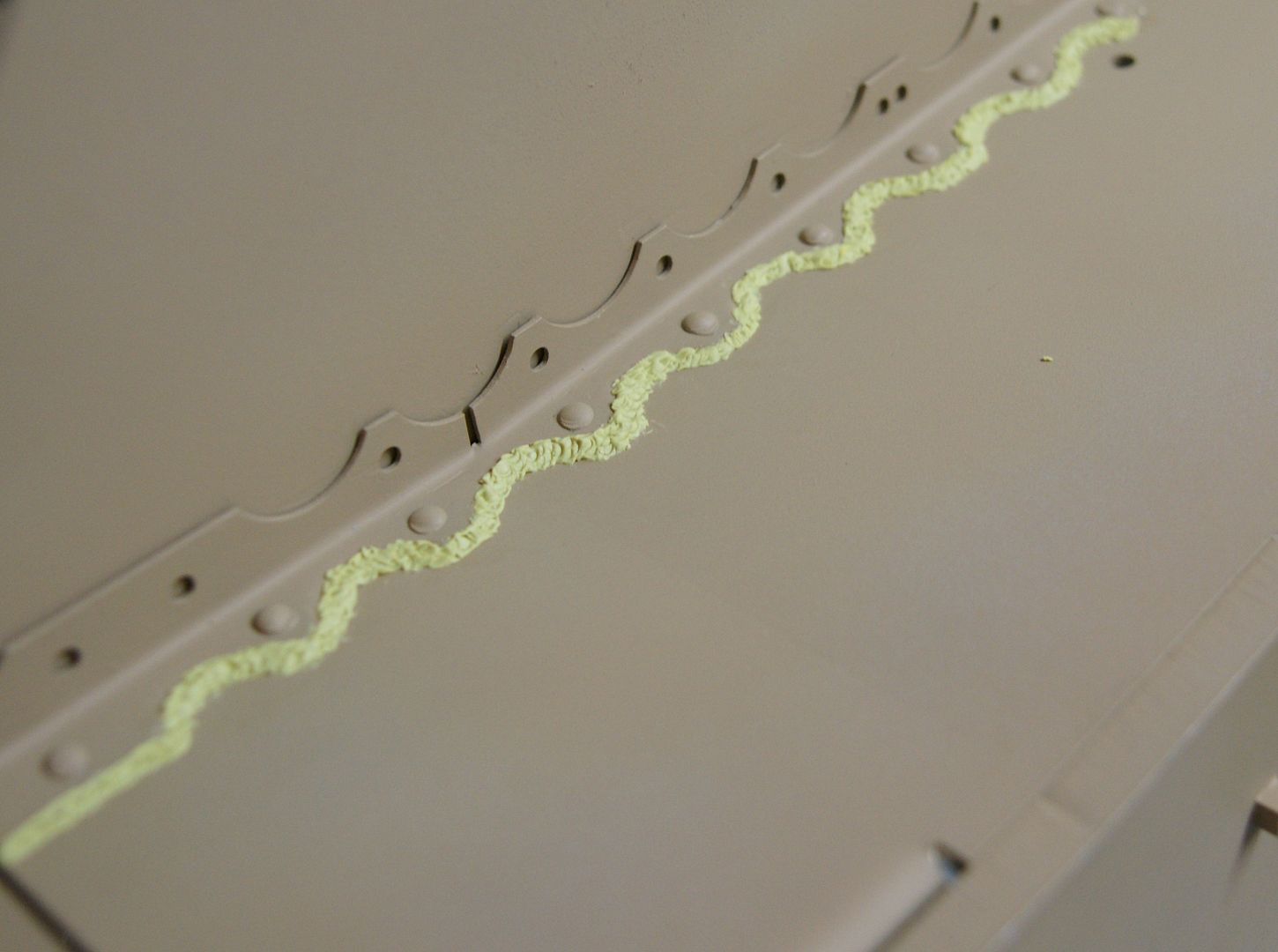

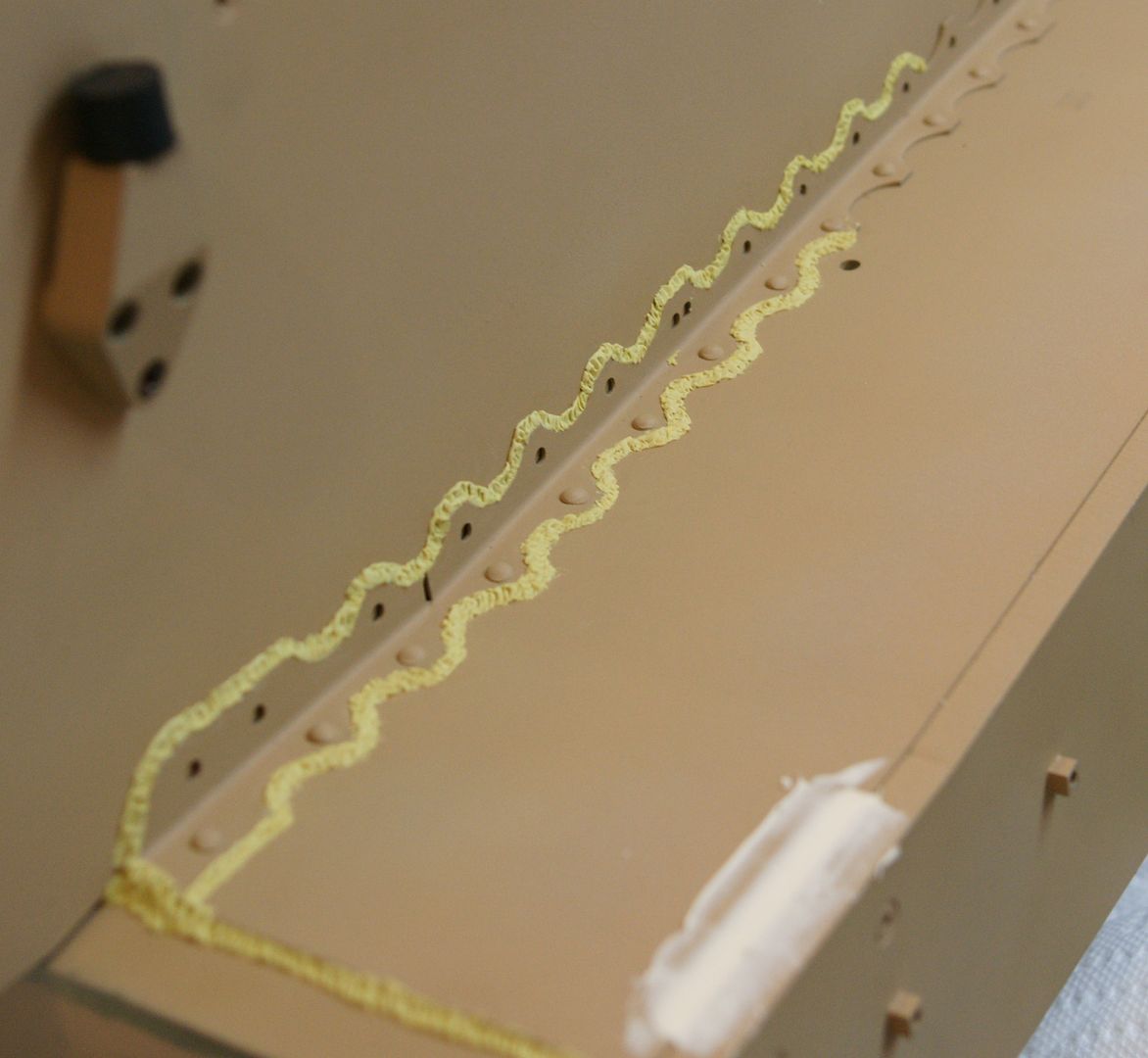

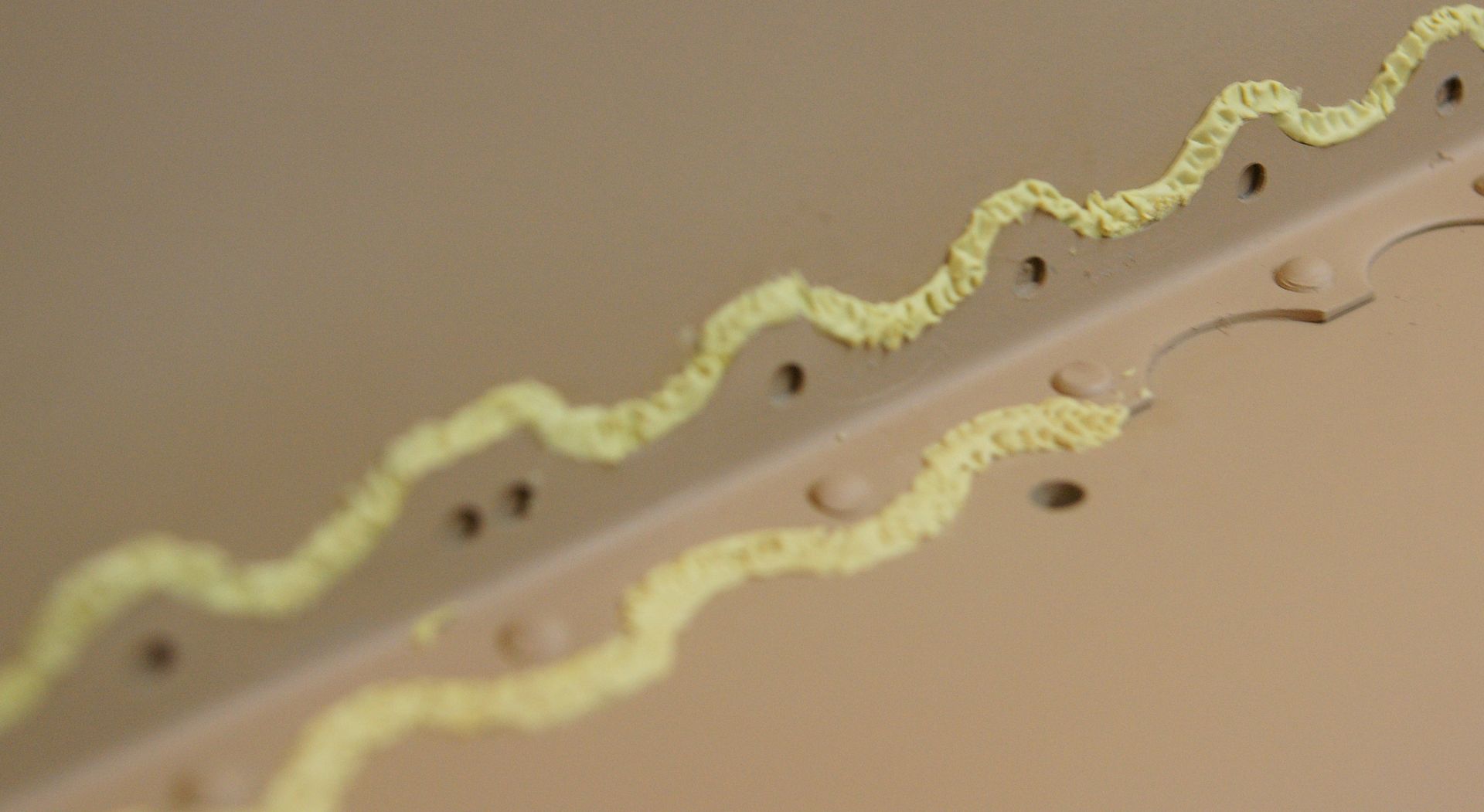

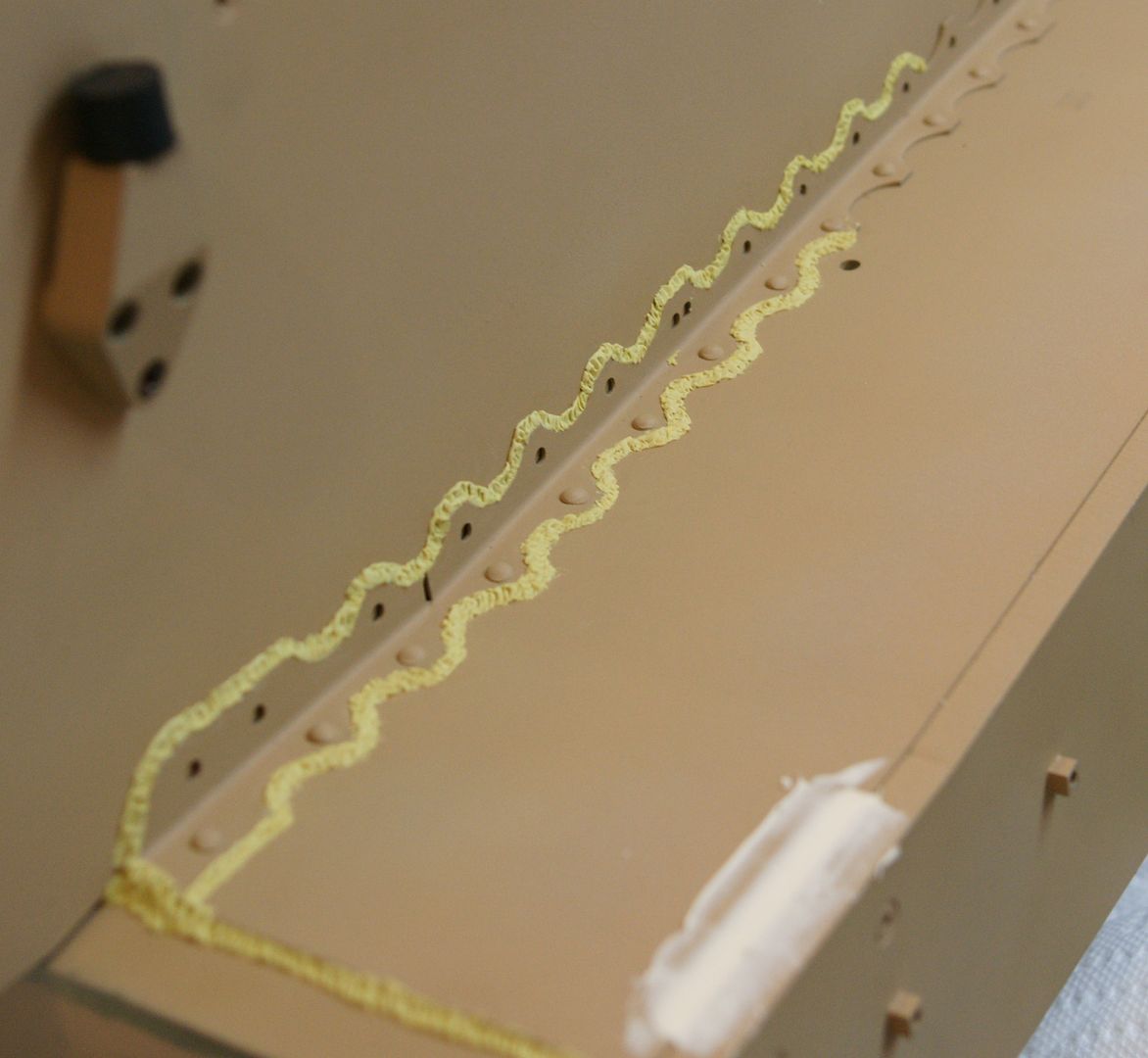

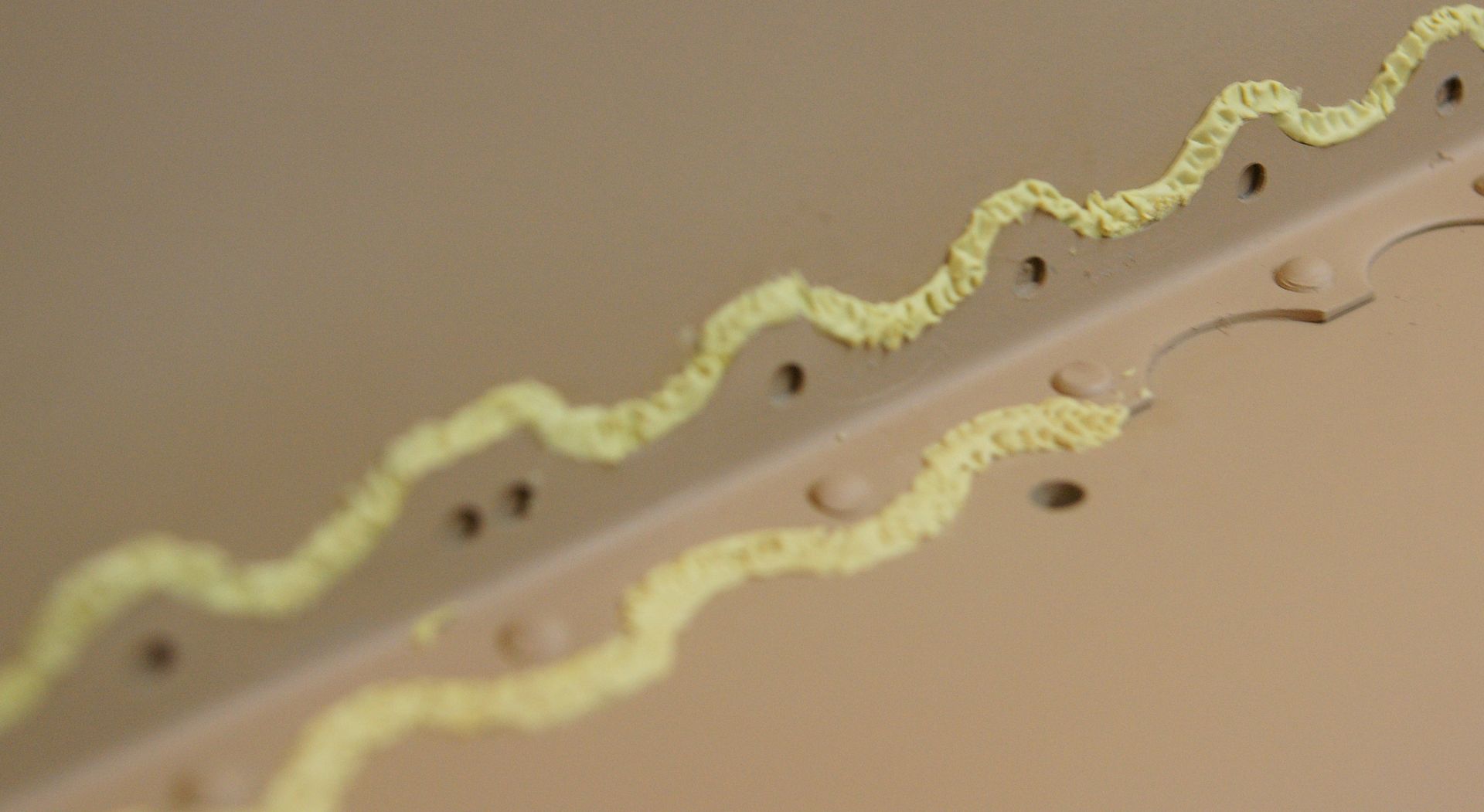

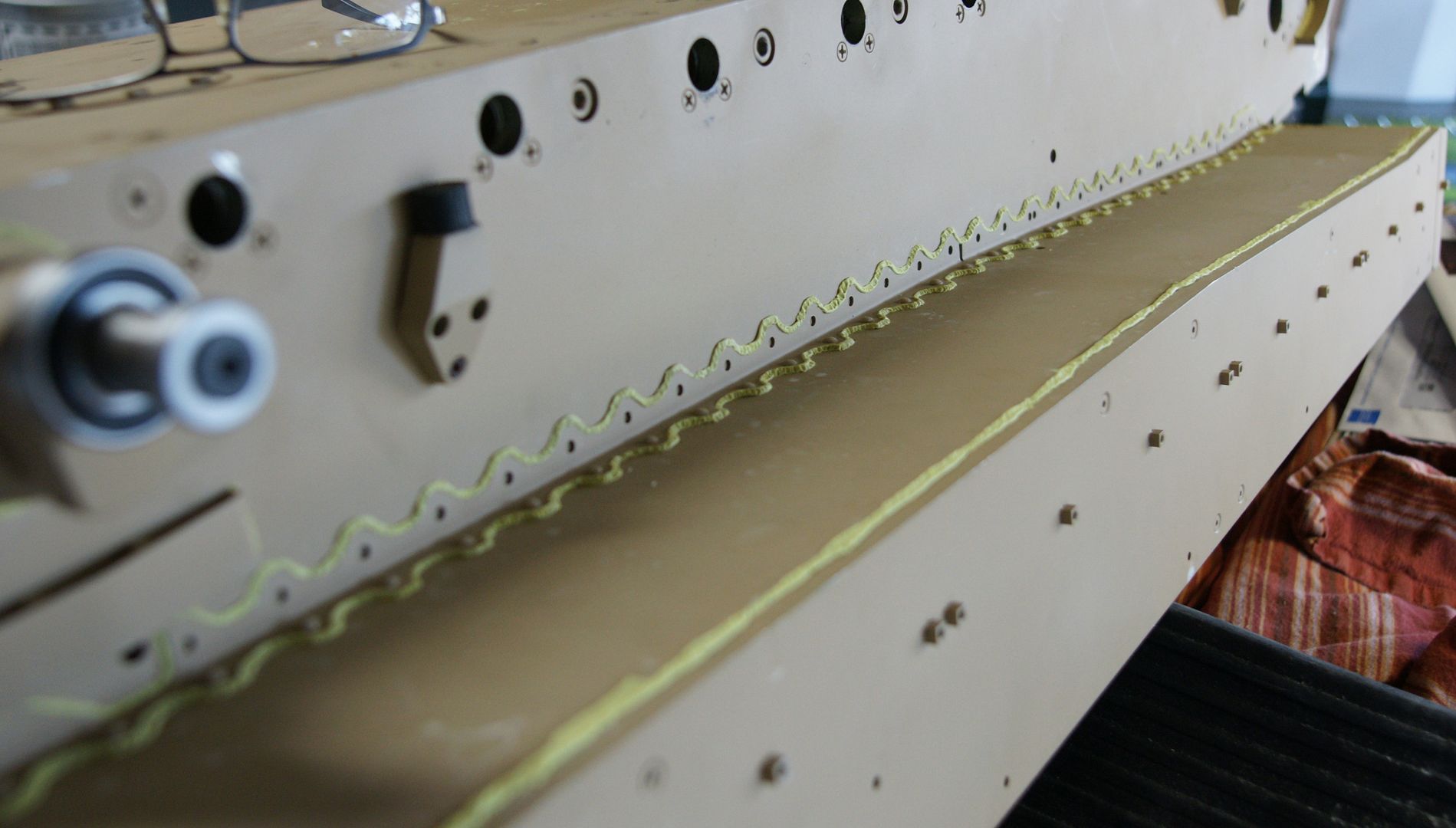

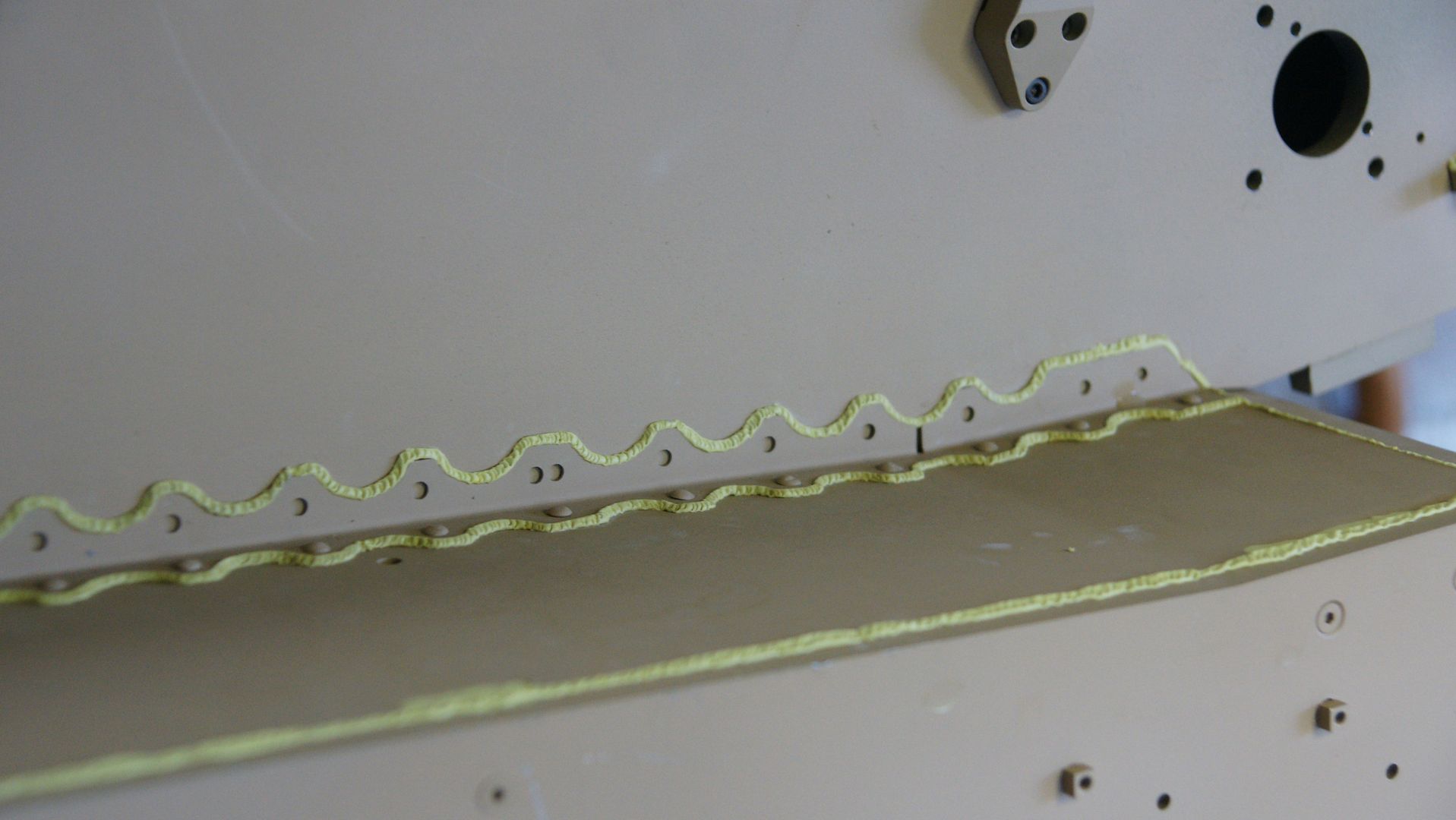

I tried my hand regarding the "weld" process and I am not that happy with it. However, I practiced on a spot that would not be easily seen unless you lay on your back.

I will try again tomorrow.

I tried my hand regarding the "weld" process and I am not that happy with it. However, I practiced on a spot that would not be easily seen unless you lay on your back.

I will try again tomorrow.

-

Tim Bowman

- Posts: 1762

- Joined: Fri Jul 13, 2007 4:53 am

- Location: Northern California

- Been liked: 177 times

- Contact:

Re: Rocky's Tiger

Hi Rocky

I can't help you with the vision port block since I thought they were all the same.

