The first thing to say is that i intend building a early G model as used in Normandy.

This is the tank i intend to build

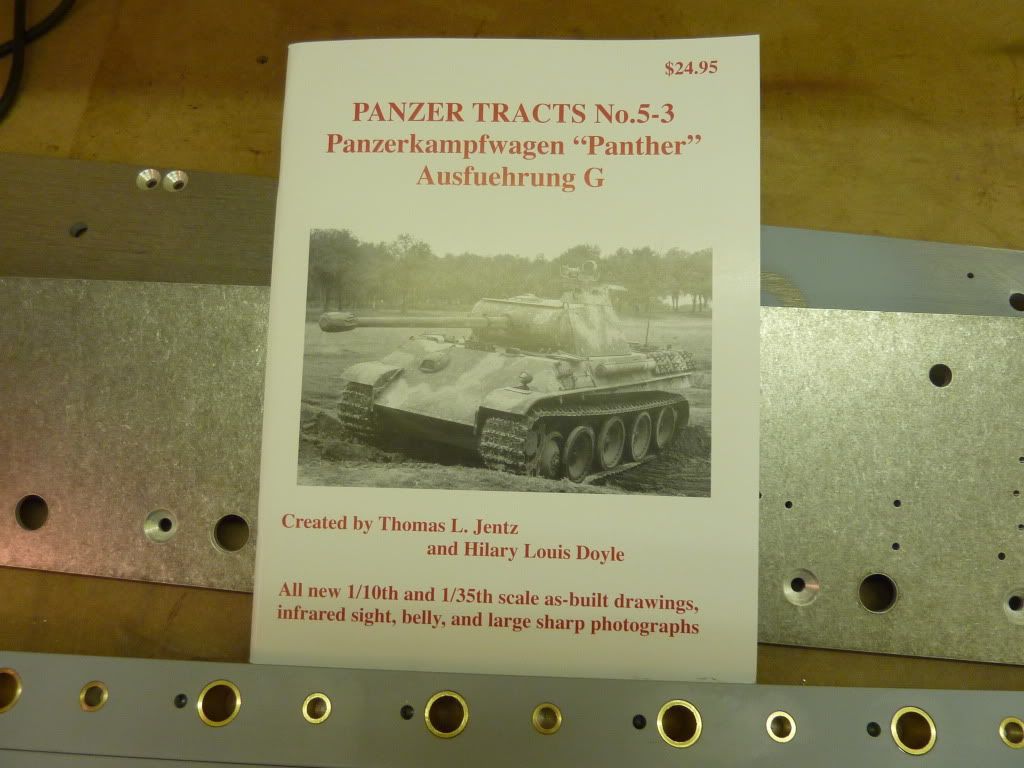

The first thing i had to do was wait for delivery of this Panzer tracts book that had been recomended by Kent, Well worth the wait.

