Tiger 066 Construction

- Robert E Morey

- Posts: 2310

- Joined: Wed Jul 18, 2007 12:59 am

- Location: Seattle, WA USA

- Has liked: 130 times

- Been liked: 776 times

-

Sven Strobbe

- Posts: 301

- Joined: Mon Jan 12, 2009 11:08 am

- Location: Belgium,Gent

- Been liked: 11 times

- Contact:

-

Mark Bennett

- Posts: 62

- Joined: Sat Feb 14, 2009 10:15 am

- Location: Texas, USA

-

John Grima

- Posts: 250

- Joined: Sun Jul 15, 2007 2:54 pm

- Location: USA

- Been liked: 48 times

- Contact:

Thanks Guys,

Mark, the torch lines are made with a Dremel cutting stone. I make numerous slices at various depths and angles. The technique is all random and once you get the hang of it, the technique becomes second nature. For best results I recommend experimenting on a piece of wood, or metal to get the feel and muscle memory.

Sven, I have always wondered about if that component is a light or a reflector. On the Aberdeen tank I could see what appears to be an old frayed wire behind the lens mount. If you have any close up images, or information let me know and I will make the change ASAP.

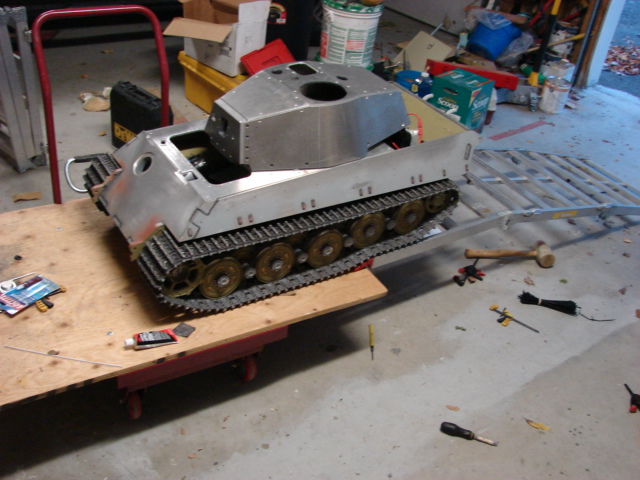

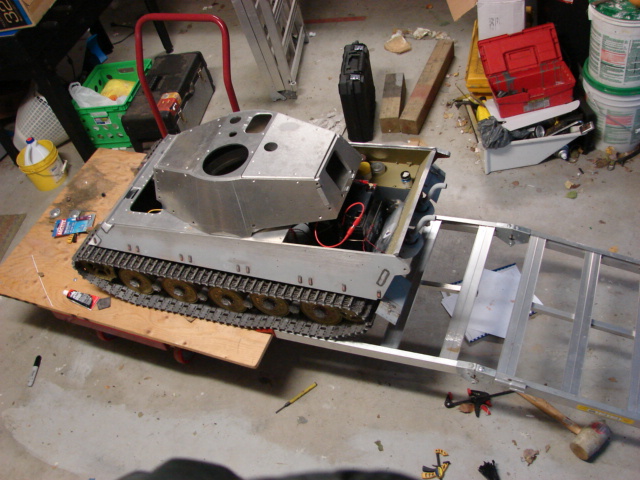

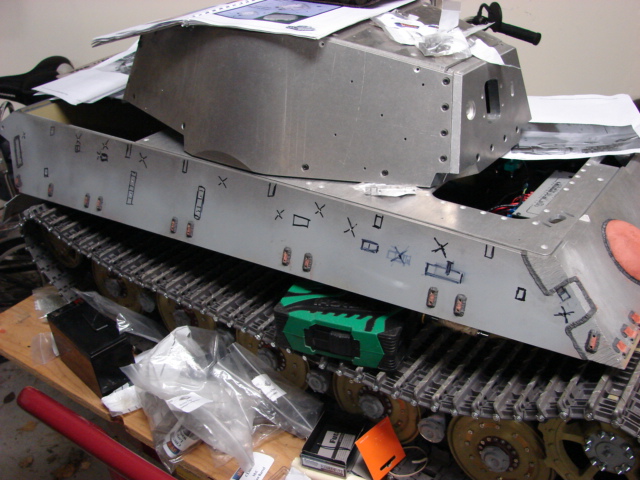

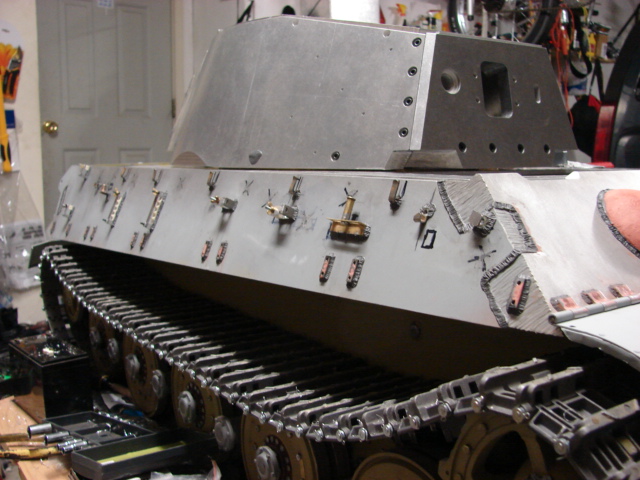

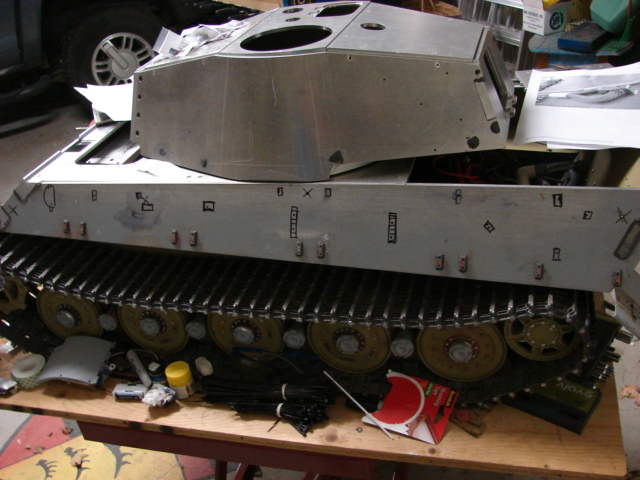

I was able to mount the tracks and take the tank on a test drive.

When the tracks were first added there were too many links and the tracks had too much slack.

After the removal of two links from each side, the track's slack was removed and the tank runs very smoothly.

I was able to make a video of the tank running for the first time. The video is now up on youtube.

http://www.youtube.com/watch?v=qr2KJD7WWpY

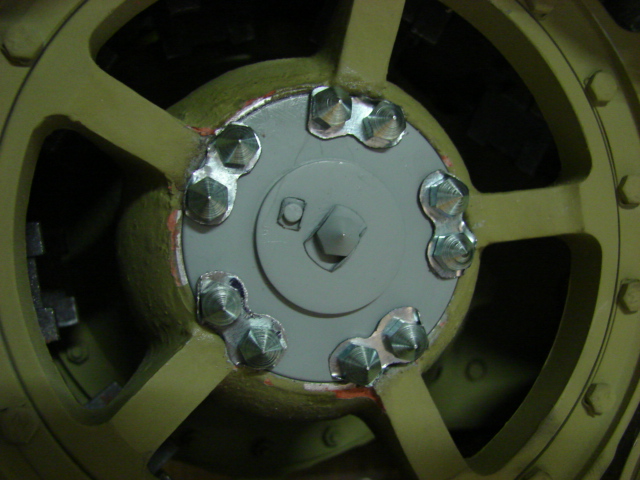

After test driving the tank I'm satisfied with the performance. I'm happy with the sprocket alignment so I can now finish off the detail for the sprocket hubs. More progress to follow.

Mark, the torch lines are made with a Dremel cutting stone. I make numerous slices at various depths and angles. The technique is all random and once you get the hang of it, the technique becomes second nature. For best results I recommend experimenting on a piece of wood, or metal to get the feel and muscle memory.

Sven, I have always wondered about if that component is a light or a reflector. On the Aberdeen tank I could see what appears to be an old frayed wire behind the lens mount. If you have any close up images, or information let me know and I will make the change ASAP.

I was able to mount the tracks and take the tank on a test drive.

When the tracks were first added there were too many links and the tracks had too much slack.

After the removal of two links from each side, the track's slack was removed and the tank runs very smoothly.

I was able to make a video of the tank running for the first time. The video is now up on youtube.

http://www.youtube.com/watch?v=qr2KJD7WWpY

After test driving the tank I'm satisfied with the performance. I'm happy with the sprocket alignment so I can now finish off the detail for the sprocket hubs. More progress to follow.

-

Tim Bowman

- Posts: 1762

- Joined: Fri Jul 13, 2007 4:53 am

- Location: Northern California

- Been liked: 177 times

- Contact:

-

Allan Richards

- Posts: 743

- Joined: Thu Jul 12, 2007 10:34 am

- Location: Kent

- Been liked: 10 times

John,

Thats a good video of the tank running. The running of the tracks will improve a lot with a bit of use. I think that the KT ran with the tracks looking a little slacker than you have them after taking the two links out. When you have completed the model and it is at its fighting weight the suspension may drop a little which will naturally slacken the track a bit. See how it goes then.

Thats a good video of the tank running. The running of the tracks will improve a lot with a bit of use. I think that the KT ran with the tracks looking a little slacker than you have them after taking the two links out. When you have completed the model and it is at its fighting weight the suspension may drop a little which will naturally slacken the track a bit. See how it goes then.

Allan Richards

-

John Grima

- Posts: 250

- Joined: Sun Jul 15, 2007 2:54 pm

- Location: USA

- Been liked: 48 times

- Contact:

Thanks Guys, I was informed by Kent that the light is actually a reflector. After looking closer at the Aberdeen photos I have seen that what I thought was a degraded wire was a clump of dead grass. So the LED was removed.

I have made more progress on the tank and have completed more of the tanks functions and details.

