Rocky's Tiger

-

Sarah Frazer

- Posts: 202

- Joined: Sat Oct 17, 2009 8:12 am

- Location: Bristol

- Been liked: 2 times

-

Rocky Sembritzky

-

Sarah Frazer

- Posts: 202

- Joined: Sat Oct 17, 2009 8:12 am

- Location: Bristol

- Been liked: 2 times

-

Derek Attree

- Posts: 1307

- Joined: Thu Jul 12, 2007 12:44 pm

- Location: london

- Has liked: 219 times

- Been liked: 200 times

-

Sarah Frazer

- Posts: 202

- Joined: Sat Oct 17, 2009 8:12 am

- Location: Bristol

- Been liked: 2 times

-

Dave Hill

- Posts: 45

- Joined: Sat Feb 14, 2009 12:32 pm

- Location: gods wonderful county

Stagonest is worth looking into.

They do individual items if wanted.

Delivery is excellent; next day if ordered am

http://www.stagonest.co.uk

They do individual items if wanted.

Delivery is excellent; next day if ordered am

http://www.stagonest.co.uk

- Adrian Harris

- Posts: 5131

- Joined: Thu Jul 12, 2007 10:46 pm

- Location: Berkshire (UK)

- Has liked: 1484 times

- Been liked: 1693 times

-

Heinz Felgemacher

- Posts: 8

- Joined: Thu Jan 08, 2009 6:43 am

- Location: Bocholt/Germany

Hello Sarah,

there are several German companies which are able to send special screws of any diameter. Try www.modellschrauben.de , www.knupfershop.de or ghw-modellbau.de.

Best wishes from Germany

Heinz

there are several German companies which are able to send special screws of any diameter. Try www.modellschrauben.de , www.knupfershop.de or ghw-modellbau.de.

Best wishes from Germany

Heinz

Si vis pacem para bellum !