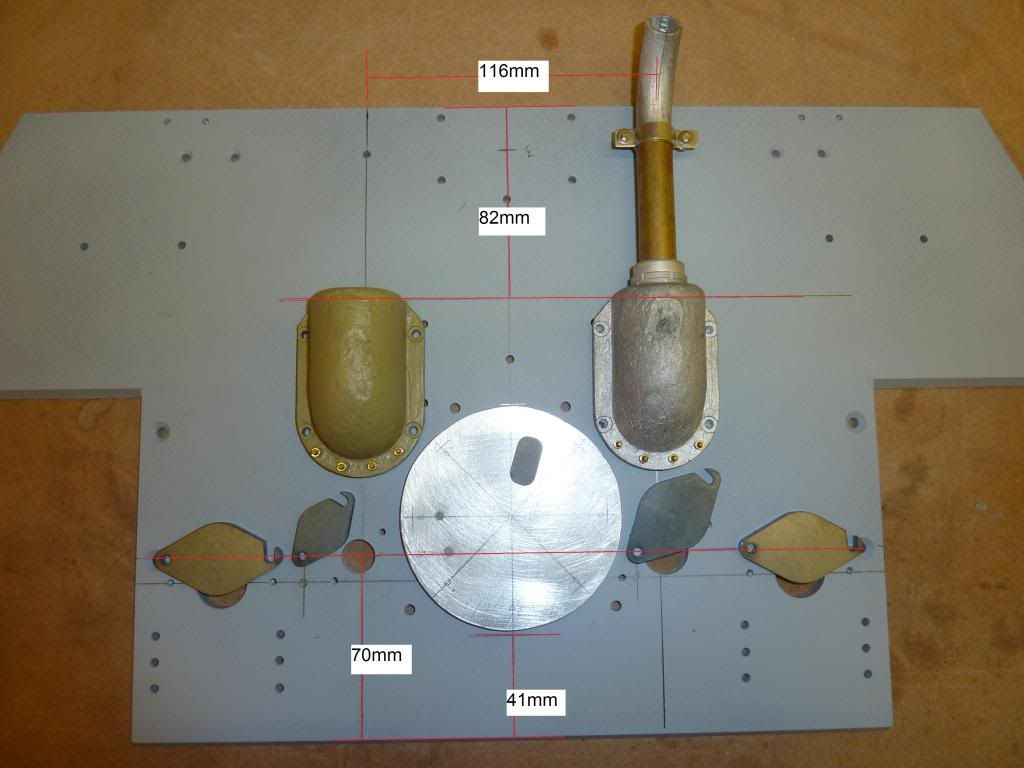

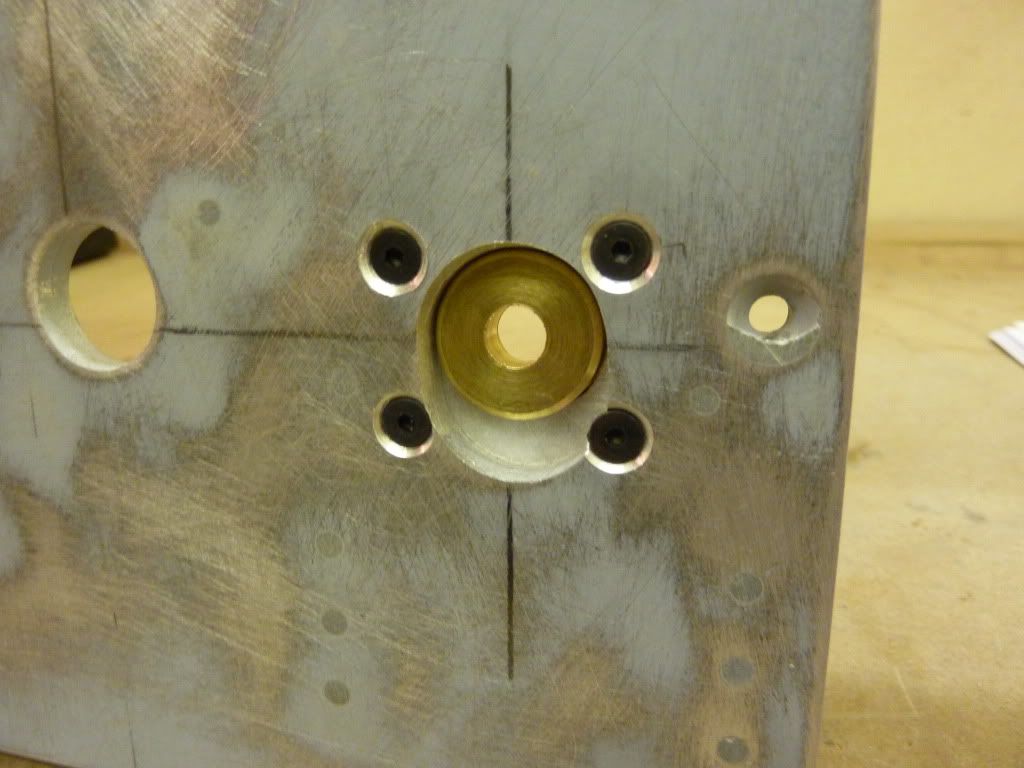

First job has been to add 5 mounting bolts around the idler mount, The bolts have locking tabs made from the thin aluminium tray that my Christmas turkey came in