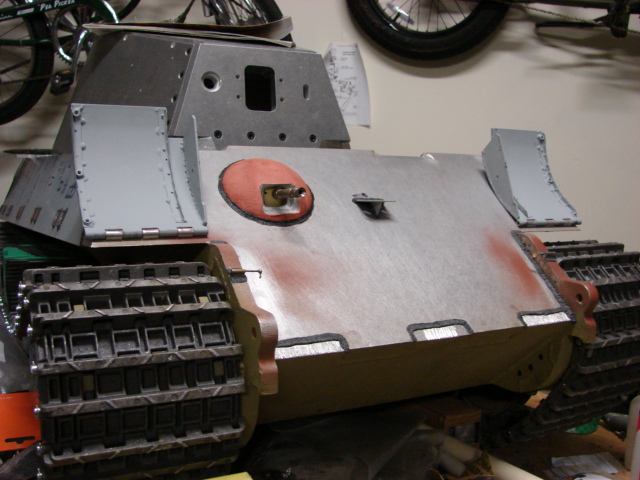

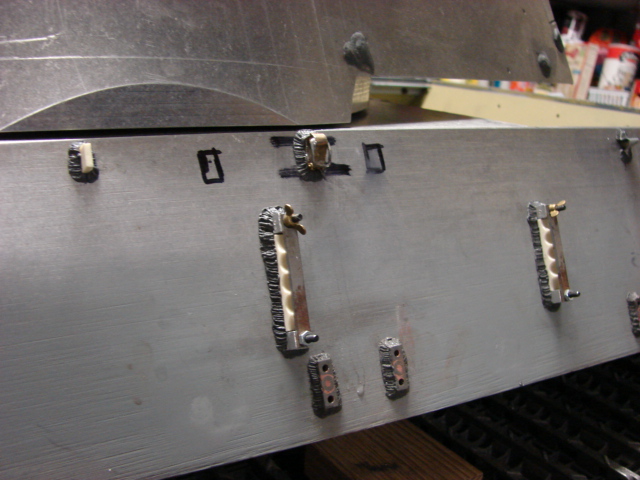

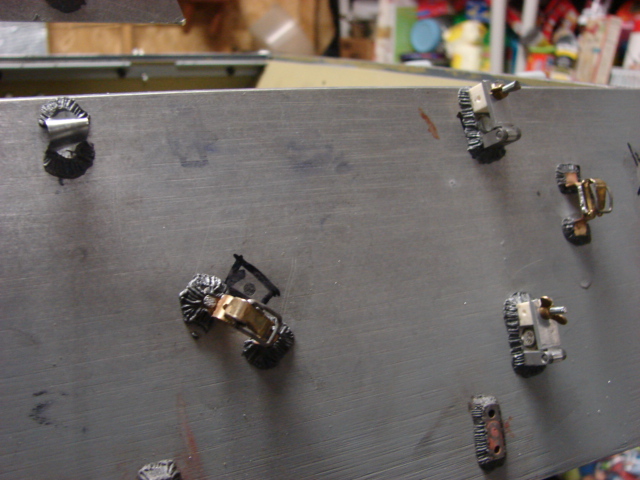

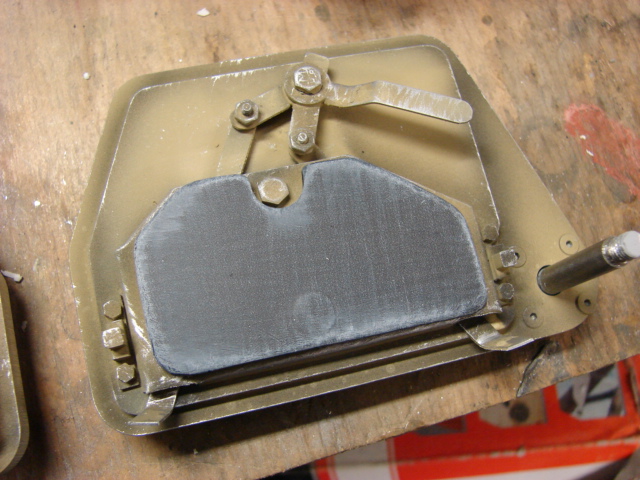

For the tank's sprockets I added the hubs, with the bolt details. All of the tension plates were scratch built out of sheet steel.

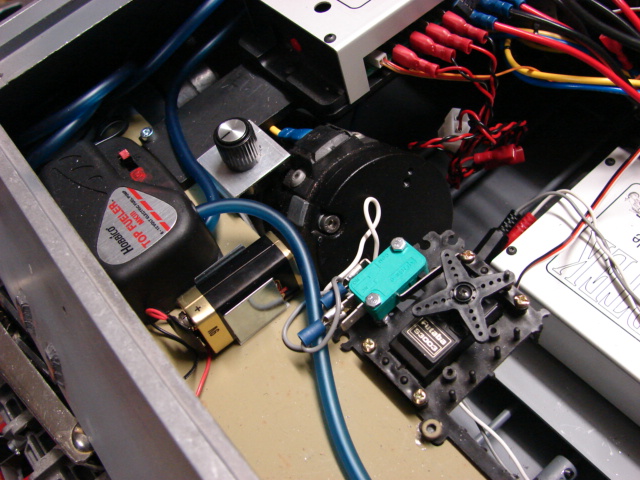

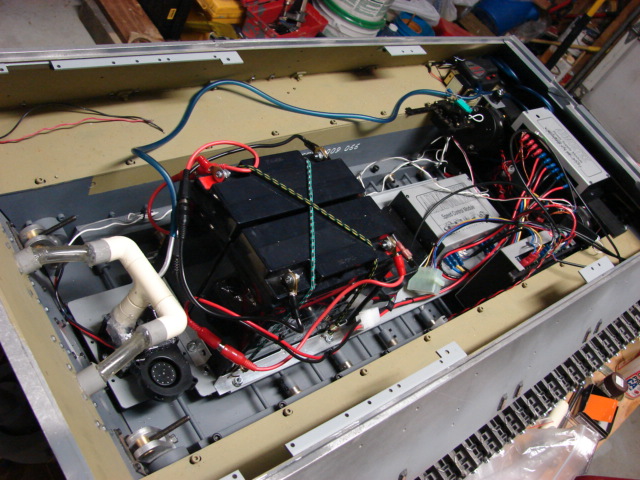

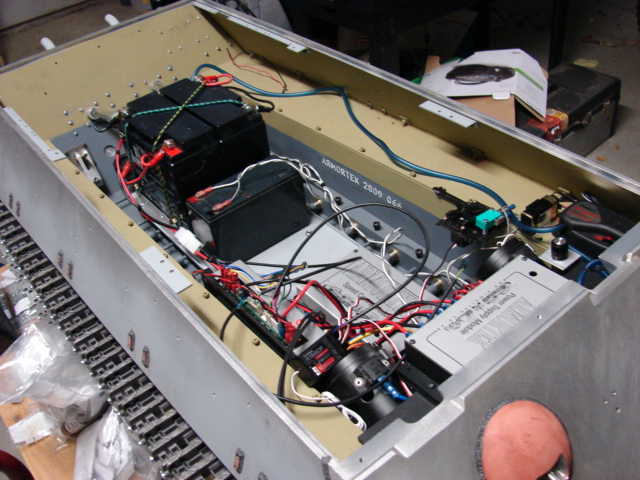

I added the tank's smoke system. For the smoke generator I used my own system that I hooked up to a remote control for throttle control.

I built into the tank a battery powered fuel pump to refuel the smoke system. With the built in system I can refill the fluid reservoir from a long rubber tube away from the tank. With this system I remove the chance of spilling the smoke fluid onto the tank which can ruin the paint finish. I have used this system on every one of my 1/6th scale RC tanks.

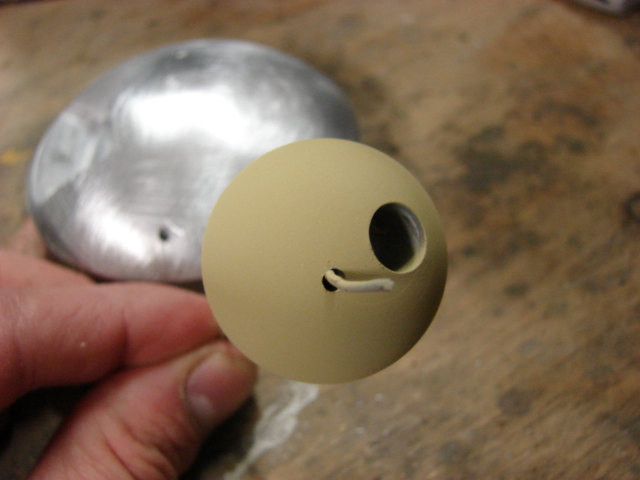

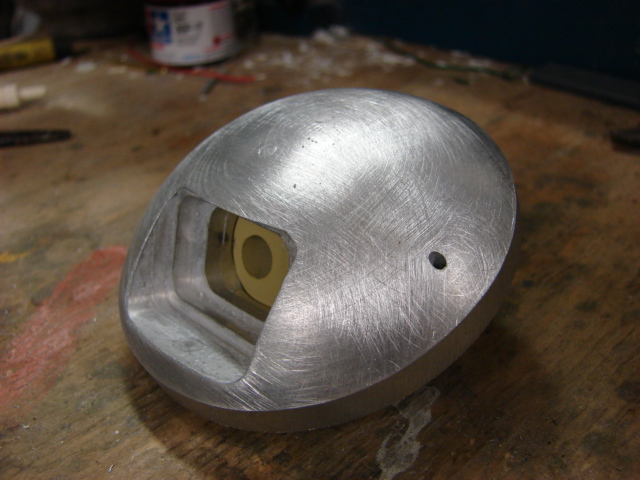

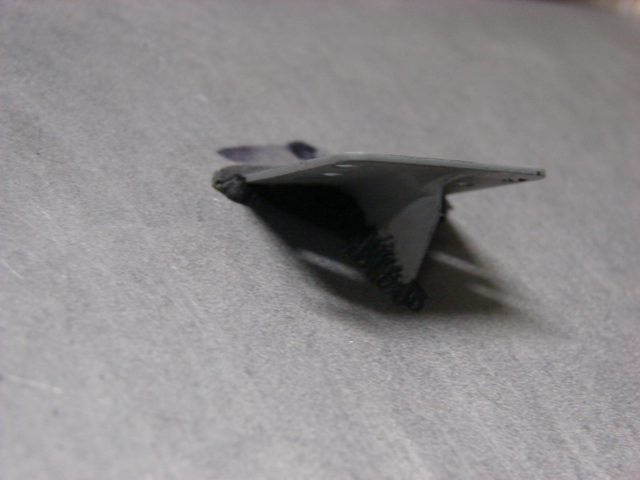

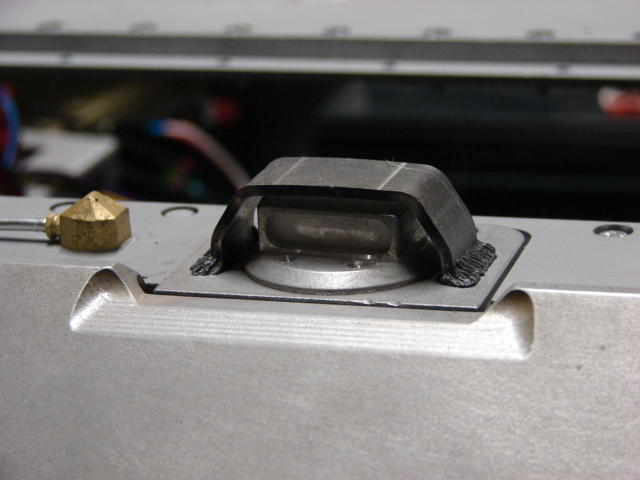

The tank's bow MG ball has been added. The kit supplied MG ball is nicely scaled and can pivot freely.