-

Sarah Frazer

- Posts: 202

- Joined: Sat Oct 17, 2009 8:12 am

- Location: Bristol

- Been liked: 2 times

-

Rocky Sembritzky

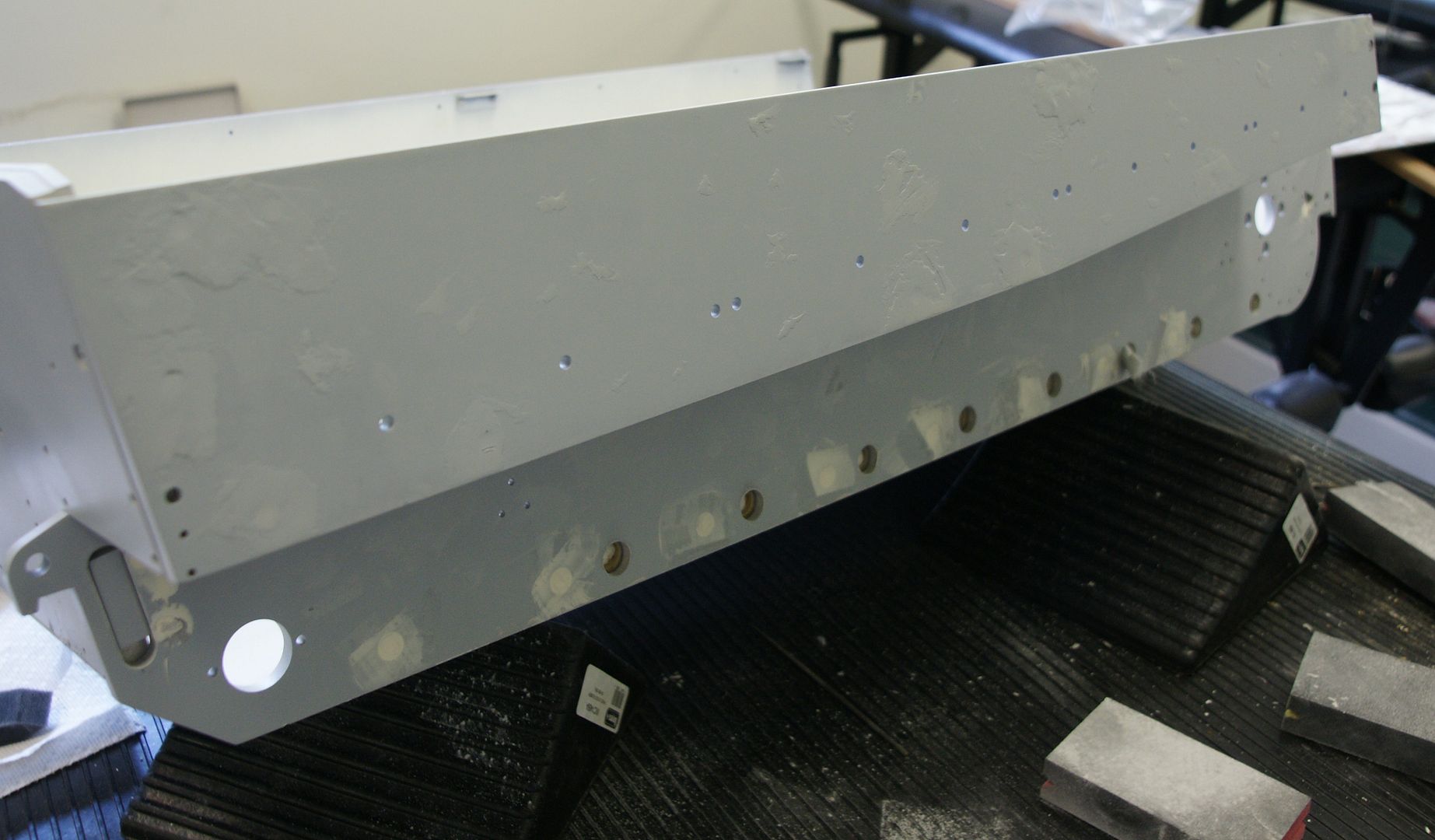

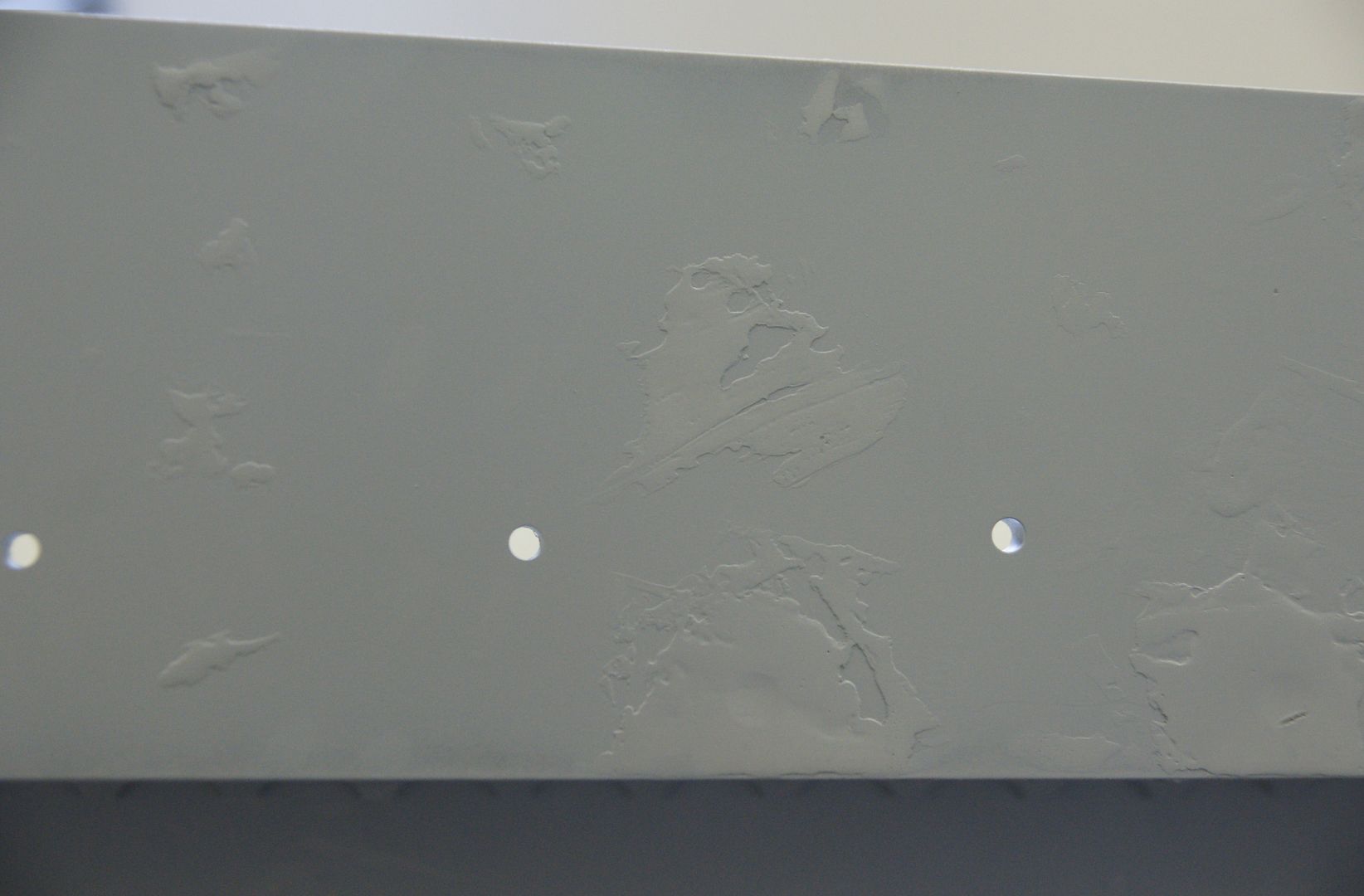

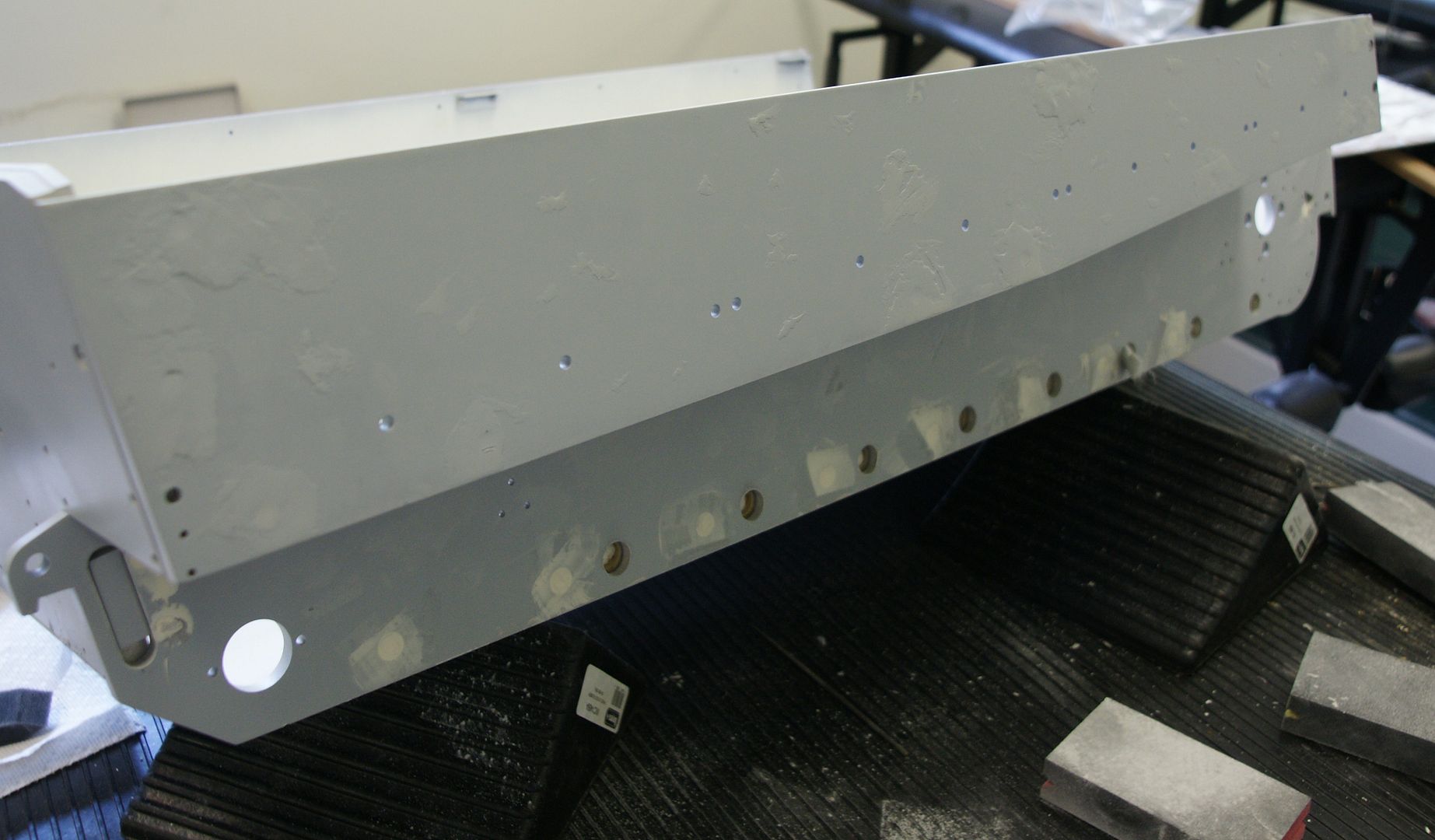

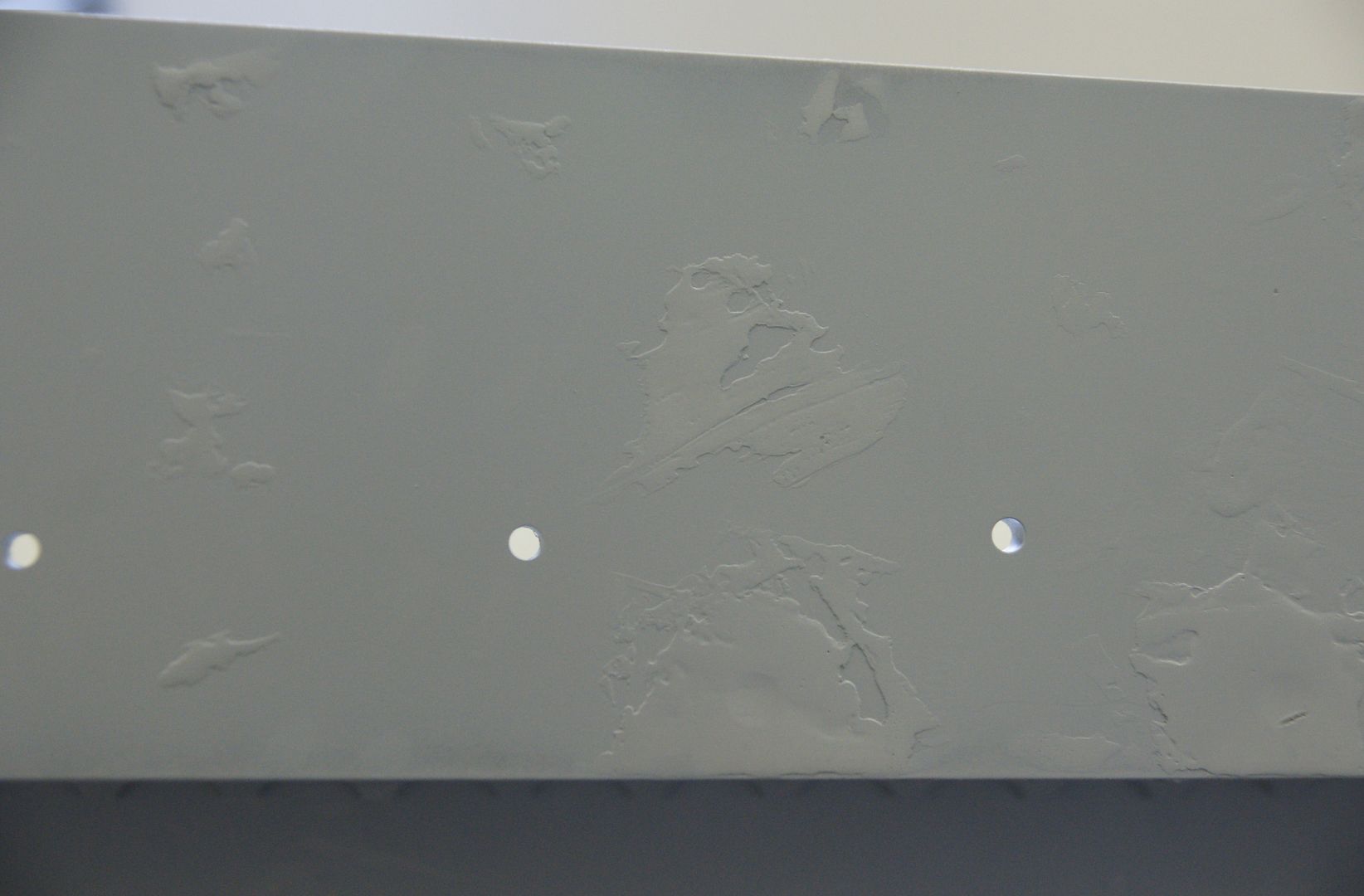

I spent some time with the Tiger today and tomorrow is a holiday so I will have all day to continue at a snails pace. The interior has now been painted Wimbledon white (odd for a Tiger) and started filling in the holes with putty. I decided to experiment with the putty to see if I could get a textured steel look.

I have never worked in this scale so I am shooting in the dark! I just decided to dab some on, sand it down see what would happen.

Sand and spray on some primer. Well it is far too thick, good idea, poor execution. Back to sanding tomorrow morning.

More to follow......

I have never worked in this scale so I am shooting in the dark! I just decided to dab some on, sand it down see what would happen.

Sand and spray on some primer. Well it is far too thick, good idea, poor execution. Back to sanding tomorrow morning.

More to follow......

