Page 2 of 7

Re: KIT No. 98 BUILD

Posted: Tue Feb 20, 2024 8:52 pm

by mick whittingham

I moved to the rear cross member for a change tonight.

I wanted to get the anti ditching handles right, that led on to making a three pin trailer socket!

Then I made an insert for the PTO tube so that it has the appearance of being welded. Not sure if it's quite right, but better than a plain drilled hole.

Re: KIT No. 98 BUILD

Posted: Tue Feb 27, 2024 9:18 pm

by mick whittingham

I have just finished reading the book about JUE 477, landrovers first production vehicle.

The restoration is nothing short of miraculous when you see how badly neglected the first series 1 ever had been, not only during its working life but after it was bought and eventually recognised as number 1 by a hill farmer in Northumberland. He left it to rot in a field before sticking it in a leaky barn even though he knew of its importance. He had hopes of being able to restore the vehicle but it was way beyond his means and it was left to Sir Jim Ratcliffe to rescue the vehicle and finance its restoration.

I was going to base my model on JUE as it stands now, but I don't think that's a worthwhile use of such a beautiful kit.

So the search goes on to find a suitable example to base my model on.

Re: KIT No. 98 BUILD

Posted: Wed Mar 13, 2024 8:43 pm

by mick whittingham

Did a little more work on the front suspension of late.

The shock absorber top bracket needed a 2mm thick spacer making to take up the play between it and the shocker eye.

Not a big job but definitely something that will help with the action of the shockers.

- 20240313_192748.jpg (65.32 KiB) Viewed 3664 times

Re: KIT No. 98 BUILD

Posted: Wed Mar 13, 2024 10:46 pm

by Charles A Stewart

Now that's a very good idea,.

Cheers Charles

Re: KIT No. 98 BUILD

Posted: Wed Mar 13, 2024 11:10 pm

by mick whittingham

Charles, I was going to make a proper bolt for the shocker mounts, so that the eye sits on a smooth surface rather than the thread of a set screw. Maybe something I will look at.

I'm also looking at turning a groove in the piston of the shocker to take a small O ring.. then I can lubricate the unit with Kilopoise grease to improve the function of it.

These are only tiny details but I enjoy the minutiae of working on these machines.

Re: KIT No. 98 BUILD

Posted: Wed Mar 20, 2024 6:23 pm

by mick whittingham

I have made a new piston for the shock absorbers to see if the modification works.

It's really pretty good and gives a nice damping effect to the movement of the piston.

I drilled a centre hole and cross drilled into it to allow air pressure to vent, the kilopoise provides all the damping.

Re: KIT No. 98 BUILD

Posted: Sun Mar 24, 2024 1:18 pm

by mick whittingham

I've been dry fitting the chassis and decided to finally bond it all together before painting it.

I saw the way Charles dealt with the spring hanger button head screws and decided to do a similar modification, but riveting rather than threading.

I bonded each hanger in place with quick metal and then made brass rivets for the through holes, swelling them out and filing them flat.

Filled all the countersinks and holes with jb weld and I'm rubbing it down ready to get some Upol primer sprayed on.

Re: KIT No. 98 BUILD

Posted: Thu Mar 28, 2024 5:37 pm

by mick whittingham

I've continued the chassis work and added in some "welding" to the appropriate areas.

When painted it should look ok, I used the same technique on the Centurion build.

