Thanks for the heads up Paul, I have fasteners hidden below the epoxie welds for the reason you listed above.

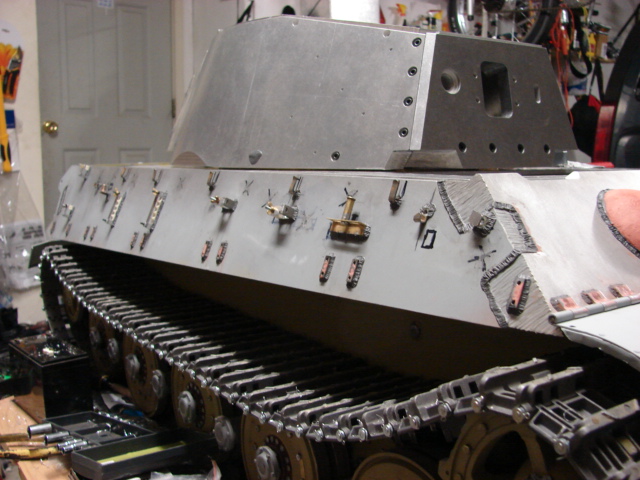

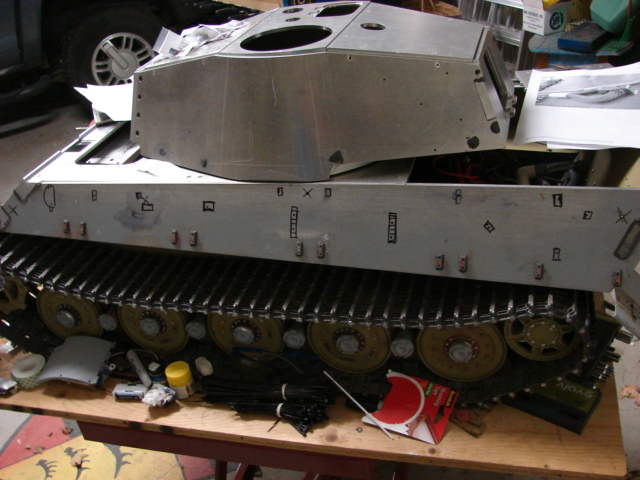

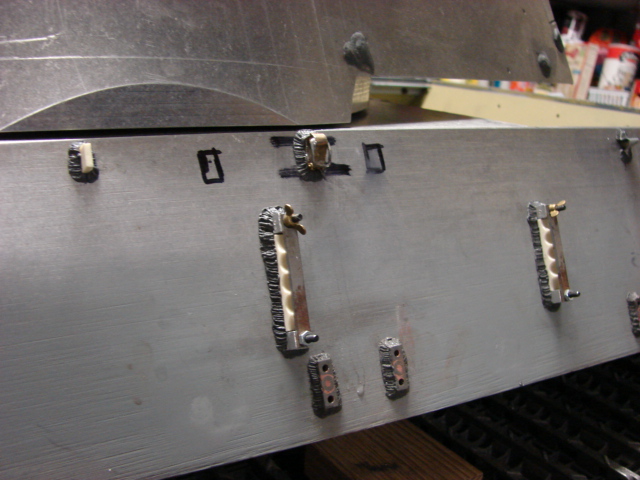

I have just finished the tank's side hull tool posts and tow cable mounts.

The kit supplies you with tools, Tow cables, basic tool posts and tow cable locks. The tank's hull is also pre drilled for all of the tool posts. To improve on the most of the tool post locations needed to be relocated. The kit's holes were filled in and will be sanded over.