To make the ball fit better onto the tank I sanded the edges slightly.

Prior to installation the ball was airbrushed in it's base coat of Dark Yellow. With the paint being airbrushed the coat is so this that it will not scratch once inside the ball housing, also I won't have any spots that I will miss on the ball once the tank is painted.

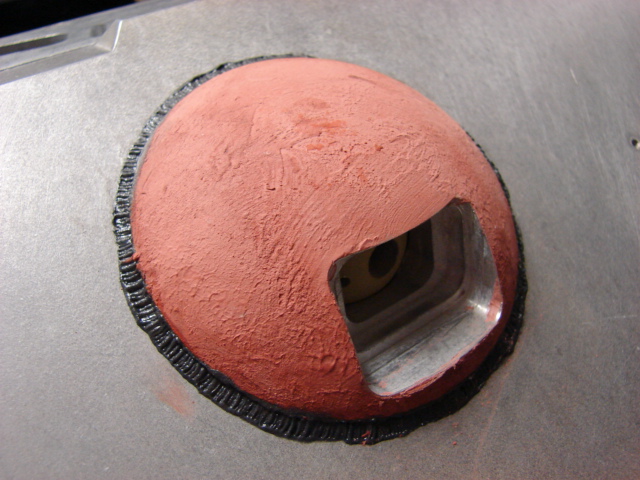

Once the ball was mounted to the tank the ball had it's rouch cast texture and weld beads added.

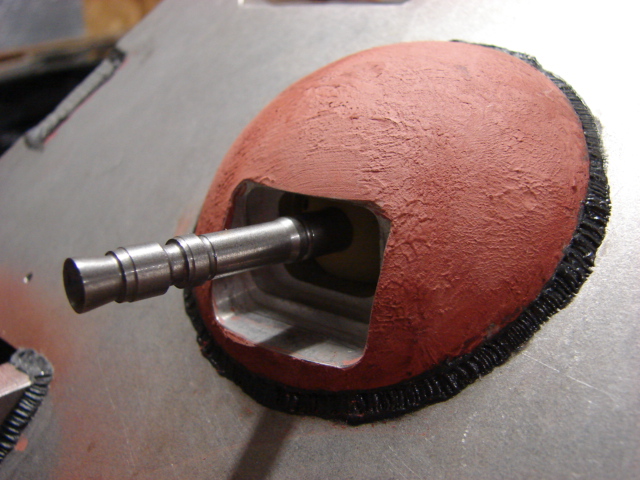

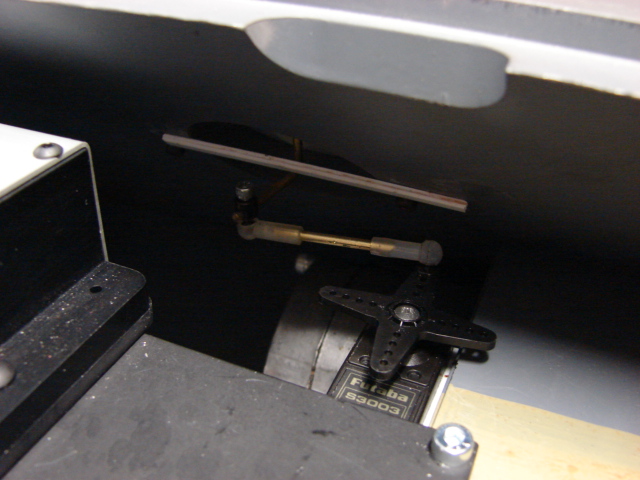

I decided to make the MG ball pivot via remote control. For the MG barrel I used the kit supplied CNCed steel MG 34 barrel.

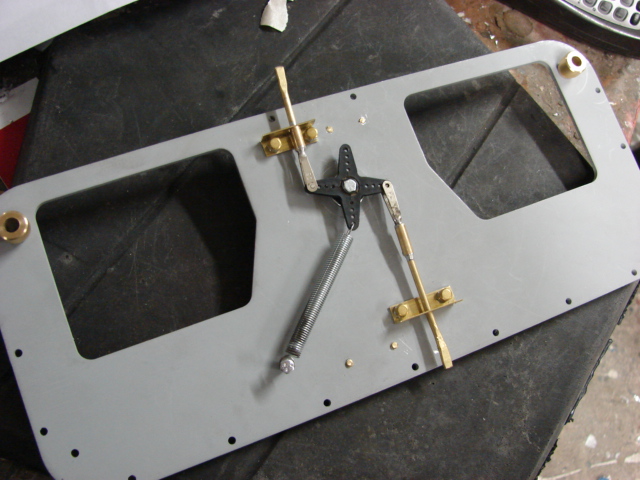

The final function I was able to add was the tank's turret transverse function. This was done with the kit supplied parts and works very smoothly. The tank's interior if filling up quickly, as are the empty functions on the tank's radio. Prior to installing the tank's upper deck I will clean up the loose wires with wire ties and cable mounts.

I have added a video of the tanks functions on youtube. The video can be seen via the following link.

http://www.youtube.com/watch?v=KEluua_YhqY

To finish up the lower hull I will now add the front fenders, headlight, and side hull tool posts. Once these are out of the way I can proceed to the top deck and top deck details. More to follow.

I have made more progress on the tank and have completed more of the tanks functions and details.

For the tank's sprockets I added the hubs, with the bolt details. All of the tension plates were scratch built out of sheet steel.

I added the tank's smoke system. For the smoke generator I used my own system that I hooked up to a remote control for throttle control.

I built into the tank a battery powered fuel pump to refuel the smoke system. With the built in system I can refill the fluid reservoir from a long rubber tube away from the tank. With this system I remove the chance of spilling the smoke fluid onto the tank which can ruin the paint finish. I have used this system on every one of my 1/6th scale RC tanks.

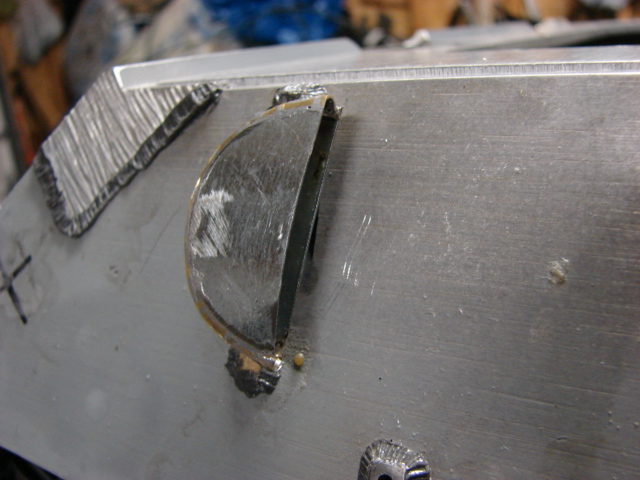

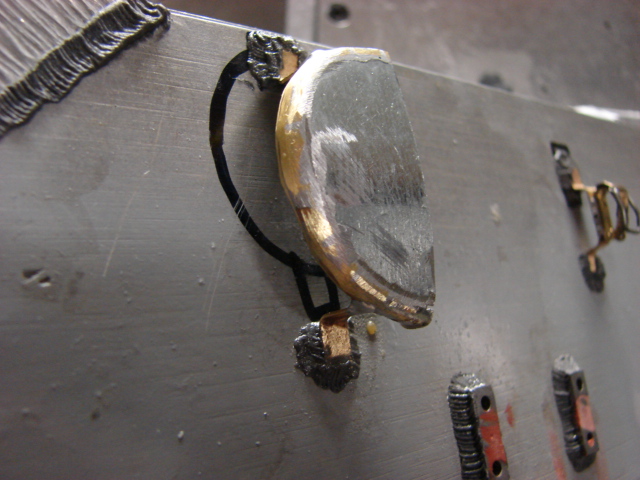

The tank's bow MG ball has been added. The kit supplied MG ball is nicely scaled and can pivot freely.

To make the ball fit better onto the tank I sanded the edges slightly.

Prior to installation the ball was airbrushed in it's base coat of Dark Yellow. With the paint being airbrushed the coat is so this that it will not scratch once inside the ball housing, also I won't have any spots that I will miss on the ball once the tank is painted.

Once the ball was mounted to the tank the ball had it's rouch cast texture and weld beads added.

I decided to make the MG ball pivot via remote control. For the MG barrel I used the kit supplied CNCed steel MG 34 barrel.

The final function I was able to add was the tank's turret transverse function. This was done with the kit supplied parts and works very smoothly. The tank's interior if filling up quickly, as are the empty functions on the tank's radio. Prior to installing the tank's upper deck I will clean up the loose wires with wire ties and cable mounts.

I have added a video of the tanks functions on youtube. The video can be seen via the following link.

http://www.youtube.com/watch?v=KEluua_YhqY

To finish up the lower hull I will now add the front fenders, headlight, and side hull tool posts. Once these are out of the way I can proceed to the top deck and top deck details. More to follow.

-

Paul Morris

- Posts: 1559

- Joined: Thu Jul 12, 2007 4:44 pm

- Location: North Lancs

- Been liked: 68 times

Hi John.

Thats a very impressive smoke unit you have fitted in your tank...I bet a lot of people would be interested in one.

Well done.

Cheers Paul

Thats a very impressive smoke unit you have fitted in your tank...I bet a lot of people would be interested in one.

Well done.

Cheers Paul

Paul's Tank Workshop. Complete Tank builds and re builds zimmerit and paint to museum quality standard. pjtigerman@aol.com

01524 720977

https://www.facebook.com/PaulsTankWorkshop

01524 720977

https://www.facebook.com/PaulsTankWorkshop

-

Paul Morris

- Posts: 1559

- Joined: Thu Jul 12, 2007 4:44 pm

- Location: North Lancs

- Been liked: 68 times

Hi John.

Thank you very much for your fast reply, much appreciated and very interesting.

Thanks again.

Paul

Thank you very much for your fast reply, much appreciated and very interesting.

Thanks again.

Paul

Paul's Tank Workshop. Complete Tank builds and re builds zimmerit and paint to museum quality standard. pjtigerman@aol.com

01524 720977

https://www.facebook.com/PaulsTankWorkshop

01524 720977

https://www.facebook.com/PaulsTankWorkshop

-

John Grima

- Posts: 250

- Joined: Sun Jul 15, 2007 2:54 pm

- Location: USA

- Been liked: 48 times

- Contact:

Thanks Paul, my pleasure

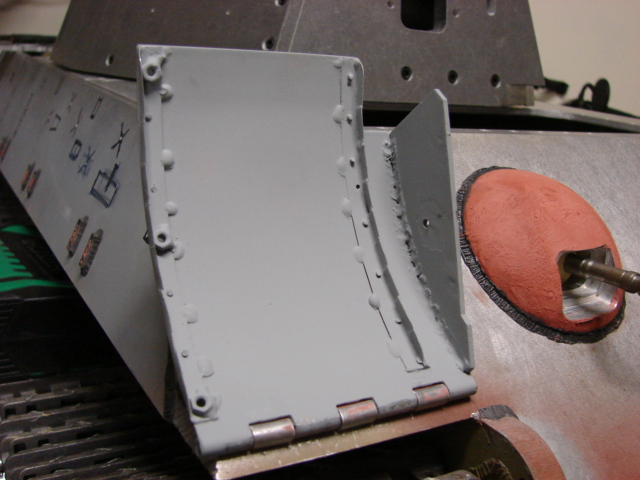

I have made some progress and I have completed the front portion of the tank.

