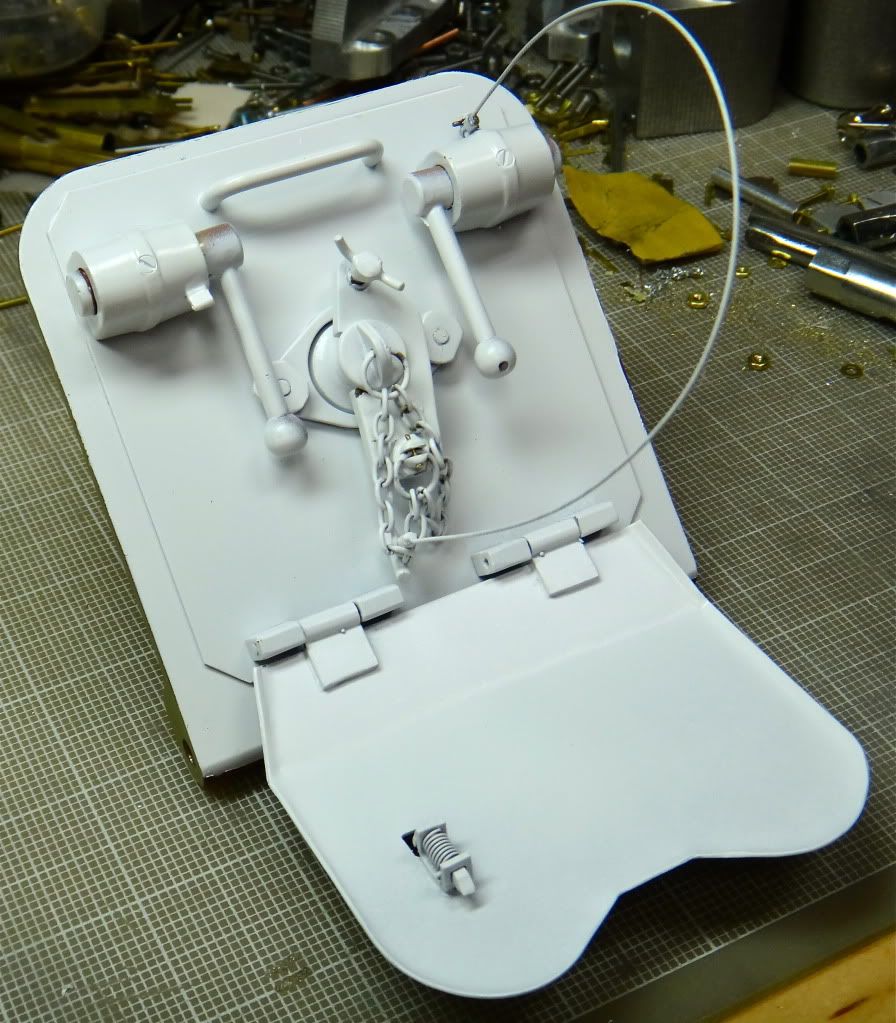

Put a base coat on the air intakes armor, made the spacers, and attached with 1" 7BA bolts:

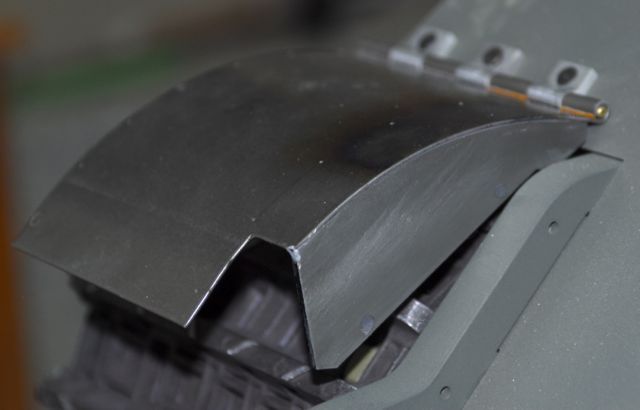

This sure does alter the look of the rear deck Not sure I like it too much. Gives the rear deck a very smooth look.

It's hard to see the basic wire mesh except with the front armor which will be covered with the rear of the turret most of the time:

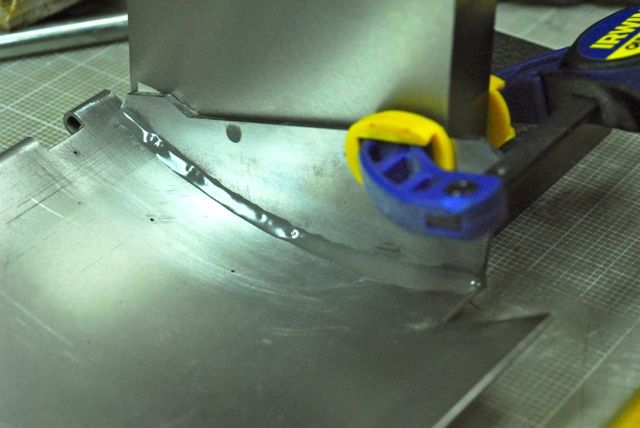

Another mod that I have been agonizing over because of my first poor milling results are the exhaust guards:

I figured out I can fill with epoxy and mill as needed until results are ok. There is a small detail on the corners of the guards (pencil marks on each end) which will be a little of a challenge. Once all the mill marks are filled the guards will be coated with Mr. Surfacer fora cast effect. They are pretty rough in all of the examples I have seen pics of.

The bolts are 2BA with small head nuts. I made the lock washers several months back. These are the same bolts and washers I used for the track tensioning covers mentioned earlier in this thread.

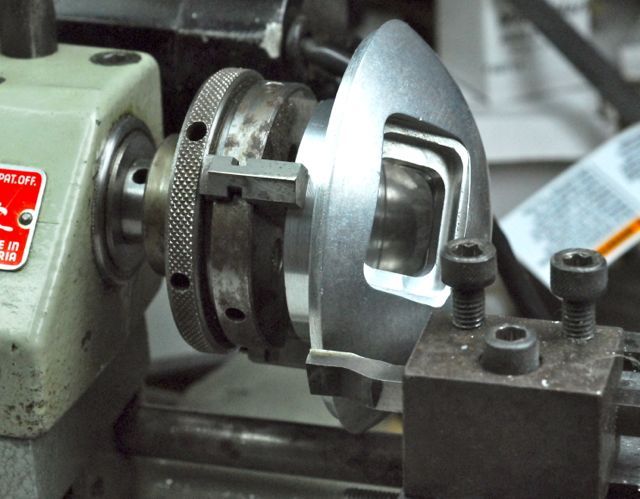

Lastly I started working on the rear turret panel taking a lesson from Mark Bennet:

My only issue is my lathe can't work on the whole panel at on time. I have to reposition 4 times to cover the needed area. I've gotten pretty good at lining things up for long cuts! I decided I'll make the final mod along the top of this piece the way Mark did on his.

B