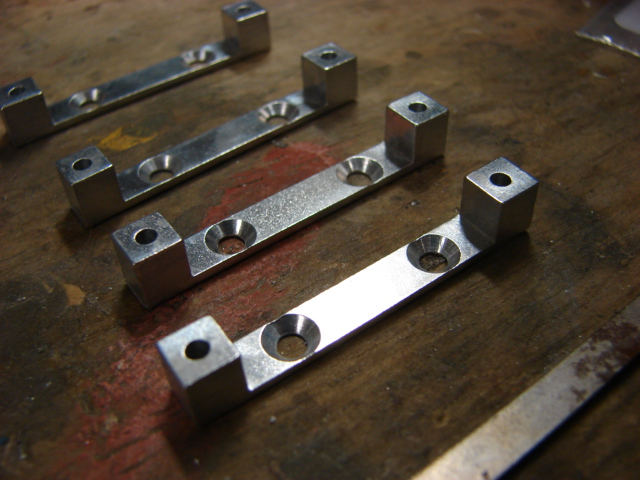

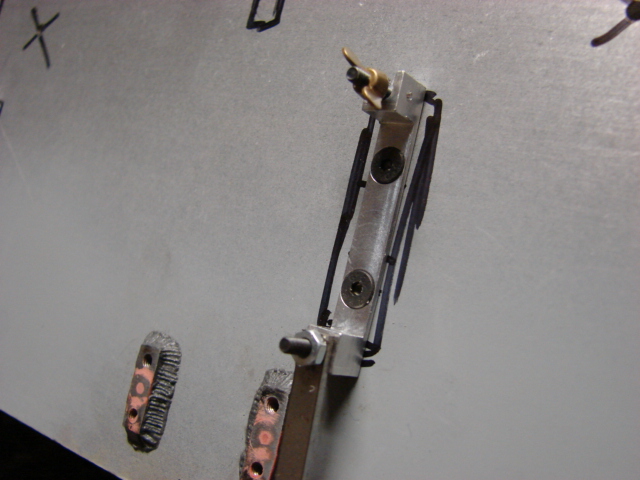

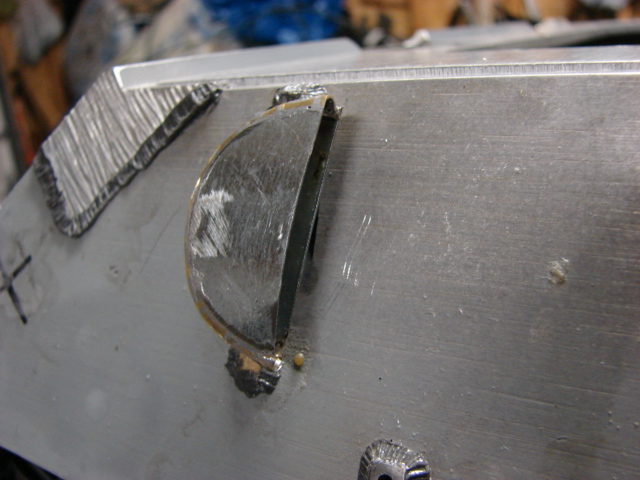

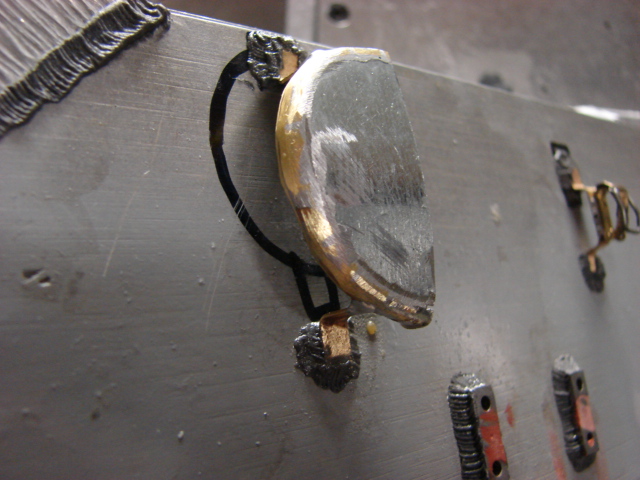

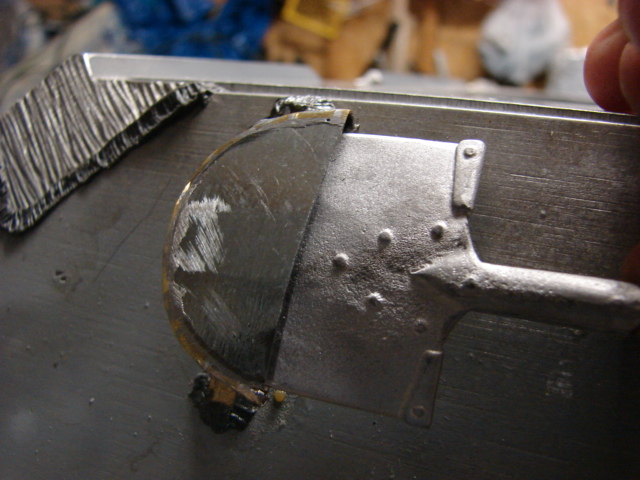

tank's tow cable mounts were the first of the tool posts that were reworked. The kit supplied cable mounts are made out of CNCed Aluminum braces with laser cut steel strips. The braces are missing the groves for the gun cleaning kit and the tow cables. The braces are also missing the pivot points on the one end for the folding retaining bolt. The braces are mounted to the tank very securely via counter sink bolts with nuts anchoring them on the inside of the vehicle.