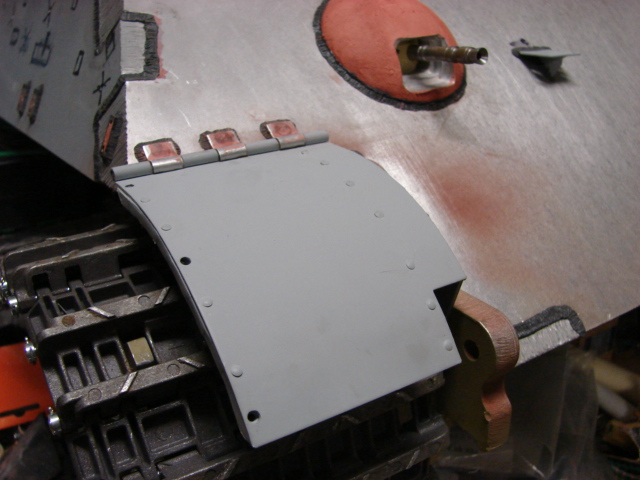

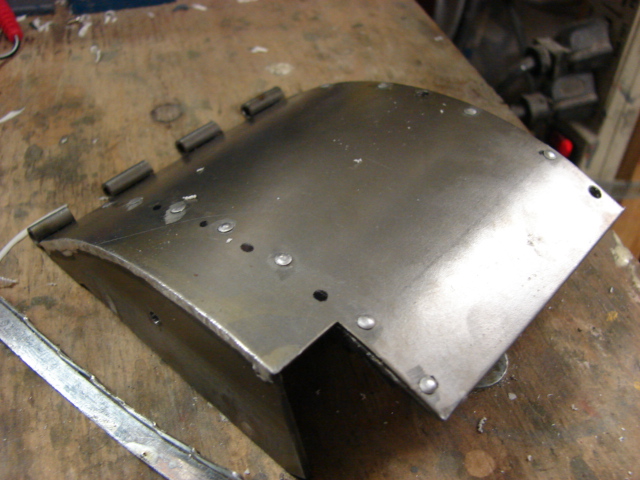

The tank's front mud flaps were completed and installed.

For the fenders I reworked the kit supplied metal mud flaps. The kit supplied mud flaps are all made out of laser cut and pre bent sheet steel plates.

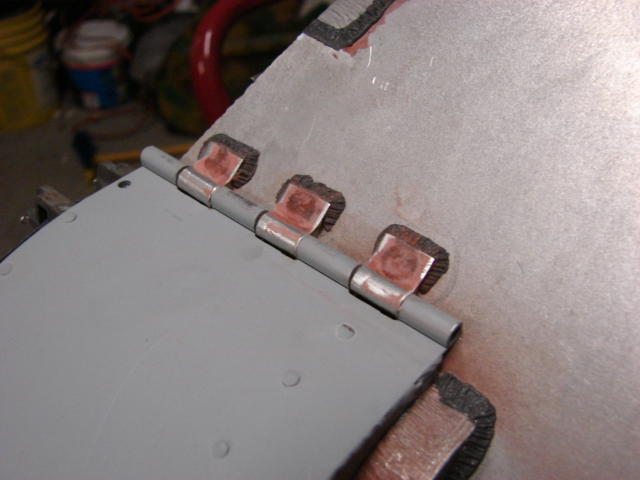

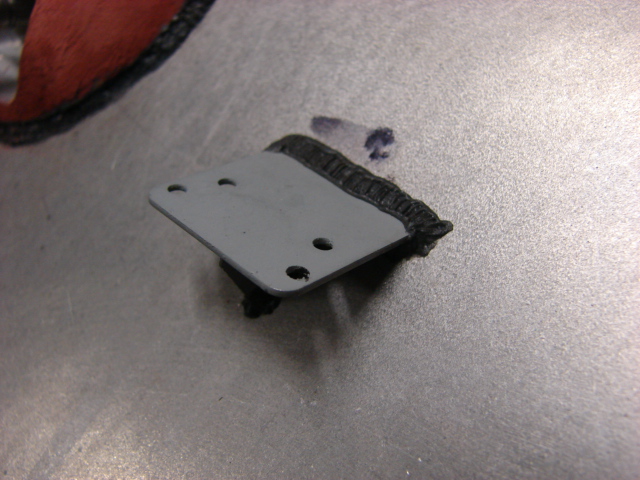

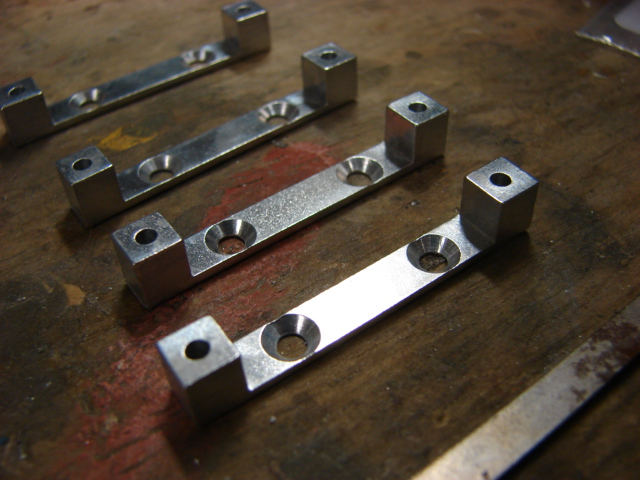

The hinges are made out CNC aluminum and come pre drilled with counter sinks.

The fenders are functional but detail wise are very basic. The fenders are missing their internal support ribs, and rivet detailing. The side portions have two holes pre cut into them to mount to the sides of the hull via two bolts.

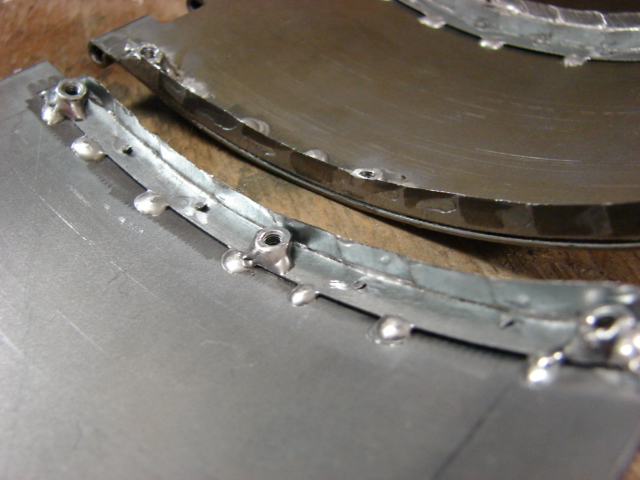

Both of the kit supplied mud flaps were used, to rework them the two holes for the bolts were deleted and the support ribs were fabricated and installed with button toped rivets. All parts were constructed out of metal and were soldered on.

The two holes were deleted because the kit way that the mud flaps were to be retained and locked in place to the tank is incorrect. On the King Tiger the front fenders were held in place via a single retaining pin that is mounted on top of the tank's front side armor.

To attach the other side portion of the fenders I soldered the nuts into the support ribs. This way I can simply bolt the fenders together without having to worry about loosing a nut. It will also make the skirt removal a lot easier.

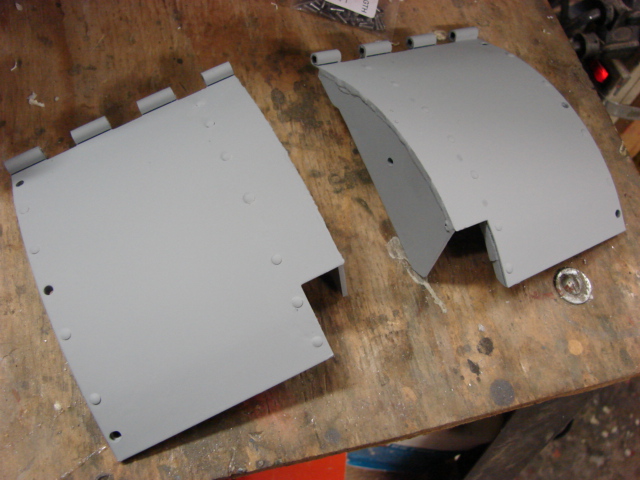

After a shot of primer they were installed onto the tank.

The body work was completed on the hinges fully removing the traces of the mounting bolts. The hinges were installed OOB with the welds being the only detail addition that was made.

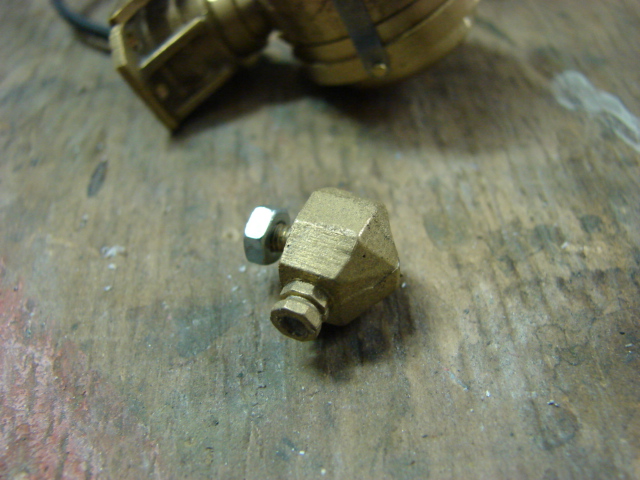

The fender locks were fabricated entirely out of brass and are made to be functional. They along with some weld details were added to the model and actually work keeping the fenders from moving up and down.

