Page 2 of 7

Re: Mick's StuG 111

Posted: Sat Nov 07, 2020 8:24 am

by michael hilton

Good morning John, you obviously read my mind, ( not a safe place to be ). I had concluded that the only reasonable cause of my problem was the bearings. I did use a socket from my Gordon Tools Socket Set,

purchased at great expense in the 1950s, and hardly ever used, to remove the bearings.

Consequently, I may have damaged one or both bearings, they do look ok though.

On Thursday last, the fateful day, I anticipated this and ordered replacement bearings. All being well they will arrive today and I can resolve, or not, the problem. I like the diagram and your reasoning, it makes so much sense. Thank you again John, I will follow your advice and try again.

However, I do have a cunning backup plan ..... Mick

Re: Mick's StuG 111

Posted: Sat Nov 07, 2020 9:17 am

by John Clarke

Always great to have a plan Mick, ordering new bearings will certainly give you a good start and tiding the recesses will really help.

It's strange, sometimes bearings just " pickup" and just don't sit correctly.

We have it sometimes at work on conveyor rollers that have multiple bearing ends.

Gorden tools, now there's a right blast from the past.

Socket sets are always handy to tap bearings in evenly. Especially if it's an old unused set.

My old 1970's "King Dick Whitworth set" was always going to be useful, though the name might be trying to tell me something ........probably

Re: Mick's StuG 111

Posted: Sat Nov 07, 2020 2:43 pm

by John Clarke

Hi Mick

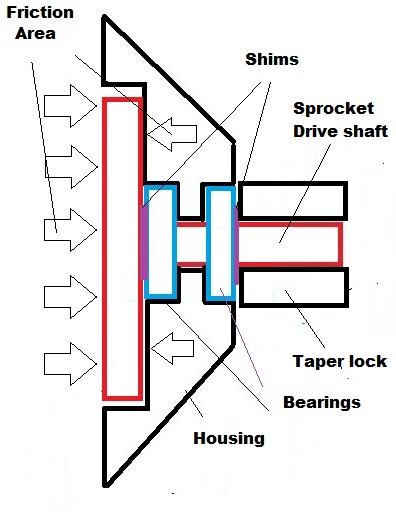

I'm still in Chieftain shimming gearbox mode at the moment, I read somewhere that it was often found when stripping the Armortek gearboxes down the output drive shaft gear wheel was often found to be rubbing on the back wall of the chassis. Counter acting this is done by loctiting the shaft to the inner ball races of the outboard gearbox housing.

But my thoughts turned to if your pulling the shaft outwards away from the chassis wall, you could pull the shaft onto the bearing or inner wall of the gearbox housing, either way the gear wheel could start rubbing against one wall or the other, wasting power,shaving aluminum and making a nice grinding paste with the grease in the gearbox (Worst case scenario)

So have you thought of placing thin shims, space allowing, between inner bearing and gear wheel. Outboard shims fitted once track alignment has been measured up. We maybe only talking 0.2mm - 0.3mm shims inboard. The outboard shim will probably be a lot thicker but when the taper lock is fitted the whole assembly will not move much from set position.

(A shim today will keep the keep the chomper away)

This is certainly how I intend to set up my gearboxes for maximum efficiency.

- bearings2.jpg (52.14 KiB) Viewed 3025 times

Re: Mick's StuG 111

Posted: Sun Nov 08, 2020 12:05 pm

by michael hilton

Hello John and thank you for your advice. Spent most of yesterday fitting and refitting, following your guidance. Ended up locking the driven gear solid on the second bearing. I thought I had succeeded at one point, however the lower bearing had not fully seated. The gear looked to be very slightly skewed, anyway....I do have an alternative plan....Gene Autry

On a completely different subject, I purchased the Gordon Tool Socket Set when I was discharged from the Army, intending to find work as a motor mechanic, this was in 1958. I think the good Lord had other ideas, and pointed me towards the Ambulance Service....Mick

Re: Mick's StuG 111

Posted: Tue Nov 10, 2020 11:19 am

by michael hilton

Oh Armortek what have you done with your new releases....I will never have any money left over to leave the grand and great grandchildren.

I do like the Sherman and I enjoyed the film. A dream world is a far better place...

Mick

Re: Mick's StuG 111

Posted: Tue Nov 10, 2020 12:52 pm

by Frank Breitenbach

Hello Mick

It is realy nice to see your buildung reports.

All the best

Frank

Re: Mick's StuG 111

Posted: Tue Nov 10, 2020 8:15 pm

by Christoffer Ahlfors

John Clarke wrote: ↑Sat Nov 07, 2020 2:43 pm

So have you thought of placing thin shims, space allowing, between inner bearing and gear wheel. Outboard shims fitted once track alignment has been measured up.

On my tiger, I used an aluminum shim on the outside, filed to thickness to provide the right track alignment. Caution has to be used, as the taper bushing can put an axial squeeze on the bearings. Just fit the motors afterwards, so you can first make sure that the bearings are running smoothly. This process is expressly discouraged by Armortek, arguing that the taper bush manufacturer insists that the bushing must be able to slide freely on the shaft. Strange, in my thinking. It sits perfectly still, but the sprocket moves, as the bushing is tightened. Anyway, it has worked well for me.