-

Rocky Sembritzky

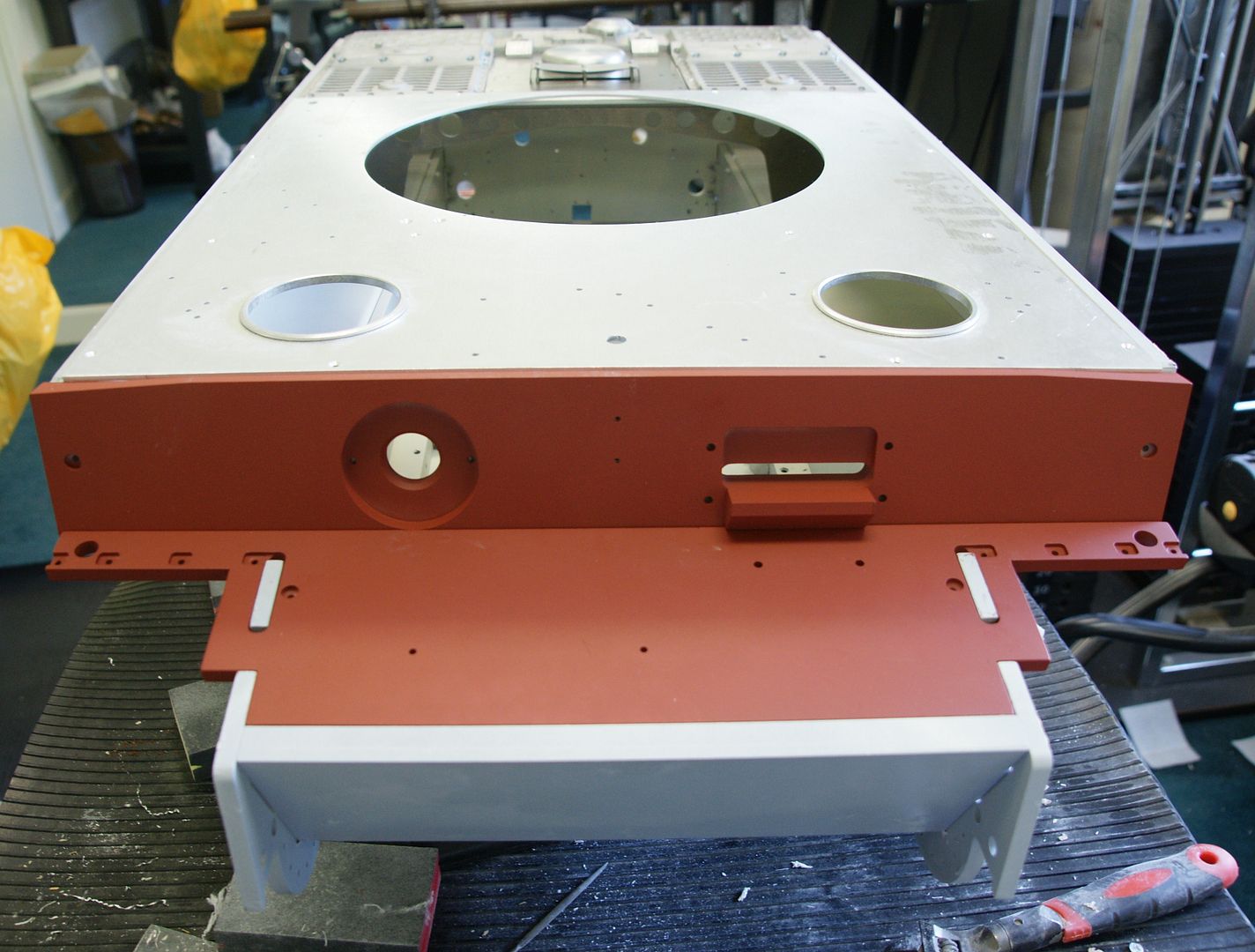

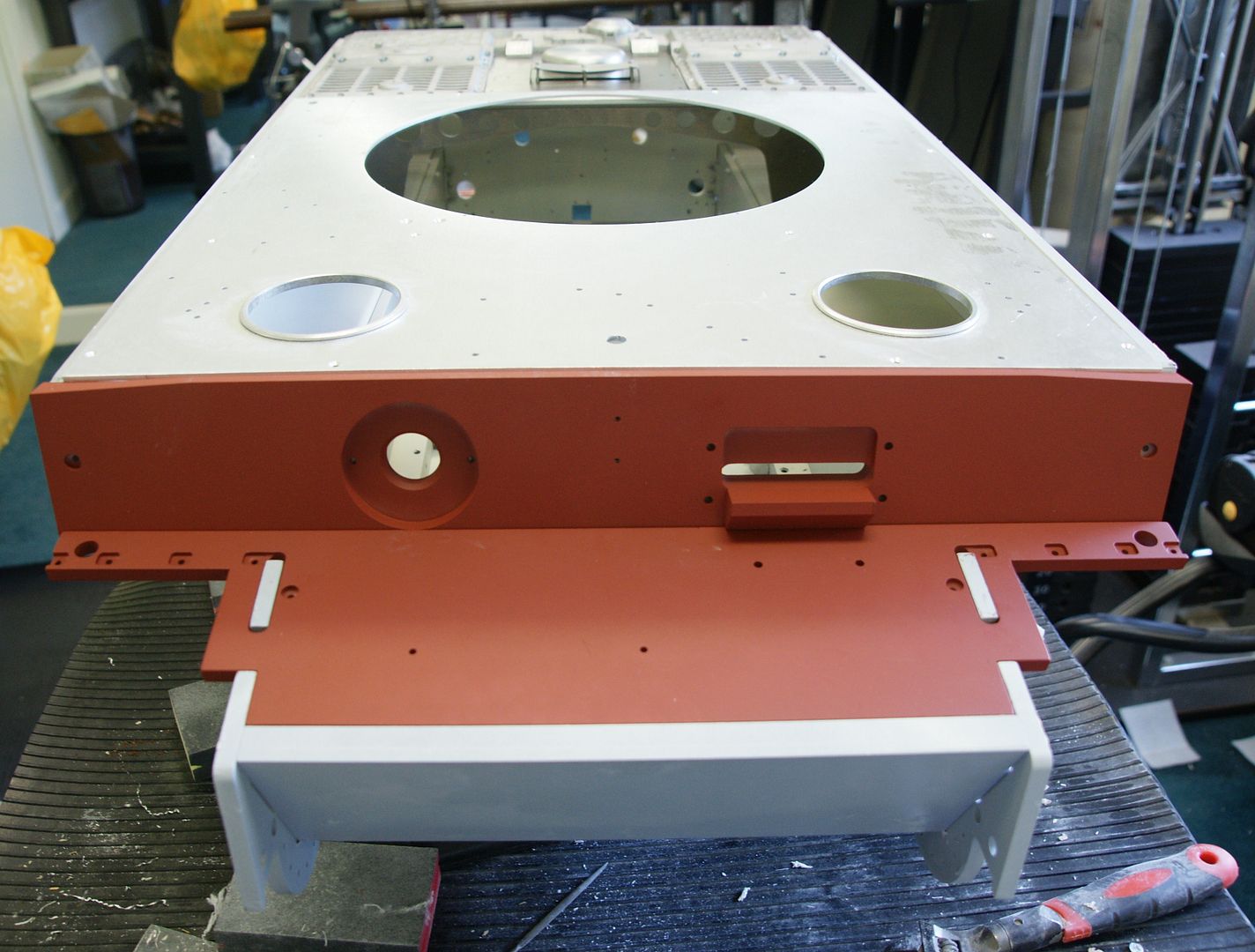

Well I am very happy that everything fits and thanks to Tim for the red oxide color.

