Kompact 25 PDR rivets

-

donharvey

- Posts: 3

- Joined: Thu May 19, 2016 11:18 am

Kompact 25 PDR rivets

I've just bought this kit. The trail arms require rivets from both sides I assume. The rivets are 1/4" and the trails are 10mm wide. The rivets seem too long. Do they need trimming and are they simply glued in?

-

Walter Mackinnon

- Posts: 54

- Joined: Tue Aug 05, 2014 3:33 pm

- Location: Biggar, Scotland.

- Has liked: 8 times

- Been liked: 4 times

Re: Kompact 25 PDR rivets

Hi Don,

The answer is yes, full lenth on one side and cut to fit on the other side, I used super glue, but if you are going with the ARMORPAX up grade kit, hold off as some rivets will have to be removed to fit parts.

Welcome to the club and I hope you enjoy bilding your kit.

Regards Walter.

The answer is yes, full lenth on one side and cut to fit on the other side, I used super glue, but if you are going with the ARMORPAX up grade kit, hold off as some rivets will have to be removed to fit parts.

Welcome to the club and I hope you enjoy bilding your kit.

Regards Walter.

-

donharvey

- Posts: 3

- Joined: Thu May 19, 2016 11:18 am

Re: Kompact 25 PDR rivets

Thanks Walter. I'm not planning an upgrade at the moment. Do some rivets on the front screen require trimming? I am working slowly on this kit and trying to assemble parts and connectors in sealable bags. I actually fired one of these back in 1970 with the Australian Army

-

Walter Mackinnon

- Posts: 54

- Joined: Tue Aug 05, 2014 3:33 pm

- Location: Biggar, Scotland.

- Has liked: 8 times

- Been liked: 4 times

Re: Kompact 25 PDR rivets

Hi Don,

Yes some rivets need to be trimmed for the shield as well.

Look at the forum for 25PDR for more hints and tips on building the kit.

Regards Walter.

Yes some rivets need to be trimmed for the shield as well.

Look at the forum for 25PDR for more hints and tips on building the kit.

Regards Walter.

