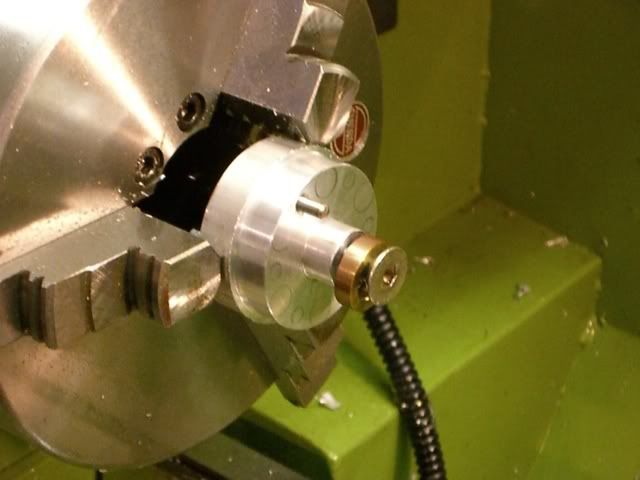

Thanks for the kind words I am going to take pictures of the form tool

tomorrow and I will also show the mandril I made to hold the wheels in place.

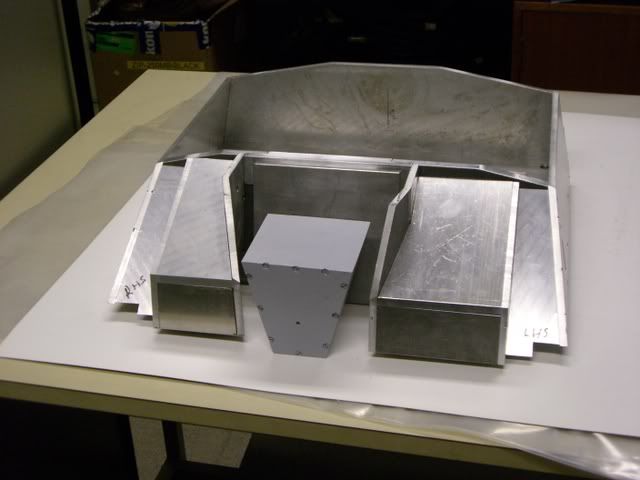

I am planing to add small lengths of brass tube to make the raised welds

round the small holes.

But that will be done much later in the build.

Regards

Derek