To keep the braces as strong as possible I didn't make the pivot bolt functional, instead I modified the kit supplied base to appear that the pivot works. The way I did this was the kit supplied braces had inlets machined into the one end. The brace now has the detail of the pivot, but still has it's full strength.

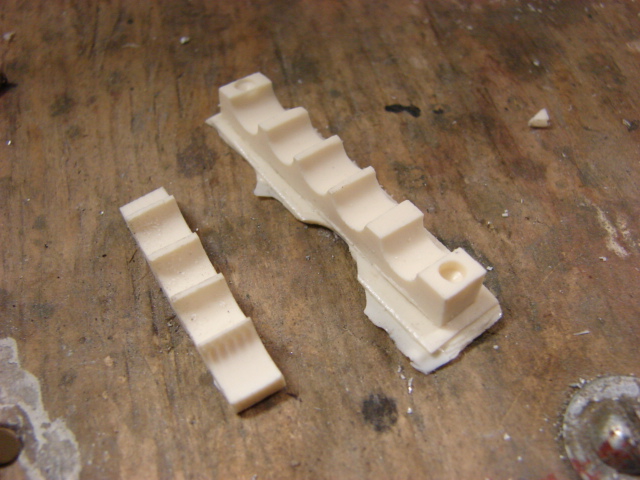

For the center grooves I took the center groove portion from one of my resin Tiger tow cable mounts. The resin center was installed over the flush counter sink bolts after the braces were added to the tank.

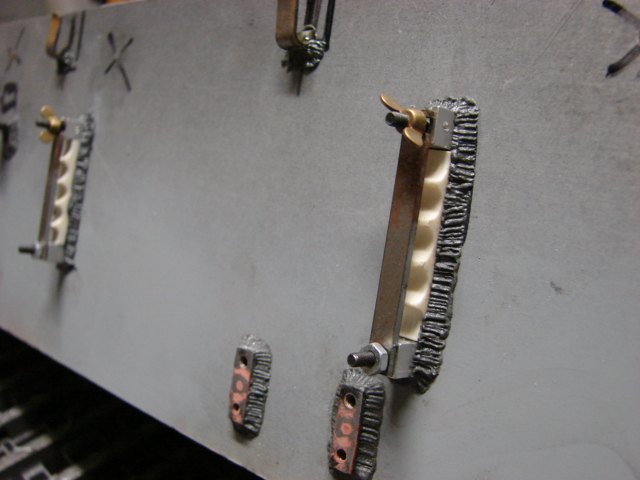

The kit also includes small tow cable mounts for retaining the tow cable ends and for retaining thee steel cable towards the rear of the vehicle. Like the other mounts these locks are produced form CNCed aluminum. The tow cable locks have a functional hinged top, but are missing the front portion of the lock with the pivot bolt.

Like the other mounts I didn't make the pivot bolt functional, instead I made a resin detail shroud that slipped over the steel bolt. This again gives me the maximum amount of strength and detail. On the hinged tops I had to transform the drilled out bolt hole into a slit that would have been used for the pivot bolt. The slit doesn't effect the strength of the mount in any way, and still locks securely.