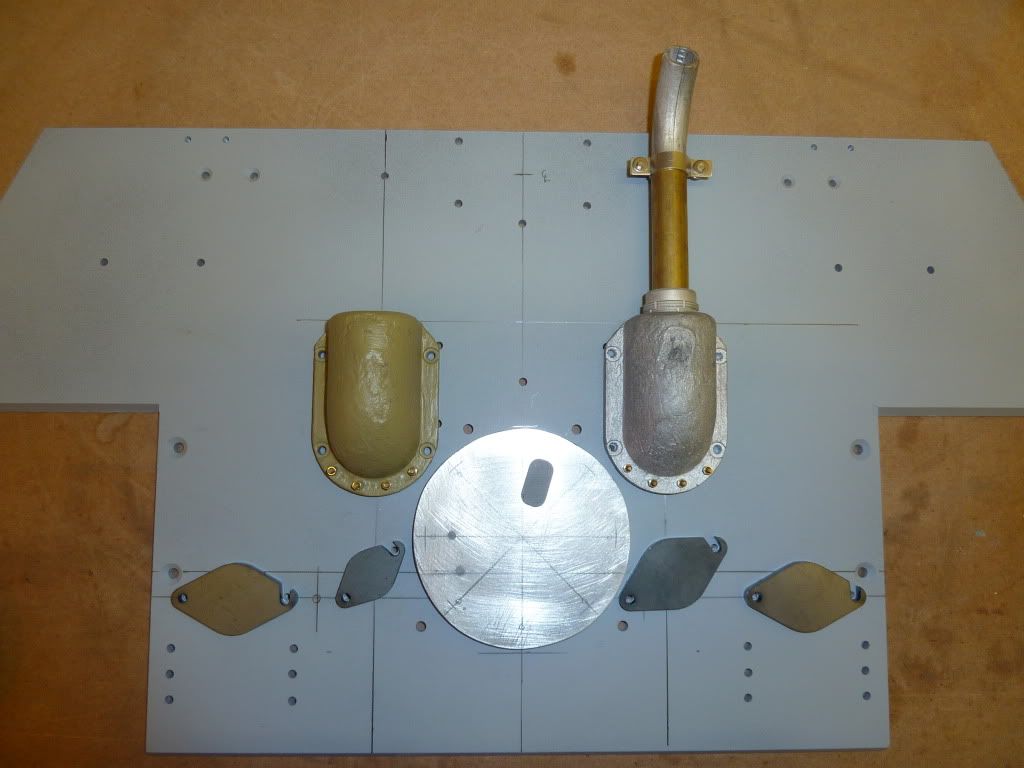

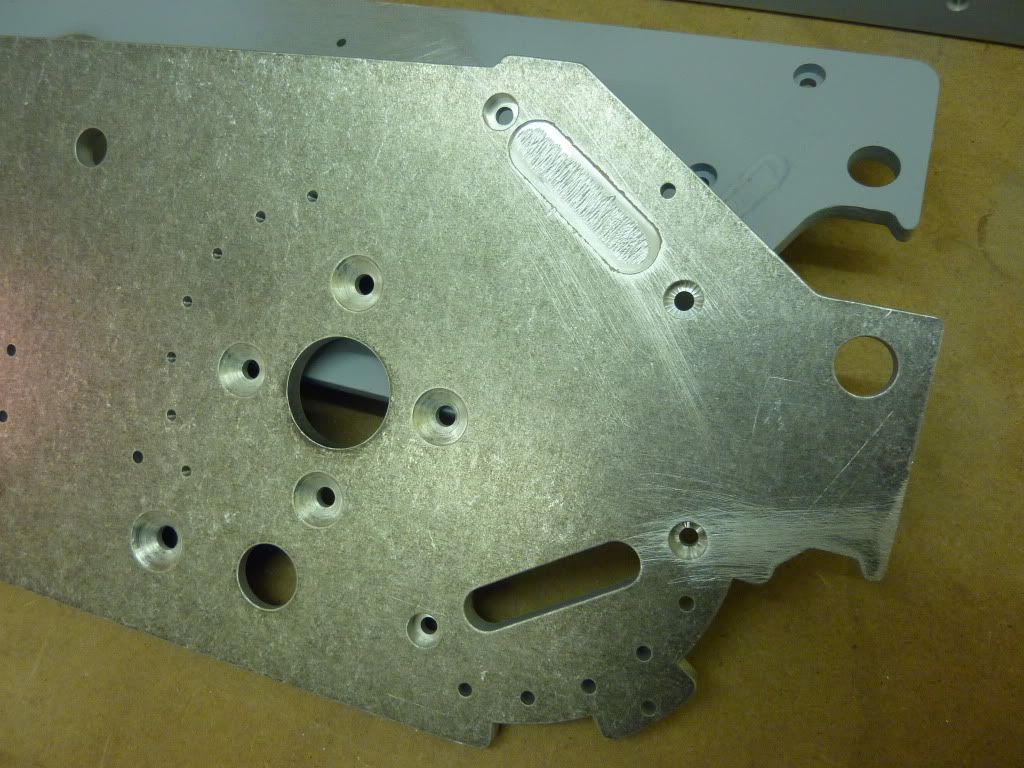

This shows the front end, again i have reprofiled the lift hooks.