As far as the welds go, I'm not sure what you are using but it looks like a 2-part putty? When I do welds in an area that has a 90 degree corner, I use a small flat head screw driver and do a clean scrape along the weld (smashing it into the corner as I go) first to remove any excess material. Once you have it as a clean 45 degree, come back and add your weld bead texture. If there is still some excess pushed up along the sides, simply scrape it away with a straight edge razor and clean up as necessary.

I use epoxy-putty and have some water on hand for your tools and fingers.

Hope that helps

best regards

Tim

I can't help you with the vision port block since I thought they were all the same.

As far as the welds go, I'm not sure what you are using but it looks like a 2-part putty? When I do welds in an area that has a 90 degree corner, I use a small flat head screw driver and do a clean scrape along the weld (smashing it into the corner as I go) first to remove any excess material. Once you have it as a clean 45 degree, come back and add your weld bead texture. If there is still some excess pushed up along the sides, simply scrape it away with a straight edge razor and clean up as necessary.

I use epoxy-putty and have some water on hand for your tools and fingers.

Hope that helps

best regards

Tim

"So long as one isn't carrying one's head under one's arm, things aren't too bad." – Erwin Rommel

-

Rocky Sembritzky

Re: Rocky's Tiger

Tim,Tim Bowman wrote:Hi Rocky

I can't help you with the vision port block since I thought they were all the same.

As far as the welds go, I'm not sure what you are using but it looks like a 2-part putty? When I do welds in an area that has a 90 degree corner, I use a small flat head screw driver and do a clean scrape along the weld (smashing it into the corner as I go) first to remove any excess material. Once you have it as a clean 45 degree, come back and add your weld bead texture. If there is still some excess pushed up along the sides, simply scrape it away with a straight edge razor and clean up as necessary.

I use epoxy-putty and have some water on hand for your tools and fingers.

Hope that helps

best regards

Tim

Many thanks for the reply and the advice!

I am using Milliput along with scotch! That may be my problem?

Rocky

-

leesellars

- Posts: 934