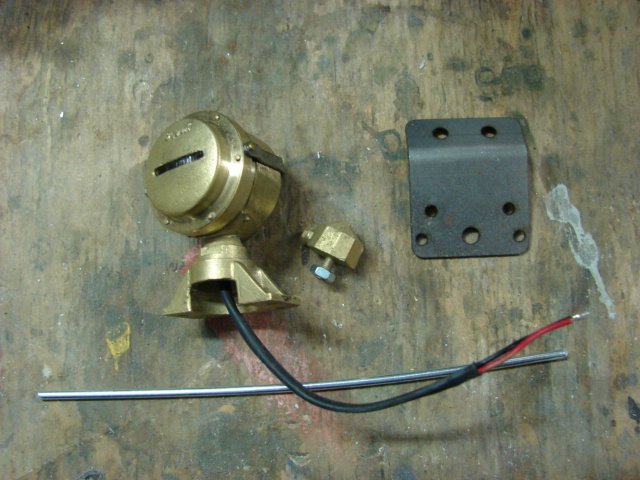

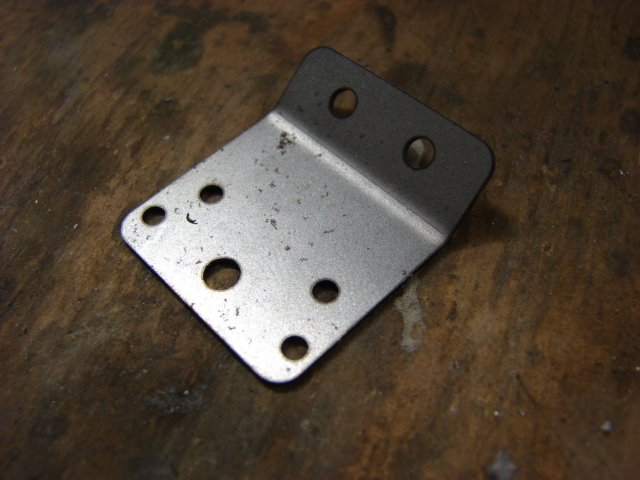

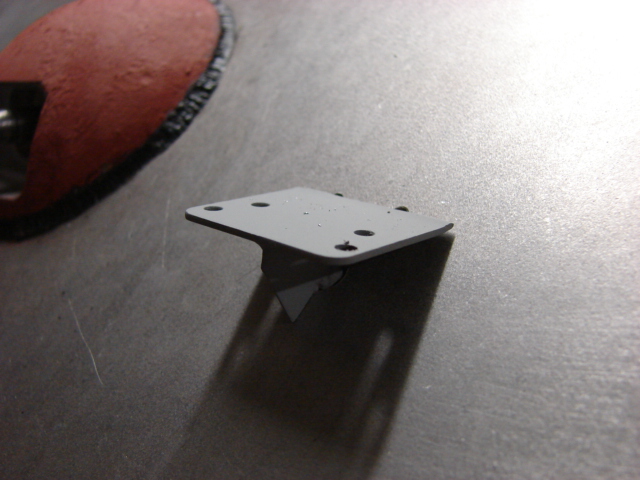

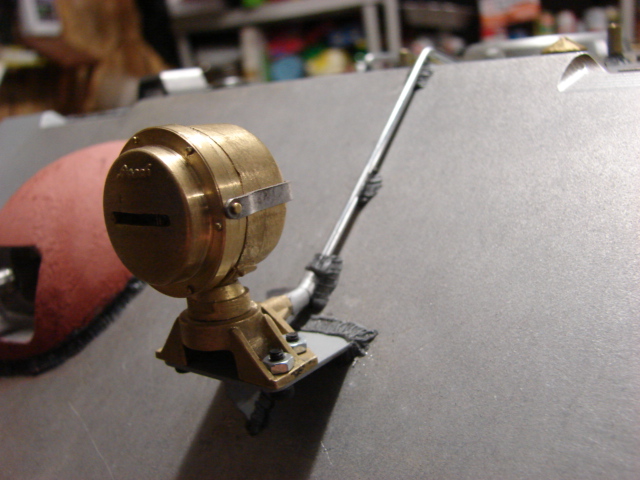

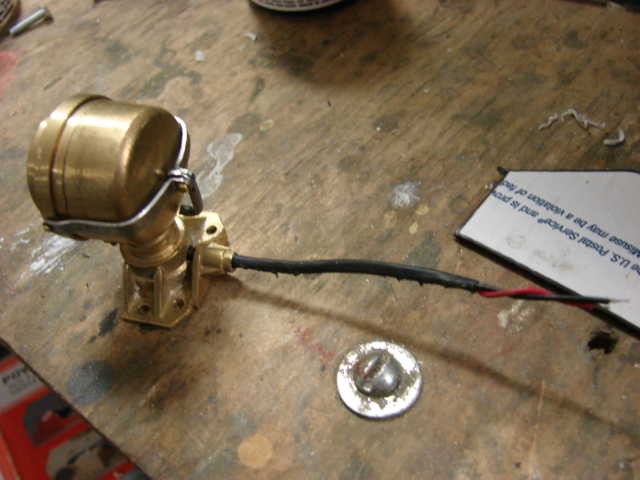

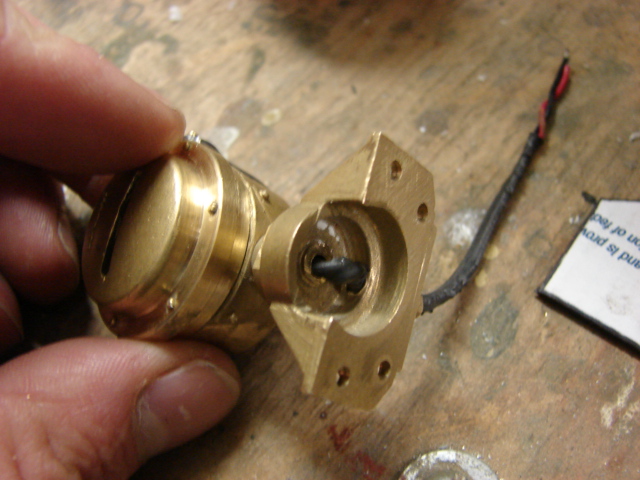

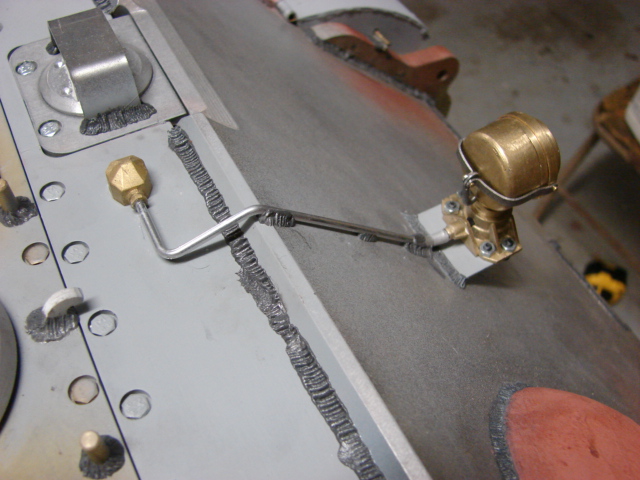

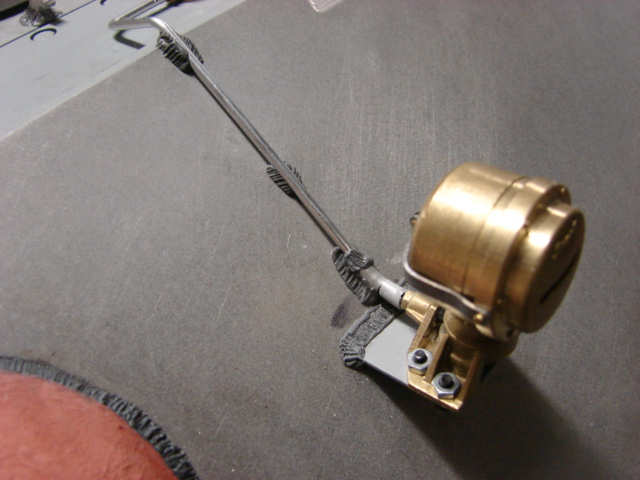

The headlight mound was another bit of detail that was added to the model. The kit supplied you with a laser cut and pre drilled steel bracket, a length of aluminum wire to be used for the light wiring conduit and a most impressive fully functional cast bronze aftermarket Bosh head lamp. The head lamp comes pre wired with a light bulb, and has a removable blackout lid with a clear injection molded plastic light diffusing lens. The headlamp itself is perfect OOB with absolutely no upgrades to be needed.

The bracket itself is very basic and is simply designed to be bolted onto the tank. The bracket itself is missing the center support and would mount to the tank in an incorrect way.

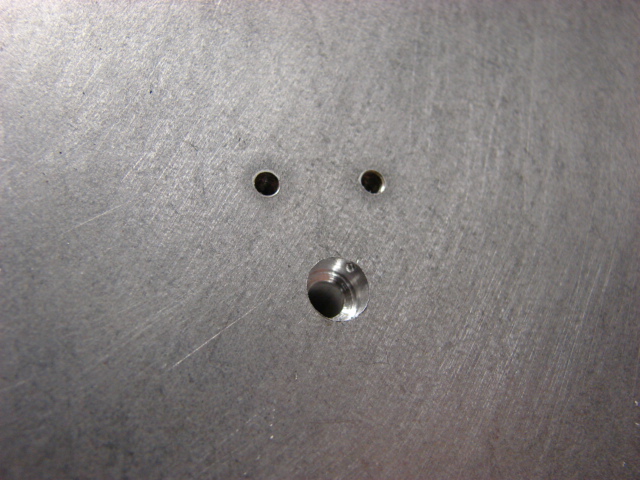

To rework the mount the bent portion that would bolt to the tank was removed. The center hole for the electrical wire was deleted and the center support was fabricated and soldered onto the plate. Now to install the plate onto the tank a M3X35mm hex bolt was soldered onto the support. The bolt had to be long enough to get through the 1 inch thick frontal plate so a nut can secure the plate onto the other end.

The tank's frontal plate has three holes pre drilled into it. Two small mounting holes for the kit mount and a single larger hole for the headlight power cable. The headlight cable hole will now be used for the mounting bolt. The hole was widened slightly to have the hex head of the mounting bolt to lie flush with the armored plate. The headlight power cable will be redirected later once it is installed to the tank after the roof gets installed.

The new mount now sits onto the front plate as it does on the real tank.

Welds were added covering up the two head light mount installation holes and further securing the mount to the tank.

Now that the front plate detailing is complete I have started the side hull tool posts and tow cable mounts. Typically I do this step last before the tank is about to the painted, but on this tank I need to secure the posts to the tank's sides with fasteners that bolt to the tanks inside. Mounting these parts will be very difficult once the tank's roof is installed so they will be done next. Here is a sneak peek on what will be coming in the next update, More to come..

I have made some progress and I have completed the front portion of the tank.

The tank's front mud flaps were completed and installed.

For the fenders I reworked the kit supplied metal mud flaps. The kit supplied mud flaps are all made out of laser cut and pre bent sheet steel plates.

The hinges are made out CNC aluminum and come pre drilled with counter sinks.

The fenders are functional but detail wise are very basic. The fenders are missing their internal support ribs, and rivet detailing. The side portions have two holes pre cut into them to mount to the sides of the hull via two bolts.

Both of the kit supplied mud flaps were used, to rework them the two holes for the bolts were deleted and the support ribs were fabricated and installed with button toped rivets. All parts were constructed out of metal and were soldered on.

The two holes were deleted because the kit way that the mud flaps were to be retained and locked in place to the tank is incorrect. On the King Tiger the front fenders were held in place via a single retaining pin that is mounted on top of the tank's front side armor.