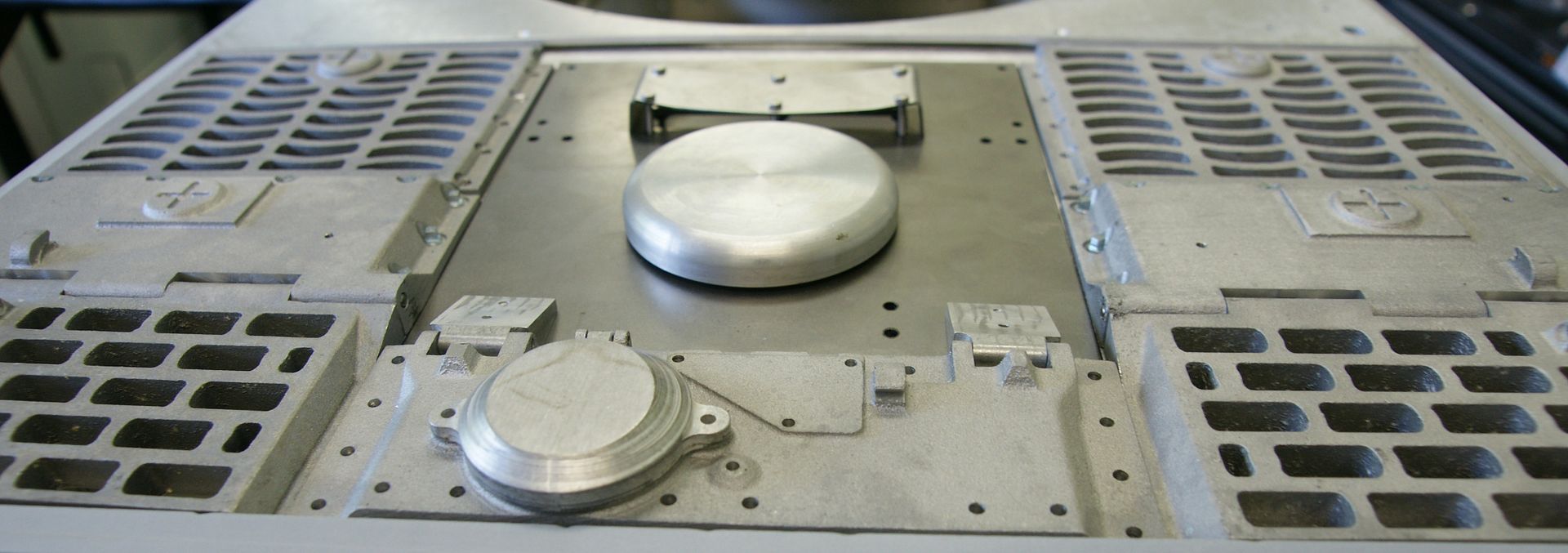

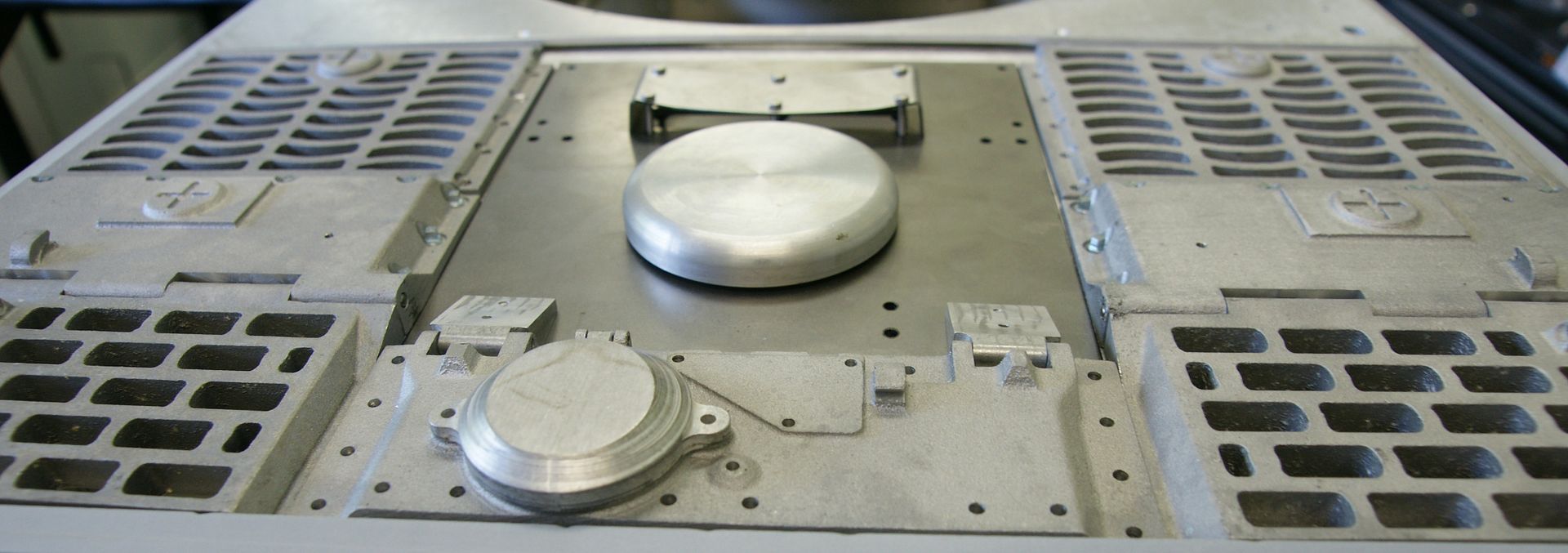

I have a bit of milling to do on the rear deck, as Luca pointed out, some of the square bolts need to be recessed. The front intakes and the back plate need to be milled to get the correct look.