The inner shim is likely not needed, but it is easy to test: Just press the gear against the housing (bearings installed) with your fingers and check for interference.

Re: Mick's StuG 111

Posted: Sat Nov 14, 2020 3:56 pm

by michael hilton

Hi Guys, wet wet wet, 'omering down here in Wales. Ok, if you recall my driven gear problems...I have the gear case re-assembled by Armortek, returned and fitted, sweet as a nut, all is well. I have spray painted the hull parts with acid etch and started the return rollers. Again, not wanting to race along as I would like this build to last until at least the Shermans...Oops! .... Mick

Re: Mick's StuG 111

Posted: Sat Nov 14, 2020 6:53 pm

by John Clarke

Hi Mick

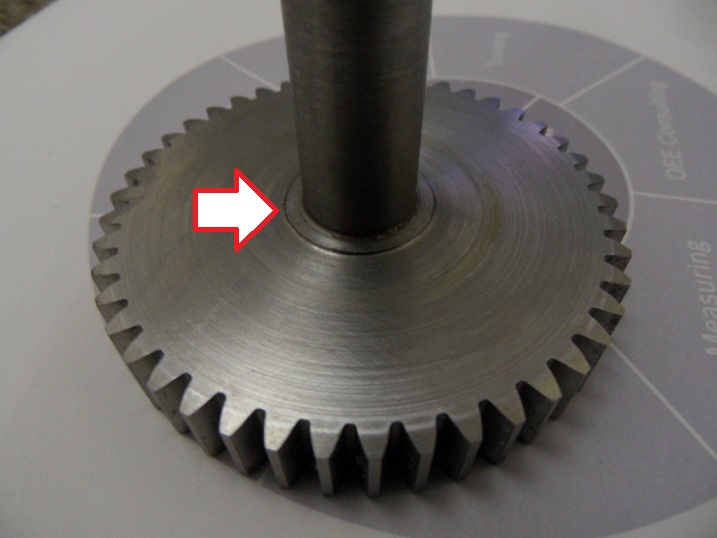

Good to the hear your gearboxes are all good, I've just dug out my final drive shafts to fit into the outboard gearboxes. I was really pleased to see a small step on the gear which will prevent any binding on the gearbox case or the bearing itself. I'll not need shims on the inside now, maybe some on the outside though.

Good news all round

It's sticky grease time!

- SAM_3181.JPG (144.86 KiB) Viewed 2830 times

Re: Mick's StuG 111

Posted: Sun Nov 15, 2020 8:12 am

by michael hilton

Good morning John, I noticed that lip on the driven gear...it's very slight...I also heard ( when rotating the gear a slight scraping sound ) so I 'ground' very carefully, the screw heads which are under the driven gear, flush with the hull side, this got rid of the sound...and the gears turn smoothly, well pleased.

I recall with my Comet build, when dismantling the gear case for a noise issue, so called 'witness marks'.. I understand this to be an engineering term

....Mick

Re: Mick's StuG 111

Posted: Sun Nov 15, 2020 9:59 am

by John Clarke

Hi Mick,

I'm very pleased on how my Chieftain outboard gearboxes are going together, their really sweet. I'm probably wrong putting them together the way I have (outside in) but I do get a good feeling the way everything lines up. The hidden factor I call it. Other than bolt alignments there are no locating points, so if everything lines up without forcing it, it has to be right by design.

Witness mark's, yes Mick their great, sometimes current, sometimes historical. Looking at your methodical way of building I sure the heart of the Stug will be top notch, stay safe and keep the posts coming.

Re: Mick's StuG 111

Posted: Wed Nov 18, 2020 11:16 am

by michael hilton

Good morning everyone, slow but steady progress. Cold in the garage for spray painting, i am restricted to this area, because of the smell of Acid Etch.

Nit picking if you ask me...Mick

Re: Mick's StuG 111

Posted: Wed Nov 18, 2020 12:02 pm

by Adrian Harris

To be fair, the solvents in Etch primer would probably kill nits

Adrian

Re: Mick's StuG 111

Posted: Fri Nov 20, 2020 7:38 pm

by michael hilton

Good evening everyone, back to the more mundane...finally replaced my worn out filing system for all those M screws/bolts /nuts/pins/ rivets. and on and on. Sixty compartments, Tool Bits Organiser Unit, on Ebay. I previously used large tray type boxes and small plastic bags, labelled. Eventually the label's fall off or become oil stained. Woe is me.

Cold weather or not it's into the garage tomorrow and out with the rattle cans for some undercoat...on the StuG of course....Mick

Re: Mick's StuG 111

Posted: Mon Nov 23, 2020 4:42 pm

by michael hilton

I am just going outside, I may be some time, Lord it's cold in the garage, careful use of the dear wife's hair drier...what on earth

I'll buy a new one for Christmas...Mick

purchased at great expense in the 1950s, and hardly ever used, to remove the bearings.

purchased at great expense in the 1950s, and hardly ever used, to remove the bearings.