To attach the other side portion of the fenders I soldered the nuts into the support ribs. This way I can simply bolt the fenders together without having to worry about loosing a nut. It will also make the skirt removal a lot easier.

After a shot of primer they were installed onto the tank.

The body work was completed on the hinges fully removing the traces of the mounting bolts. The hinges were installed OOB with the welds being the only detail addition that was made.

The fender locks were fabricated entirely out of brass and are made to be functional. They along with some weld details were added to the model and actually work keeping the fenders from moving up and down.

The headlight mound was another bit of detail that was added to the model. The kit supplied you with a laser cut and pre drilled steel bracket, a length of aluminum wire to be used for the light wiring conduit and a most impressive fully functional cast bronze aftermarket Bosh head lamp. The head lamp comes pre wired with a light bulb, and has a removable blackout lid with a clear injection molded plastic light diffusing lens. The headlamp itself is perfect OOB with absolutely no upgrades to be needed.

The bracket itself is very basic and is simply designed to be bolted onto the tank. The bracket itself is missing the center support and would mount to the tank in an incorrect way.

To rework the mount the bent portion that would bolt to the tank was removed. The center hole for the electrical wire was deleted and the center support was fabricated and soldered onto the plate. Now to install the plate onto the tank a M3X35mm hex bolt was soldered onto the support. The bolt had to be long enough to get through the 1 inch thick frontal plate so a nut can secure the plate onto the other end.

The tank's frontal plate has three holes pre drilled into it. Two small mounting holes for the kit mount and a single larger hole for the headlight power cable. The headlight cable hole will now be used for the mounting bolt. The hole was widened slightly to have the hex head of the mounting bolt to lie flush with the armored plate. The headlight power cable will be redirected later once it is installed to the tank after the roof gets installed.

The new mount now sits onto the front plate as it does on the real tank.

Welds were added covering up the two head light mount installation holes and further securing the mount to the tank.

Now that the front plate detailing is complete I have started the side hull tool posts and tow cable mounts. Typically I do this step last before the tank is about to the painted, but on this tank I need to secure the posts to the tank's sides with fasteners that bolt to the tanks inside. Mounting these parts will be very difficult once the tank's roof is installed so they will be done next. Here is a sneak peek on what will be coming in the next update, More to come..

-

Paul Morris

- Posts: 1559

- Joined: Thu Jul 12, 2007 4:44 pm

- Location: North Lancs

- Been liked: 68 times

Mudguard retaining pins

Hi John.

Its all starting to come together now my friend...a little word to the wise the retaining pins look and work great but...we have found that due to the amount of leverage that is created when a pebble or small stick goes around with the track and under the mudguard no matter what glue you use to stick them you lose the retaining pin that you have invested time i making!

My idea to overcome this is to re make mine with a small brass pin say 10mm soldered to the bottom of the tube [baseplate in your case] and drill a hole down into the hull side plate to accept the pin if you see what I mean? much like gluing and pinning the arms etc on a metal miniature figure kit.

Just thought I would mention it before you painted.

Cheers Paul

Its all starting to come together now my friend...a little word to the wise the retaining pins look and work great but...we have found that due to the amount of leverage that is created when a pebble or small stick goes around with the track and under the mudguard no matter what glue you use to stick them you lose the retaining pin that you have invested time i making!

My idea to overcome this is to re make mine with a small brass pin say 10mm soldered to the bottom of the tube [baseplate in your case] and drill a hole down into the hull side plate to accept the pin if you see what I mean? much like gluing and pinning the arms etc on a metal miniature figure kit.

Just thought I would mention it before you painted.

Cheers Paul

Paul's Tank Workshop. Complete Tank builds and re builds zimmerit and paint to museum quality standard. pjtigerman@aol.com

01524 720977

https://www.facebook.com/PaulsTankWorkshop

01524 720977

https://www.facebook.com/PaulsTankWorkshop

-

John Grima

- Posts: 250

- Joined: Sun Jul 15, 2007 2:54 pm

- Location: USA

- Been liked: 48 times

- Contact:

Thanks for the heads up Paul, I have fasteners hidden below the epoxie welds for the reason you listed above.

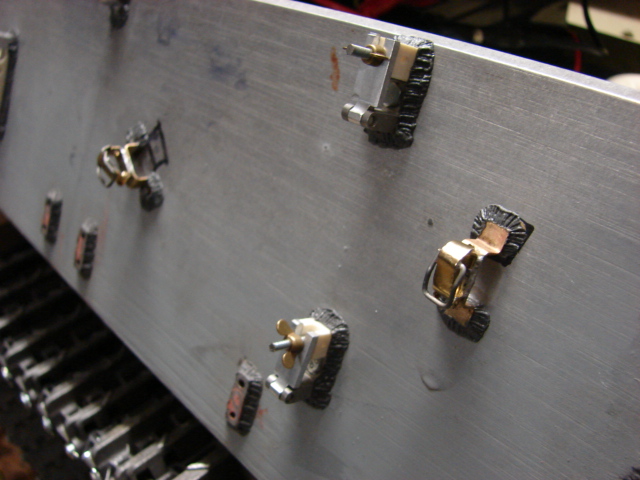

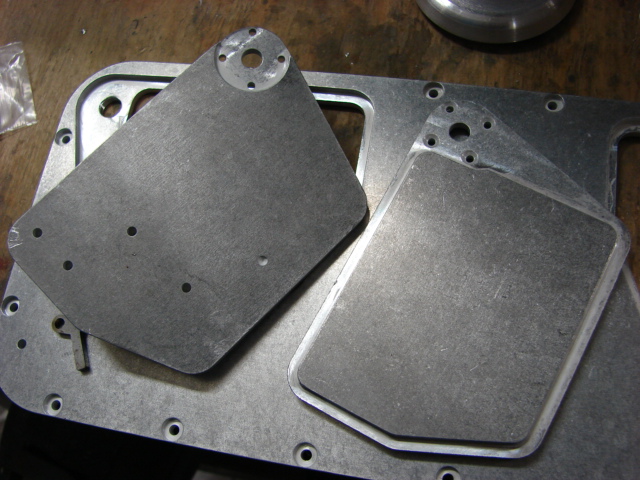

I have just finished the tank's side hull tool posts and tow cable mounts.

The kit supplies you with tools, Tow cables, basic tool posts and tow cable locks. The tank's hull is also pre drilled for all of the tool posts. To improve on the most of the tool post locations needed to be relocated. The kit's holes were filled in and will be sanded over.

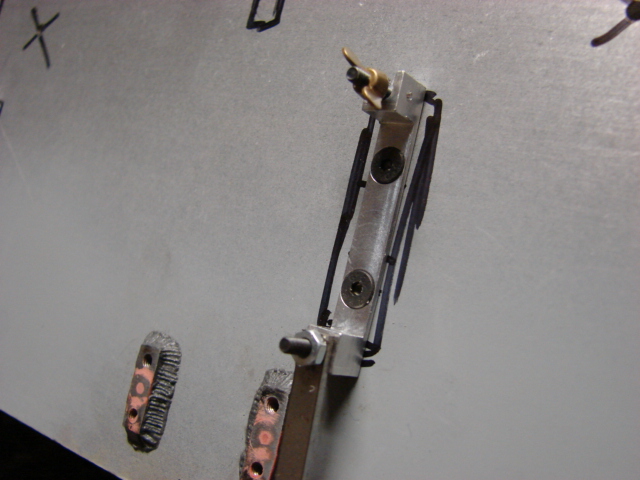

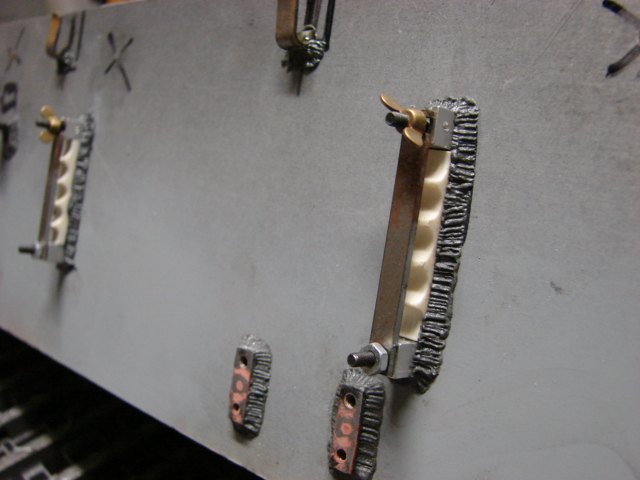

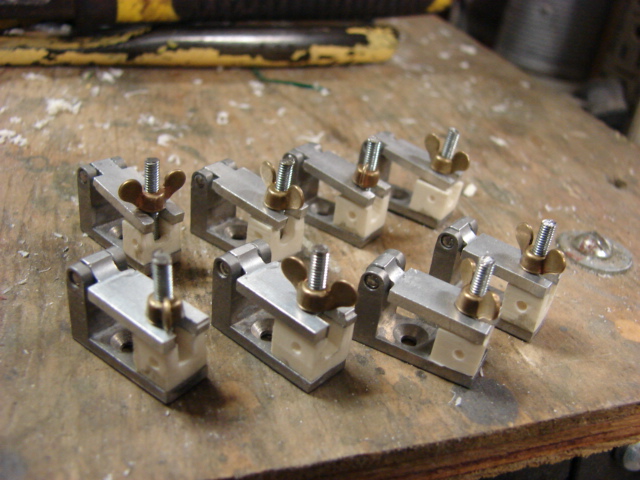

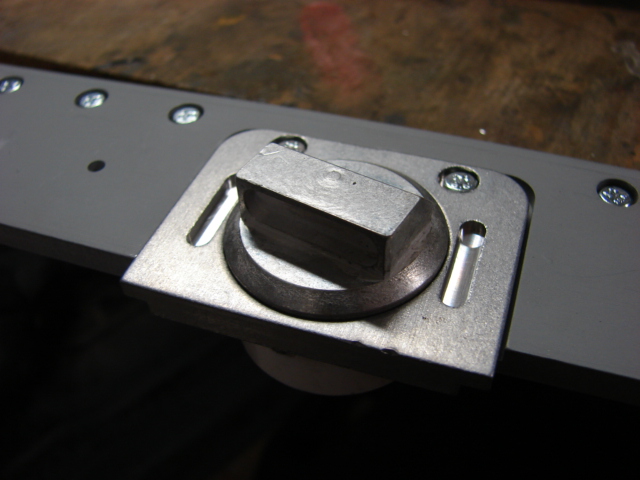

tank's tow cable mounts were the first of the tool posts that were reworked. The kit supplied cable mounts are made out of CNCed Aluminum braces with laser cut steel strips. The braces are missing the groves for the gun cleaning kit and the tow cables. The braces are also missing the pivot points on the one end for the folding retaining bolt. The braces are mounted to the tank very securely via counter sink bolts with nuts anchoring them on the inside of the vehicle.

To keep the braces as strong as possible I didn't make the pivot bolt functional, instead I modified the kit supplied base to appear that the pivot works. The way I did this was the kit supplied braces had inlets machined into the one end. The brace now has the detail of the pivot, but still has it's full strength.