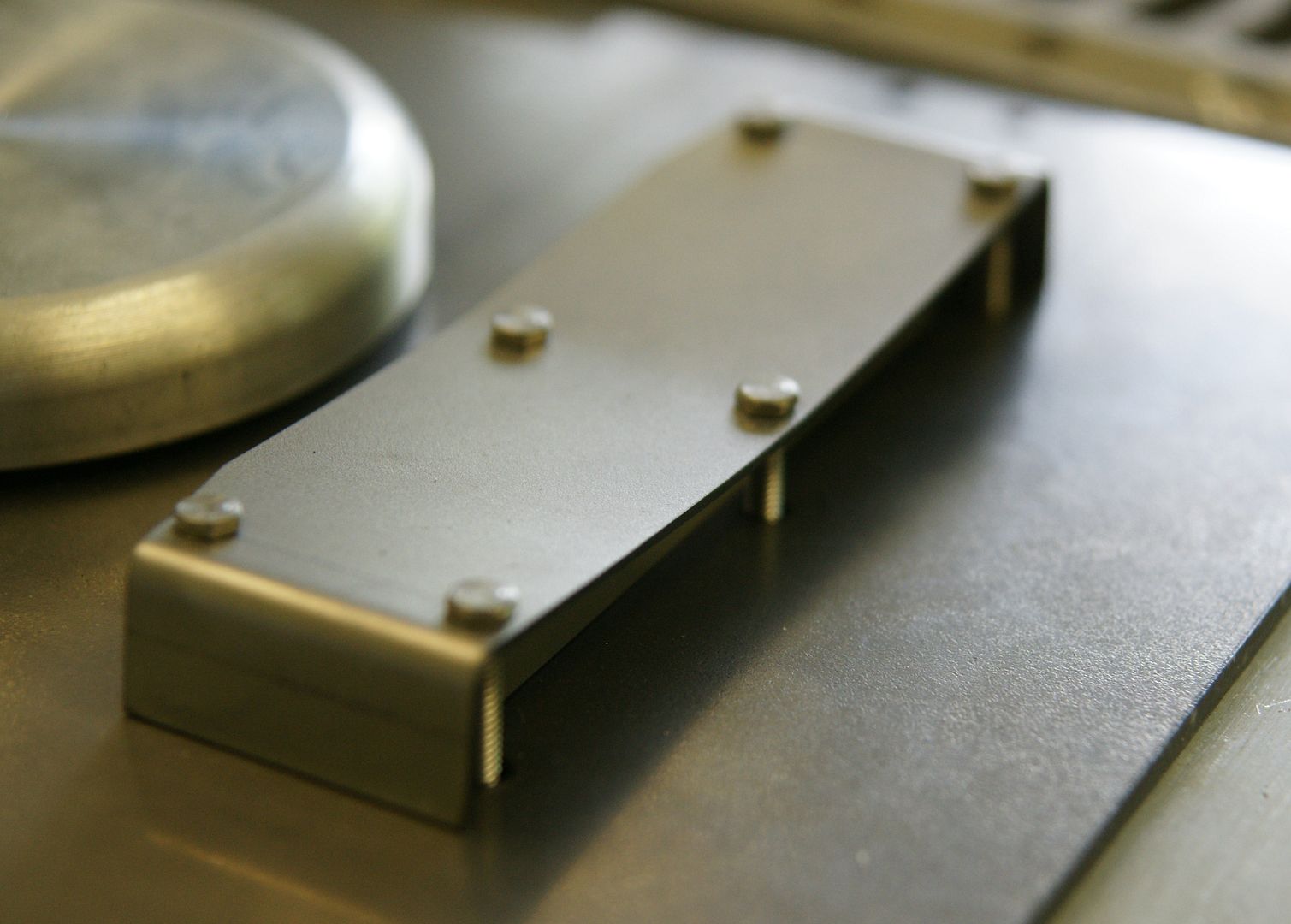

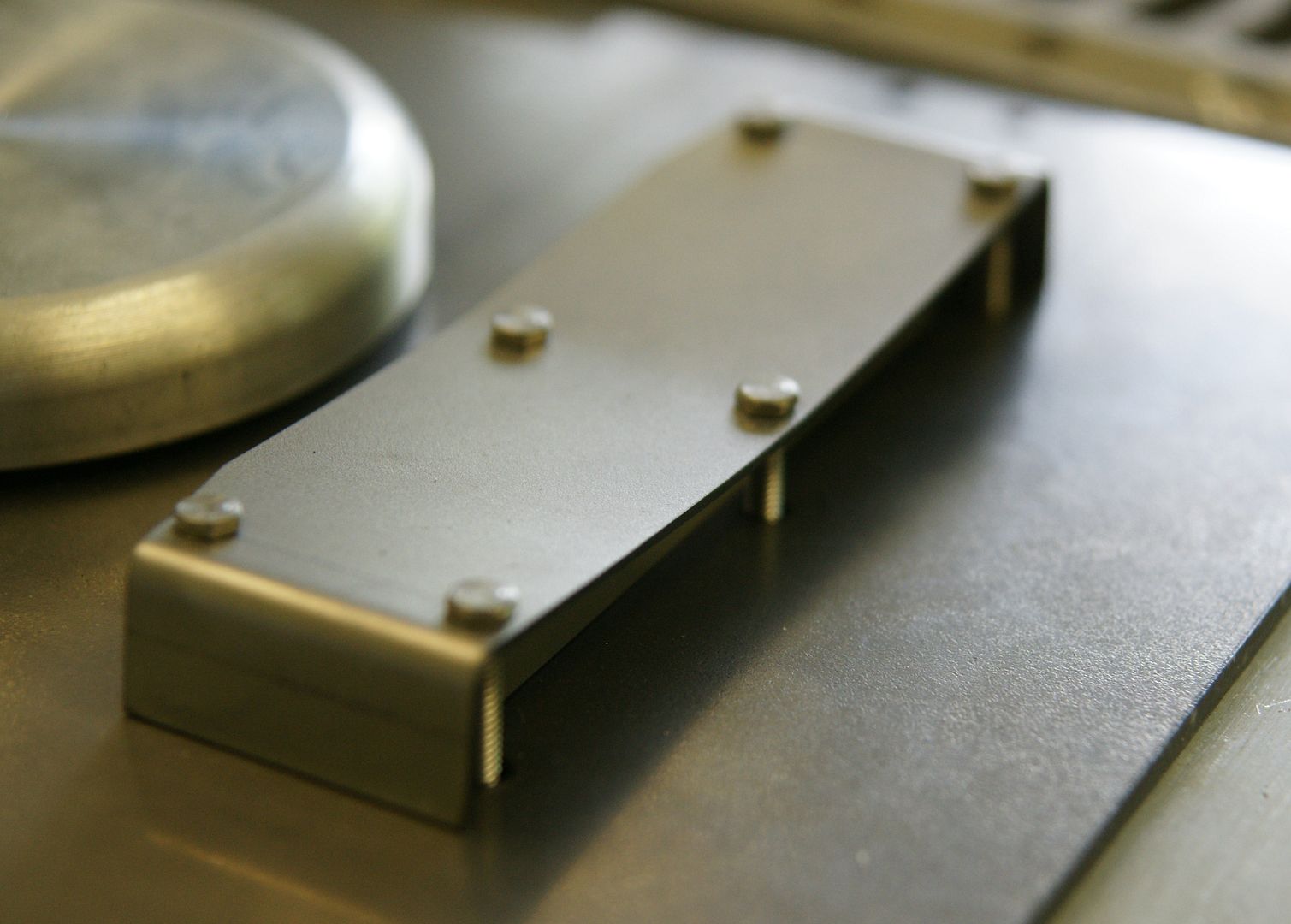

Now for the engine vent. I do not like the sag once the bolts have been secured nor do I like seeing those threads! I was thinking of ordering new bolts and then I thought why not cut some aluminum or SS tubing!

That was when my battery died. It works and it looks great. I will post some pictures tomorrow.