-

Marcus Kwa

- Posts: 176

- Joined: Wed Nov 13, 2013 6:22 pm

- Been liked: 39 times

Re: Kompact 25 PDR rivets

Hi Don,

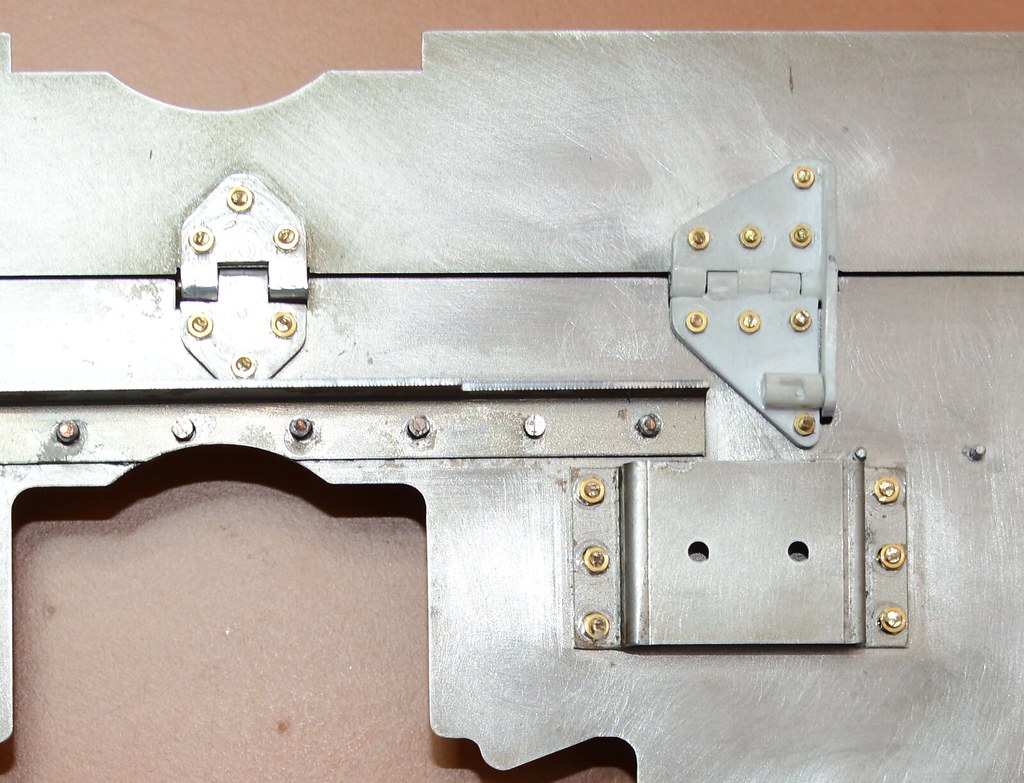

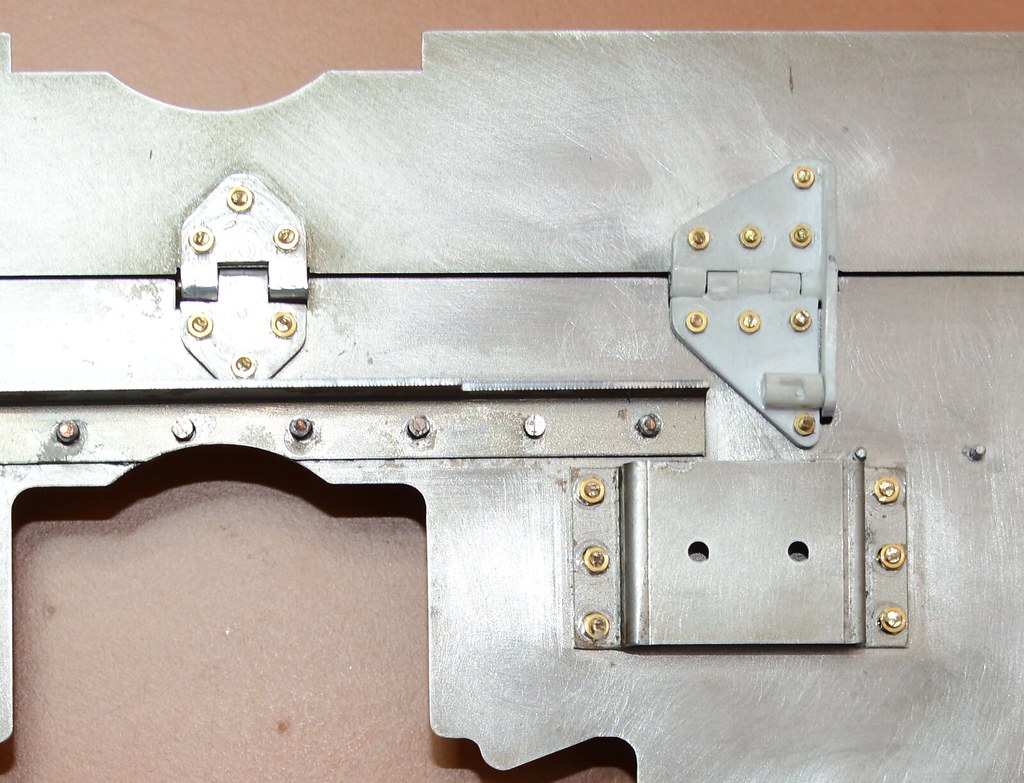

For the rivets in the shield for holding the reinforcement angle lines and equipment brackets I chose to install the rivet first (full length). On the inside of the shield I slid and glued a piece of aluminium tubular (same diameter as the rivet head with an ID of the rivet shank) over the exposed rivet shank. After the glue had set I trimmed the tube and rivet shank (to rivet head height).

With a file I profiled the aluminium tube to resemble a rivet head. This gives a strong connection. Of course you can also use other tubing like plastic what is easier to sand down and shape.

In the picture the upper shield reinforcement angle line is shown with the aluminium tubing and rivet shanks trimmed down, ready to be profiled to resemble a rivet head by rounding the edges with a file and sandpaper. You can clearly see the rivet with the aluminium tube around it.

Happy building!

Marcus

For the rivets in the shield for holding the reinforcement angle lines and equipment brackets I chose to install the rivet first (full length). On the inside of the shield I slid and glued a piece of aluminium tubular (same diameter as the rivet head with an ID of the rivet shank) over the exposed rivet shank. After the glue had set I trimmed the tube and rivet shank (to rivet head height).

With a file I profiled the aluminium tube to resemble a rivet head. This gives a strong connection. Of course you can also use other tubing like plastic what is easier to sand down and shape.

In the picture the upper shield reinforcement angle line is shown with the aluminium tubing and rivet shanks trimmed down, ready to be profiled to resemble a rivet head by rounding the edges with a file and sandpaper. You can clearly see the rivet with the aluminium tube around it.

Happy building!

Marcus