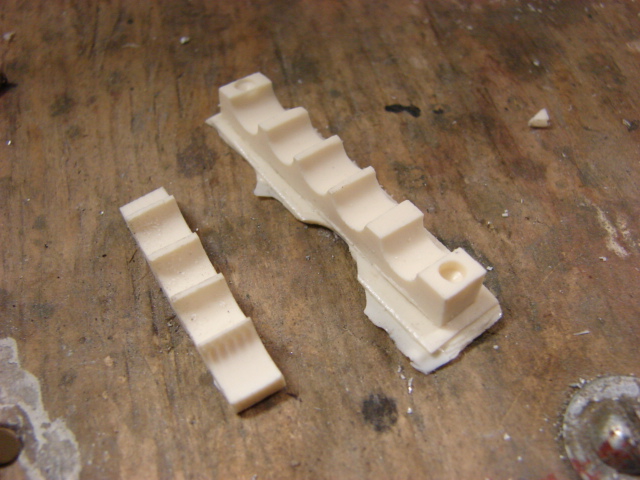

For the center grooves I took the center groove portion from one of my resin Tiger tow cable mounts. The resin center was installed over the flush counter sink bolts after the braces were added to the tank.

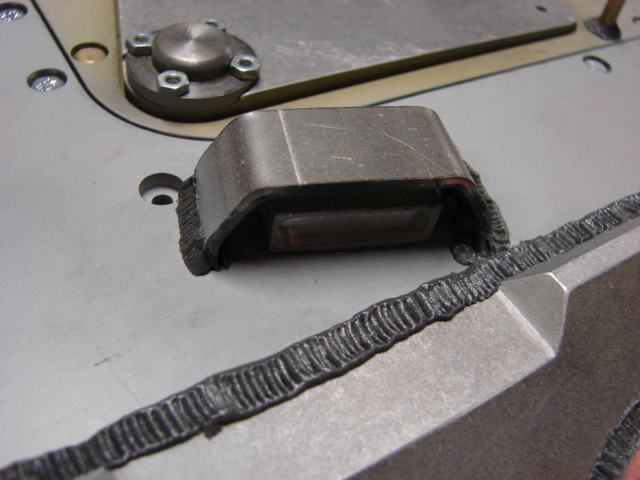

The kit also includes small tow cable mounts for retaining the tow cable ends and for retaining thee steel cable towards the rear of the vehicle. Like the other mounts these locks are produced form CNCed aluminum. The tow cable locks have a functional hinged top, but are missing the front portion of the lock with the pivot bolt.

Like the other mounts I didn't make the pivot bolt functional, instead I made a resin detail shroud that slipped over the steel bolt. This again gives me the maximum amount of strength and detail. On the hinged tops I had to transform the drilled out bolt hole into a slit that would have been used for the pivot bolt. The slit doesn't effect the strength of the mount in any way, and still locks securely.

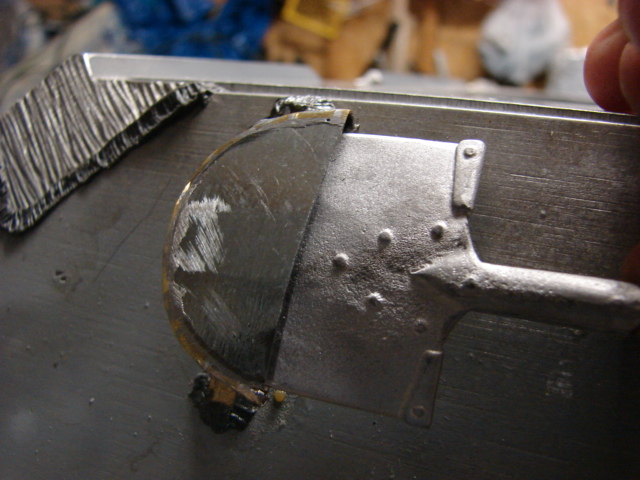

The kit supplied track cable mounts were also very basic and needed to be reworked.

The mounts were re bent and had a M3X16mm bolt soldered to the the inner end.

This procedure was done with the other Armortek cable mounts.

Before

After

Before

After

For some of the tool posts I had to scratch build some completely. These would include the track cable end mounts, shovel mount, and tool handle locks.

The front transport cable end mount was fabricated out of a brass angle and a spent .22 cal shell casing. The angle has a slot milled into the top and a nut was soldered to the shell casing. This allows the end mount to be adjusted along the brace to adjust the tension of the cable.

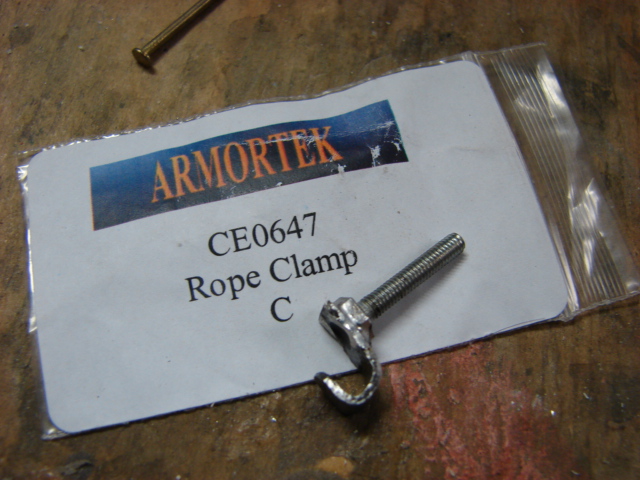

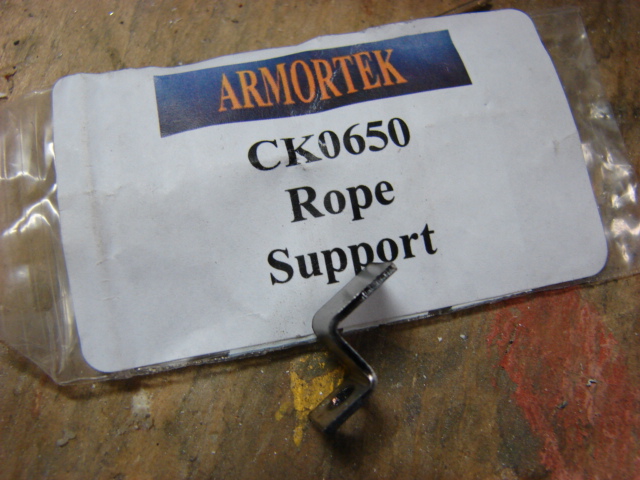

For the rear cable end mount a spent .22cal shell casing and a M3X16 hex bolt was soldered to a reshaped Armortek rope support mount.

For the front shovel the kit does supply you with a shovel head mount. The mount itself is made out of CNC aluminum, however I decided to fabricate an all new one out of steel and brass. For the shovel the kit supplies you with a white metal armorpax shovel which is a nice addition and will be used on this model.

Kit supplied component

New scratch built mount.

All of the added components had epoxie welds added completeing the side hull details.

Now that the side is complete I can now install the top deck and work on the top deck details. More to come.

I have just finished the tank's side hull tool posts and tow cable mounts.

The kit supplies you with tools, Tow cables, basic tool posts and tow cable locks. The tank's hull is also pre drilled for all of the tool posts. To improve on the most of the tool post locations needed to be relocated. The kit's holes were filled in and will be sanded over.

tank's tow cable mounts were the first of the tool posts that were reworked. The kit supplied cable mounts are made out of CNCed Aluminum braces with laser cut steel strips. The braces are missing the groves for the gun cleaning kit and the tow cables. The braces are also missing the pivot points on the one end for the folding retaining bolt. The braces are mounted to the tank very securely via counter sink bolts with nuts anchoring them on the inside of the vehicle.

To keep the braces as strong as possible I didn't make the pivot bolt functional, instead I modified the kit supplied base to appear that the pivot works. The way I did this was the kit supplied braces had inlets machined into the one end. The brace now has the detail of the pivot, but still has it's full strength.

For the center grooves I took the center groove portion from one of my resin Tiger tow cable mounts. The resin center was installed over the flush counter sink bolts after the braces were added to the tank.

The kit also includes small tow cable mounts for retaining the tow cable ends and for retaining thee steel cable towards the rear of the vehicle. Like the other mounts these locks are produced form CNCed aluminum. The tow cable locks have a functional hinged top, but are missing the front portion of the lock with the pivot bolt.

Like the other mounts I didn't make the pivot bolt functional, instead I made a resin detail shroud that slipped over the steel bolt. This again gives me the maximum amount of strength and detail. On the hinged tops I had to transform the drilled out bolt hole into a slit that would have been used for the pivot bolt. The slit doesn't effect the strength of the mount in any way, and still locks securely.

The kit supplied track cable mounts were also very basic and needed to be reworked.

The mounts were re bent and had a M3X16mm bolt soldered to the the inner end.

This procedure was done with the other Armortek cable mounts.

Before

After

Before

After

For some of the tool posts I had to scratch build some completely. These would include the track cable end mounts, shovel mount, and tool handle locks.

The front transport cable end mount was fabricated out of a brass angle and a spent .22 cal shell casing. The angle has a slot milled into the top and a nut was soldered to the shell casing. This allows the end mount to be adjusted along the brace to adjust the tension of the cable.

For the rear cable end mount a spent .22cal shell casing and a M3X16 hex bolt was soldered to a reshaped Armortek rope support mount.

For the front shovel the kit does supply you with a shovel head mount. The mount itself is made out of CNC aluminum, however I decided to fabricate an all new one out of steel and brass. For the shovel the kit supplies you with a white metal armorpax shovel which is a nice addition and will be used on this model.

Kit supplied component

New scratch built mount.

All of the added components had epoxie welds added completeing the side hull details.

Now that the side is complete I can now install the top deck and work on the top deck details. More to come.

Last edited by John Grima on Wed Nov 10, 2010 3:58 am, edited 2 times in total.

- Robert E Morey

- Posts: 2310

- Joined: Wed Jul 18, 2007 12:59 am

- Location: Seattle, WA USA

- Has liked: 130 times

- Been liked: 776 times

-

John Grima

- Posts: 250

- Joined: Sun Jul 15, 2007 2:54 pm

- Location: USA

- Been liked: 48 times

- Contact:

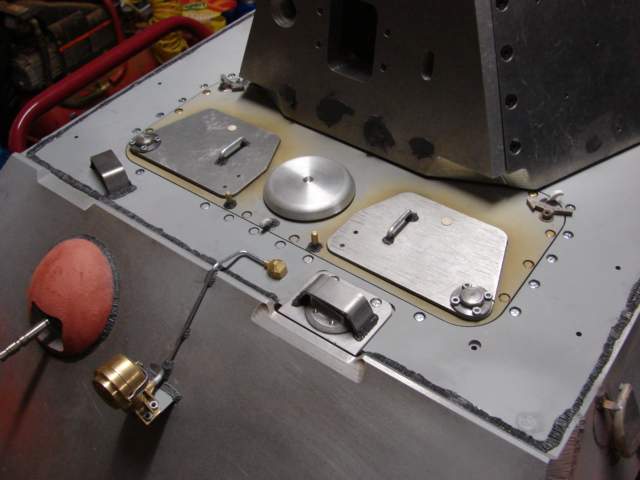

Thanks guys, More progress has been made on the tank.