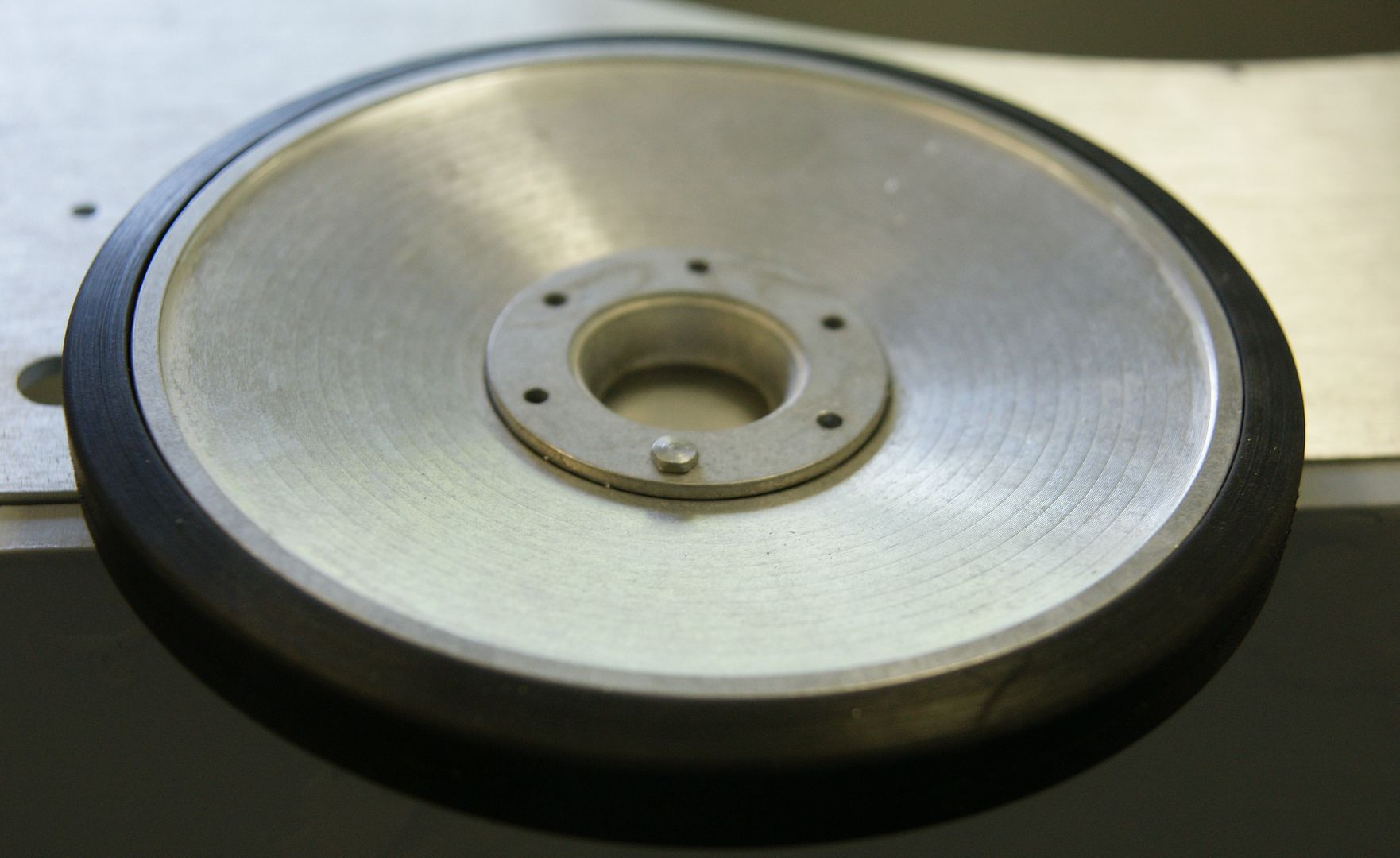

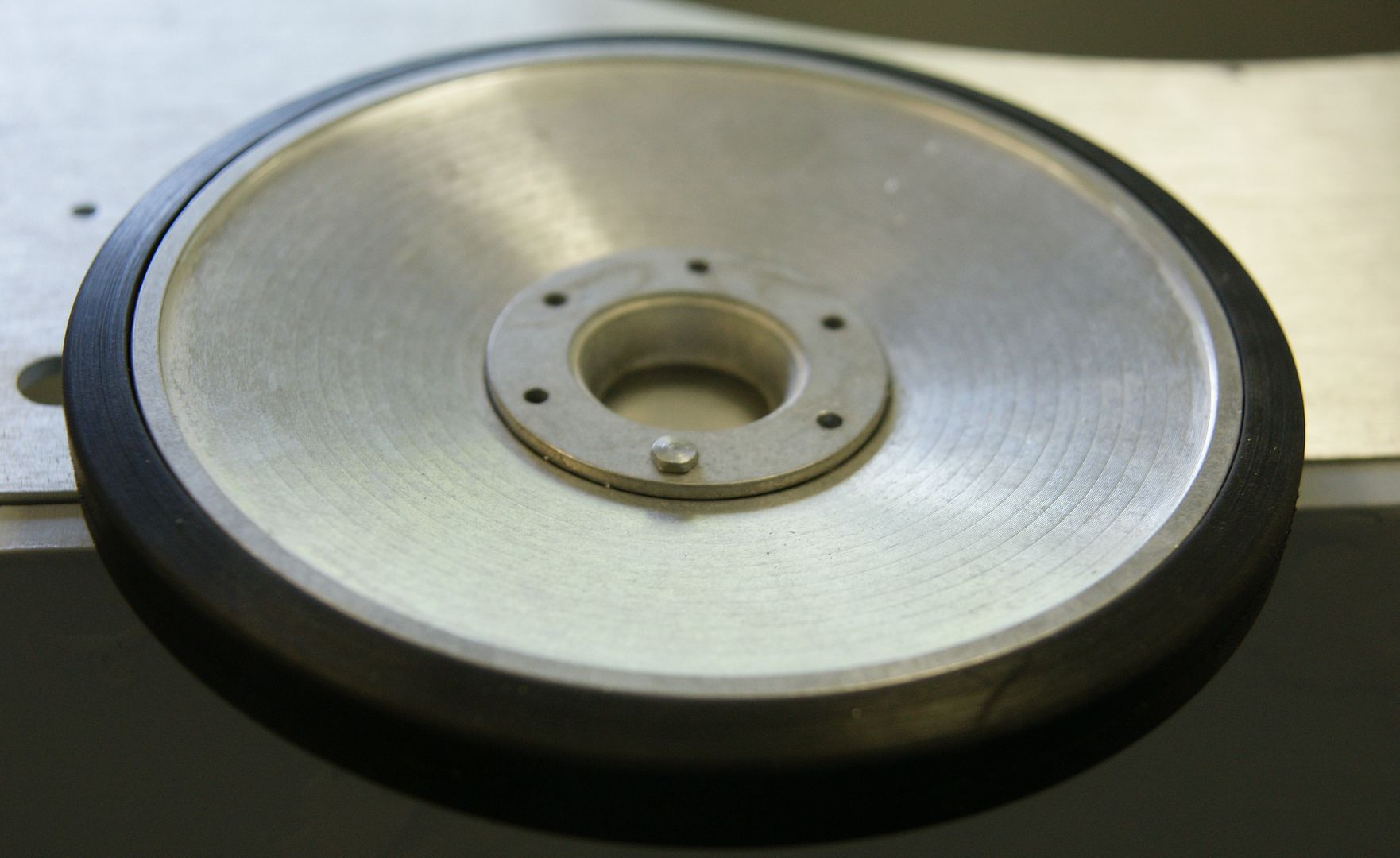

Lastly, for Dale and Sarah, the 4x40's work but drilling each piece of the wheel will take some time and I would rather find 2.5's instead.

Sarah, if you have found the 2.5's please let me know.

My back is killing me and it is time for a scotch!

Cheers!

Rocky

I have a bit of milling to do on the rear deck, as Luca pointed out, some of the square bolts need to be recessed. The front intakes and the back plate need to be milled to get the correct look.

Now for the engine vent. I do not like the sag once the bolts have been secured nor do I like seeing those threads! I was thinking of ordering new bolts and then I thought why not cut some aluminum or SS tubing!

That was when my battery died. It works and it looks great. I will post some pictures tomorrow.

Lastly, for Dale and Sarah, the 4x40's work but drilling each piece of the wheel will take some time and I would rather find 2.5's instead.

Sarah, if you have found the 2.5's please let me know.

My back is killing me and it is time for a scotch!

Cheers!

Rocky

-

Sarah Frazer

- Posts: 202

- Joined: Sat Oct 17, 2009 8:12 am

- Location: Bristol

- Been liked: 2 times

Hi Rocky,

The longest M2.5 hex head screws I can find are only 16mm long.

For a 2.5mm hole 7BA should do fine, as the threaded diameter is 2.499mm. The hex head size is 4.37mm across the flats. You can also get 7BA screws with a smaller hex head size which would be 3.86mm across the flats.

Would any of those hex head sizes be okay?

Regards,

Sarah

The longest M2.5 hex head screws I can find are only 16mm long.

For a 2.5mm hole 7BA should do fine, as the threaded diameter is 2.499mm. The hex head size is 4.37mm across the flats. You can also get 7BA screws with a smaller hex head size which would be 3.86mm across the flats.

Would any of those hex head sizes be okay?

Regards,

Sarah

'I reject your reality and substitute my own'

-

Mike Kasputis

- Posts: 104

- Joined: Thu Jul 26, 2007 2:17 am

- Location: Maryland, USA

- Been liked: 54 times

Looking good so far.