- Joined: Thu Jul 12, 2007 11:19 am

- Location: Nottingham

- Has liked: 2 times

- Been liked: 15 times

Re: Rocky's Tiger

Hello rocky

As Tim says use some water when you are doing the welds and not the scotch

Lee

As Tim says use some water when you are doing the welds and not the scotch

Lee

Last edited by leesellars on Sun Oct 23, 2011 9:48 am, edited 1 time in total.

http://www.Facebook.com/newthorpemodels

Dont hit me so early in the morning with those negative waves.

Listen carefully i shall say this only once.

If its not broke dont fix it.

Ich Hatt Einen Kameraden

Dont hit me so early in the morning with those negative waves.

Listen carefully i shall say this only once.

If its not broke dont fix it.

Ich Hatt Einen Kameraden

-

Christoffer Ahlfors

- Posts: 683

- Joined: Sun Feb 14, 2010 5:19 pm

- Location: Stockholm, Sweden

- Has liked: 704 times

- Been liked: 306 times

Re: Rocky's Tiger

Hi Rocky!

Check some prototype photos. Many of the welds were quite irregular:

http://vincesgallery.smugmug.com/Histor ... 4161_4yU6W

Regarding the driver's protective bar, I have been looking for a drawing. I know I have seen one somewhere and finally found it:

http://tiger1.info/EN/DriversPortProtector.html

Hope this helps!

Cheers,

/Chris

That sounds like two-part to me!Rocky Sembritzky wrote: I am using Milliput along with scotch!

Rocky

Check some prototype photos. Many of the welds were quite irregular:

http://vincesgallery.smugmug.com/Histor ... 4161_4yU6W

Regarding the driver's protective bar, I have been looking for a drawing. I know I have seen one somewhere and finally found it:

http://tiger1.info/EN/DriversPortProtector.html

Hope this helps!

Cheers,

/Chris

A little too much is about right...

-

Ken Molchanow

- Posts: 39

- Joined: Wed Apr 14, 2010 8:04 am

- Location: Southern New Jersey

- Been liked: 21 times

Re: Rocky's Tiger

Rocky:

Check this link.

http://www.bigscalemodels.com/tips/tips ... leweld.pdf

I saw this artical before I started the welds on my T-1, it helped alot.

Check this link.

http://www.bigscalemodels.com/tips/tips ... leweld.pdf

I saw this artical before I started the welds on my T-1, it helped alot.