The tank's front portion is now mostly complete.

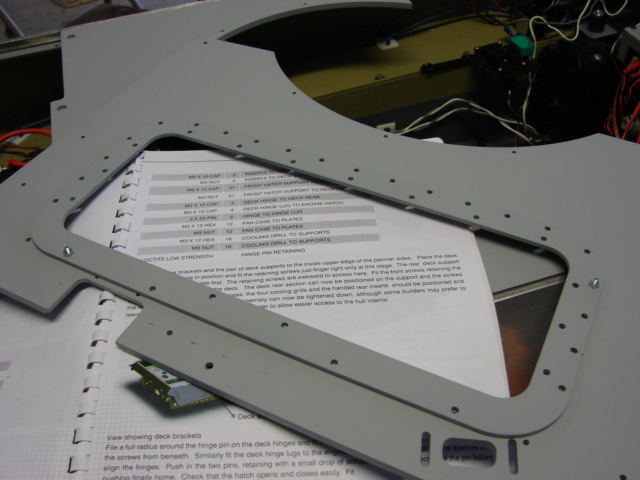

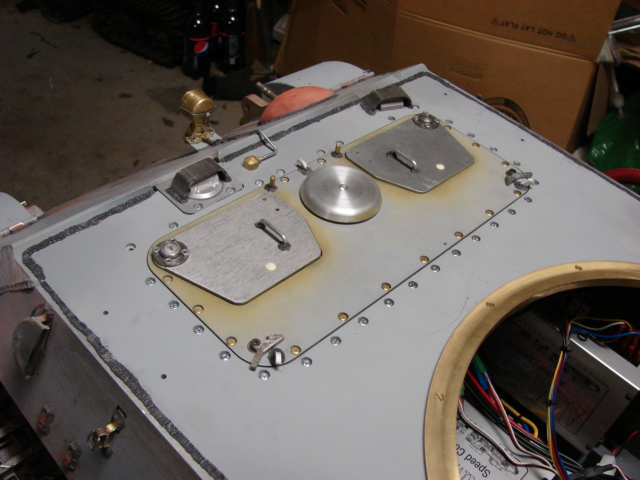

The top deck has also been mounted permanently to the tank. The turret's one piece brass bearing ring was also mounted. All of the bolt holes have been filled and sanded. Epoxie welds have also been added

The tank's headlamp has been mounted to the head light mount

Prior to mounting the head lamp the electrical wiring was relocated to the rear portion of the light where the actual conduit would connect to the lamp.

The wiring is too large to fit into a tube that would be used for the conduit. For the head light to work I made the wiring enter the tank through the front armor plate. The hole is concealed with the dummy conduit and the conduit welds.

The front periscopes were also installed to the tank. The kit supplied periscopes are made out of CNCed aluminum periscopes and two steel brush guards.

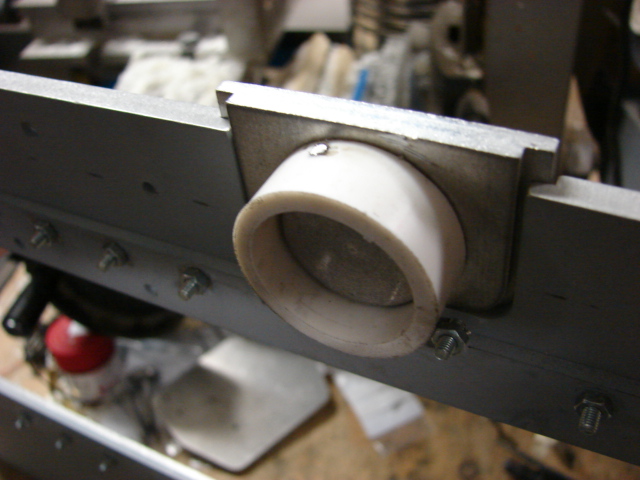

For the pivoting drivers scope the kit wants you to permanently glue the scope to the scope mount

Instead of gluing the scope on permanently I was able to make the scope pivot. This was done by attaching a small length of PVC pipe to the scope's bottom. The scope was then hooked up to a servo and the driver’s scope now pivots remotely. Once more of the functions are hooked up I will post a youtube video showing the periscope in action.

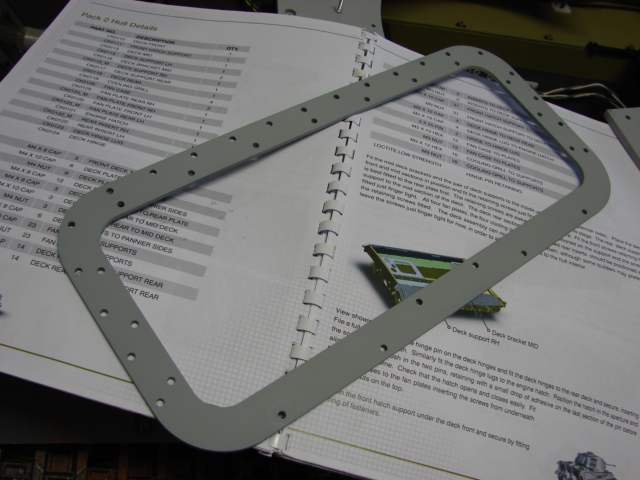

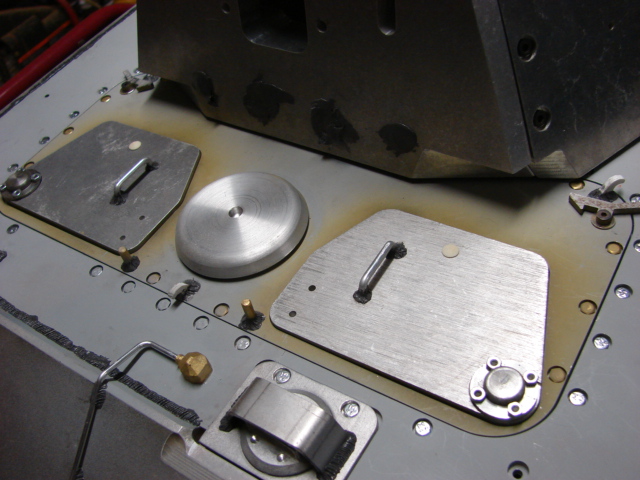

For the front bow hatches the kit supplies you with a lot of components that are made from numerous types of materials such as steel, aluminum and brass. All of these components were used on my model with some alterations.

The kit supplied hatches are designed to open and swing like te real hatch. This is done on nicely machined brass and steel pivots.

The hatch plate and the top deck are two separate panels as per the real vehicle. To mount the hatch plate to the top deck the kit supplies you with a laser cut steel plate that bolts to the bottom of top deck and to the bottom of the hatch plate.

The kit supplied hatches don't have any interior detailing. New interior detailing had to be scratch built.

All details were scratch built out of brass and steel. Due to the design of the hatches making the hach locks functional was easier than making them static.

The hatches were pre painted and weathered.

The hatches were mounted to the hatch plate, along with scratch built lift hooks, reworked air filter and hatch locks.

The kit requires you to bolt the hatch plate to the upper hull permanently, but for this model I need the access to the functions and to the smoke generator refueling pump.

The solution was to make the plate removable. To do this I designed the plate to lock onto the top plate with two locking lugs. To remove the plate the lugs are attached to the air filter which becomes a knob that when twisted will unlock the two lugs simultaneously allowing me to remove the plate.

I have also made a youtube video showing the hatch plate removal in detail.

http://www.youtube.com/watch?v=u8c4SEBBliI

All that is needed to finish up the top front is the addition of the tool posts and then I will be able to focus on the grill work. More to come

The tank's front portion is now mostly complete.

The top deck has also been mounted permanently to the tank. The turret's one piece brass bearing ring was also mounted. All of the bolt holes have been filled and sanded. Epoxie welds have also been added

The tank's headlamp has been mounted to the head light mount

Prior to mounting the head lamp the electrical wiring was relocated to the rear portion of the light where the actual conduit would connect to the lamp.

The wiring is too large to fit into a tube that would be used for the conduit. For the head light to work I made the wiring enter the tank through the front armor plate. The hole is concealed with the dummy conduit and the conduit welds.

The front periscopes were also installed to the tank. The kit supplied periscopes are made out of CNCed aluminum periscopes and two steel brush guards.

For the pivoting drivers scope the kit wants you to permanently glue the scope to the scope mount

Instead of gluing the scope on permanently I was able to make the scope pivot. This was done by attaching a small length of PVC pipe to the scope's bottom. The scope was then hooked up to a servo and the driver’s scope now pivots remotely. Once more of the functions are hooked up I will post a youtube video showing the periscope in action.

For the front bow hatches the kit supplies you with a lot of components that are made from numerous types of materials such as steel, aluminum and brass. All of these components were used on my model with some alterations.

The kit supplied hatches are designed to open and swing like te real hatch. This is done on nicely machined brass and steel pivots.

The hatch plate and the top deck are two separate panels as per the real vehicle. To mount the hatch plate to the top deck the kit supplies you with a laser cut steel plate that bolts to the bottom of top deck and to the bottom of the hatch plate.

The kit supplied hatches don't have any interior detailing. New interior detailing had to be scratch built.

All details were scratch built out of brass and steel. Due to the design of the hatches making the hach locks functional was easier than making them static.

The hatches were pre painted and weathered.

The hatches were mounted to the hatch plate, along with scratch built lift hooks, reworked air filter and hatch locks.

The kit requires you to bolt the hatch plate to the upper hull permanently, but for this model I need the access to the functions and to the smoke generator refueling pump.

The solution was to make the plate removable. To do this I designed the plate to lock onto the top plate with two locking lugs. To remove the plate the lugs are attached to the air filter which becomes a knob that when twisted will unlock the two lugs simultaneously allowing me to remove the plate.

I have also made a youtube video showing the hatch plate removal in detail.

http://www.youtube.com/watch?v=u8c4SEBBliI

All that is needed to finish up the top front is the addition of the tool posts and then I will be able to focus on the grill work. More to come

-

martin pitcairn

- Posts: 172

- Joined: Thu Jul 12, 2007 5:53 pm

- Has liked: 782 times

- Been liked: 8 times

john,i have been watching your build with great interest, i will be honest when i first saw some of the early work on the welds, i thought it was a bit agricultural almost "russian",BUT the more i look the more i think you are doing a terrific job.I think the work you are doing is FANTASTIC,i love the moving hatches,the locks etc are just as they say over here "the Dogs B*ll*cks" i cannot wait to see the final tank,i am sure that the model will be fantastic,keepthis going i am loving it!