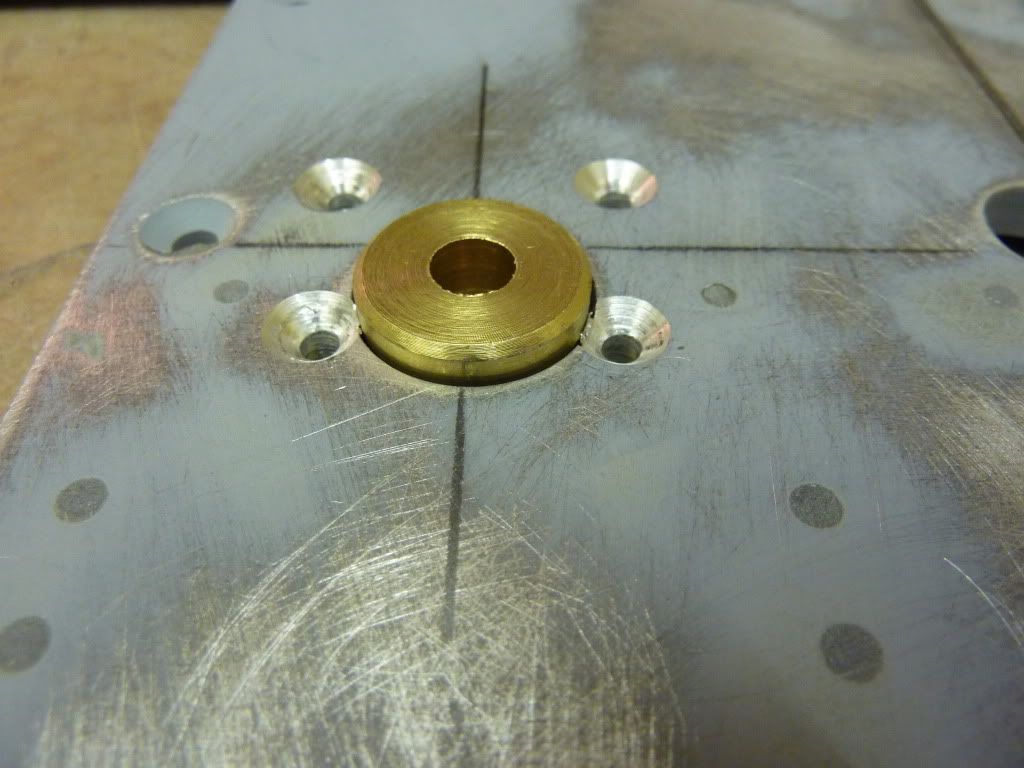

The interlock here comes as a machined recess, all it needs is a little detailing with the Dremel and some Milliput welding.

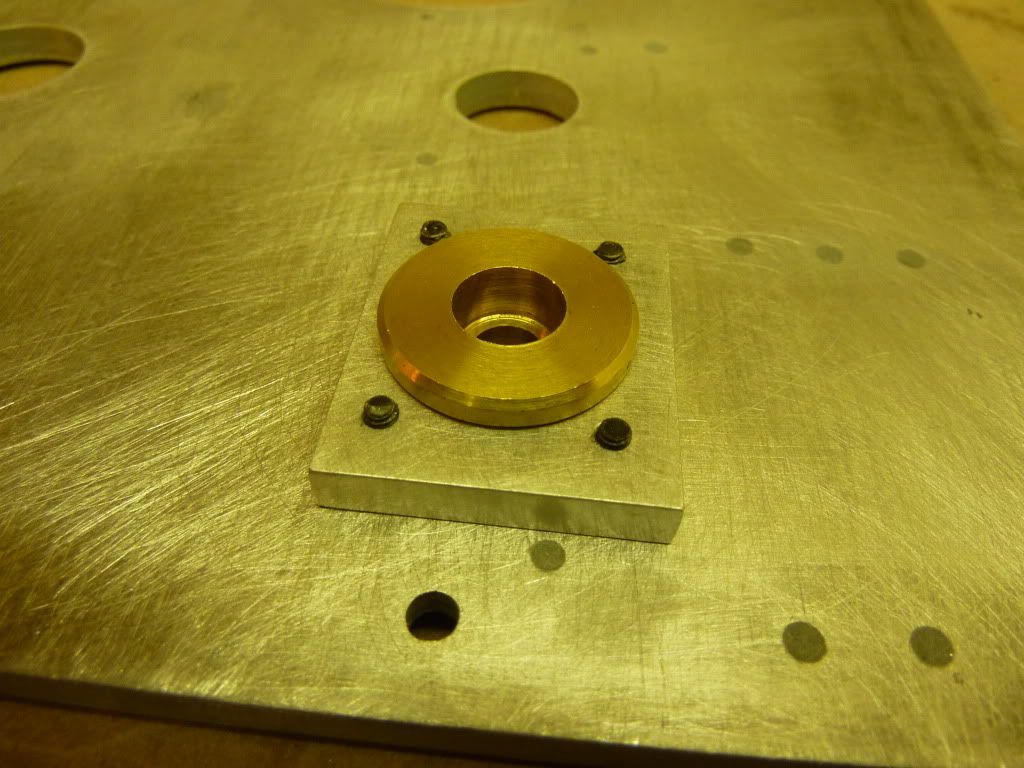

Final bit for now. The suspension bars have had there bushes added, as can be seen these bars have an extra set of bushings for the double torsion bar set up.

More to come later

regards

Steve