Regards,

Ken

"You can lead a horse to water but a pencil must be lead".

Soupy Sales

2010 Mid-Tiger Nr. 045

Ken

"You can lead a horse to water but a pencil must be lead".

Soupy Sales

2010 Mid-Tiger Nr. 045

- Adrian Harris

- Posts: 5060

- Joined: Thu Jul 12, 2007 10:46 pm

- Location: Berkshire (UK)

- Has liked: 1365 times

- Been liked: 1564 times

Re: Rocky's Tiger

That's an excellent article Ken - many thanks for posting the link

The tool he makes looks surprisingly like a leather punch, though I don't think they go small enough to be useful for us

Adrian.

The tool he makes looks surprisingly like a leather punch, though I don't think they go small enough to be useful for us

Adrian.

Contact me at sales@armortekaddict.uk for details of my smoker fan control module

-

Tim Bowman

- Posts: 1762

- Joined: Fri Jul 13, 2007 4:53 am

- Location: Northern California

- Been liked: 177 times

- Contact:

Re: Rocky's Tiger

HI Adrian

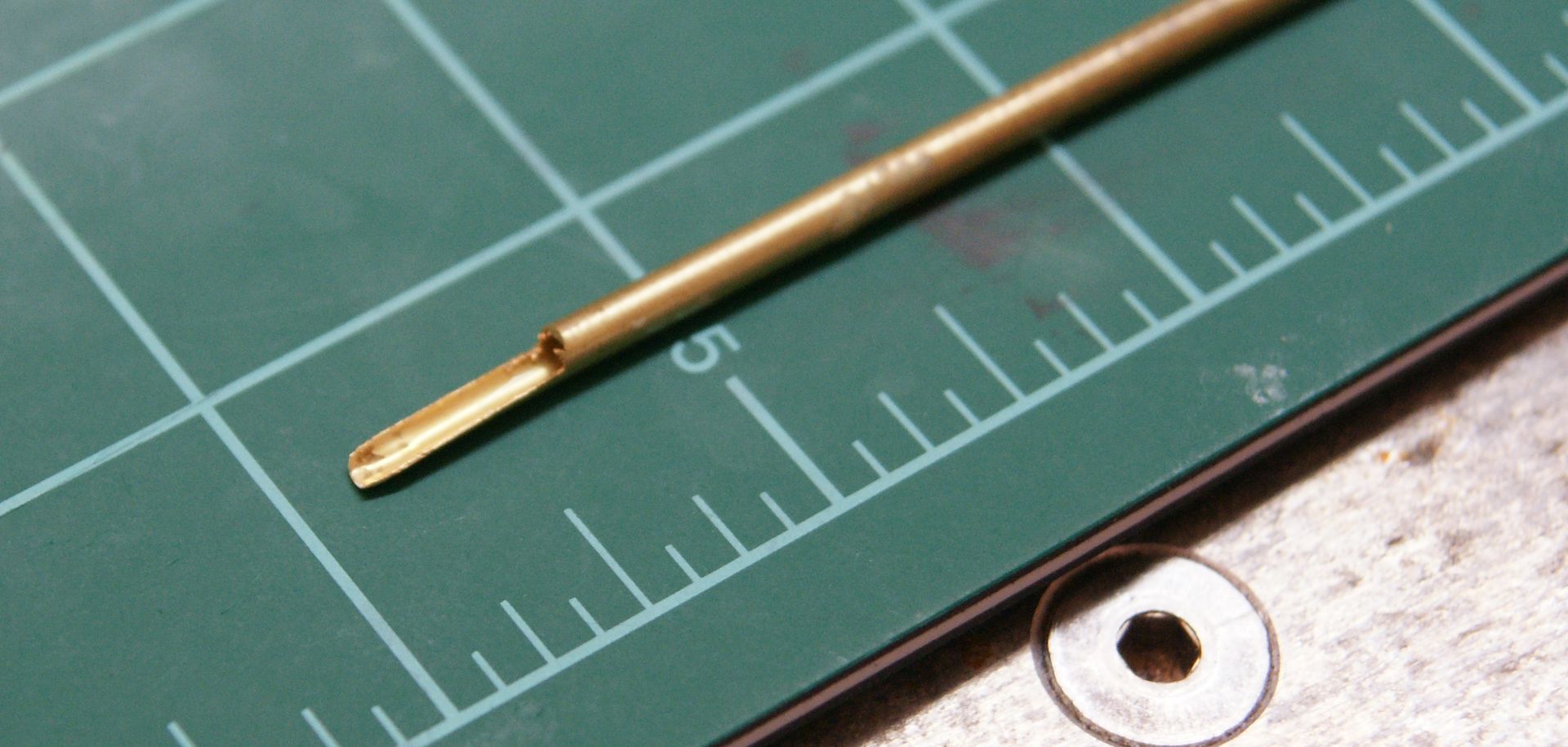

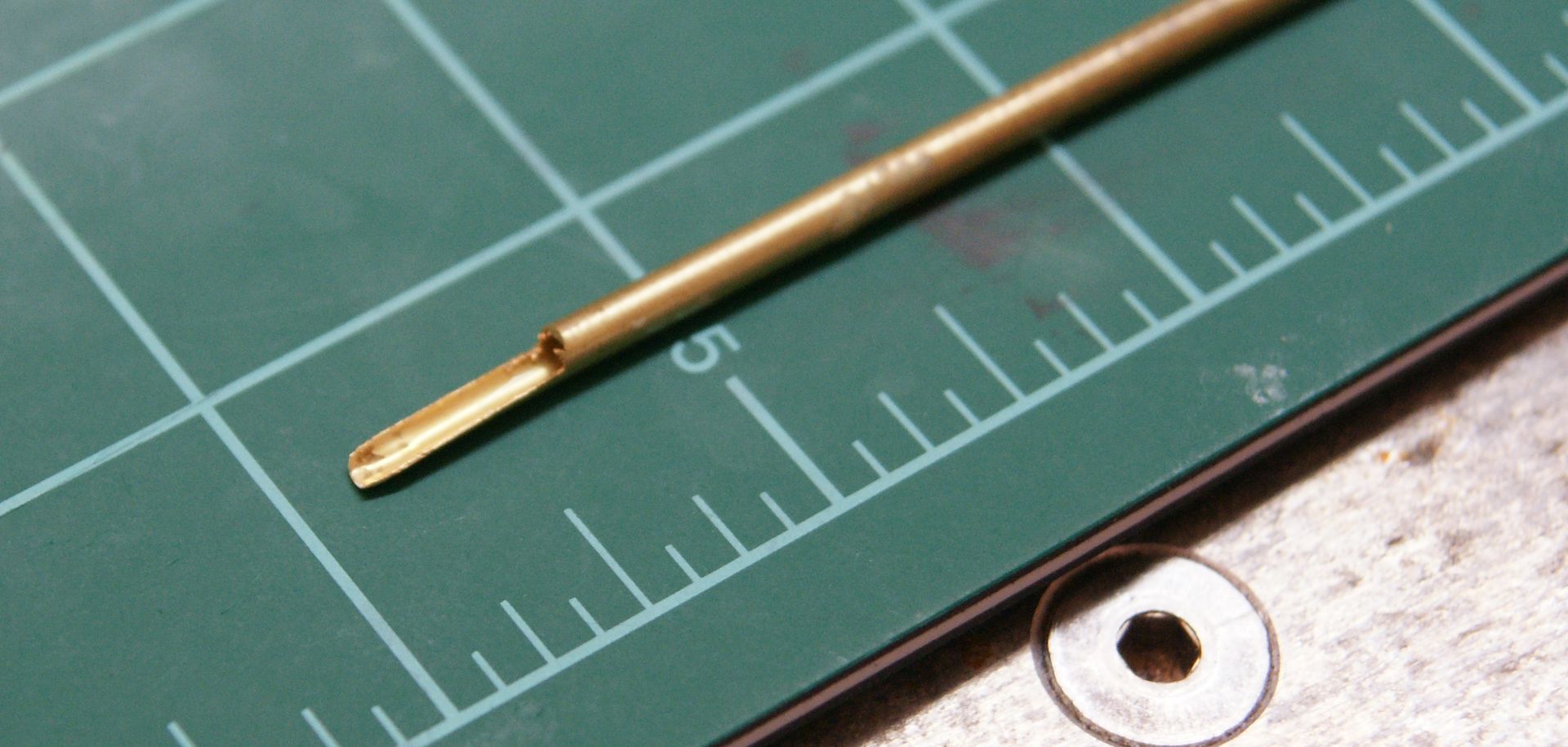

I just take sections of brass tubing and hit it on the belt sander.

Happy welding

Tim

I just take sections of brass tubing and hit it on the belt sander.

Happy welding

Tim

"So long as one isn't carrying one's head under one's arm, things aren't too bad." – Erwin Rommel

-

Rocky Sembritzky

Re: Rocky's Tiger

Lee, Chris & Ken,

Many thanks for the links and information!

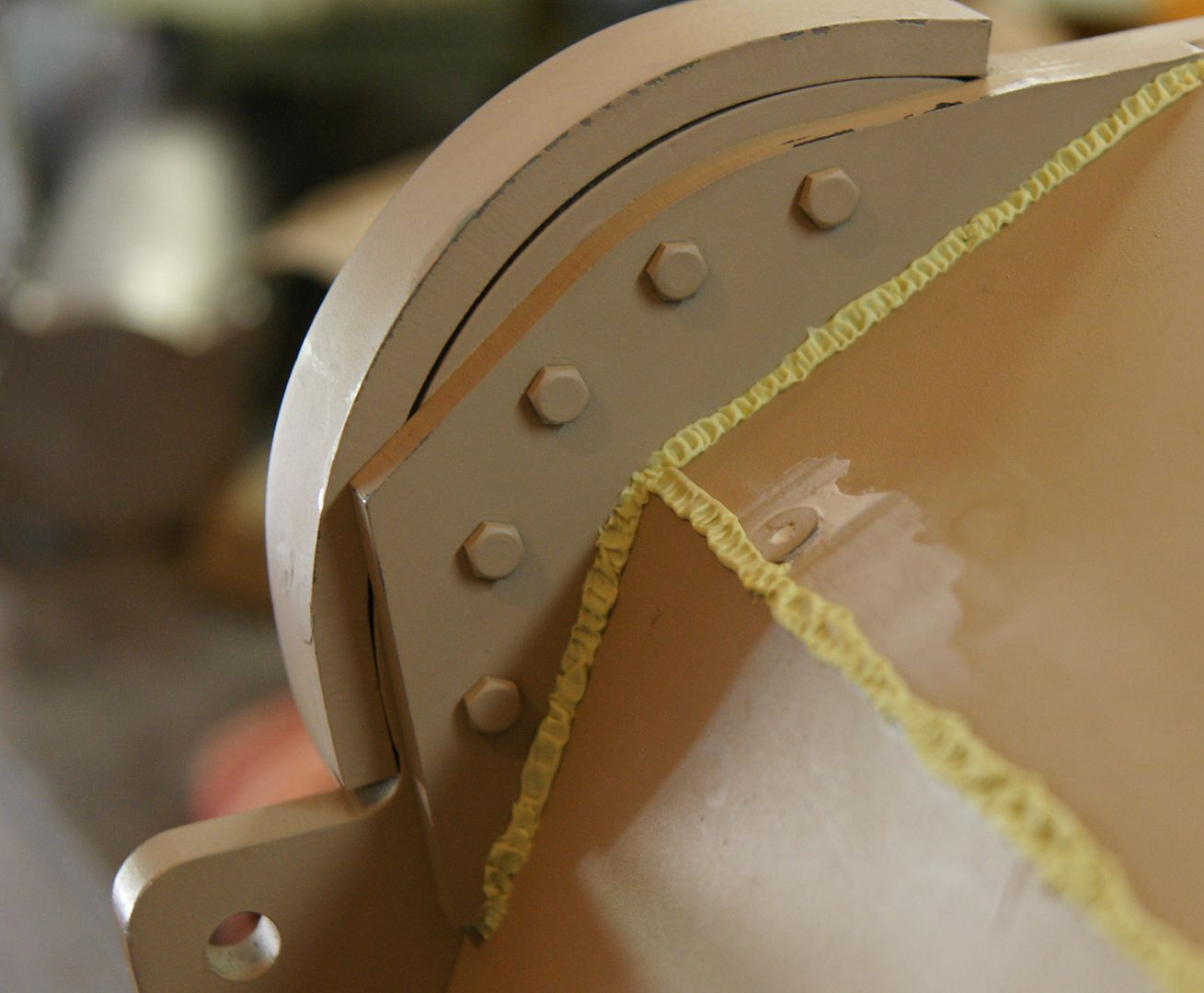

The original armor cover for the driver is too tall and I will correct that very soon, thank you Chris.