Just to let you know you have the engine vent on backwards and it should be more to the rear. Here is a picture of mine to show you what I am talking about. The red outline is where it is from Armortek. I also moved the location of the bolts and used smaller ones and I used brass tubing.

Check out this also http://www.armortek.co.uk/forum/viewtopic.php?t=988

[/img]

[/img]

And the piece on the front glacis that sticks out the side towards the track that the mudguard sits on should be shortened to 1/4". Here's mine.

[/img]

Here is a link to the thread on my Tiger and some of the mods I did.

http://www.armortek.co.uk/forum/viewtopic.php?t=1219

Just to let you know you have the engine vent on backwards and it should be more to the rear. Here is a picture of mine to show you what I am talking about. The red outline is where it is from Armortek. I also moved the location of the bolts and used smaller ones and I used brass tubing.

Check out this also http://www.armortek.co.uk/forum/viewtopic.php?t=988

[/img]

[/img]And the piece on the front glacis that sticks out the side towards the track that the mudguard sits on should be shortened to 1/4". Here's mine.

[/img]

Here is a link to the thread on my Tiger and some of the mods I did.

http://www.armortek.co.uk/forum/viewtopic.php?t=1219

-

Rocky Sembritzky

-

Rocky Sembritzky

Re: Rocky's Tiger

Now that I have 2 Tigers on the bench, I need to ask a couple of questions...

Joe has done a great job on the early Tiger, but I need to make a few modifications. First, which screw do you recommend for the idler?

and the gear housing?

I also need to know the spacing and preferred mill end to use for the center cover.....

I have a lot of welds to do.....

And replace the bump stops with the Steve & Tim magic!

Thanks for looking in and any advice would be greatly appreciated.

Rocky

Joe has done a great job on the early Tiger, but I need to make a few modifications. First, which screw do you recommend for the idler?

and the gear housing?

I also need to know the spacing and preferred mill end to use for the center cover.....

I have a lot of welds to do.....

And replace the bump stops with the Steve & Tim magic!

Thanks for looking in and any advice would be greatly appreciated.

Rocky