Hi Willie.

I will try to help out here done three of these hulls now, I think I know what you are asking is it the location of the holes in the suspension shafts thats causing the problem for you? i.e. how to tighten the torsion bars when you have pushed the assembled arm through the side of the tank?

If so this is how I do it.

I think the instuctions can be a little bit mis leading at first glance, assemble the arms and shafts by holding the shaft on the shoulder with a set of mole grips this will slightly mark the shaft but it makes no difference as this part does not go through the suspension bar. once this is done I personally cross drill and roll pin straight through the arm and threaded portion of the shaft . . . they can and do unscrew themselves in time.

Then remove about 1.5 mm from the base of your grub screws I do this with an old screwdriver type allen key and a power file, if you don't have the file you could try a bench grinder but watch they don't fly back at you!!

flattening the base of the grub screw allows you to fit and lock down your torsion bar as the grub screws are now short enough to be below the surface of the shaft and the whole assembly can be passed through the suspension bar and tightened down at the other side of the tank.

I hope this helps you out? if not I am at the other end of the e mail and always happy to help.

Kind regards Paul

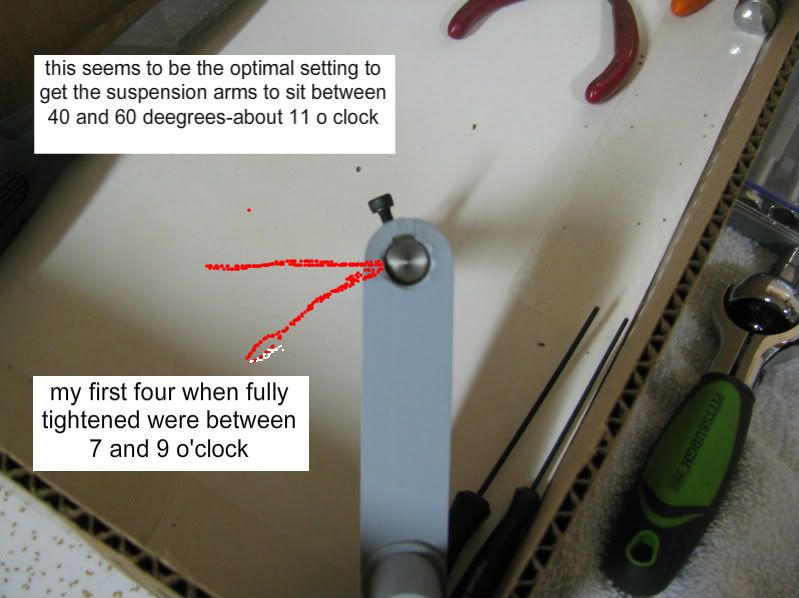

Thanks Steve and Paul for your prompt response. Very much enjoying following both you guys on the forum,and can't wait to see your finnished products,especially the Jadgtiger.Acording to the Offiicial Armortek Advice Section of the forum, the optimal setting for the suspension arms is between 40 and 60 degrees.When I fully tightened the first four shafts to the arms the grub holes were at between 7 and 9 o'clock when it seems they should be at about 11 o'clock. It took about 5 to 7 shims each to get them about right. At this rate im going to be running out of shims within the first six suspension arms. I was just wondering if anyone else ran into this problem.

Thanks Steve and Paul for your prompt response. Very much enjoying following both you guys on the forum,and can't wait to see your finnished products,especially the Jadgtiger.Acording to the Offiicial Armortek Advice Section of the forum, the optimal setting for the suspension arms is between 40 and 60 degrees.When I fully tightened the first four shafts to the arms the grub holes were at between 7 and 9 o'clock when it seems they should be at about 11 o'clock. It took about 5 to 7 shims each to get them about right. At this rate im going to be running out of shims within the first six suspension arms. I was just wondering if anyone else ran into this problem.