Re: KIT No. 98 BUILD

Posted: Thu Mar 28, 2024 7:50 pm

by Charles A Stewart

Nice welding, looking good

Charles

Re: KIT No. 98 BUILD

Posted: Thu Mar 28, 2024 9:00 pm

by mick whittingham

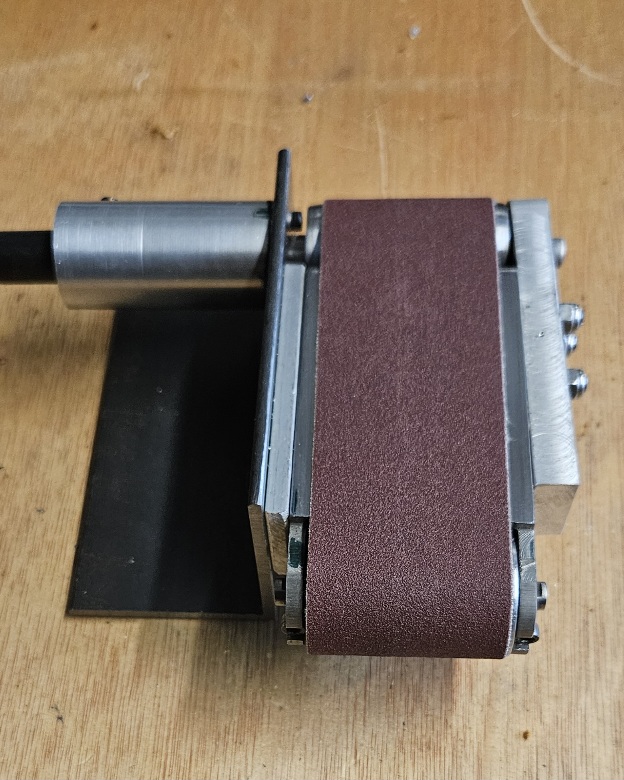

Thanks Charles. I'm taking a day out tomorrow to build a miniature belt linishing machine.

I saw a proxxon hand held one and bought a pack of belts for it. They are 40mm wide x 260mm long.

I will make a steel bench mounted version to help in doing the metalwork.

I just bought a Foredom flexi drive shaft which fits on the bench polisher I treated myself to, I'm planning on making the bench linisher run from that, copying the key drive.

I have three larger belt machines but a mini version will be very useful so it's a good little project for a rainy day.

Mick

Re: KIT No. 98 BUILD

Posted: Fri Mar 29, 2024 7:13 pm

by mick whittingham

I managed to make the linisher bed and front idler folder today, quite a bit of machining to get the channel section in shape.

Next job is to come up with a drive unit to accept the flexi shaft fitting. Then I can mate the two together with a drive pulley.

Re: KIT No. 98 BUILD

Posted: Sun Mar 31, 2024 3:41 pm

by mick whittingham

- 20240331_144313.jpg (258.16 KiB) Viewed 3163 times

Re: KIT No. 98 BUILD

Posted: Thu Apr 04, 2024 4:37 pm

by mick whittingham

I'm stuck waiting for bearings for the linisher project. Plus I've had other jobs crop up so build time has been nil just about.

I think I'm just about ready to paint the chassis, I can't see much more detailing that is worth doing because the model requires to be a runner not just a static, on which I could spend a lot more time.

Once the chassis is primed and painted I can start on the build proper.

I'm still not set on what to base my model on. Finding enough reference material for a specific vehicle might be difficult, unless it's one I can visit and photograph myself.

But I could just go for a generic production model and put on the detail I choose, even if its not strictly correct.

From the reading I've done so far it seams Rover were pretty blasé about what and when they fitted upgrades and modifications, even the pre production models were fitted with production parts before they were released from the factory. So it's hard to find a pure vehicke to work from.

Re: KIT No. 98 BUILD

Posted: Sun Apr 07, 2024 5:01 pm

by mick whittingham

Did a little work on the linisher machine, machining bearing pockets and the like.

But back on the build I decided to look at the dash board layout.

The thin outer "ring" is designed to mimic the pressed steel of the dash fascia plate so I rounded the edges inside and out to look like the original. I silver soldered it to the dash fascia and then drilled the new holes required for 4x mounting screws and the choke knob and 12v outlets.

It looks pretty neat just with some primer on.

Next will be making the choke knob, warning lights and 12v sockets, and if I'm bored enough some polished aluminium bezels for the gauges.

Re: KIT No. 98 BUILD

Posted: Wed Apr 10, 2024 2:41 pm

by mick whittingham

Finally finished machining the mini linisher.

I'm quite happy with it, certainly will come in handy as a bench mounted unit. And much cheaper than the proxxon machine that the belts fit.

- 20240410_135955.jpg (180.81 KiB) Viewed 2954 times