I used the scale converter App on my iPad, comparing the 1/25 Tamiya Tiger kit and the drawings, Armortek is very close.

Now, on to the welds and the new tool, thanks Ken!

It may not be pretty, but I am having fun!

Cheers!

Rocky

Many thanks for the links and information!

The original armor cover for the driver is too tall and I will correct that very soon, thank you Chris.

I used the scale converter App on my iPad, comparing the 1/25 Tamiya Tiger kit and the drawings, Armortek is very close.

Now, on to the welds and the new tool, thanks Ken!

It may not be pretty, but I am having fun!

Cheers!

Rocky

-

Rocky Sembritzky

Re: Rocky's Tiger

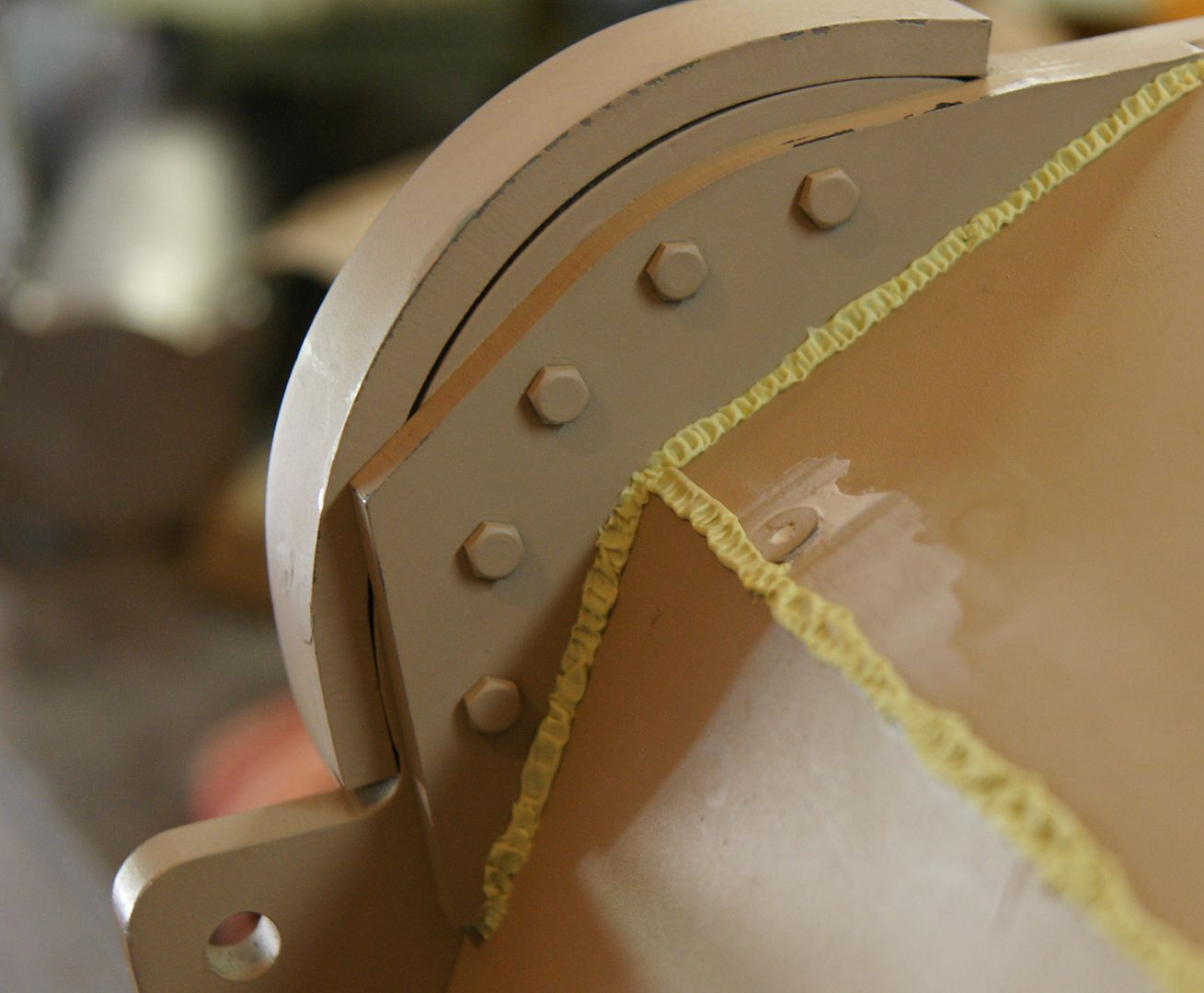

I received the bump stops from Steve and they are outstanding and so are the castle nuts!

My only question is do you use one of the existing three mounting holes or remount using new holes?

I finished all the welds on this side and started the texture process.

My only question is do you use one of the existing three mounting holes or remount using new holes?

I finished all the welds on this side and started the texture process.

-

John Fitzsimons

- Posts: 1816

- Joined: Tue Dec 14, 2010 3:11 pm

- Location: IRELAND,Dublin/Meath

- Has liked: 5 times

- Been liked: 629 times

- Contact:

Re: Rocky's Tiger

http://www.armortek.co.uk/Forum3b/viewt ... 8&start=15

See above re positioning although some contradictions. Hope it helps. What a pity once fitted you hardly see them but at least you know they are there.

See above re positioning although some contradictions. Hope it helps. What a pity once fitted you hardly see them but at least you know they are there.

If interested in any parts used in my builds contact me at johnfitzsimons@msn.com for a price list.

http://www.armortek.co.uk/Forum3b/viewt ... f=4&t=4770

https://youtube.com/@16rctankworkshop-y ... TlMwTalnX5

http://www.armortek.co.uk/Forum3b/viewt ... f=4&t=4770

https://youtube.com/@16rctankworkshop-y ... TlMwTalnX5

-

Rocky Sembritzky

Re: Rocky's Tiger

John,John Fitzsimons wrote:http://www.armortek.co.uk/Forum3b/viewt ... 8&start=15

See above re positioning although some contradictions. Hope it helps. What a pity once fitted you hardly see them but at least you know they are there.

Many thanks! I have no idea how I missed that post? I have been through Tim's thread many times, must have been the scotch.

I was a little motivated and decided to finish the welds on the other side....

The paint arrives tomorrow, a little more texture and I hope to have the wheels on by next weekend.

Cheers!