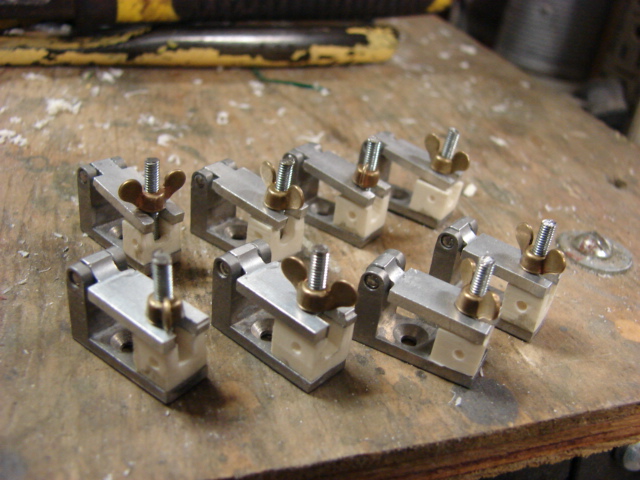

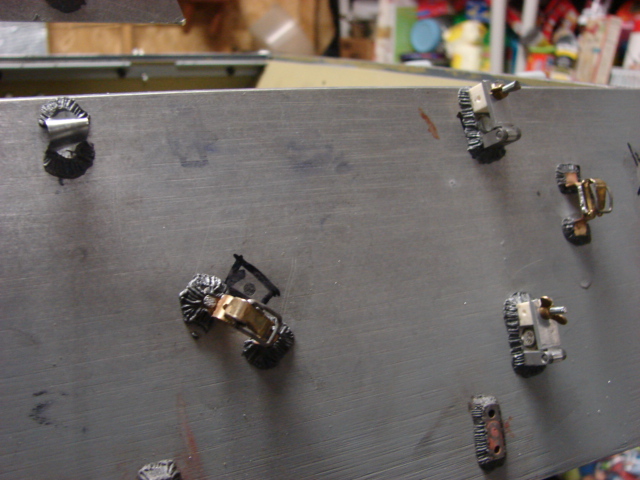

The kit supplied track cable mounts were also very basic and needed to be reworked.

The mounts were re bent and had a M3X16mm bolt soldered to the the inner end.

This procedure was done with the other Armortek cable mounts.

Before

After

After

Before

Before

After

After

For some of the tool posts I had to scratch build some completely. These would include the track cable end mounts, shovel mount, and tool handle locks.

The front transport cable end mount was fabricated out of a brass angle and a spent .22 cal shell casing. The angle has a slot milled into the top and a nut was soldered to the shell casing. This allows the end mount to be adjusted along the brace to adjust the tension of the cable.

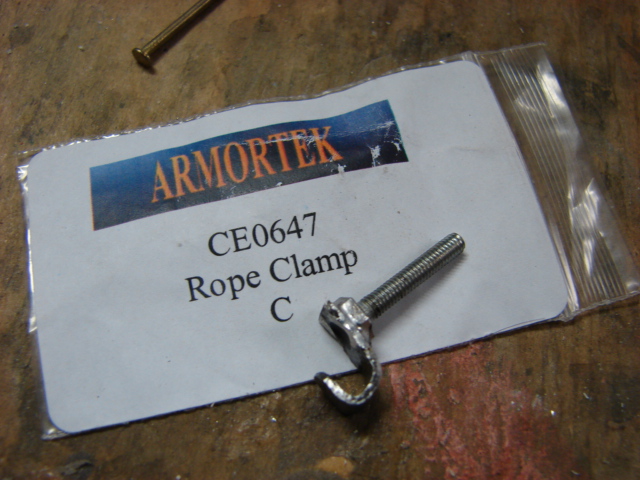

For the rear cable end mount a spent .22cal shell casing and a M3X16 hex bolt was soldered to a reshaped Armortek rope support mount.

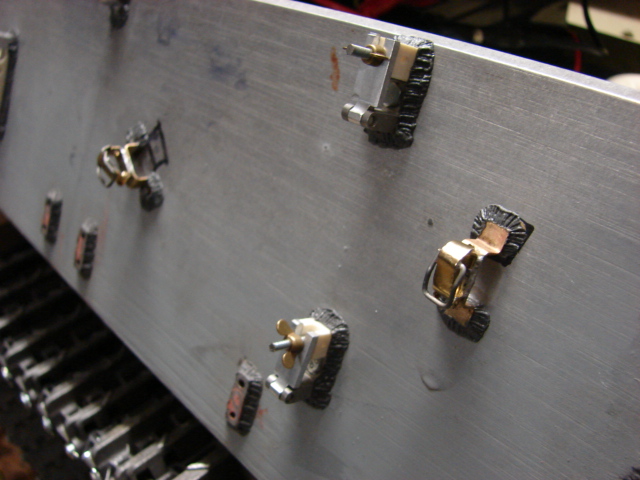

For the front shovel the kit does supply you with a shovel head mount. The mount itself is made out of CNC aluminum, however I decided to fabricate an all new one out of steel and brass. For the shovel the kit supplies you with a white metal armorpax shovel which is a nice addition and will be used on this model.

Kit supplied component

New scratch built mount.

All of the added components had epoxie welds added completeing the side hull details.

Now that the side is complete I can now install the top deck and work on the top deck details. More to come.